The Talk of the Show

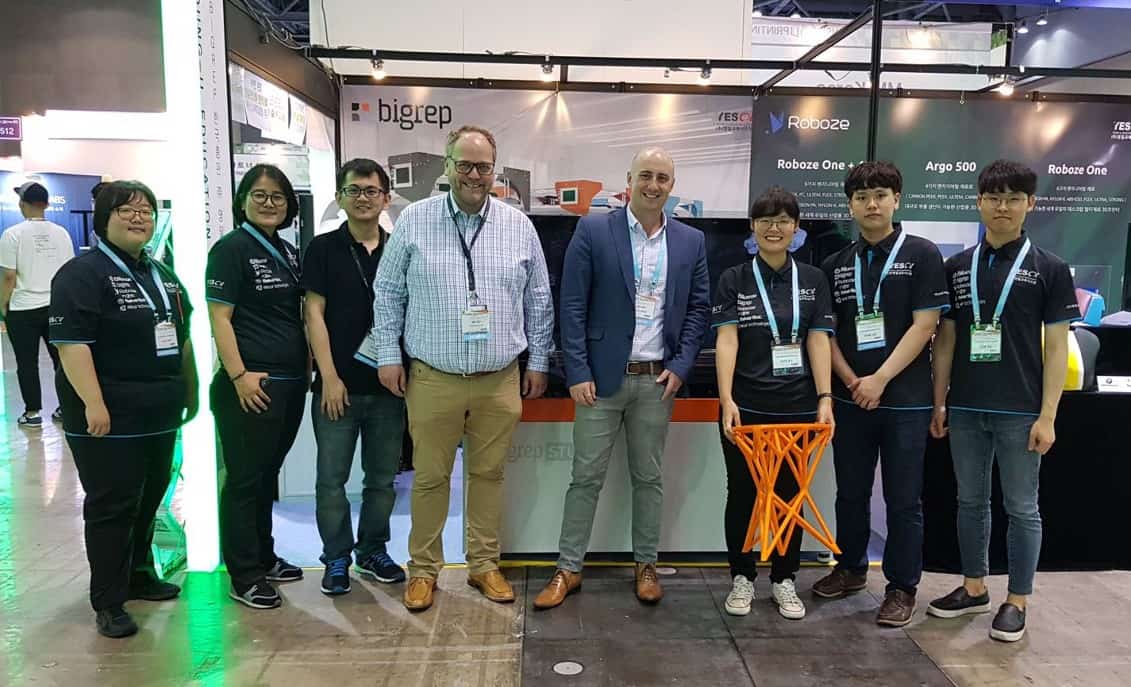

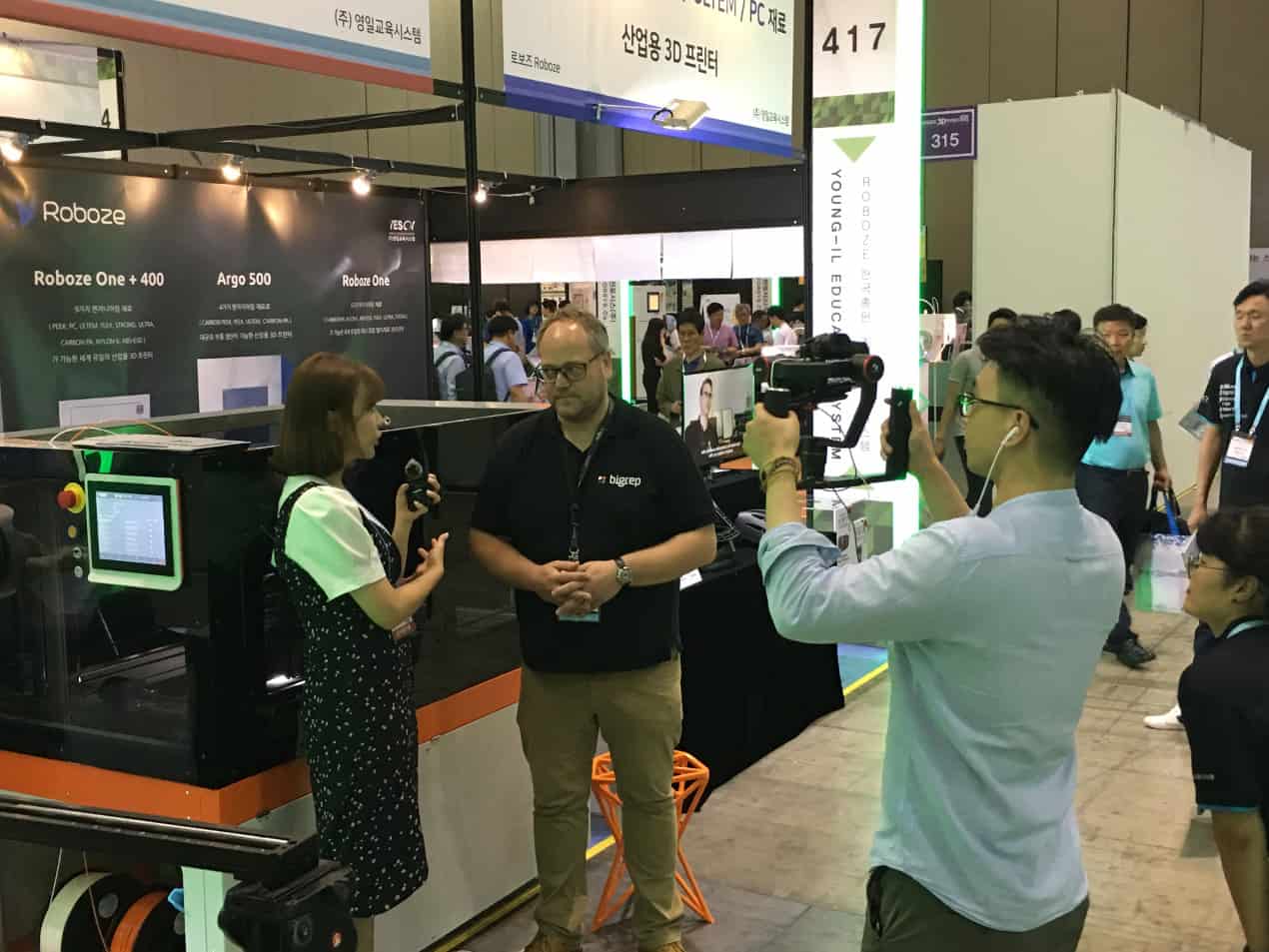

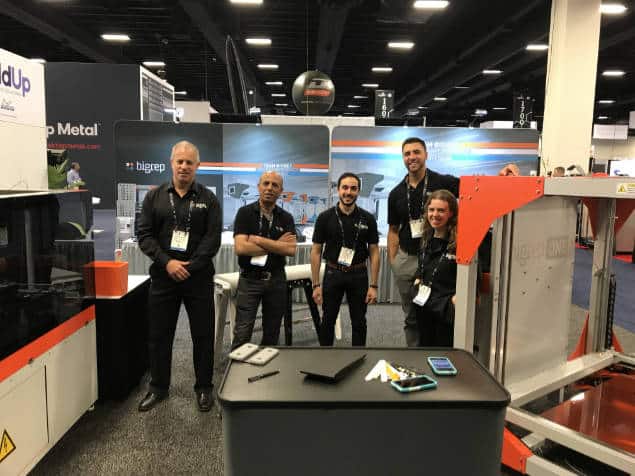

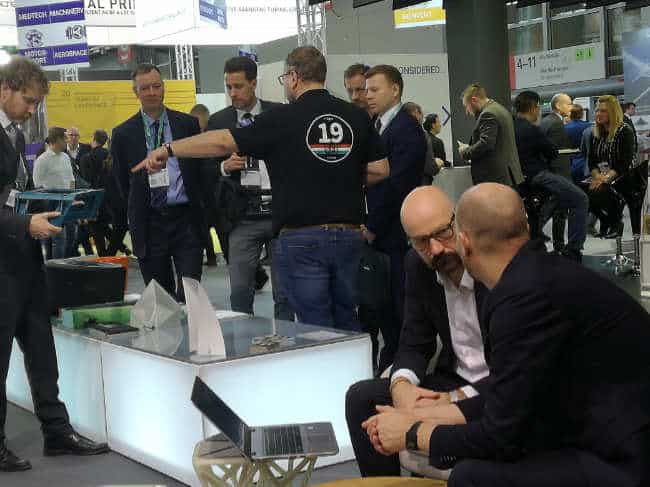

BigRep’s large-scale 3D printers attracted a lot of attention, positioned front and center of the additive section. Both the BigRep ONE and STUDIO were running 24/7 printing high quality parts throughout the show. We talked with engineers, product designers, professors, managements and C-levels about both the benefit of 3D printing and the value that large-scale can provide.

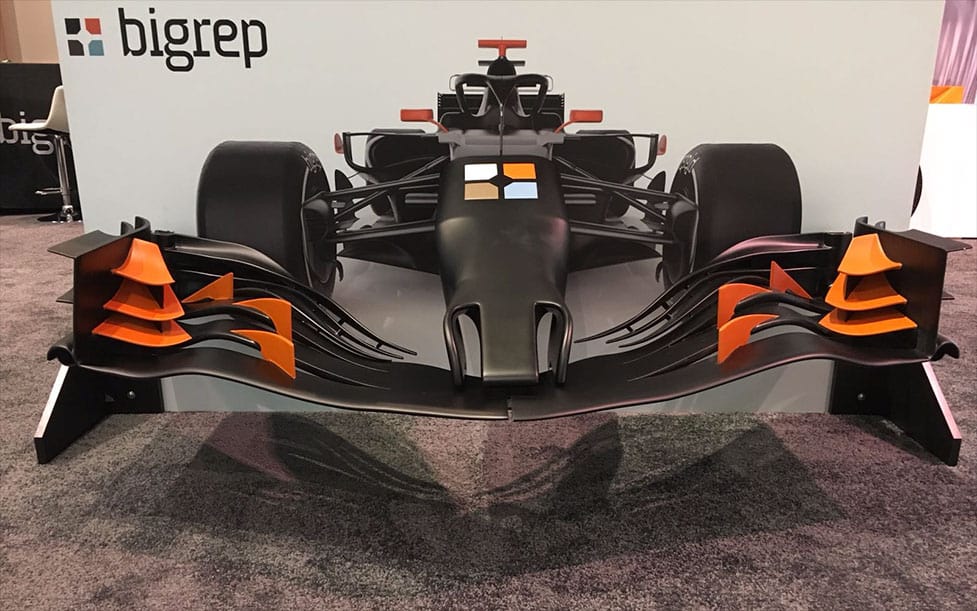

When attendees learned how big the build platform was, we could immediately see the wheels start turning and attendees imagining all that they could do. Many challenges we heard throughout the week was – “My printer is too small and I’m spending lot of time gluing and combining parts.” “I’m not getting quality parts off my larger-scale 3D printer.” “The strength of my parts isn’t adequate.” These challenges and more can be solved with a BigRep solution. From jigs and fixtures to 1:1 parts for prototyping and one off parts to patterns and molds, the possibilities are endless and can help get products to market faster and edge out the competition.

In 2018 and beyond, if companies want to continue innovating, getting bigger and better, then additive needs to be in their portfolio.

A Changing Landscape for Additive & BigRep

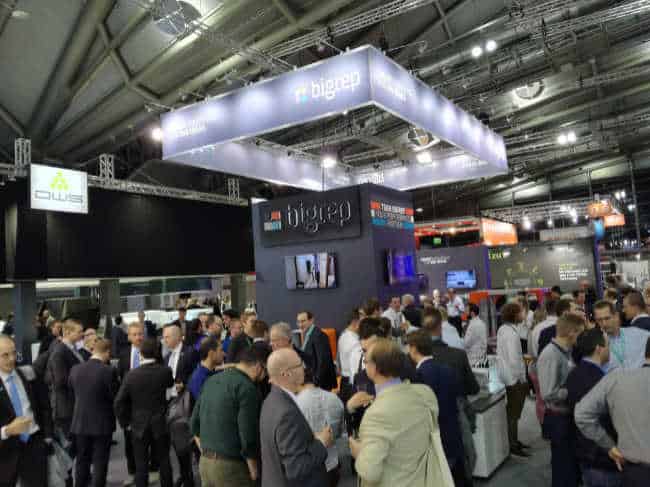

No BigRep booth visitor could have missed our enormous banner promoting our next-generation additive machines – our soon-to-come industrial large-scale printers. They’ll be unveiled at formnext (so don’t miss that announcement). While the excitement and interest was evident around the next generation of BigRep printers, we know there are many more to come when we unveil the new machines.

BigRep America president, Frank Marangell had this to say, “IMTS was a great show for BigRep and the additive community. It’s come a long way in the past years and by IMTS 2020, I expect BigRep and additive to be helping reshape manufacturing.”

Thanks to all our team, partners and visitors for making IMTS 2018 a spectacular success for us!

Stay tuned with BigRep’s upcoming events by signing up to the BigRep Newsletter.

The team could be coming to a city near you – read here about our upcoming events.