3D PRINTED JIGS & FIXTURES

ON THE FACTORY FLOOR

Save time and money with lightweight, 3D printed factory tooling produced on-demand

You can't wait to find out, how you could use 3D printed tools in your production?

REDUCE LEAD TIME BY 90%

Minimize logistics by manufacturing jigs and fixtures in-house.

up to 94% cheaper tooling

Cut tooling costs with digitized production and reduced assembly.

DIGITAL INVENTORY ON DEMAND

Print tools on demand from a digital inventory to save time and storage space.

Production aids and inspection tools are expensive and slow to manufacture, typically outsourced and requiring many design iterations prototyped over 8 to 10 weeks. Handheld jigs can be heavy and cumbersome to use, while complex fixtures may require extensive assembly and costly components.

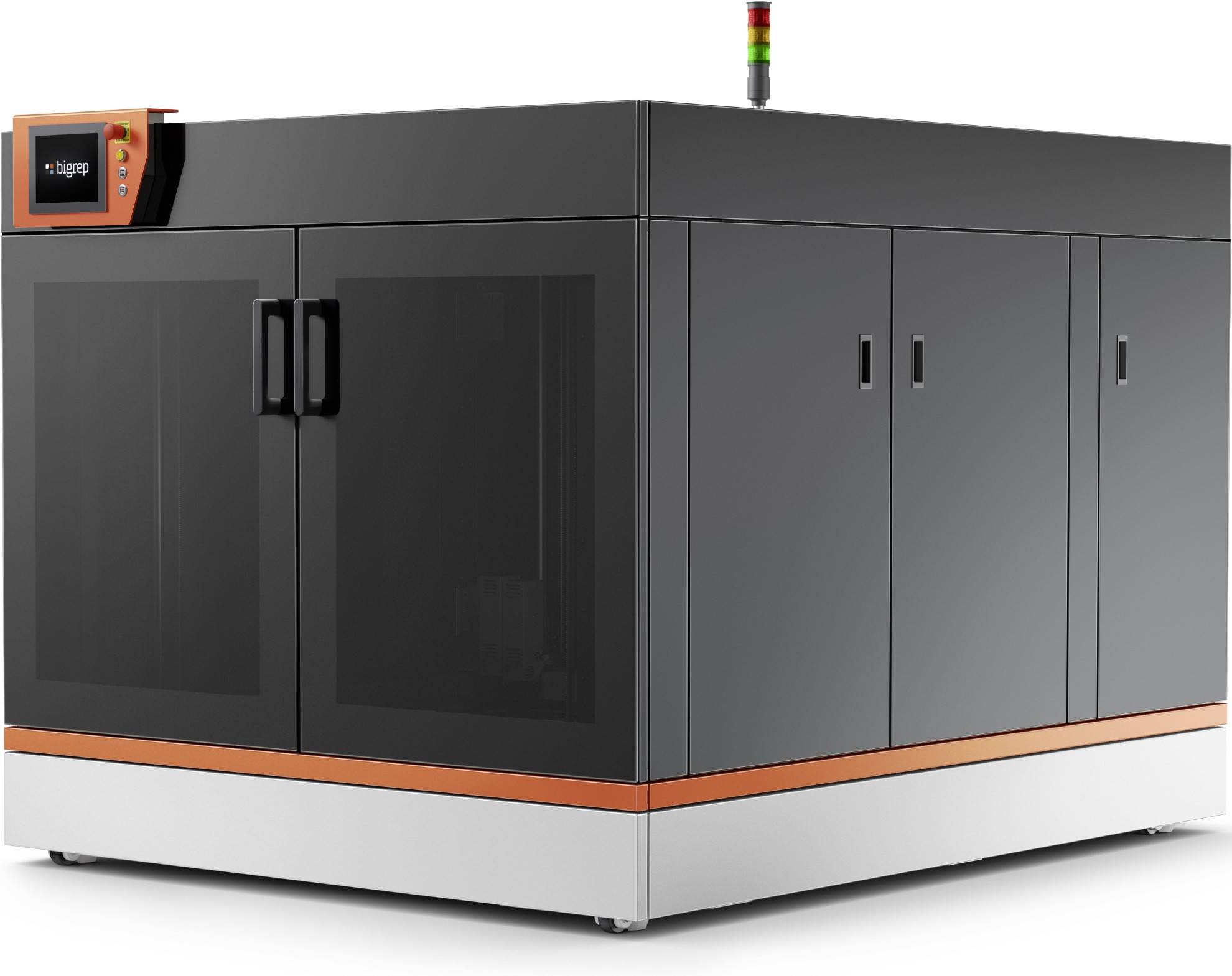

BigRep 3D printers are a game-changer for virtually any factory tooling aid from production and assembly to quality assurance. Produced in-house and on-demand, 3D printed tooling drastically simplifies logistics and lead times, while significantly cutting costs up to 94%. Lightweight, strong, and ergonomic 3D printed factory aids are customizable and multi-functional.

Problems of Traditional Factory Tooling

Expensive material and labor costs

Slow to iterate and produce

Large, costly inventory storage

Heavy and non-ergonomic

Outsourced to third party supplier

NDA required for external providers

Solutions with 3D Printed Factory Tooling

Minimal material and labor cost

Agile production easy to iterate and customize

Digitized with no physical inventory

Lighter and topology optimized

Produced in-house on demand

Design knowledge is protected in-house

3D Printed Production and Assembly Aids

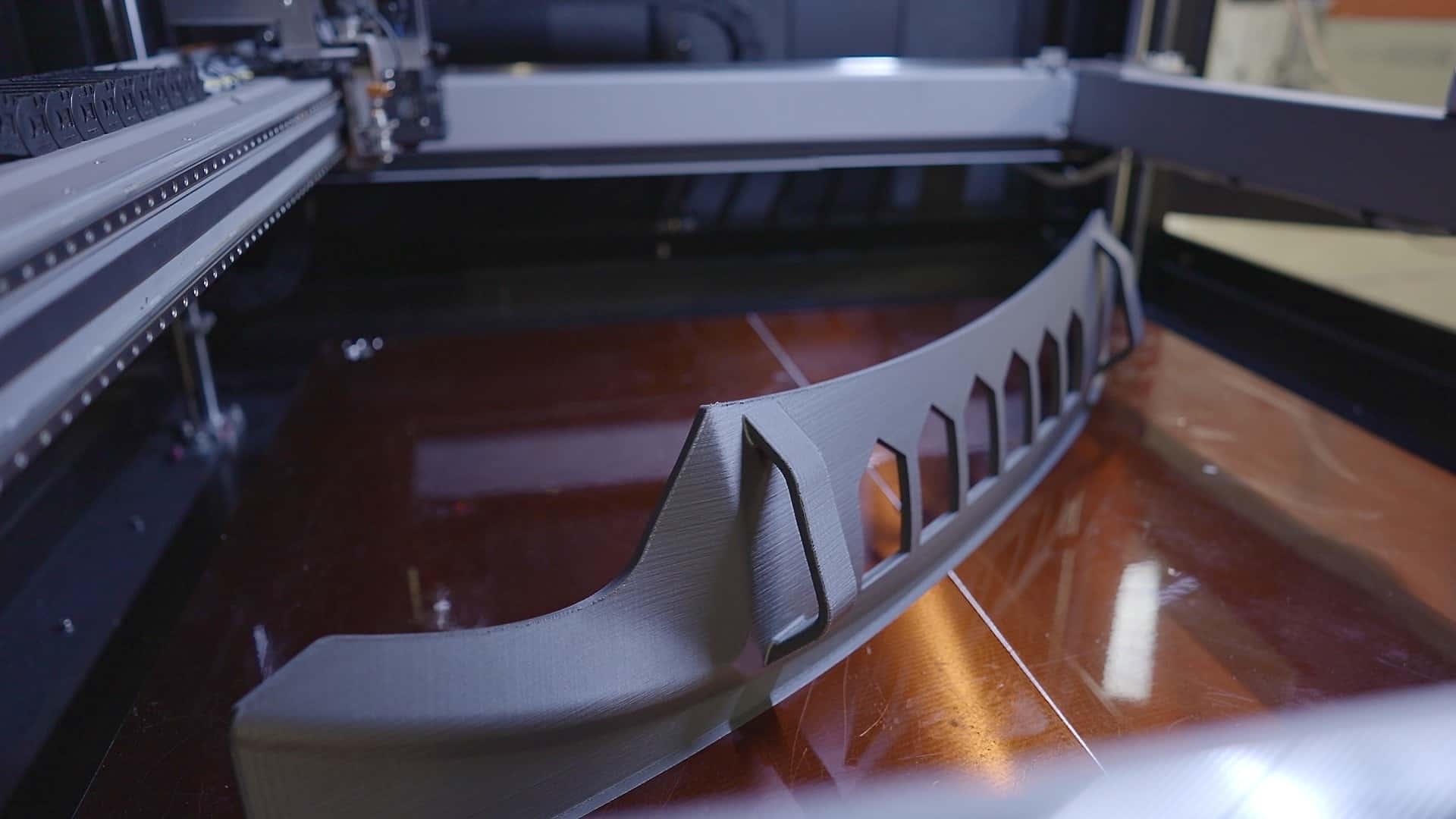

Ford embraced additive manufacturing 30 years ago and now relies on BigRep for large-format 3D printing to produce full-scale jigs and quality assurance tools in one single piece. For Ford, the cost savings are huge, as their BigRep machine paid for itself after just the first few prints.

Handheld Alignment Jig

Ford uses lightweight 3D printed alignment jigs to correctly place logos and decals on their cars.

Assembly Jig

Fast and easy to customize, 3D printed assembly jigs ensure correct alignment, attachment, and securing of workpieces.

End-of-Arm Robotic Gripper

The Adaptive Robotic Gripper is capable of gently gripping any geometry, even small and delicate parts.

Welding and Milling Fixtures

Produced in a fraction of the time, 3D printed fixtures can greatly improve the quality of welding and milling jobs.

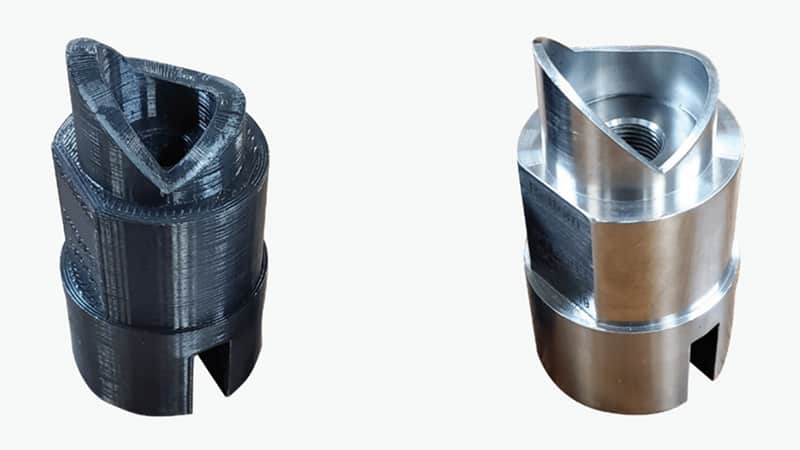

Tube Bender Collet

Kawasaki uses customized 3D printed bender collets to grip and guide tubes during CNC bending.

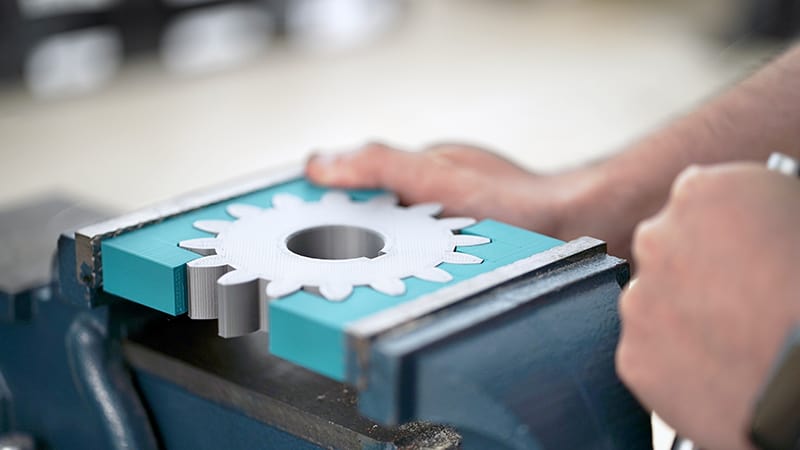

Soft Jaw

3D printed soft jaws perfectly hold workpieces too complex for standard vice jaws and can be produced faster and cheaper than standard methods.

Quality Assurance with 3D Printed Tooling

Walther Automobiltechnik (WAT) makes the most of their BigRep 3D printer by producing all kinds of factory tooling and production aids. From inspection fixtures and tool holders to mistake-proofing, WAT had thoroughly embedded additive manufacturing into their production processes and has seen massive benefits thanks to BigRep.

Inspection Fixture

Ford uses 3D printed inspection fixtures to check that the fit between the car body and door achieves acceptable tolerances.

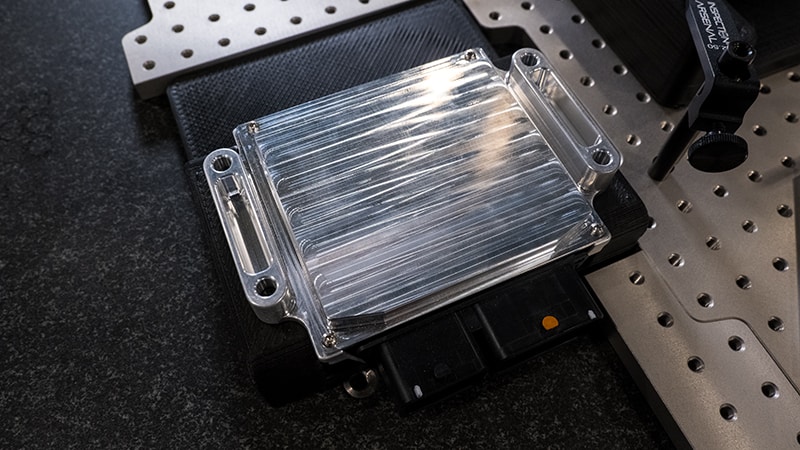

Coordinate Measuring Machine (CMM) Fixtures

This 3D printed multifunctional CMM fixture allows Nikola to simultaneously assemble and inspect electronic components.

Go/No-Go gauge

WAT is using smart go/no-go gauge to check gap tolerances on car frames after galvanization.

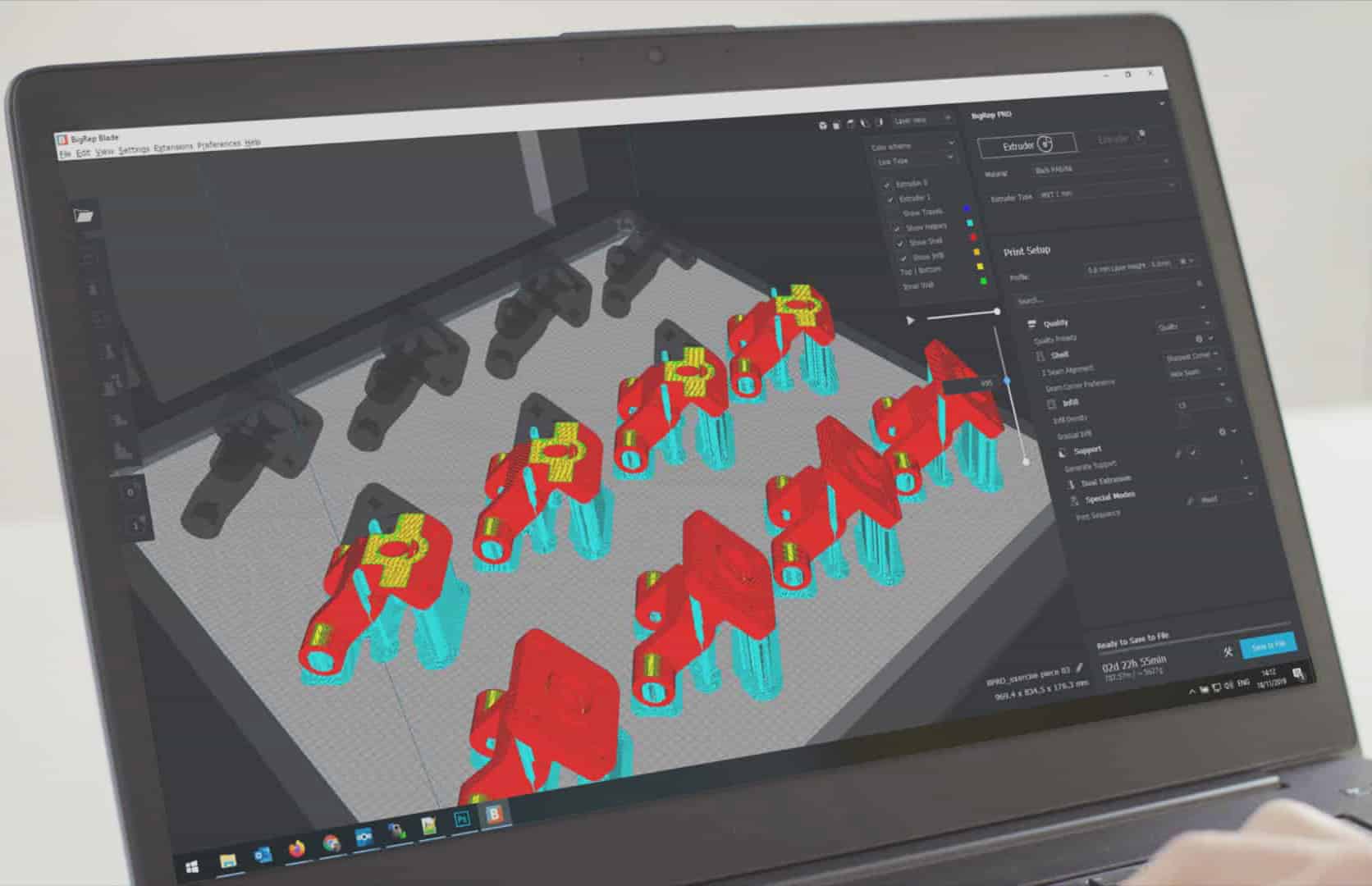

A Simple Workflow for 3D Printed Jigs & Fixtures

- Design the 3D model (export an STL or OBJ file)

- Prepare the 3D file for printing with BigRep Blade (slice and export a gCode file)

- 3D Print the part

Want to learn more?

Watch the on-demand webinar to learn about:

- Large-format 3D printing and the benefits of 3D printed tooling

- Opportunities to reduce material and labor costs

- Agile production, short iteration cycles, and rapid prototyping

- Success stories of our customers, including Ford Motor Company, Kawasaki USA, Nikola Motor Company, and more

Talk to an Expert

We have a team of experts ready to answer all your questions. Do not hesitate to get in touch to get more information about Additive Manufacturing, best materials for your application, and how to implement it in your business!

You THINK BIG, we'll help you get there!