3D PRINTER FILAMENT BY BIGREP

BigRep's portfolio of industrial 3D printer filaments are created under carefully controlled conditions to guarantee uniform diameter and consistent composition. They are sealed in controlled, low-humidity conditions for safe storage and transportation - ensuring reliable, even extrusion regardless of whether they're used today or after a reasonable shelf life.

With a wide variety of filament types from affordable, general use materials to high-quality, engineering-grade materials for demanding industrial applications, BigRep has what you need - specialized for large-format 3D printing to bring your designs to life in full scale.

3D PRINTER FILAMENT BY BIGREP

BigRep's portfolio of industrial 3D printing filaments are created under carefully controlled conditions to guarantee uniform diameter and consistent composition. They are sealed in controlled, low-humidity conditions for safe storage and transportation - ensuring reliable, even extrusion regardless of whether they're used today or after a reasonable shelf life.

With a wide variety of filament types from affordable, general use materials to high-quality, engineering-grade materials for demanding industrial applications, BigRep has what you need - specialized for large-format 3D printing to bring your designs to life in full scale.

BigRep 3D-Printer Compatibility

- ALL

- ONE

- PRO

- STUDIO

- STUDIO G2

Large Selection of 3D Printer Filament

The variety of 3D printing filaments on the market has exploded. This gives ample options to manufacturers and makers alike to quickly produce parts with complex geometries and material properties, once limited to traditional manufacturing techniques. But with so many options comes a difficult question: Which 3D printing material is right for you and your part?

Finding the perfect filament for your part might be as simple as finding the right balance between quality and price. A good PLA is usually the go-to as an affordable material for hobbyists and product designers. But what if your part needs something a little more? Are you creating a functional prototype or end-use part that will be exposed to hazardous environmental conditions? Chemical, water, heat, or UV resistance might be an important part of picking your material. Or, does your part just not look quite the way you want? Upgrading to a higher-quality surface finish might be the simple answer you need.

How to Pick the Perfect Filament

In addition to large-format 3D printers, BigRep provides an extensive selection of printing materials. While BigRep 3D printers are open, meaning they are compatible with third-party filaments, BigRep offers its own range of materials specifically designed for optimal results in large-format printing. BigRep filaments are conveniently available in spools ranging from 2.0 kg to 8 kg, enabling uninterrupted printing for large-scale projects. Every filament ensures a uniform composition and diameter for consistent printing quality. Each material undergoes thorough testing to ensure compatibility with BigRep printers and meet their specific requirements.

When you are choosing a filament, consider the mechanical properties you would like your final part to have. Some common properties are:

When it comes to 3D printing materials, mechanical resistance plays a crucial role in determining the suitability of a material for various applications that involve physical stress. BigRep's ASA and TPU 98A are two highly resistant options, both known for their excellent impact strength. If stiffness is a priority, consider using filaments reinforced with carbon fiber, such as HI-TEMP CF and PA12 CF, which offer exceptional mechanical properties and durability.

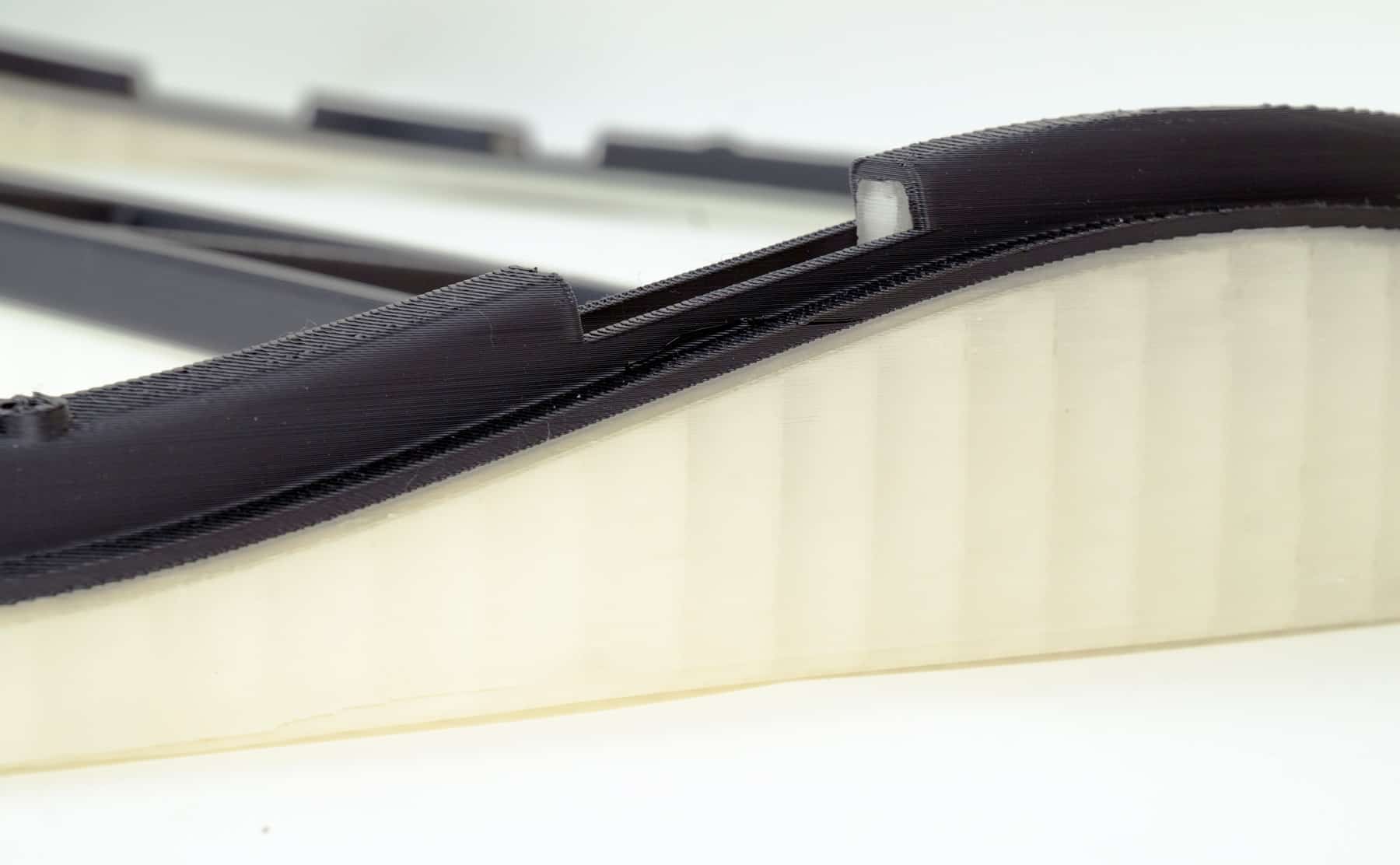

For applications requiring flexibility, TPU 98A has a Shore hardness value of 98A, striking the perfect balance between flexibility and strength. Sustainability is another important aspect to consider, as many 3D printing filaments are derived from petrochemicals. However, in BigRep's material portfolio, you can find a range of bio-derived polymers that offer competitive mechanical properties, from the affordable PLA to versatile PLX.

Resistance to environmental degradation is crucial because UV exposure, high temperatures, and chemical corrosion can significantly impact the structural integrity and longevity of 3D-printed parts.

ASA and TPU 98A excel in terms of UV resistance, making them ideal choices for applications exposed to sunlight. TPU 98A exhibits excellent chemical resistance and can withstand temperatures up to 100 °C. PA12 CF offers resistance to various chemicals, including bases, oils, alcohols, and salts.

In the realm of bio-derived materials, if you require a high-temperature resistant alternative to PLA, consider PRO HT, HI-TEMP, and HI-TEMP CF. Moreover, HI-TEMP CF possesses low moisture absorption properties, making it particularly suitable for humid environments.

Achieving the right balance between extrusion speed and part quality is a significant challenge in additive manufacturing. PLA is well-known as one of the best materials for high-speed printing. In BigRep’s portfolio, PETG and PLX also provide excellent printing speed. In particular, PLX can be printed up to 80% faster than a standard PLA material, with consistent quality results.

Production speed of a 3D printed part isn’t limited to extrusion speed, but should also consider post-processing time. This includes sanding, polishing, and coating. Thanks to its excellent surface quality, PA12 CF doesn’t require any additional post-processing and can be used immediately after printing. Another time-consuming post-processing step is the removal of support structures needed for printing complex parts. BVOH is a water-soluble polymer ideal for printing support structures that can be easily and rapidly dissolved in water.

If you’re looking for user-friendly materials that simplify the printing process, BigRep’s portfolio provides several solutions. PRO-HT offers a user-friendly and straightforward printing process, ensuring easy removal of breakaway supports with minimal residue on the adjacent print surface. Consistently achieves high-quality results, PLX also exhibits versatility, with the option to fine-tune printer settings for either high-speed printing or smooth surface finishes.

Both PLA and PETG can be printed at low to moderate temperatures, between 190°C and 240°C. Compared to other polymers used in 3D printing, PLA demonstrates minimal warping, making it an excellent choice for hassle-free printing. BigRep’s PETG readily achieves a smooth flow with consistent quality. For stiffer parts, opt for HI-TEMP CF, which also displays minimal shrinkage and warping, ensuring reliable and accurate print results.

The surface finish of 3D prints is an important feature for aesthetic applications. However, surface quality also affects other significant properties of the printed object, even for functional components where aesthetics aren’t a concern. For example, grip and paint adhesion improve with surface texture.

BigRep’s HI-TEMP bio-derived filament provides a matte finish, while PLX and PETG deliver attractive smooth surface finishes. If you’re looking to combine the mechanical strength and thermal resistance of carbon fiber-reinforced materials with optimal surface quality, you could consider opting for HI-TEMP CF or PA12 CF.

For lower environmental impact, consider using bio-derived polymers as your printing material, such as PLA, HI-TEMP, and PRO-HT. Both HI-TEMP and PRO-HT are CO2 neutral and fully bio-degradable under the appropriate conditions, making them much more sustainable alternatives to thermoplastics derived from petrochemicals like ABS. PET-based materials, like PETG, are highly recyclable as they can be reheated and remolded without a loss of quality.

BigRep's BVOH, a water-soluble polymer used for support structures in complex prints, is also environmentally friendly and non-toxic. Because it fully dissolves in water, its use reduces plastic waste resulting from the printing process.

Pick Filaments Depending on Use Cases

Filaments for Rapid Prototyping

In rapid prototyping applications, there are two main considerations: cost and lead time. Maintaining a low cost and lead time will help ensure your team can produce more iterations in less time than outsourcing or traditional production methods, helping you design the best quality product possible.

When choosing 3D printing filaments for rapid prototyping, you need to consider the price of that material and its recommended throughput – which denotes how fast materials should travel through an extruder for its best quality. Though cost is important, it’s also a balancing act. Make sure you purchase quality material with a uniform diameter and consistent composition to avoid costly and time-consuming disruptions from warping or otherwise failed prints.

Filaments for Forms and Molds

From patterns for sand casting metal parts to carbon fiber molds, urethane casting, and large-scale concrete formwork, 3D printing is an excellent tool for customized and low-volume production, resulting in a significant reduction of lead time, logistics, and costs.

Your choice of filament will greatly depend on the requirements of your forming or casting process. Carbon fiber parts cured in an autoclave may require 3D-printed molds using stiff filaments that are able to withstand higher temperatures. Patterns for sand casting applications can be printed with lower-temperature filaments, such as those typically recommended for prototyping. Concrete formwork may require filaments with a smoother surface finish, while urethane casting can benefit from chemically resistant, flexible filaments.

Filaments for Tooling

The term tooling represents a wide range of equipment essential in manufacturing, such as jigs, fixtures, transport devices, inspection aids, and much more. 3D-printed tooling offers massive savings, like up to 90% reduced lead times and 94% cheaper costs. Additional game-changing benefits include digital on-demand inventories, lighter ergonomic tools, and protected in-house design knowledge, just to name a few.

Materials best suited for tooling and manufacturing aids are mechanically resistant and durable, able to withstand constant use, abrasive chemicals, or higher temperatures. Surface quality and haptics may also be important for adequate grip and functional ergonomics.

Filaments for End-Use Parts

When 3D printing end-use parts, it’s important to consider where and how the part will be used. Will it be under significant pressure? Exposed to hazardous environmental conditions? Exposed to water or some sort of chemical? All these factors will help determine the material you need to manufacture a functional, effective product.

Choosing a material that’s right for the conditions your product will be in is essential. Luckily 3D printing filaments come in many of the materials familiar to injection molding and other traditional processes, so you can achieve familiar mechanical properties and can later scale production with the same material.

Filaments for Support Structures

Post-processing at any scale can be a huge time sink, even if you’re just removing support structures. In worst-case scenarios, a complex geometry can even make internal supports difficult to reach, if not impossible. Fortunately, with a dual-extrusion 3D printer, you can use specialized support materials to make finishing your parts easy.

Water-soluble supports are an incredibly useful material to reduce time spent post-processing your 3D printed parts. Simply set your printer to create support structures with its second extruder and dissolvable support material, then submerge your finished part to the material’s recommended specification for a perfect final product.

Filaments for Every 3D Printer

While optimized for BigRep’s industrial large-format 3D printers, BigRep filaments are compatible with any third-party 3D printer with the appropriate diameter nozzle. BigRep’s 3D printers are also compatible with third-party filaments because we believe that experimentation and versatility are key to creating the perfect products.

BigRep’s Industrial Filaments are…

- Available in MASSIVE spools up to 8 kg for uninterrupted prints in full scale.

- Optimized for industrial users, with uniform diameters and consistent composition.

- Thoroughly tested for high-quality performance with BigRep 3D printers.