GRADUATE FROM DESKTOP.

GET INDUSTRIAL.

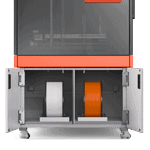

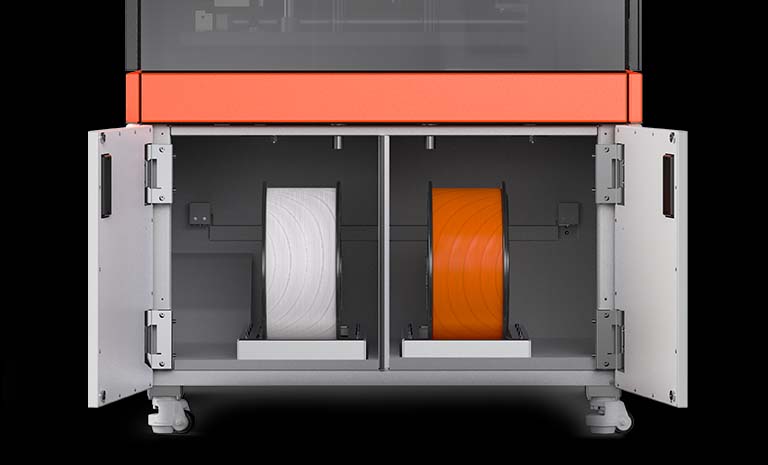

THE HEATED FILAMENT CHAMBERS

Two heated filament chambers ensure that engineering-grade materials with sensitive environmental requirements remain dry in a consistently controlled environment for best-in-class quality. Both the chambers, the print bed and the build envelope also feature independent temperature controls - going beyond industry standards to give you maximum control of your 3D printing environment.

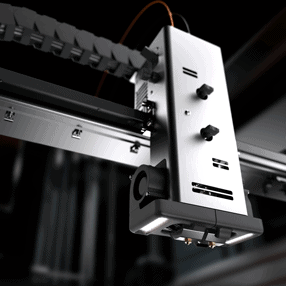

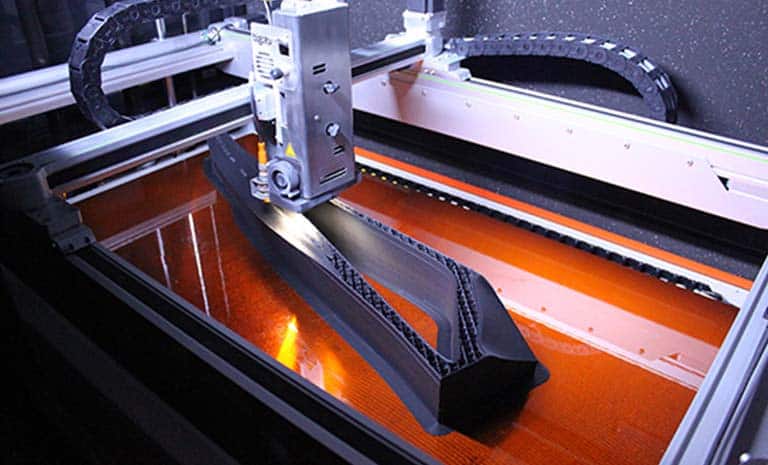

THE TOOL-STEEL NOZZLES

With the inclusion of specialized tool-steel nozzles for carbon-fiber reinforced filament and other abrasive materials, the STUDIO G2 is our most versatile additive manufacturing system. Made for printing with advanced, engineering-grade filaments at high speed, the specially designed extruder achieves reliable, high flow rates to quickly produce industrial tooling up to a meter long with the options you need to perfect a part's mechanical properties.

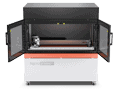

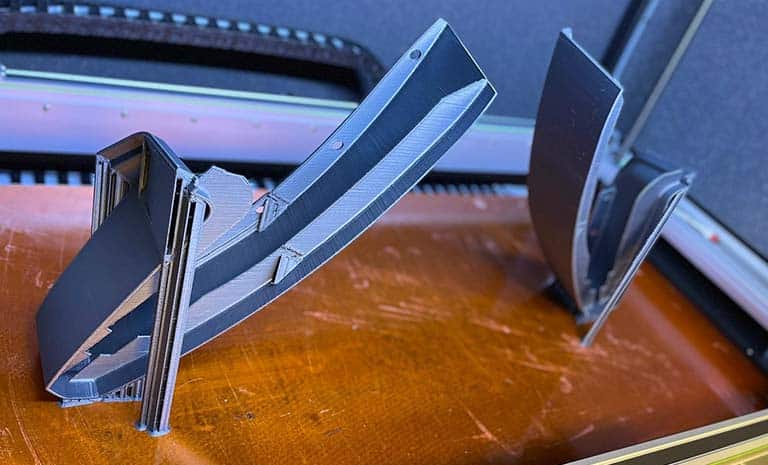

THE INSULATED BUILD ENVELOPE

The fully enclosed, temperature-controlled build envelope is the perfect environment to achieve consistent, high-quality print results. It provides users with safe and easy access to the print bed and the ability to visually monitor the printing process in a contained space. Environmental fail-safes like an auto-abort upon opening the envelope ensure a smooth and safe printing process in any setting.

THE BOFA FILTRATION SYSTEM

With the BOFA air filtration system, you're taking every step to ensure health and safety and compliance with present and future regulations while working with any potentially hazardous materials. The G2's insulated enclosure with dedicated output safely directs any and all fumes into its filtration system which then utilizes HEPA filters to purify air to a certified minimum efficiency of 99.997% down to 0.3 microns and 95% to 0.1 micron.

THE FAST-HEATING PRINT BED

Preparation time is significantly reduced for all print projects with the G2's fast-heating print bed, capable of reaching 80 °C for optimal print bed adhesion with a variety of high-quality materials in just 15 minutes. Coupled with an inductive sensor that enables semi-automatic print bed leveling to ensure optimal calibration and maximum control, the STUDIO G2 is made to work fast and work well.

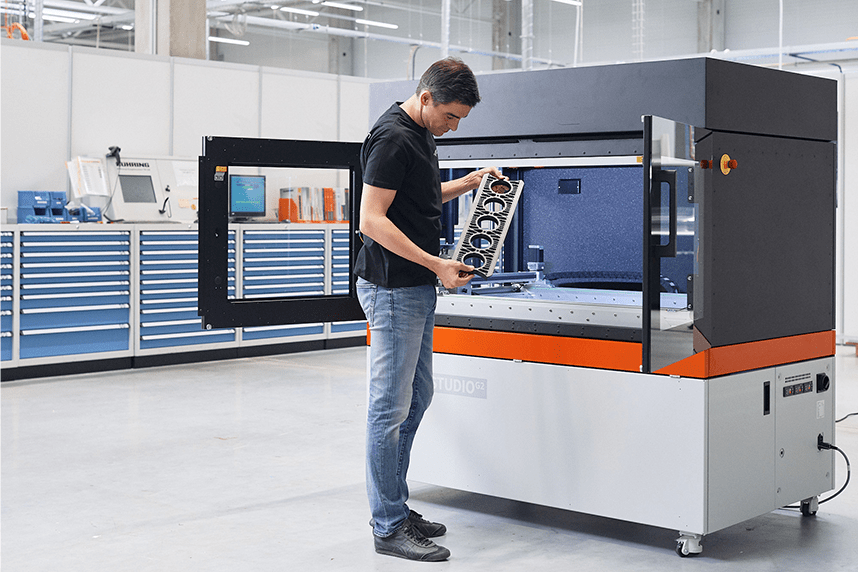

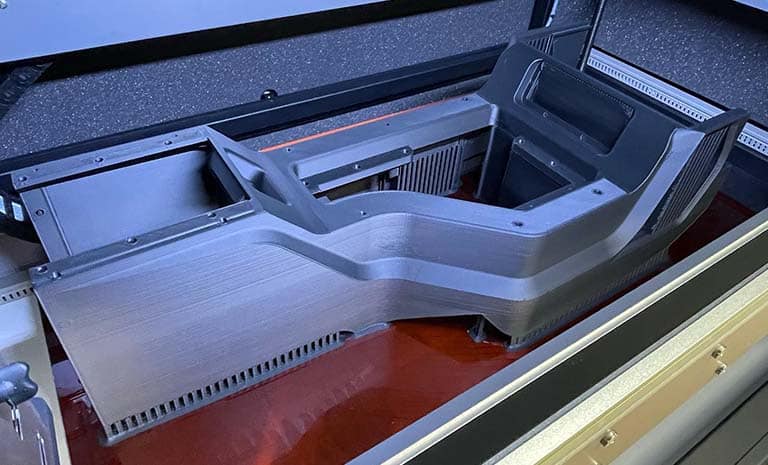

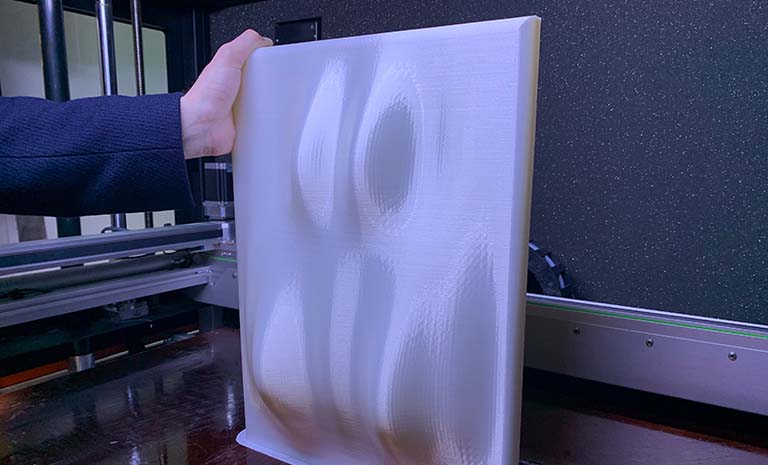

THE INDUSTRIAL BUILD VOLUME

The STUDIO G2’s incredible 1000 x 500 x 500 (mm) build volume creates room for innovation by unlocking full-scale additive manufacturing. Features combine to create a premium environment for printing large-format, engineering-grade parts quickly and safely. It’s an industrial 3D printer in a sleek, space-conscious package to fit any production environment.

GRADUATE FROM DESKTOP.

GET INDUSTRIAL.

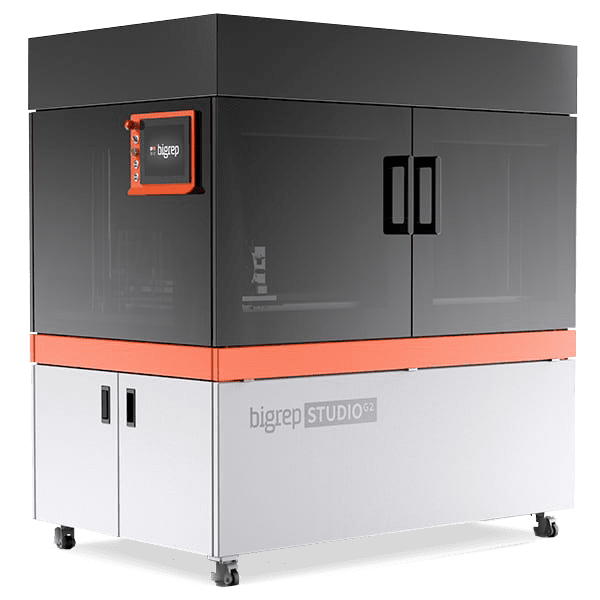

PREMIUM EFFICIENCY FOR INDUSTRIAL 3D PRINTING

German-engineered to work around the clock

The BigRep STUDIO is an easy-to-use, large-format 3D printer specially designed for industrial applications using engineering-grade materials. With a sleek, space-conscious body, perfect for the production of quality parts in any setting, the STUDIO is optimal for any workspace, from the office to the factory floor. Whether it's factory tooling, prototypes, or end-use parts, the BigRep STUDIO is a durable and cost-effective way to manufacture large-format, quality parts.

The STUDIO boasts a generous build volume of 1000 x 500 x 500 mm, 10 times that of standard desktop 3D printers. Featuring a fully enclosed build envelope and temperature-controlled filament chamber, the fast-heating STUDIO produces incredible results with advanced materials. Its high-flow STUDIO Dual Extruder (SDX) is equipped with two nozzles (either 0.6 mm or 1.0 mm diameter) optimal for printing geometrically complex parts with ASA, PETG, water-soluble support, and abrasive materials like carbon-fiber-reinforced plastic quickly and reliably.

Industrial Applications with the BigRep STUDIO

PROTOTYPES

- Produce full-scale, functional parts from the alpha phase to zero series

- Learn faster and iterate designs in hours and days, not weeks and months

- Avoid expensive, outsourced, and traditional slow production

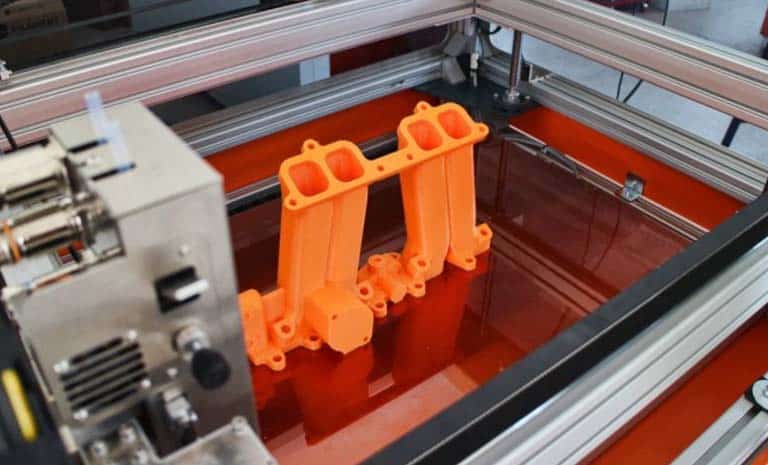

TOOLING, JIGS, FIXTURES

- Customize tools for perfect fit, reduced weight, and ergonomic design

- Slash lead times with on-demand production and avoid outsourcing logistics

- Reduce production and material costs of optimized tooling

PATTERNS AND MOLDS

- Replace high-cost patterns and molds made from expensive materials

- Speed up design iteration, product testing, and production

- Minimize outsourcing, external logistics, and supply chain dependence

END-USE PARTS

- From small-series production to unique parts without added costs

- Produce on-demand to reduce inventory and warehousing

- Reduce lead times and get to market fast to stay ahead of the competition

Your Partner for Industrial Production

3D PRINT IN FULL SCALE

BOOST PRODUCTIVITY

Join industrial leaders and increase your productivity by up to 94%. Create products and tooling in-house and on demand. Iterate fast, and get immediate results.

CUT YOUR COSTS

BigRep customers have cut up to 85% of costs, and you can too. Replace slow, expensive, outsourcing with in-house 3D printing and realize massive savings today.

COMPATIBLE 3D PRINTING MATERIALS

COMPATIBLE 3D PRINTING MATERIALS

BigRep's ABS material is a classic FFF filament that enables the production of a wide variety of products in large-format additive manufacturing.

BigRep’s TPU is flexible 3D printing filament opens up a wealth of possibilities for manufacturers and customers.

BigRep ASA is an engineering-grade UV-resistant filament for high-strength and environmentally exposed applications.

BigRep PETG is ideal for 3D printing projects requiring strength, toughness, and thermal resistance in a filament.

BigRep’s BVOH support material is an ecologically friendly advanced water-soluble filament that eliminates post-processing for 3D printed parts.

BigRep PLA is an easy-to-use filament optimized for producing prototypes and pattern making, for end-use parts to the wide range of tooling applications.

BigRep’s HI-TEMP is an ecological engineering-grade 3D printing filament for a wide variety of industrial and general applications.

BigRep's PLX filament is a PLA-derived, general-use bio performance material for open-environment 3D printing.

BigRep's Pro HT is a general-use bio performance material for open-environment 3D printing.

DURABLE PARTS EFFICIENTLY & AFFORDABLY

An Advanced 3D printer for Industrial Applications

LARGE-FORMAT

3D PRINTING

The Industrial Build Volume

The STUDIO’s incredible 1000 x 500 x 500 (mm) build volume creates room for innovation by unlocking full-scale additive manufacturing. Features combine to create a premium environment for printing large-format, engineering-grade parts quickly and safely. It’s an industrial 3D printer in a sleek, space-conscious package to fit any production environment.

ABRASIVE MATERIAL COMPATIBLE

The Tool-Steel Nozzles

With the inclusion of specialized tool-steel nozzles for carbon-fiber reinforced filament and other abrasive materials, the STUDIO is our most versatile additive manufacturing system. Made for 3D printing with advanced, engineering-grade filaments at high speed, the specially designed extruder achieves reliable, high flow rates to quickly produce industrial tooling up to a meter long with the options you need to perfect a part's mechanical properties.

FULLY ENCLOSED ENVIRONMENT

The Insulated Build Envelope

The fully enclosed, temperature-controlled build envelope is the perfect environment to achieve consistent, high-quality print results. It provides users with safe and easy access to the print bed and the ability to visually monitor the printing process in a contained space. Environmental fail-safes like an auto-abort upon opening the envelope ensure a smooth and safe printing process in any setting.

HAZARDOUS

MATERIAL SAFETY

The BOFA Filtration System

With the BOFA air filtration system, you're taking every step to ensure health and safety and compliance with present and future regulations while working with any potentially hazardous materials. The STUDIO's insulated enclosure with dedicated output safely directs any and all fumes into its filtration system which then utilizes HEPA filters to purify air to a certified minimum efficiency of 99.997% down to 0.3 microns and 95% to 0.1 micron.

OPTIMAL PRINTING TEMPERATURES

The Fast-Heating Print Bed

Preparation time is significantly reduced for all print projects with the STUDIO's fast-heating print bed, capable of reaching 80 °C for optimal print bed adhesion with a variety of high-quality materials in just 15 minutes. Coupled with an inductive sensor that enables semi-automatic print bed leveling to ensure optimal calibration and maximum control, the STUDIO is made to work fast and work well.

INDEPENDENT TEMPERATURE CONTROLS

The Heated Filament Chambers

Two heated filament chambers ensure that engineering-grade materials with sensitive environmental requirements remain dry in a consistently controlled environment for best-in-class quality. Both the chambers, the print bed and the build envelope also feature independent temperature controls - going beyond industry standards to give you maximum control of your 3D printing environment.

“ I didn’t think I needed 3D printing and now I can’t live without it. ”

- Charles Boyce, President of Boyce Technologies Inc.

Technical Specifications

| Build Volume | x 1000 y 500 z 500 mm | |

|---|---|---|

| Materials | BigRep ASA, BigRep ABS, BigRep BVOH, BigRep HI-TEMP, BigRep HI-TEMP CF, BigRep PA6/66, BigRep PETG, BigRep PLA, BigRep PLX, BigRep PRO HT, BigRep TPU 98A Open for use of 3rd party materials |

|

| Filament Diameter | 2.85 mm | |

| Extruder Type | Dual Fiber-Ready Extruder | |

| Nozzle Type | Tool Steel Nozzle | |

| Nozzle Diameter | 0.6 mm or 1.0 mm | |

| Layer Height | 0.1-0.6 mm | |

| Nozzle Temperature | 280°C max. | |

| Build Volume Temperature | 40°C max. | |

| Print Speed | 100 mm/s max. | |

| Position Repeatability | ± 0.1 mm | |

| Bed Surface | Polyimide | |

| Bed Temperature | 100°C max. | |

| Bed Heating Time | 80°C in 15 min | |

| Materials Storage | Heated Filament Chamber (max. 60°C) | |

| Monitoring | Out of Filament Sensor, Door Sensor, Webcam | |

| Machine Dimensions | x 1715 y 1170 z 1765 (mm) | |

| Approx. Weight | 550 kg | |

| Power | 208-240 V, 16 A, 50/60 Hz | |

| Connectivity | USB, LAN | |

| Optional Fume Extraction Airflow | 150 m3/h min. | |

| Safety Certification | CE | |