EBOOK

3D Printing in the Automotive Aftermarket: Custom & Low-Volume Production

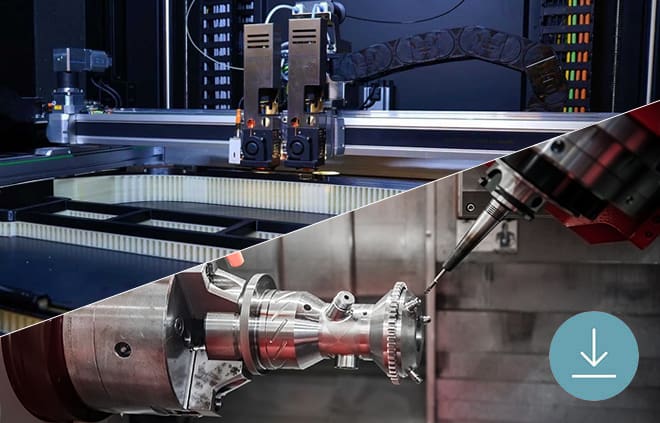

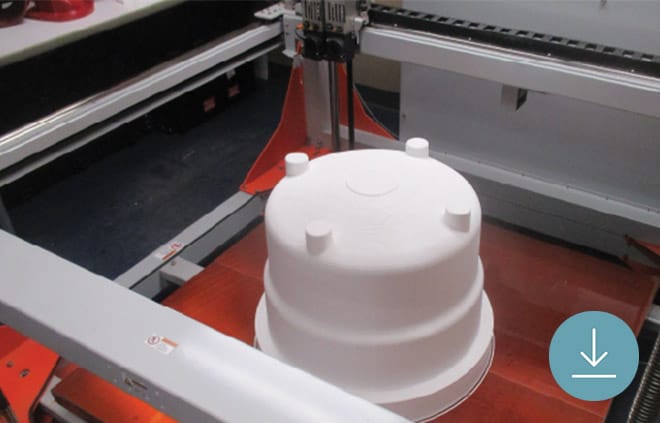

The automotive industry was one of the first to fully grasp the magnitude of customization with 3D printing and add it to their factory floor. With decades of additive experience, the sector largely uses 3D printing not just for prototyping but has expanded to manufacturing custom end-use vehicle parts.

AM customization is commonly used for car tuning, specialized commercial vehicles, and car modifications for people with disabilities. The reason is simple – one of the biggest wins of 3D printing is affordable low-volume production. Read more about how the industry makes the most of additive technology by exploring AM applications and examples from automotive giants.

In this eBook, we deep dive into:

- Different types of Low Volume Production

- The need for 3d Printing in Vehicle Customization

- The main Barriers to Vehicle Customization

- 3D Printing in different Product Development Stages

- The benefits of 3D Printing in vehicle customization

DOWNLOAD

[PDF 8 MO]