What is 3d printing?

3D printing is a process of making three dimensional solid objects from a digital file using additive processes. The object is created by laying down successive layers of material, which can then be seen as a thin horizontal cross-section of the created object.

Steps to create a 3D printed object

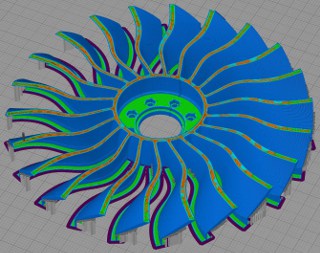

Creation of a digital model using CAD software and/or scanners. If you don’t have the possibility create your own digital model, it is possible to obtain 3D files from online depositories such as Thingiverse or Grabcad.

You will have to use a slicing software (Cura, Slic3r, Simplify 3D, etc.) to prepare the 3D model for the printer. It will slice your 3D model into layers and translate it into the “language” of the 3D printer.

Prepare the machine for printing (material, heat, etc.) and transfer your file to the printer. Press print and wait to see your 3D file becoming a real object.

“3D printing is the meeting point of the virtual with the physical” – Michel David, 3D Printing Specialist at BigRep GmbH

3D printing technologies

- SLS – Selective laser sintering, melting plastic or metal powders in layers using lasers. This is a very cost-intensive printing technology, which also needs a lot of power, usually used for applications such as low-volume production in the industry.

- SLA – Stereolithography, curing liquids (photopolymer) layer by layer using UV light. Because photopolymers are photosensitive under ultraviolet light, the resin is solidified and forms a single layer of the desired 3D object. The price of the material used makes it a very-intensive technology. This technology is used in medicine for creating accurate 3D models of various anatomical regions of the human body and also for rapid-prototyping of small parts.

- FDM – Fused Deposition Modeling, melting filament through a hot nozzle layer by layer. This technology is the most cost-effective printing method, from desktop size printers to large-scale printers. There is a very large choice of material on the market, from low-end to high-quality environmentally-friendly filaments.

Benefits

3D printing has now fully emerged and is revolutionizing businesses. Applications for 3D printing have also extended beyond rapid prototyping into industrial production. Today, 3D printers have the capability to build large components with greater precision at higher speed and lower costs. It is becoming a new dimension for manufacturing, leading to profound changes in the way things are designed, developed and produced.

3D printing, especially with a large-scale printer, gives you a future-proof solution for your business. If you need big parts or a lot of small parts and you need them fast.

- Produce better and faster results

- Use your 3D printer like a small production line

- Save money by printing sequentially

- Not happy with the result? Modify your model and print it again.

- Personalize your production according to individual needs and requirements.

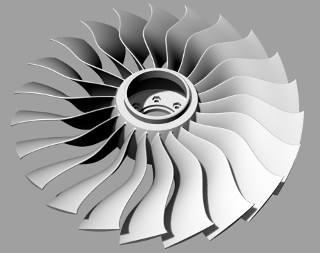

- Reach a level of product complexity not attainable with traditional methods.

Find the perfect 3D Printer for your needs

Who uses 3D printing?

3D printing is used in architecture, art design and for industrial applications. The 3D printing technology is becoming a viable alternative for industries to rapidly produce parts. 3D printed parts can be used in a variety of processes and final products. A lot more different material can be used with our machines.

- Customized products: add value to your products by enabling customization with 3D printing.

- Combine functions: you can build in one print an object with multiple functions.

- Complete mechanism in one print.

Real life examples of 3D Printing

Villeroy & Boch

Manufacturer of Ceramics

Revolutionizing prototyping

"That was unthinkable without this 3D printer." - Johan de Groot, Product Designer, Villeroy & Boch

Concrete Casting

by NOWlab@BigRep

The Nowlab Team presents a 3D printed formwork solution for concrete casting. This giant mold was printed with the BigRep ONE for the Geiger GmbH, a german construction company based in Ansbach.

Paravan

A life for mobility

Paravan renowned around the world for adapting vehicles for drivers with special medical needs. The size of the BigRep ONE allows the engineers at Paravan to use it for large-scale rapid prototyping.

BIGREP’S 3D PRINTING SOLUTIONS

We have clients across all industries: aerospace, automotive, railways, marine. Discover who uses BigRep 3D printers or services.

If you need more information about BigRep solutions: