- Software Improvements

- Auto orientation plugin now operates via a tool bar

- Add Tab Anti Warping plugin (https://github.com/5axes/TabAntiWarping v1.3.0)

- BigRep materials now have a link to their web page

- PRO.1 and PRO.2

- Added material profile: HI-TEMP

- ONE.4

- Added PEX CU 1mm and PEX CU 0.6mm

- New material profile: Pro HT for PEX CU 1mm

- New material profile: HI-TEMP for PEX CU 1mm

- New material profile: HI-TEMP-CF for PEX CU 1mm

Uncategorized

BLADE 3.7.2 Released!

- Software Improvements

- Better error reporting

- Added 3D mouse plugin (https://github.com/smartavionics/RawMouse)

- Fixed issue with GCODE hashing

- PRO.1 and PRO.2

- Improved material profile: PA12-CF

- ONE.4

- Added PEX 2mm: A 2mm nozzle for the ONE.4

- Improved PEX FR 0.6mm: added multiple new profiles

- Improved PEX FR 1mm: added multiple new profiles

- STUDIO.2

- Added 1mm: Added a 1mm nozzle option for PLA, HI-TEMP and HI-TEMP-CF

BLADE 3.6.2

- PRO.1 and PRO.2

- New material profile: PA12-CF

- Added ACE TC 0.6mm: A new Tungsten Carbide nozzle for use with PA12-CF (HMI v2.9.0 needed)

BLADE 3.6.1

- Fix tandem mode issues with improved GCODE formatting

BLADE 3.5.0

- Update to Cura 4.12

- Improved UI

- Better surfaces by using monotonic ordering

- Faster startup times

- Speed management

- Speed is now calculated during the slicing process and dynamically adapted based on the (non-fixed) line width and layer height

- Speed values were replaced with upper speed limits, which do not take into account extruder flow rate limits

- Introduced the "Maximal Print Speed Estimation" which shows the maximum speed based extruder flow rate limits for fixed line width and layer height

- Fixes in mixed mode and multi layer brim

- Materials:

- Added: PRO.1/PRO.2 ACE 1.0/0.6 LH06: TPU and PLA

- Improved: PRO.1/PRO.2 ACE 0.6 LH03: PA6/66

3D Printer Connectivity – From Monitoring to Smart Manufacturing

“We are currently in the fourth industrial revolution."

If you are into production somehow, statements like this one come from every direction: "We're in the middle of the transformation from the non-connected to a connected industrial world. Machines are no longer isolated systems. Connectivity enables machine to machine and machine to human communication. Getting convenient and constant access to data is one driver for machine connectivity.”

At the same time you hear about data security problems and you may wonder: Why is the whole industrial world in the wake of Industry 4.0 opening up their machines and systems for communication with the outside world, may it be with the internet or just local factory floor network zones?

The Basics of Digital Machines:

3D Printers are by nature digital machines. So other than conventional machines, which need to be equipped with additional sensors to get data about the process, every 3D printer from the very beginning is filled with data.

They know their state. They know in which phase of the print process they are. They know their next steps, their upcoming axis’ movements and extrusions. There are commands decoded in a G-Code and there are manual commands from the 3D printer operator, all collected in printer log files. Professional printers get additional data on their actions from sensors (e.g. closed-loop-control actuators tell the control system that they reached a certain location and monitor the forces they needed on the way), they know temperatures of components and spaces. And sometimes even have webcam footage.

This data is there. It can be used far beyond just controlling the print process in that very moment. It can give tremendous benefits not only to machine manufacturers, but to printer owners, operators, production floor planners & managers, service engineers and in the end the maturity of the printing process itself. Let’s see how:

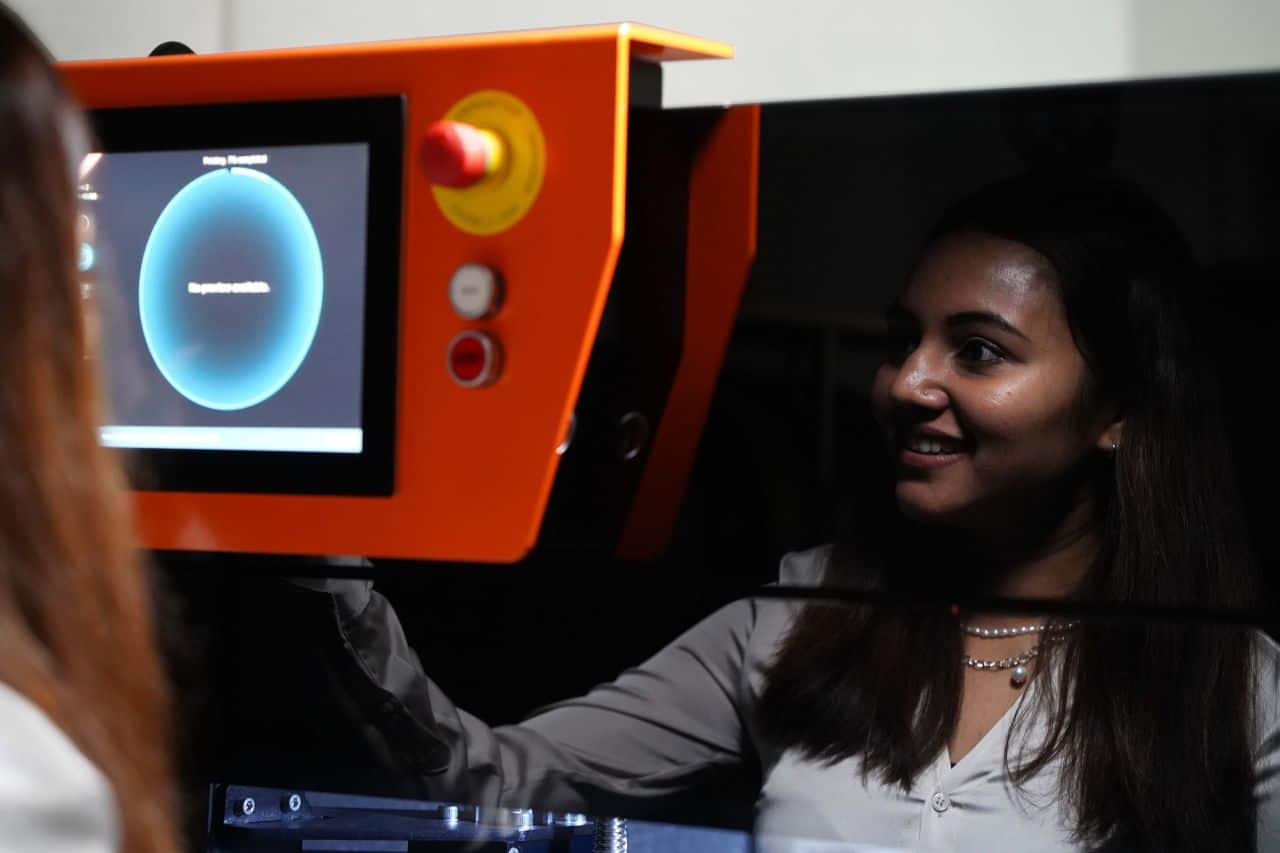

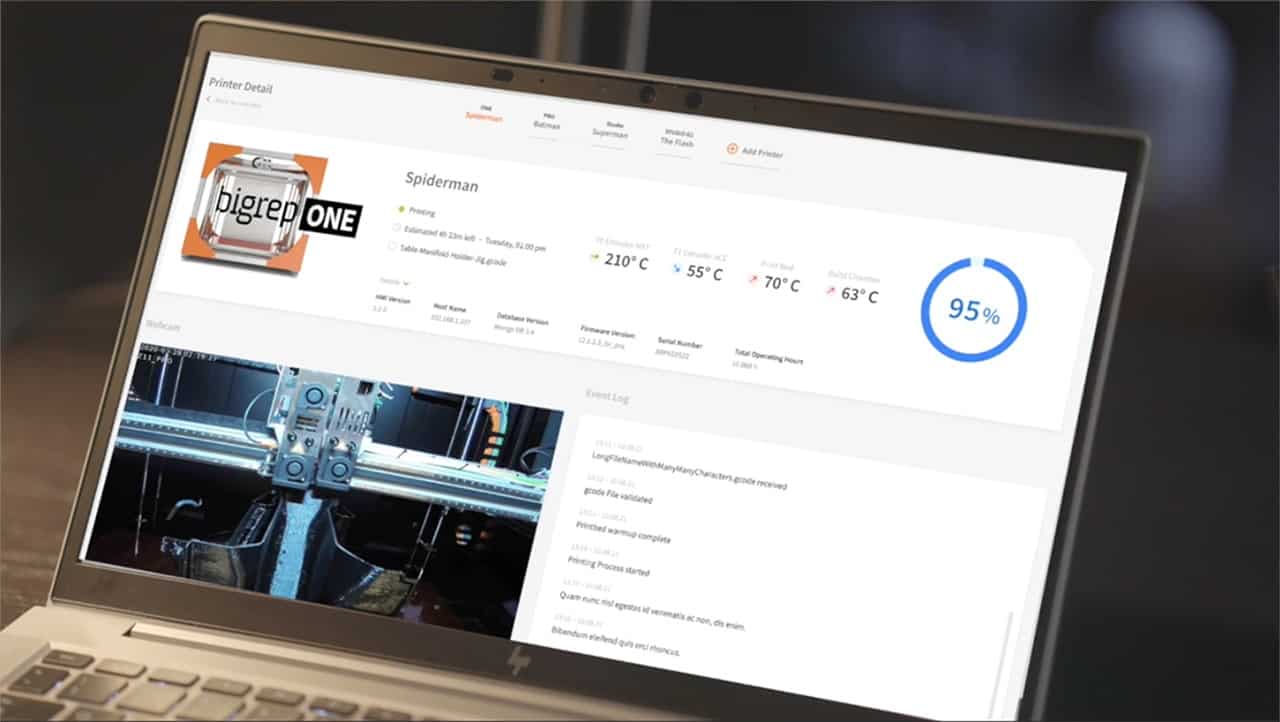

Level 1: Monitoring & Notifications

The first benefit of getting a 3D printer connected, is being able to monitor it. Data streaming over accessible interfaces lets you gather information on printer’s states and print progresses. This makes centralized visualizations over all your connected printers possible.

This adds a great level of convenience, even efficiency: You can see which of them are currently idle, heating up, printing or paused. You can see which of them are healthy and which are not. You can see how far into the print process each of them already is, which layer is currently being printed and what is the remaining print time which is especially important in large-format 3D printing.

Apart from actively monitoring machines, getting access to live printer data also enables alerting and notifications. Being immediately notified, when a print unexpectedly stops, the printer runs out of filament or the current print is about to finish, boosts efficiency and reduces unplanned idle time to a minimum.

Level 2: Machine Analytics

Printer data can not only be used to indicate the current state of the machine, but it can also be collected centrally to enable analysis over time. The collection of printer states data and visualization of print statistics lets you easily see how your printer capacity usage has developed over time. The same can be done with filament usage or print success rates. Having a good understanding of the current situation as well as the development until now is the basis for planning. And a great fact base to trigger constant improvement in your organization.

Bringing different data sets together for cross-data analysis lays the groundwork for pattern and anomaly detection. A database with slicer, extruder and printer settings, temperature sensor data and material data can be a good foundation for print part optimization, where for different print iterations of one part all data are compared and patterns for quality are identified.

With recording all process-relevant parameters throughout the whole print, this data can be turned into a high-level quality assurance. Giving you more information and so better confidence than any conventional quality inspection method (remember: for 3D printed part, you should check the inner structures as well).

And again: It does not need to be rocket science. With simply setting up algorithms to compare the dataset of the latest print to a previous one (where the part came out in specs) your production can tell you on the spot and fully automized if your part will be in specs or if deviations were found.

Level 3: Prediction

When patterns and anomalies are identified and a sufficient amount of data is being considered, future prediction is nothing but the next natural step. When you know the indicators of optimized print parts and the combination of settings, material etc., you will be able to predict the quality of a print part in advance, without the need for print iterations. You will get the first print right.

The same can be done with printer capacities. If you know the evolution of printer usage capacity, you will likely be able to plan capacities and make data driven decisions. You will be able to predict the exact point in time when a new printer is needed and when the invest is returned. Maintenance can be predicted when the indicators of a part’s nearing end of life are identified.

Level 4: Smart 3D Printing

At the end of the process stands its supreme discipline: smart printing. When adjustments to the print are being done during the print by the printer based on sensor and prediction data. When the machine itself learns from past’s faults, the technology will finally fully mature. When all print process related know-how and data interpretation ability is transferred from human to machine, people can finally concentrate on the parts they want to print and not on how to print them.

Until then there are a few steps still to go technology wise. But companies are pushing the development here with every new machine and software generation.

3D printing is by nature the most digital manufacturing process of all. So, to connect and to smarten up this technology can push the efficiency, the quality, the costs and even the convenience of 3D printing to higher levels than what most other production processes can do.

Want to Learn More About 3D Printer Connectivity?

Learn how BigRep CONNECT, a one-stop platform connecting you with your BigRep 3D printers, can boost productivity with remote monitoring and data analytics. It's fully web-based, giving you access no matter where you are or what device you use. Don't miss out, watch the webinar now:

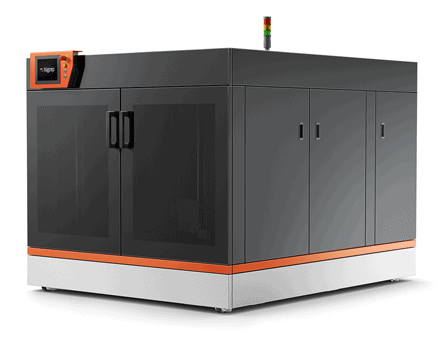

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

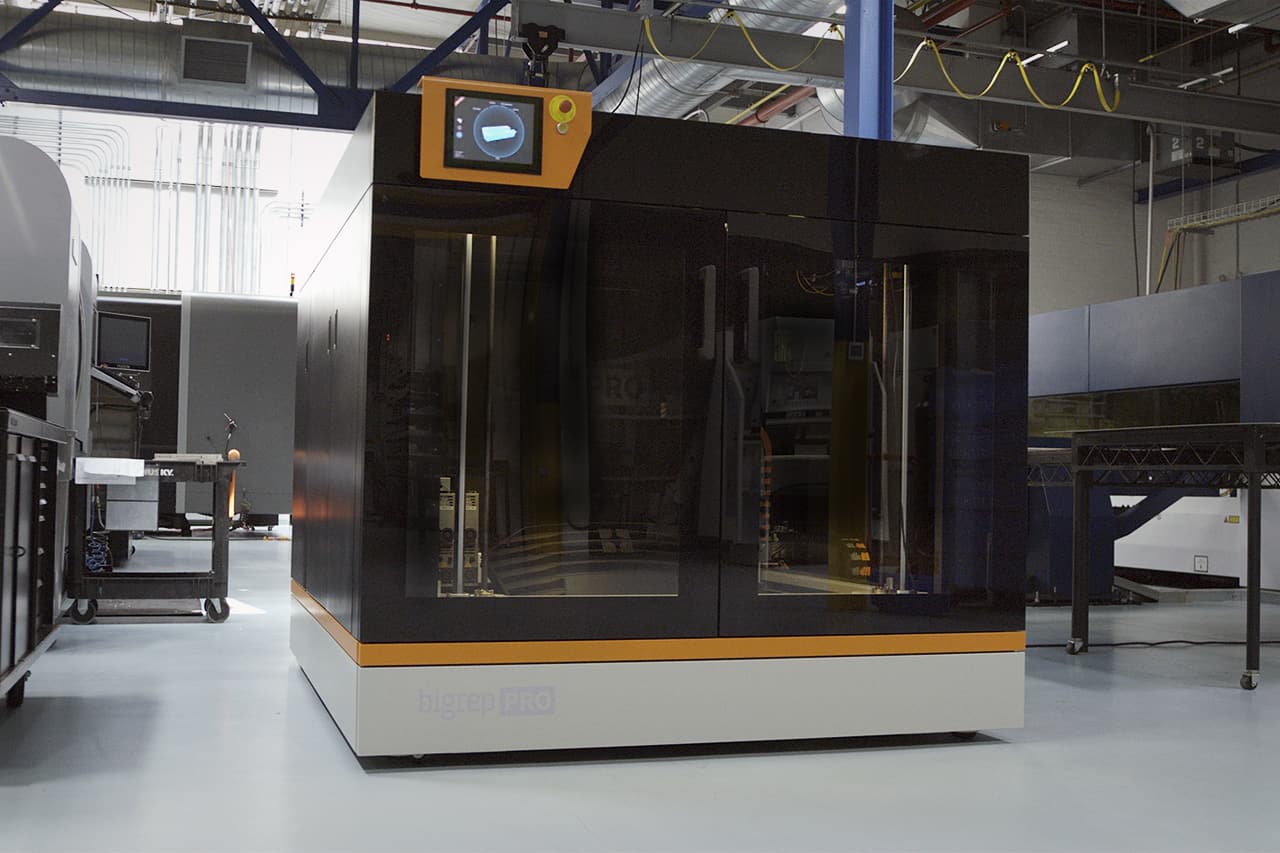

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

BigRep and Forward AM Expand Strategic Partnership with new Material, CONCRETE FORMWORK

BigRep and Forward AM, the 3D printing business of BASF, are excited to introduce a new material, CONCRETE FORMWORK, targeted to the architecture and construction industry.

Berlin, Germany. May 10, 2021. Architecture is the representation of a cultural era. By transforming its design language, creators can redefine the world around us. However, reality comes crashing down when conventional formwork solutions quickly reach their limits as construction elements become more complex. To overcome this challenge, Forward AM and BigRep are expanding their partnership and have joined forces again to leverage the synergies between their main areas of expertise: Virtual Engineering, Additive Manufacturing, advanced material development, and large-format printing.

“We are excited to work with Forward AM to bring more solutions to the architecture and construction industry,” said Dr. Sven Thate, Managing Director of BigRep. “Our customers are seeing huge gains in terms of cost and speed thanks to our large-format machines and the new CONCRETE FORMWORK filament. Our solutions are opening the doors to many new possibilities.“

BigRep 3D printers, which are up to 1 cubic meter in build volume, can produce large, complex formwork up to 3x faster at a fraction of the cost of traditional methods. With BigRep's new CONCRETE FORMWORK filament enabled by Forward AM, the massive benefits of 3D printed formwork are yours for the taking.

“At Forward AM, we developed a highly dimensionally stable, rigid formwork material, especially tailored to work seamlessly on the BigRep’s large-format3D printers. We are excited to be able to deliver this ready-to-use, end-to-end fabrication solution for bespoke formwork,” says François Minec, Managing Director BASF 3D Printing Solutions.

Demonstrating the material's effectiveness and advantages for the construction industry, Forward AM and BigRep showcase the “Bespoke Stair at Nest Step2,” designed by DBT at ETH Zürich with ROK, SW Umwelttechnik, and WaltGalmarini. The innovative concrete staircase expands the design possibilities of structural architectural elements, while minimizing costs, material waste, and skilled labor. NEST, to be built at EMPA in Zürich, is an innovative building utilizing digital fabrication and circular economy.

For more information on the partnership and to see the printers and material in action, visit

• BigRep https://bigrep.com/applications/concrete-formwork/

• Forward AM https://forward-am.com/use-cases-and-whitepapers/concrete-formwork/

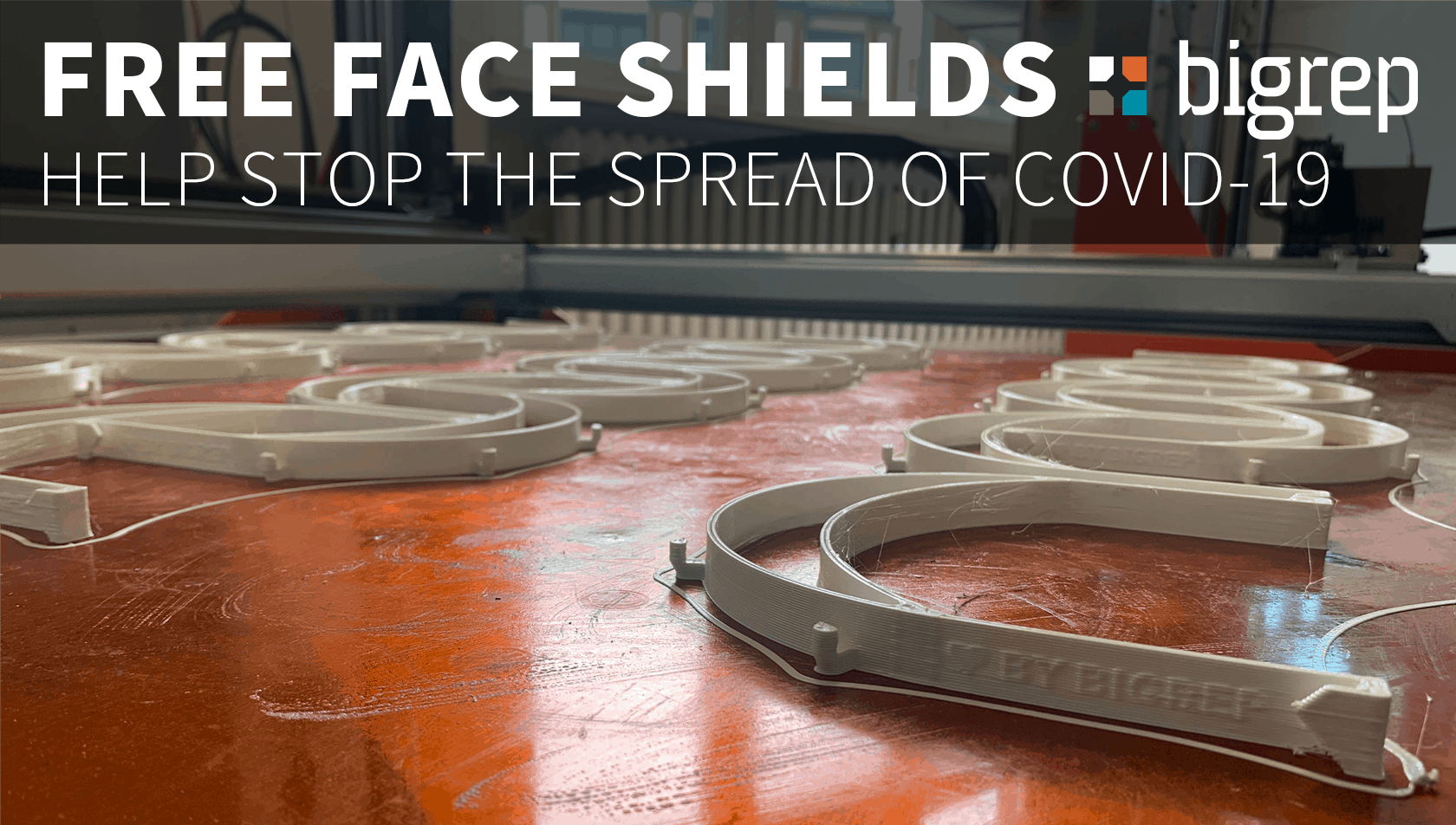

Help Stop the Spread of COVID-19 with BigRep

Get involved by additively manufacturing protective equipment for your local community with BigRep.

The ongoing effects of COVID-19 are overwhelming many hospital and organizations who lack the supplies to respond as effectively as they can, and additive manufacturing is a technology with a unique capacity to make a difference. We’re asking you to be part of the solution and print protective face shields for organizations and citizens in your local community.

BigRep is already donating face shields to local organizations to provide protection from the novel coronavirus and we’d like you to join us. With the following face shield design you can help provide some desperately needed equipment in your community. On a BigRep ONE users can print up to 24 of the masks at once, so we're asking our network of partners and customers to get involved. To help, we’re offering a complementary 2.3kg spool of PLA in exchange for video footage of you producing the equipment on your BigRep 3D printers. We’ll use that footage to continue our call for action, getting more and more people involved in this movement.

The process is simple:

- Download our face shield design file (130 mb)

- Print as many face shields as you can

- Source clear plastic screens for the shields

- Donate the equipment to organizations in your community

- Send video footage of your local action to BigRep for more material

Send your video footage to Amir Fattal ([email protected]), and if you need any help connecting to local organizations who might need these supplies please reach out to Alexander Levit ([email protected]).

About BigRep

BigRep develops the world’s largest serial production 3D printers, creating the industry benchmark for large-scale printing with the aim to reshape manufacturing. Its award-winning, German-engineered machines are establishing new standards in speed, reliability and efficiency. BigRep’s printers are the preferred choice of engineers, designers and manufacturers at leading companies in the industrial, automotive and aerospace sectors. Through collaborations with its strategic partners – including Bosch Rexroth, Etihad Airways and Deutsche Bahn – and key investors – including BASF, Koehler, Klöckner and Körber – BigRep continues to develop complete solutions for integrated additive manufacturing systems, as well as a wide range of printing materials on an open-choice source. Founded in 2014, BigRep is headquartered in Berlin with offices in Boston and Singapore. Leading the way in one of the world’s key technologies, our multinational engineering teams are highly trained, interdisciplinary and customer-focused.

For additional information, please contact:

To arrange an interview with BigRep’s executive management or NOWLAB team, and for more information on BigRep and its solutions, please contact:

Jürgen Scheunemann

PR & Communications BigRep GmbH

T: +49 30 9487 1430

E: [email protected]

Post-Processing for FFF Prints

EBOOK

Post-Processing for FFF prints

BigRep provides high-quality prints straight off the print bed, but post-processing can improve geometric and mechanical properties and creates a wowing aesthetic effect. By improving surface characteristics, post-processing widely extents the range of use cases and applications across all industries.

This eBook will explore the three types of FFF post-processing techniques: 1) Material Removal, 2) Material Addition and 3) Material Property Change. Also, learn how various techniques like high resolution tumbling, resin coating and aluminum plating are transforming 3D printed parts.

COMPLETE THE FORM TO DOWNLOAD OUR POST-PROCESSING EBOOK

DOWNLOAD EBOOK

WATCH WEBINAR

Watch WEBINARTwo centuries of design meets 3D printing

EBOOK

VILLEROY & BOCH 3D PRINTING INDUSTRIAL DESIGN PROTOTYPES

Villeroy & Boch, a well known manufacturer of ceramics, is using the BigRep ONE to maximize prototyping and designing speed.

Johan de Groot, who works as a product designer, describes how the use of the BigRep ONE revolutionized the way they create prototypes and designs.

They are now able to produce bathtubs and shower trays one-to-one at high levels in about three weeks. This was unthinkable before the introduction of the BigRep ONE.

Firms across industries use BigRep’s large-format industrial 3D printer technology to reduce costs, develop better products and get to market quicker.

COMPLETE THE FORM TO DOWNLOAD OUR VILLEROY & BOCH EBOOK

DOWNLOAD

[PDF 3,23MO]