Neofab, BigRep’s reseller in France, is part of Hava3D group – the national leader in the distribution and commercialization of additive manufacturing solutions. Specializing in industrial additive solutions like BigRep’s large-format 3D pritners, Neofab are experts in a variety of industrial printing technologies including high temperature and metal.

We asked Neofab’s Guillaume Coudreuse to answer a few questions about why they’re excited to offer BigRep’s industrial additive manufacturing solutions in France, and which industrial applications they find ripe for large-format additive manufacturing.

1. What value has large-format brought your prospects?

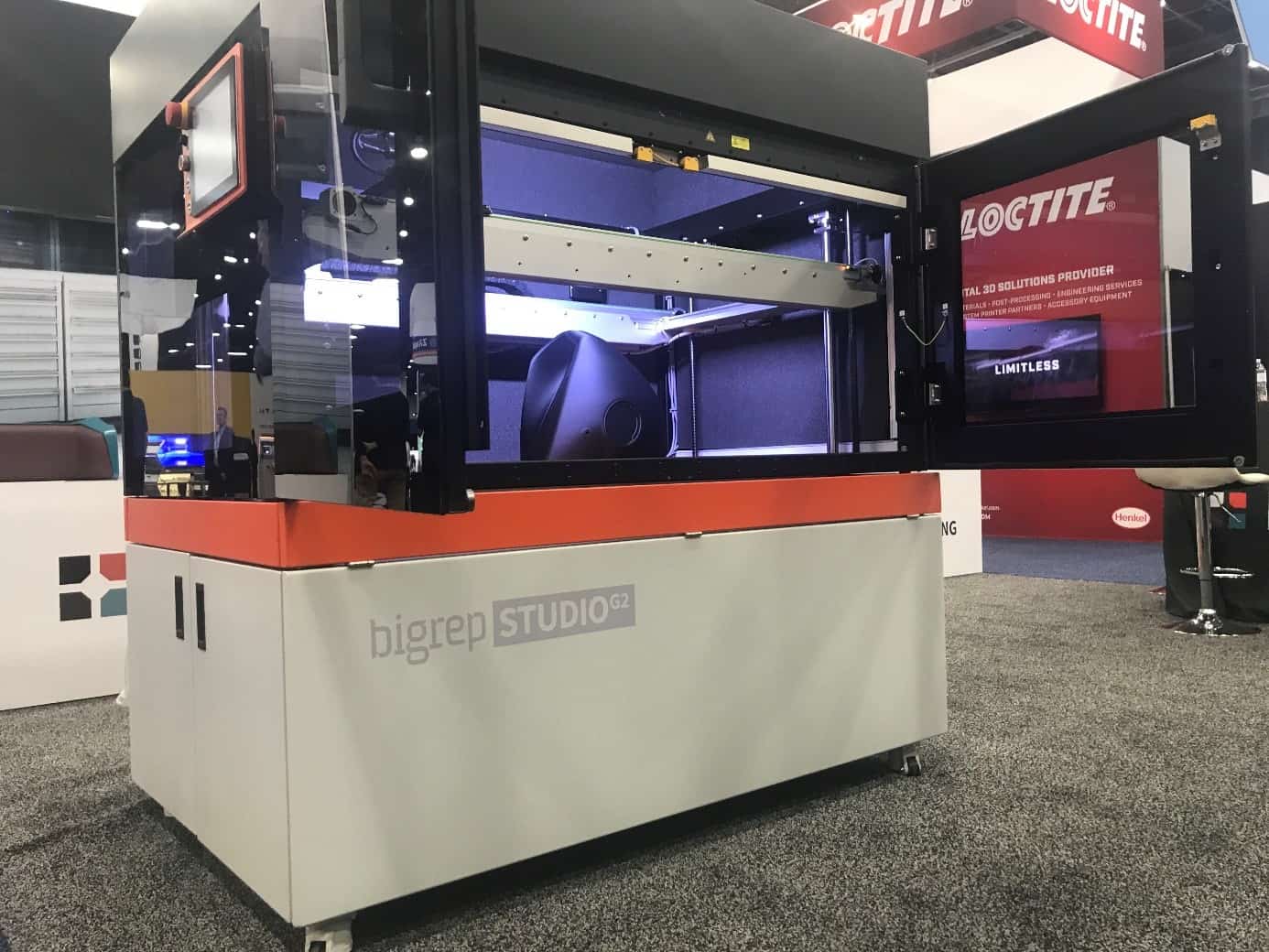

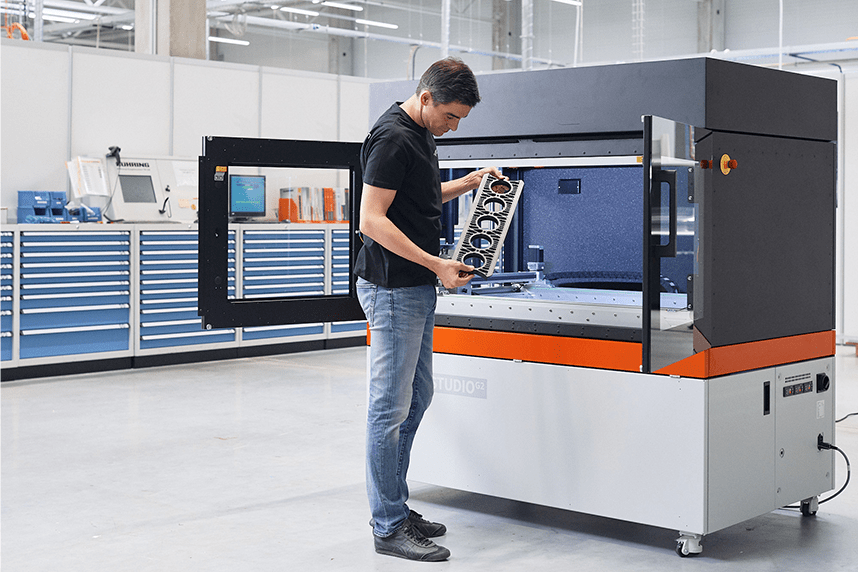

Large format brings a lot of value to our prospects. Some of them need to print large parts for a variety of projects, so having the option to print many parts at once saves a lot of production time while also eliminating the restrictions on parts dimensions that smaller printers have.

The interesting part is that even if our prospect doesn’t need to print large parts, they can benefit from the dimension. Thanks to the build size of BigRep printers they can print multiple parts in the same job and reach a higher level of productivity.

2. What applications and industries do you see benefiting the most from additive?

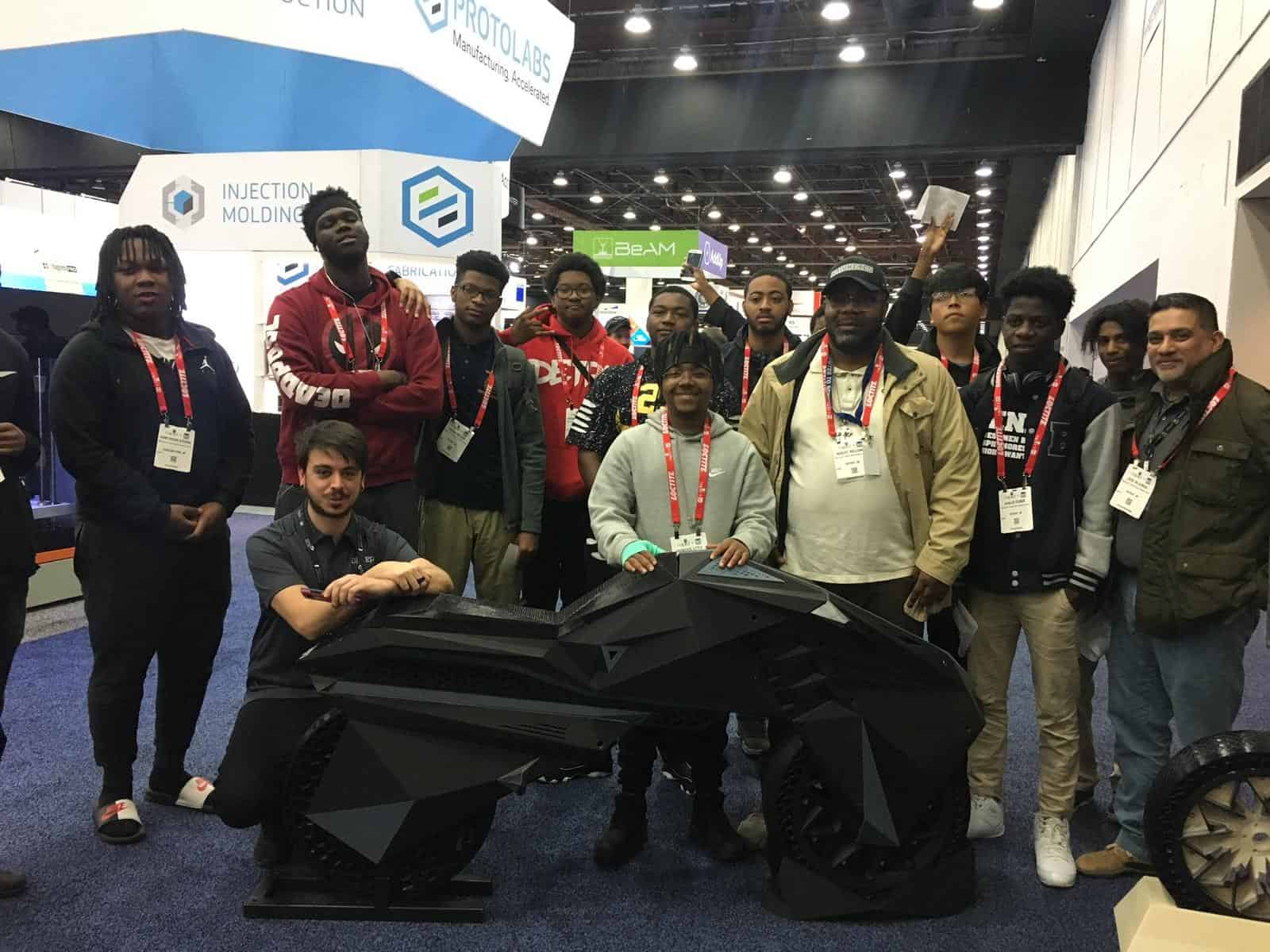

At first, we saw a lot of applications for the design industry, then prospects from other industries saw the potential for printing large parts. Now we see interest from automotive, education, research, aerospace, and more.

3. What are some of the questions or myths that you address the most?

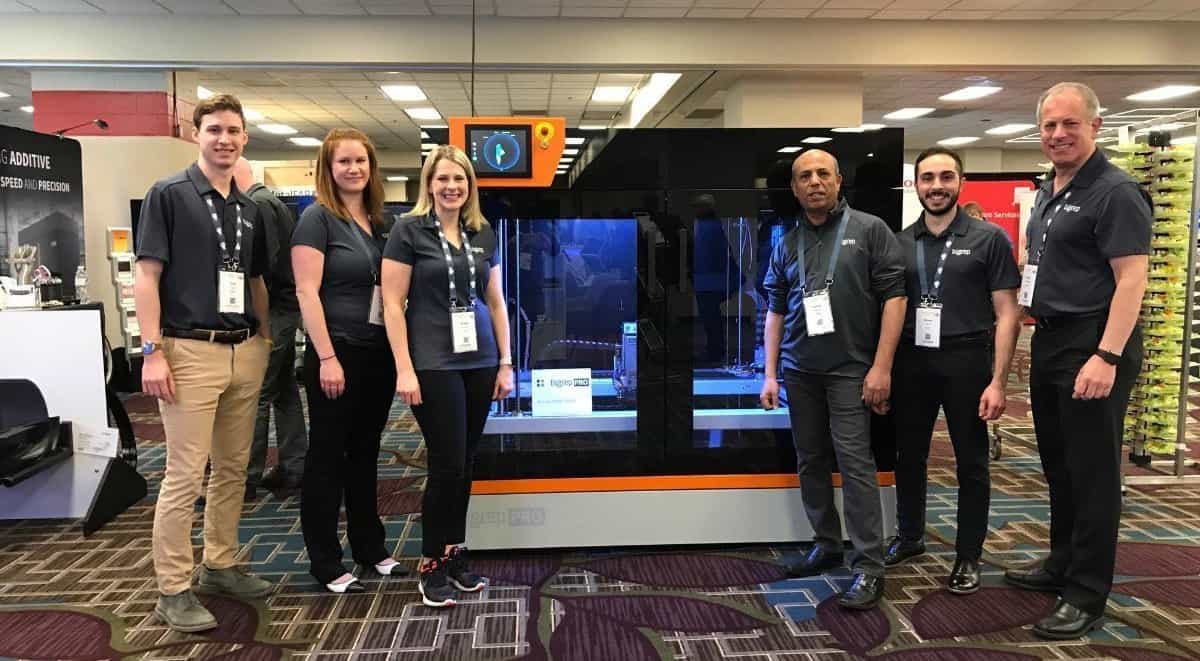

Right now we have a lot of questions about the upcoming BigRep PRO. Prospects are really intrigued about the MXT® extruders and want to see them print. The technology looks really promising and has the potential to revolutionize 3D printing. We have a lot of questions about the PRO’s print speed and the new slicer, Blade.

4. Where do you see the biggest growth opportunities?

For me, the biggest growth opportunities I see is about developing new materials. Large-format allows us to print for a lot of new applications, but the temperature can be difficult to control. With the BigRep PRO’s new enclosed print envelope, temperature control will be more precise, so our prospects will be able to print with new engineering-grade materials.

5. Why BigRep?

BigRep allowed us to reach new industries and develop new applications for our prospects. Having this large format technology is important for us and for our contacts. Last year BigRep was one of our top selling printers, and all of our customers are really happy with the printers.

We plan to film testimonials in our customers’ offices to showcase how they’re using the printers. Follow Neofab to find out more about BigRep’s printers in France!