3D-GEDRUCKTE VORRICHTUNGEN

FÜR DIE FABRIKHALLE

Zeit sparen und Kosten senken mit leichtgewichtigen, auf Abruf 3D-gedruckten Halterungen, Vorrichtungen und Werkzeugen für Ihre Fabrik.

Möchten Sie wissen, wie Sie von 3D-gedruckten Werkzeugen und Vorrichtungen in der Produktion profitieren können?

VORLAUFZEITEN UM 90% REDUZIEREN

Reduzieren Sie Ihren Logistikaufwand, indem Sie Werkezuge und Vorrichtungen selbst drucken

WERKZEUG 94% SCHNELLER BEREITSTELLEN

Reduzieren Sie die Kosten für die Werkzeugbereitstellung durch digitalisierte Produktion und weniger Zusammenbau

DIGITALER LAGERBESTAND AUF ABRUF

Drucken Sie Werkzeug auf Abruf aus einem digitalen Inventar, um Zeit und Lagerraum zu sparen

Die Herstellung von Produktionshilfen und Inspektionswerkzeugen ist teuer und zeitaufwändig, und wird oft extern vergeben. Prototypen müssen für jede Design-Iteration produziert werden, was 8 bis 10 Wochen dauern kann. Manche Handgeräte sind schwer und unhandlich, während komplexe Vorrichtungen oft aufwändig aus teuren Komponenten zusammengebaut werden müssen.

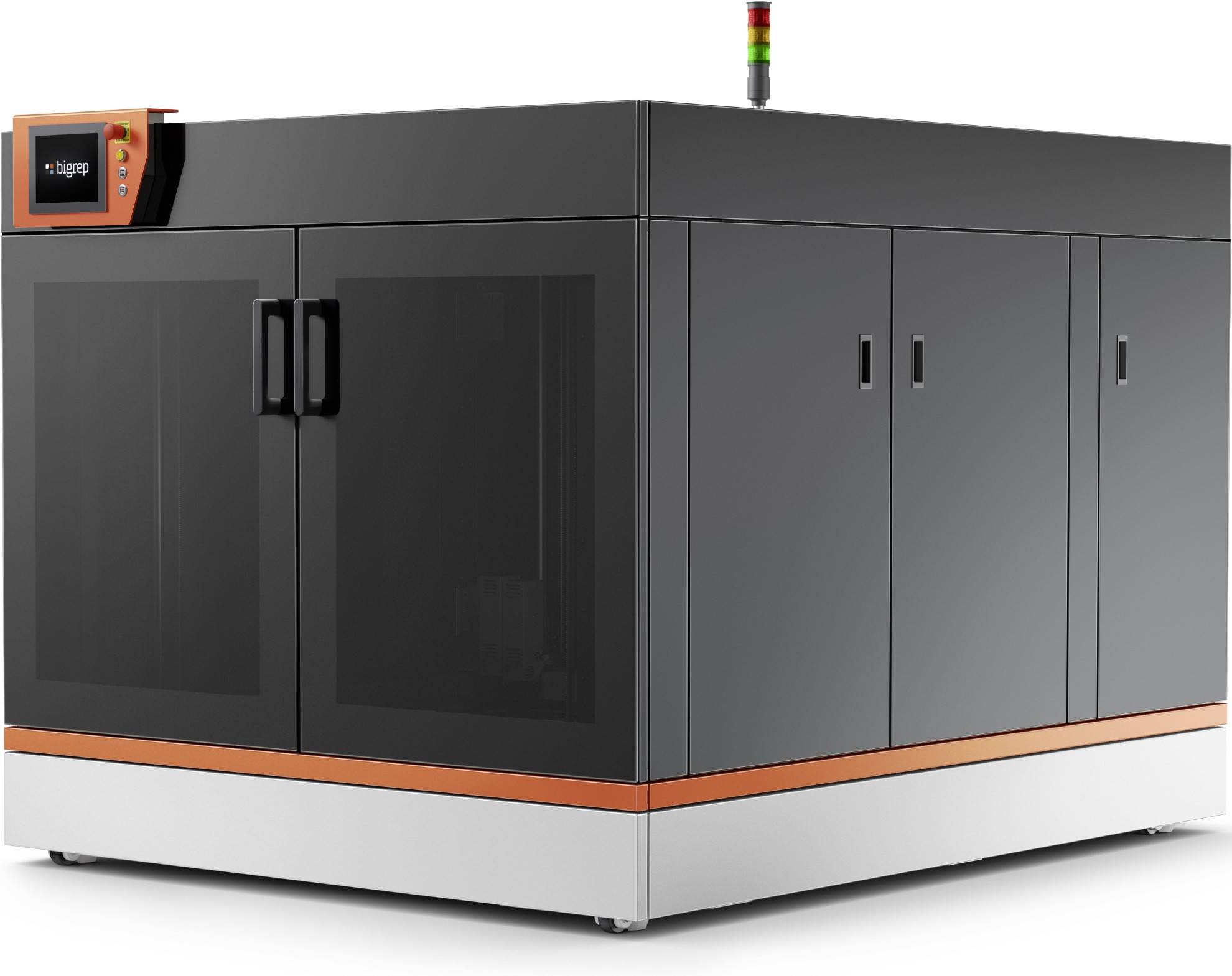

Die 3D-Drucker von BigRep schaffen hier Abhilfe: Sie können für Fabriken fast jede Produktionshilfe herstellen, für alle Bereiche, von der Fertigung über den Zusammenbau bis hin zur Qualitätssicherung. Mit intern 3D-gedrucktem Tooling reduzieren Sie Ihre Logistik und Vorlaufzeiten erheblich, und erreichen zugleich Kosteneinsparungen von bis zu 94%. 3D-gedruckte Fabrikhilfen sind leicht, stark, ergonomisch, multifunktional und anpassbar.

NACHTEILE DER TRADITIONELLEN WERKZEUGBEREITSTELLUNG

Hohe Material- und Lohnkosten

Langsame Iteration und Produktion

Großes Inventar mit teurer Lagerung

Schwer und unergonomisch

Produktion an externe Zulieferer vergeben

NDA für externe Zulieferer benötigt

VORTEILE DER 3D-GEDRUCKTEN VORRICHTUNGEN FÜR FABRIKEN

Minimale Material- und Lohnkosten

Agile Produktion, die leicht iteriert und angepasst werden kann

Digitalisiert, kein physischer Bestand

Leichter, mit optimierter Topologie

Intern auf Abruf produziert

Designwissen wird intern geschützt

3D-gedruckte Produktions- und Montagehilfen

Ford hat die additive Fertigung vor 30 Jahren für sich entdeckt, und setzt heute auf die großformatigen 3D-Drucker von BigRep, um Vorrichtungen und Qualitätssicherungswerkzeug in Originalgröße und aus einem einzigen Teil zu fertigen. Ford erzielt dadurch erhebliche Kosteneinsparungen, da die BigRep-Geräte sich schon nach den ersten paar Drucken rechnen.

Tragbare Justiervorrichtung

Ford verwendet leichte 3D-gedruckte Justiervorrichtungen, um Logos und Aufkleber korrekt auf den Autos zu produzieren.

MONTAGEVORRICHTUNG

3D-gedruckte Montagevorrichtungen können schnell und einfach angepasst werden, um die betreffenden Werkstücke korrekt auszurichten, zu befestigen und zu sichern.

GREIFER FÜR ROBOTER

Der adaptive Greifer für Roboter ist in der Lage, alle möglichen Geometrien zu greifen, sogar kleine und empfindliche Teile.

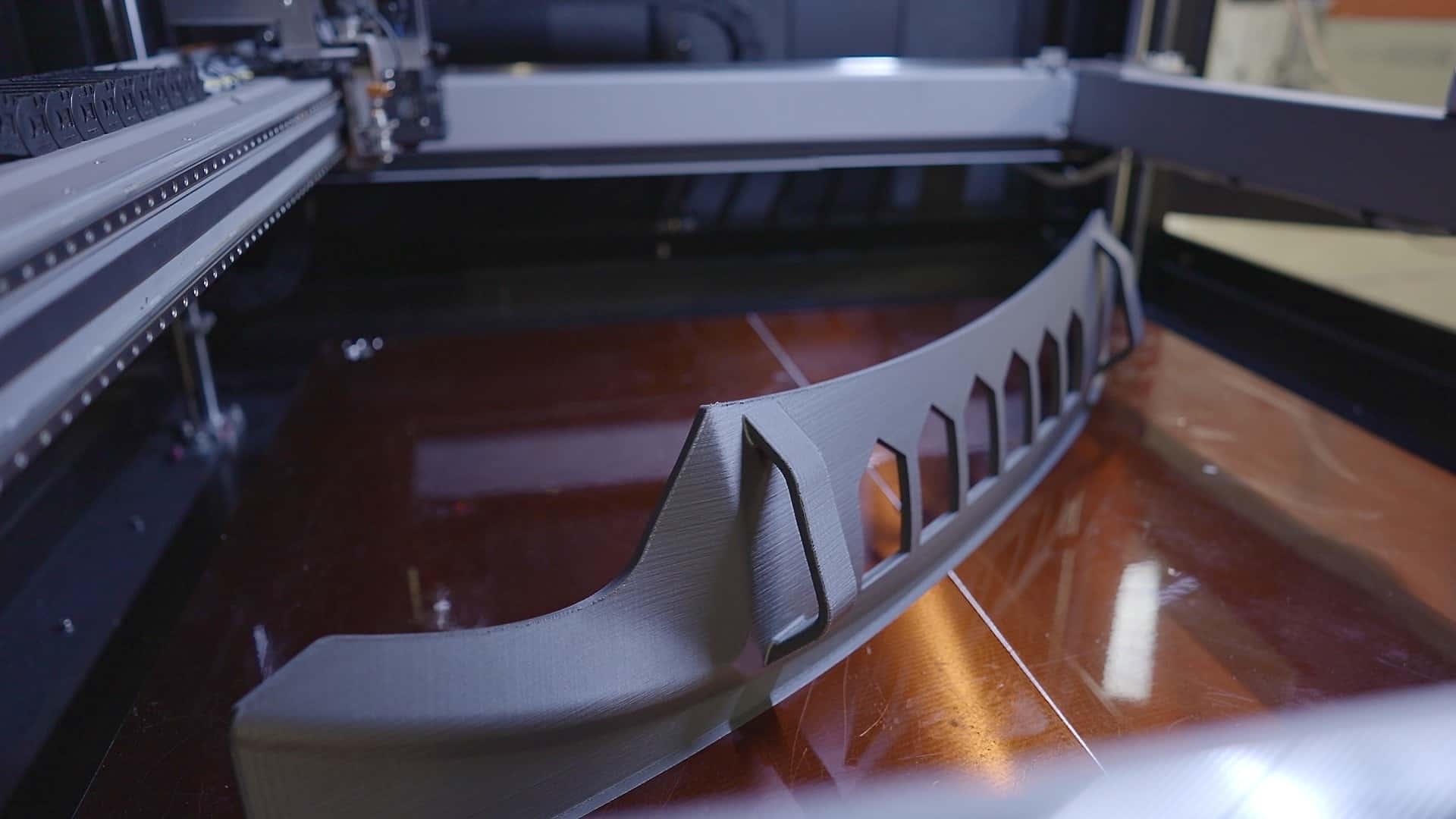

SCHWEISS- UND FRÄSVORRICHTUNGEN

3D-gedruckte Vorrichtungen können nicht nur extrem schnell hergestellt werden; sie können auch erheblich die Qualität bei Schweiß- und Fräsaufgaben verbessern.

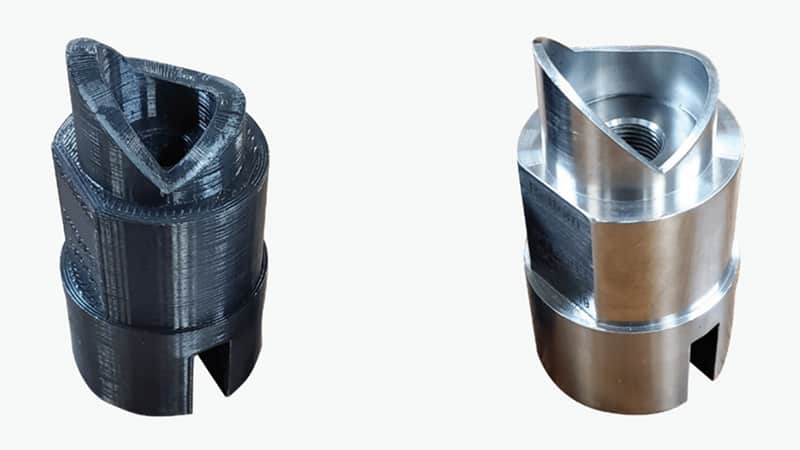

ROHRBIEGEDORN

Kawasaki verwendet maßgeschneiderte 3D-gedruckte Biegedorne, mit denen die Rohre während des CNC-Biegens gehalten und geführt werden.

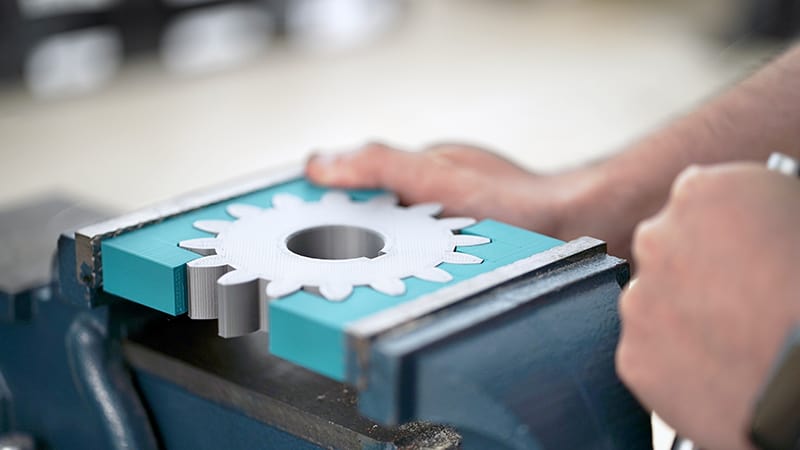

WEICHE SPANNBACKEN

3D-gedruckte weiche Spannbacken sind perfekt für Werkstücke, die zu komplex für Standardschraubstöcke sind; zudem sind sie schneller und kostengünstiger in der Herstellung.

Qualitätssicherung mit 3D-gedrucktem Tooling

Walther Automobiltechnik (WAT) nutzt alle Möglichkeiten, die der firmeneigene BigRep 3D-Drucker bietet, und produziert damit alle möglichen Vorrichtungen und Produktionshilfen. Von Prüfvorrichtungen und Werkzeughalterungen bis hin zu Hilfen zur Fehlervermeidung hat WAT die additive Fertigung in die Produktionsabläufe integriert und davon stark profitiert.

PRÜFVORRICHTUNGEN

Ford verwendet 3D-gedruckte Vorrichtungen, um zu prüfen, ob der Sitz einer Autotür in der Karosserie innerhalb der Toleranzen liegt.

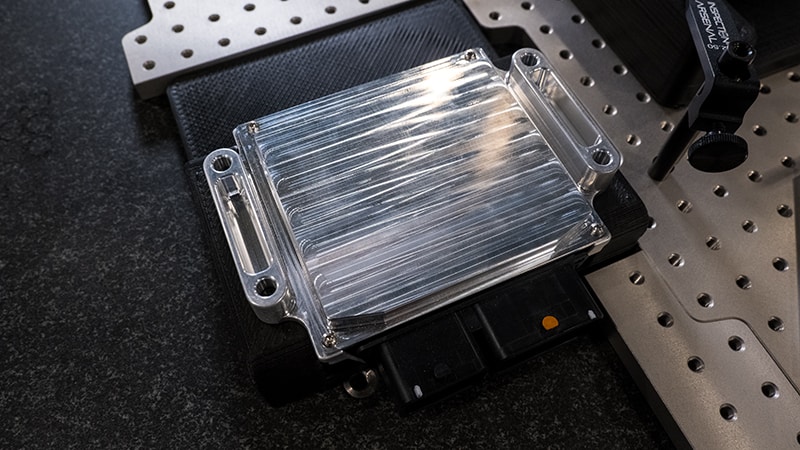

VORRICHTUNGEN FÜR KMG (KOORDINATENMESSGERÄTE)

Mit dieser 3D-gedruckte multifunktionale KMG-Vorrichtung kann Nikola elektronische Komponenten gleichzeitig zusammenbauen und analysieren.

GRENZLEHREN

WAT verwendet intelligente Grenzlehren, um Spalttoleranzen in Kfz-Fahrgestellen nach der Galvanisierung zu prüfen.

Simpler Workflow für 3D-gedruckte Vorrichtungen & Halterungen

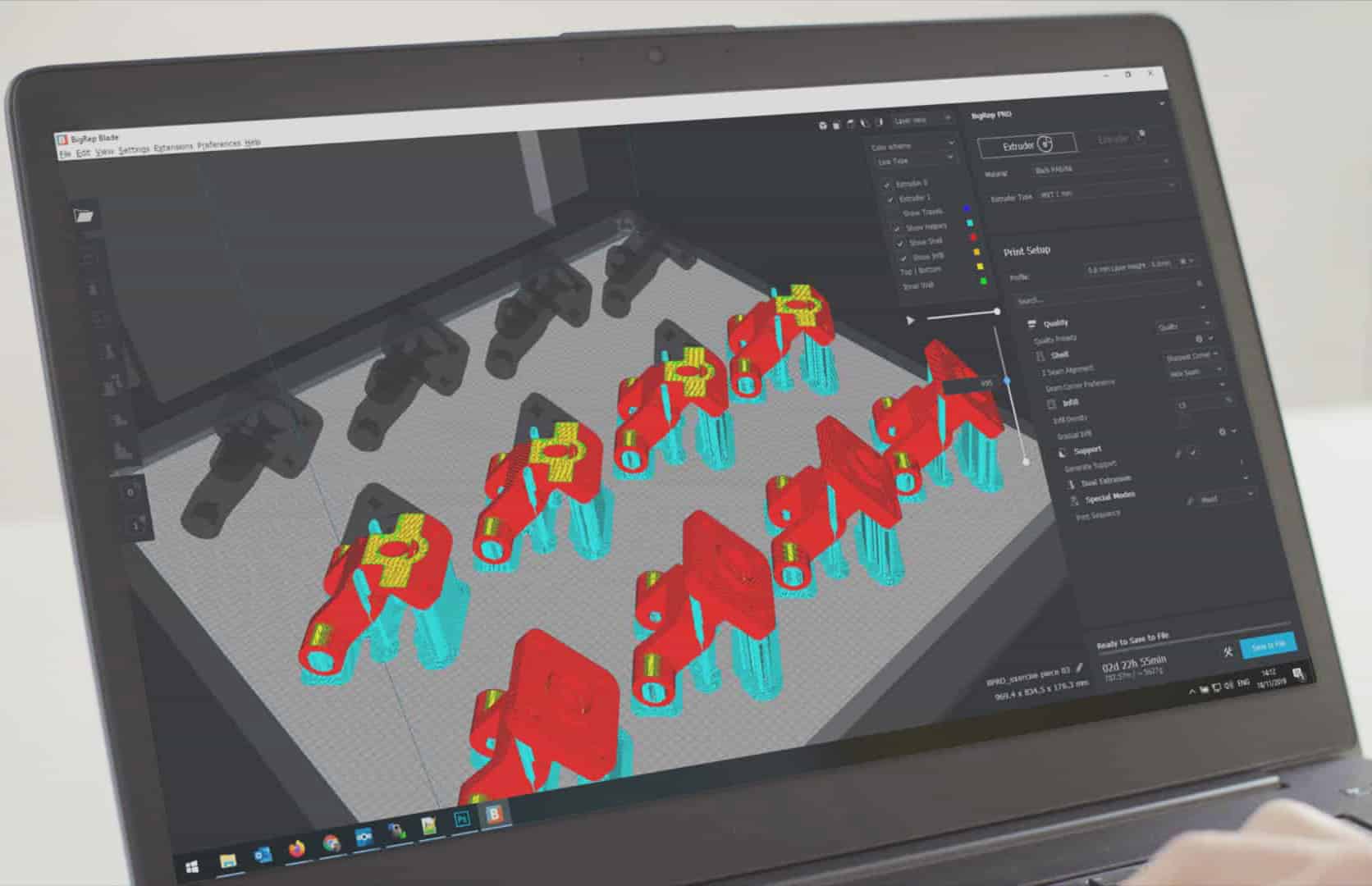

- Entwurf Das 3D-Modell wird entworfen (Export in STL oder OBJ-Datei)

- Vorbereitung Die 3D-Datei wird mit BigRep Blade vorbereitet (Slicen und Export einer G-Code-Datei)

- 3D Druck Das Teil wird auf dem 3D-Drucker produziert

Sie wollen mehr Informationen dazu?

Dann schauen Sie unser On-Demand-Webinar.

- 3D-Druck im Großformat und Vorteile von 3D-gedrucktem Tooling

- Potentielle Einsparungen bei Material und Personalaufwand

- Agile Produktion, kurze Iterationszyklen und Rapid Prototyping

- Erfolgsgeschichten von unseren Kunden, darunter Ford Motor Company, Kawasaki USA, Nikola Motor Company und viele mehr.

SPRECHEN SIE MIT EINEM SPEZIALISTEN

Füllen Sie das untenstehende Formular aus und einer unserer Experten wird sich mit Ihnen in Verbindung setzen.

Ohne weitere Verpflichtungen.