Streamline automotive manufacturing workflows with industrial 3D printing.

Keeping up with innovation can make or break in the high-demand, high-competition automotive industry. With industrial 3D printing you’ll simplify production with fast-paced, in-house manufacturing on-demand and in full scale. Create factory tooling like jigs and fixtures without bottlenecks by eliminating third-party supply chains. Streamline prototypes with an affordable, hands-off process to unlock high efficiency product iterations and designer creativity with it.

Empower automotive manufacturing from the drafting table to the assembly line, with BigRep’s proven industrial solutions. Modernize your production today.

AUTOMOTIVE APPLICATIONS FOR LARGE-FORMAT 3D PRINTERS

WHAT COULD YOU CREATE IN FULL SCALE?

EBOOK

FORD UPSCALES THEIR IN-HOUSE TOOLING WITH BIGREP 3D PRINTERS

Learn how Ford Motor Company optimized factory-floor tooling production with a 94% lead time reduction by introducing BigRep large-format additive manufacturing. With over 30 years of experience in additive manufacturing, Ford upscaled their Cologne prototyping facilities with two BigRep additive systems. After first acquiring a BigRep ONE, Ford returned their investment with just one application. Following such incredible success, Ford expanded their BigRep ONE’s use and eventually needed more additive manufacturing capacity – leading to their next investment in a BigRep PRO!

Find out about Ford’s highly efficient industrial applications.

Read this large-format additive use case to find out…

- How to reduce factory tooling lead times by 94%.

- How to earn first application ROI with BigRep systems.

- Why leading additive experts choose BigRep printers.

- What the BigRep PRO offers industrial leaders like Ford.

EBOOK

HOW KAWASAKI OPTIMIZED PRODUCTION WITH 3D PRINTED TOOLING

Learn how Kawasaki Motors Corp.’s Lincoln, USA manufacturing facility saved up to 85% of costs on production tooling by optimizing automotive and aerospace production with BigRep’s large-format additive manufacturing systems.

Kawasaki wasn’t a stranger to 3D printing before diving into large-format with their BigRep, and their wealth of experience with advanced manufacturing equipment helped inform their purchase. By opting to invest in their own facility instead of depending on outsourced parts and production tooling, Kawasaki brought supply chains in house, streamlined engineering and logistical workflows, and returned their investment in just 6 months.

Read this large-format additive guide to find out…

- How in-house supply chains create incredible savings on production tooling

- Why automotive engineers trust BigRep’s AM materials in their manufacturing processes

- How on-demand additive can quickly solve unexpected production bottlenecks

- How large-format 3D printers bring added value to manufacturing and research facilities

START 3D PRINTING IN FULL SCALE WITH BIGREP

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

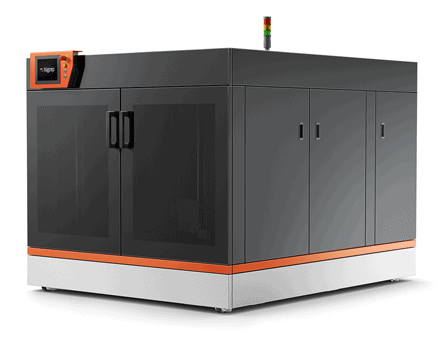

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL 3D PRINTING FILAMENTS

With BigRep’s line of engineering-grade filaments – offering trusted automotive materials like PA6/66, ABA, ASA and more – you can apply the same end-production materials at every stage in a product’s development for accurate functional representation throughout.

INDUSTRIAL 3D PRINTING FILAMENTS

With BigRep’s line of engineering-grade filaments – offering trusted automotive materials like PA6/66, ABA, ASA and more – you can apply the same end-production materials at every stage in a product’s development for accurate functional representation throughout.