BVOH

WATER-SOLUBLE SUPPORT

AVAILABLE COLORS

BigRep's BVOH support material is a water-soluble filament that drastically reduces post-processing for 3D-printed parts. Created for use with dual-extruder printers, BigRep BVOH is compatible with a wide range of materials to provide efficient support during the printing process. BVOH is ideal when 3D printing complex geometries where breakaway support be difficult to remove or impossible to access after printing. When the surface appearance of your part is paramount, BigRep BVOH results in better surface quality with less post-processing effort.

BVOH easily dissolves in water, cleanly freeing parts from support structures without manual post-processing. While the dissolving time depends on part geometry and slicing settings, BVOH’s solubility increases with higher water

temperature and delivers faster results.

MADE FOR

Water Soluble for

Easy Removal

Saves Time

Post-Processing

Nontoxic and

Odorless

Excellent Support

Adhesion

Compatible with Many BigRep Materials

What is BVOH 3D Printing Filament?

BVOH (Butenediol vinyl alcohol co-polymer) is a water-soluble support material. That means it is designed to print temporary support structures that can be dissolved in tap water — cold or warm.

Many 3D printer users prefer water-soluble supports because removal is faster, easier, and doesn’t leave unsightly marks. Supports printed in an insoluble material typically have to be removed with a knife, which creates a surface blemish.

Overall, BVOH behaves a lot like PVA, another common support material. However, BVOH offers superior adhesion to build materials like ABS and is less likely to cause nozzle clogs. It also dissolves at a faster rate, making the support removal process as short as possible.

Why Use BigRep BVOH Filament?

BigRep BVOH filament is compatible with all BigRep large-scale 3D printers (and other open-material FFF printers with dual extruders). By 3D printing support structures in BVOH, the support removal process is drastically shortened.

Although BVOH works best with PLA — it has similar temperature requirements and good natural adhesion to it — it is compatible with all BigRep filaments. By contrast, some water-soluble materials on the market are not compatible with certain build materials such as ABS. Naturally, BigRep BVOH is especially practical for large-format 3D printing, as it is available in very large spools: available sizes include 0.75 kg, 2.5 kg, and 4.5 kg (8 kg upon request).

Users of BigRep’s industrial 3D printers will find it easy to incorporate BVOH into their workflow. This is because BigRep has developed a preconfigured BVOH print profile for its BLADE slicing software.

End Use Parts

Factory Tooling

COMPLEX MOLDING

Functional Prototypes

Benefits of 3D Printing BigRep BVOH

There are several benefits to 3D printing BigRep BVOH over other water-soluble support materials like PVA. These include superior adhesion to build materials — even tricky materials like ABS — and ultra-short dissolving times. The fastest speeds can be achieved with warm water, but cold water also works.

So, what makes BigRep BVOH stand out over other BVOH filaments on the market? In addition to the range of spool sizes, BigRep BVOH has been optimized for improved melt flow to prevent clogging and has a slightly lower print temperature than some comparable products.

Unique advantages of BigRep BVOH:

- Improved melt flow to prevent clogging

- Adequate tensile strength (34 MPa) to support large prints

- Wide material and machine compatibility

- Available in large spool sizes: 0.75 kg, 2.5 kg, and 4.5 kg (8 kg upon request)

Recommended print settings

- Nozzle temperature: 190 - 210 °C

- Print Bed Temperature: >60 °C

- Chamber Temperature: n/a

- Print Speed: >30 mm/s

BigRep BVOH filament has a low melting temperature of 175 °C. This makes it easy to print: the required nozzle temperature is 190–210 °C, with a bed temperature of 60 °C. These print settings are similar to those for PLA.

Since the purpose of support material is to hold up heavy structures, it also needs to be strong. BigRep BVOH has a fairly high tensile strength of 34 MPa, which is slightly higher than ABS.

The most important property of BVOH is its solubility in water. Support structures can be washed away in cool or warm water, although warm water helps speed up the process. However, keep in mind that the material’s solubility can make it vulnerable to humidity.

What to Look Out for When 3D Printing BigRep BVOH

Newcomers to dual extrusion additive manufacturing may encounter some challenges when 3D printing BVOH. Although the material prints well at moderate temperatures, it has some quirks that require care and attention.

The most common issue with any water-soluble support material is nozzle clogging. And while BigRep has developed a highly clog-resistant BVOH formulation, users should still take steps to minimize clogging by performing regular nozzle cleaning. One option is to perform a cold pull with a dedicated cleaning filament; another is to use a long needle to manually clear out debris.

Finally, users of standard and professional 3D printers may find that BigRep BVOH adheres better to the build surface with the help of an adhesive coating like Magigoo glue stick.

Best Practices for Storing and Handling BigRep BVOH

Like other soluble support materials, BigRep BVOH is highly hygroscopic. This means it absorbs moisture easily, which can become an issue in humid environments.

Because of its hygroscopic nature, BVOH should always be stored in dry conditions at a temperature of 15–25 °C. With a humidity of just 0.01%, the BigRep SHIELD filament dry cabinet is an ideal form of storage, holding up to 60 kg of filament. For non-industrial users, a sealed container with a desiccant should be the bare minimum.

Drying out BVOH filament before use can also lead to better printing results and prolonged printer life. BigRep recommends drying the filament at 60 °C in a hot air dryer or vacuum oven for four to 16 hours.

Use Cases: See How Customers Use BigRep BVOH

BigRep BVOH filament can be used for any build that requires support structures. Suitable parts include those with overhanging areas that cannot support themselves.

Water-soluble support material like BVOH is especially useful for parts that have internal or otherwise inaccessible overhangs. This is because cavities in the part can be easily filled with water to remove soluble internal supports. Conversely, it is not always possible to reach into a cavity to remove insoluble supports with a knife.

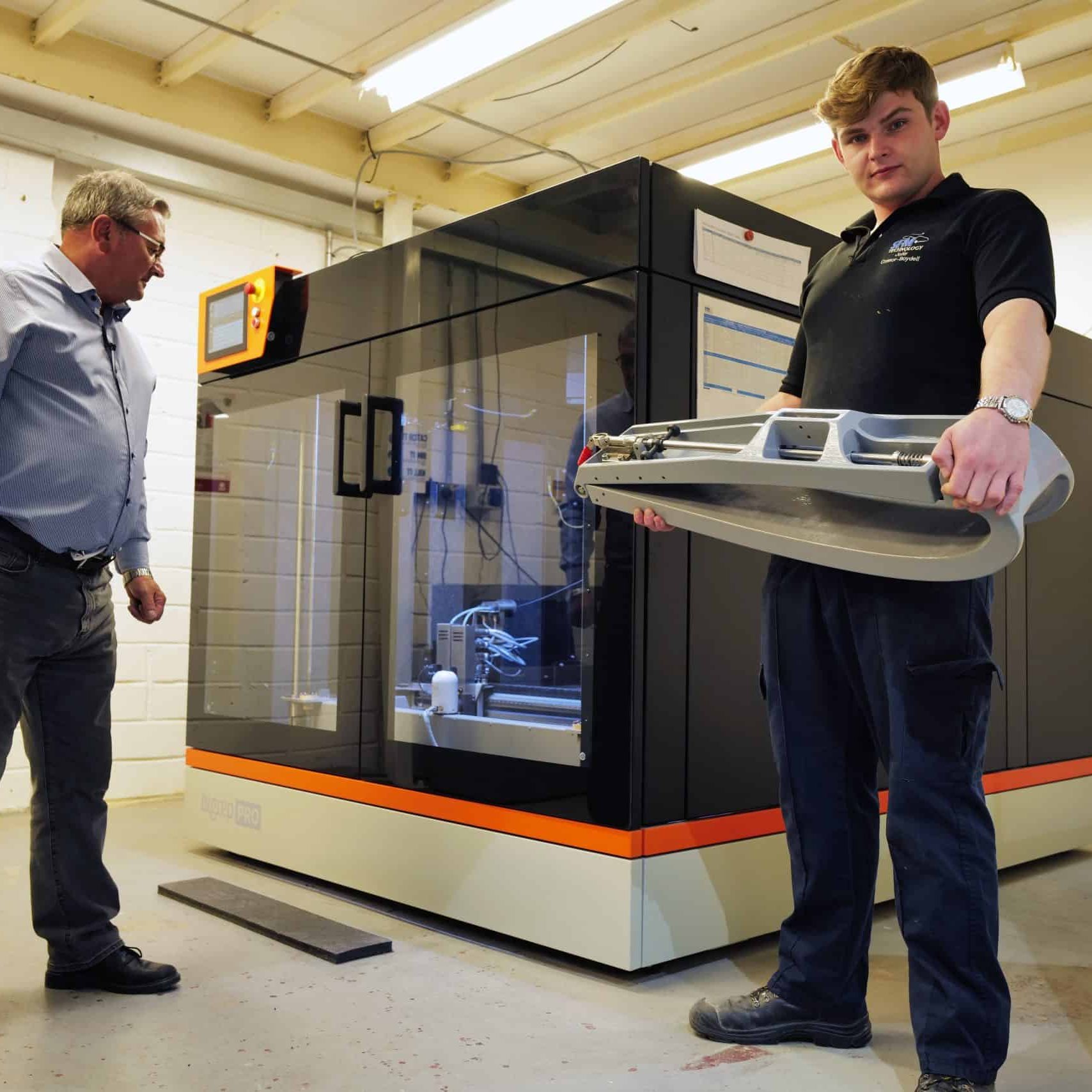

AVI Boston seamlessly weaves technology into crafting personalized and bespoke automotive parts like dashboards, radar installations, door panels, and beyond.

What puts them ahead of the curve is their expertise in integrating cutting-edge audio and visual systems, elevating both the car’s aesthetics and functionality. Their innovative approach is amplified by their use of 3D printing to manufacture end-use parts with BigRep’s STUDIO 3D printer to bring their concepts to life.

Many of these complex parts would be impossible to produce without BigRep's water-soluble BVOH support filament. Owner of AVI Boston, Safi Barqawi, says “We’ve been designing these parts in-house and building clean structures for such intricate pieces. We would never be able to do that by hand. Getting down to that small of a detail is really hard.”

Physical properties:

| Material: | Butenediol vinyl alcohol copolymer |

| Filament Sizes: | 750g, 2.5 and 4.5kg (8.0 kg on request |

| Diameter: | 2.85 mm |

| Density: | 1.14 g/cm³ |

| Flexural Modulus (ISO 178): | 2200 MPa |

| Tensile Strength (ISO 527): | 34 MPa |

| Young's Modulus (ISO 527): | 78 MPa |

| Vicat Softening Temp (ISO 306): | ≺60 °C |

Recommended printing conditions:

| Nozzle Temperature: | 190 °C |

| Print Bed Temperature: | 60 °C |

| Environmental Temperature: | n.a. |

| Printing Speed: | >30 mm/s |

Additional comment: Material is sensitive to moisture and should be stored in dry conditions at all times.