DOWNLOAD OUR EBOOKS

- All

- Ads LP

- Advantages

- ALTRA 280

- Applications

- Best Practice

- Blade-Version

- Blog

- Company

- Company News

- Connect-Version

- Filament

- From the Web

- Guides

- Industriell

- Interviews

- IPSO 105

- No-Banner

- NOWLAB

- On demand

- ONE

- Press & Media

- PRO

- Products

- Resellers

- STUDIO

- Studio

- Technology

- Tradeshows

- Uncategorized

- User Stories

- VIIO 250

- Webinar

- Webinars

3D Printing in the Automotive Aftermarket: Custom & Low-Volume Production

The automotive industry was one of the first to grasp the magnitude of customization with 3D printing and add it to their factory floor. Read more about how the industry makes the most of additive technology by exploring AM applications and examples from automotive giants.

From the Print Bed to the Sky: 3D Printing Aerospace-Grade Parts

Discover how the aerospace industry leverages 3D printing to deliver purpose-built, qualified tools to explore the skies and beyond. Learn from 3 use cases how industry giants test and certify 3D printed parts resulting in safer aircraft swiftly taking to the skies.

Paravan 3D Prints Life-Saving Vehicle Customization

Learn how Paravan GmbH incorporated large-format 3D printing as crucial part of their shift towards Industry 4.0. Paravan has been a leading international provider of vehicle adaptations for people with a disability or special needs since 2005, as part of a wider mobility concept based around modifying vehicles, cartridge lifts, and ramp systems.

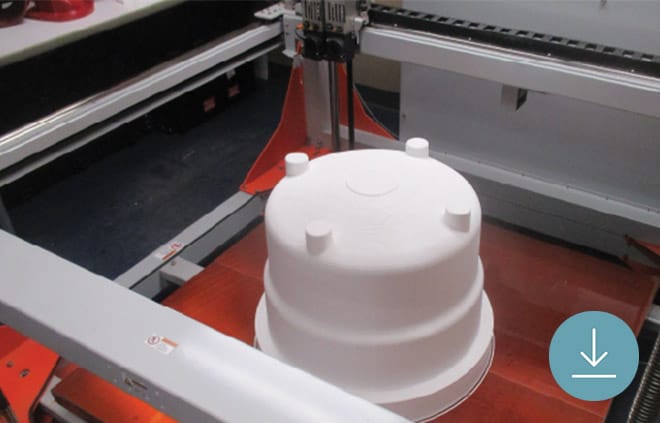

3D Print Jigs, Fixtures, and other Production Tools

When talking about production processes and the relevant equipment, most people think of large milling machines, hydraulic presses, injection molding machines, or robots assembling cars and other industrial goods. While this is true, small and seemingly unremarkable tools are used throughout various manufacturing steps, namely jigs and fixtures.

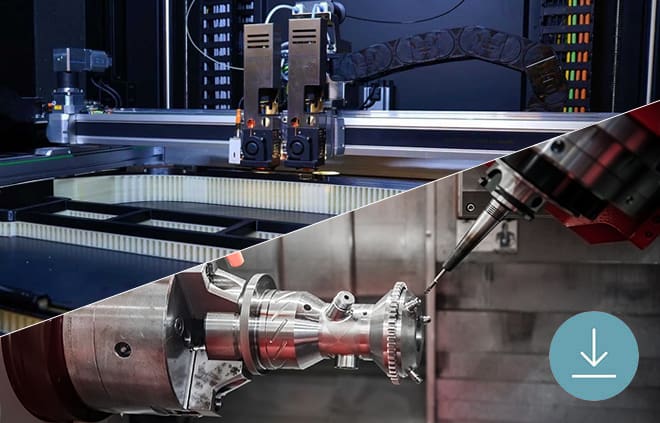

CNC and 3D Printing – Two Manufacturing Methods

CNC has been the backbone of manufacturing for centuries. Over the past few decades, additive manufacturing has started to gain traction. Each manufacturing method has its strengths and weaknesses, and it’s important to understand your application and usage before selecting the appropriate method.

How Kennedy Valve Revived in-house Patternmaking with Additive

Kennedy Valve was working with an aging workflow in sand casting applications, developing patterns and tooling with an external supply strategy that replaced their long retired in-house pattern shop.

How RH-Engineering & manoFigura 3D Print Luxury Furniture

With 3D printing and artisan finishing techniques, René Helmreich and Enrico Klemmer create 100% custom furnishings that create a personalized ambiance in a room. The two have partnered their respective businesses and skills for a truly unique, and highly efficient, manufacturing process.

Supply Chain Risk

Learn 3 procurement strategies to reduce supply chain risk and how 3 industrial leaders use BigRep large-format additive manufacturing for a stable, on-demand supply chain.

POLYAERO’s Mixed Reality Aerospace Programs

Learn how POLYAERO (Aix-Marseille University) used large-format additive manufacturing to create their mixed-reality aeronautical engineering program.

How to Reduce Lead Time with In-House Supply Chains

Find out how designers and manufacturers across industries have created incredible efficiencies in their usual project timelines by adopting large-format 3D printing technologies.

Kawasaki’s 3D Printed Tooling

Learn how Kawasaki Motors Corp.’s Lincoln, USA manufacturing facility saved up to 85% of costs on production tooling by optimizing automotive and aerospace production with BigRep’s large-format additive manufacturing systems.

7 Ways BigRep 3D Printers Unlock Profit Instantly

EBOOK 7 ways BigRep 3D Printers Unlock Profit Instantly Learn how world-leading companies like Ford, Steelcase, and more made instant returns on their investment in BigRep’s large-format additive manufacturing systems. Industry leaders have modernized their businesses and created incredible cost efficiencies by introducing 3D printing to their various workflows. BigRep’s additive manufacturing systems offer reliable … Read more