BIGREP的3D打印机细丝

BigRep的工业3D打印机细丝组合是在精心控制的条件下生产的,保证直径均匀和成分一致。它们被密封保存在受控的低湿度条件下,以便安全储存和运输,确保可靠、均匀地挤出,无论您是即用还是在合理的保质期内使用。

从价格低廉的通用细丝到用于要求严格的工业应用的高质量工程级材料,BigRep拥有您所需要的产品——专门用于大尺寸3D打印,将您的设计全面付诸现实。

BIGREP的3D打印机细丝

BigRep的工业3D打印机细丝组合是在精心控制的条件下生产的,保证直径均匀和成分一致。它们被密封保存在受控的低湿度条件下,以便安全储存和运输,确保可靠、均匀地挤出,无论您是即用还是在合理的保质期内使用。

从价格低廉的通用细丝到用于要求严格的工业应用的高质量工程级材料,BigRep拥有您所需要的产品——专门用于大尺寸3D打印,将您的设计全面付诸现实。

兼容的3D打印材料

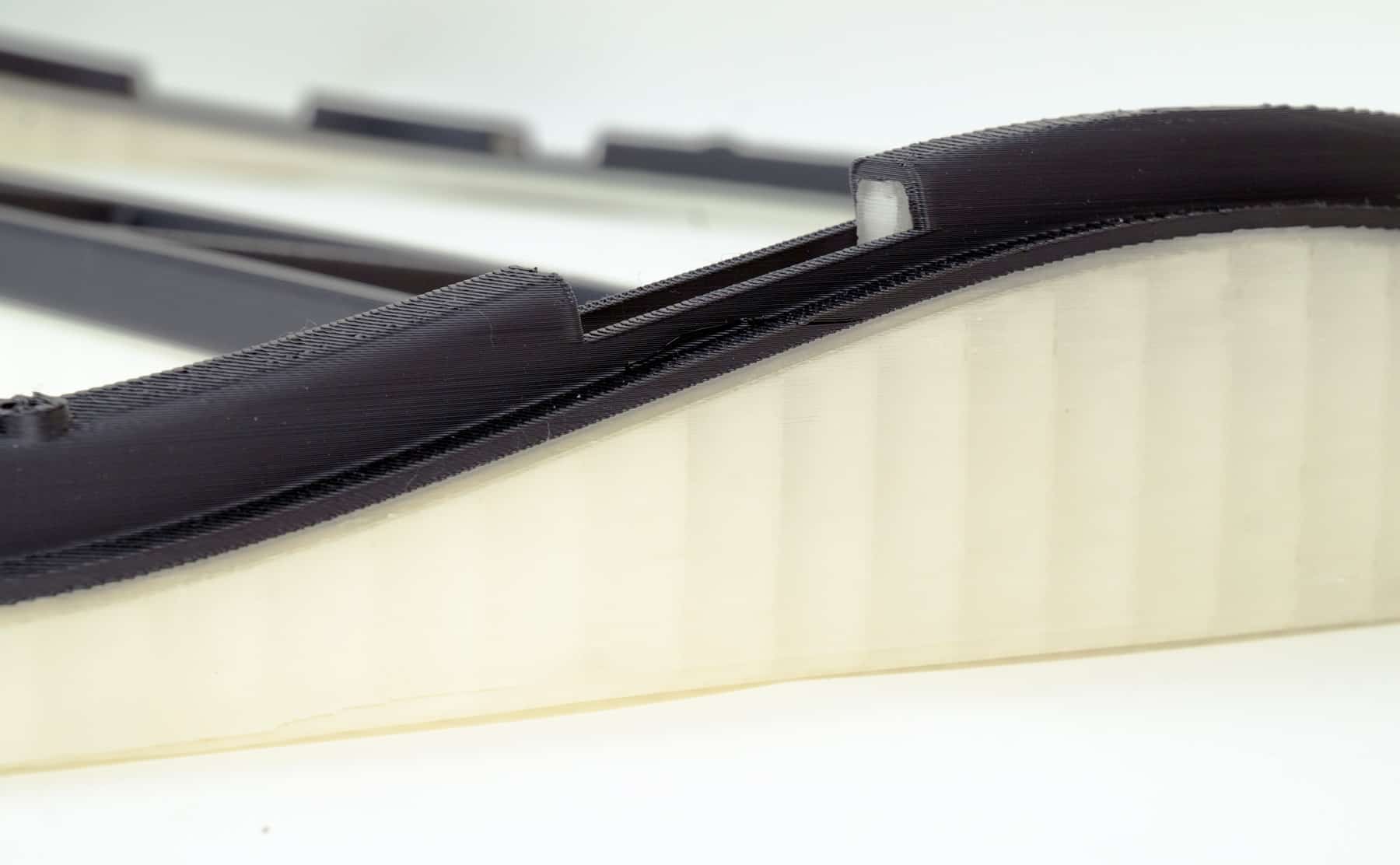

PA12CF

兼容的 3D 打印材料

3D打印机细丝的多种选择

市场上3D打印细丝的种类已经成爆炸性增长,这给制造商和制造商提供了充分的选择,得以快速生产具有复杂几何形状和材料特性的部件,而这曾经仅限于传统制造技术。但是,拥有这么多选择后,就迎来了一个困难的问题:哪种3D打印材料更适合您和您的零件?

为部件找到完美的细丝似乎就像在质量和价格之间找到适当平衡一样简单。优质的聚乳酸(PLA)通常是爱好者和产品设计师的首选,是一种经济实惠的材料。但如果部件需要更多材料呢?您是否正在创建一个将暴露在危险环境条件下的功能原型或最终用途部件?耐化学、水、热或紫外线可能是挑选材料的重要因素,或者您的零件看起来并不像你想要的那样?您可能希望升级到更高质量的表面光洁度。

如何挑选完美的细丝

当您选择长丝时,请考虑最终部件具有的机械性能。一些常见的特性是:

根据不同的使用情况,选择不同的细丝

适用于所有3D打印机的细丝

BigRep细丝虽然对BigRep的工业增材制造系统进行了优化,但与具有适当直径喷嘴的第三方3D打印机兼容。BigRep的3D打印机也与适当直径的第三方细丝兼容,因为我们相信,实验和多功能性是创造完美产品的关键。

BigRep的工业细丝...

- 可提供重达8公斤的巨型线轴,可实现不间断地全尺寸打印

- 已为工业用户进行优化,具有统一的直径和一致的成分

- 全面测试了BigRep 3D打印机的高质量性能