3D Printing Webinars on

Industrial use Cases and Applications

- All

- On demand

Integrating Large-Format 3D Printing in Universities

Universities and research institutes have long been at the forefront of driving innovation and progress. While educators are tasked with teaching the latest advancements, students must be inspired to leverage new technologies, such as 3D printing, that can relieve the restrictions of traditional production methods.

In this webinar, we discuss with some of the top universities, the projects and research they’ve conducted using large-scale 3D printing.

Ideation to Installation: 3D Printed Parts for Aftermarket Car Customization

From fabricating carbon fiber molds to perfectly finished speaker enclosures, the automotive aftermarket explores all avenues of 3D printing applications. Hear from JT Torres, owner of Automotive Entertainment, about how 3D printing takes the front seat in delivering bespoke interior door panels, center consoles, and a range of custom car parts.

Become a 3D Printing Expert with BigRep Academy

BigRep Academy covers all aspects of large-format 3D printing, including design, slicing, printer operation, troubleshooting, and so much more. This webinar will explain the value of in-depth 3D printing knowledge, demo the eLearning platform where you can access Academy courses, and explain how Academy users can get certified with their training.

Aerospace and Beyond: How SFM Technology Leverages Large Format AM

SFM Technology utilizes large format AM for a range of applications including massive fit-check prototypes and low-volume production of aerospace equipment. Learn how SFM successfully produces massive prints, how they manufacture parts with their BigRep PRO, and how they post-process 3D-printed products for a perfect finish.

Maximize Efficiency for Localized Production

Learn how 3D printing can make a huge impact to reduce production costs and speed up manufacturing times, particularly for low-volume and custom parts.

3D-Printed Gyroid: Improving Structurally Demanding Applications

Learn how gyroid infill can improve mechanical properties and reduce material usage and weight in Additive Manufacturing, ranging from renewable energy to biomedical applications.

Webinar: Carbon Fiber 3D Printing

Adding carbon fiber (CF) to filaments improves both strength and stiffness. The added strength and increased stiffness provided by the addition of CF leads to a better strength-to-weight ratio, achieving lighter, stronger parts with less printing time.

BigRep CONNECT webinar

Learn how BigRep CONNECT, a one-stop platform connecting you with your BigRep 3D printers, can boost productivity with remote monitoring and data analytics. It’s fully web-based, giving you access no matter where you are or what device you use.

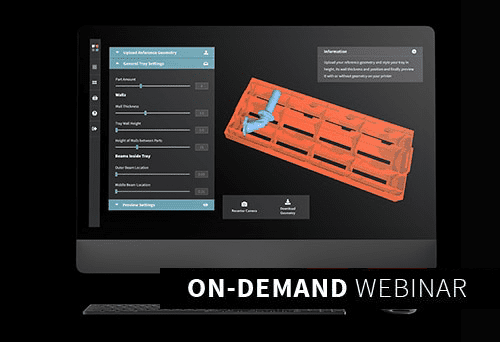

Webinar: BigRep FLOW

BigRep FLOW Learn how FLOW – BigRep’s customizable SaaS service and workflow automation tool can drastically reduce production time & costs by parameterizing recurring applications and designs. Mirek Classen will guide you through this webinar, showing examples from real applications and the potential which lies within the tool.Example applications we will present will be jigs, … Read more