Carbon Fiber 3D Printer

BigRep carbon fiber 3D printers allow you to produce strong, light weight parts. With the BigRep PRO 3D printer and carbon fiber filaments, you can get started with the push of a button.

Request Pricing

Carbon Fiber 3D Printer

BigRep carbon fiber 3D printers allow you to produce strong, light weight parts. With the BigRep PRO 3D printer and carbon fiber filaments, you can get started with the push of a button.

Request Pricing

NEXT LEVEL INDUSTRIAL 3D PRINTING

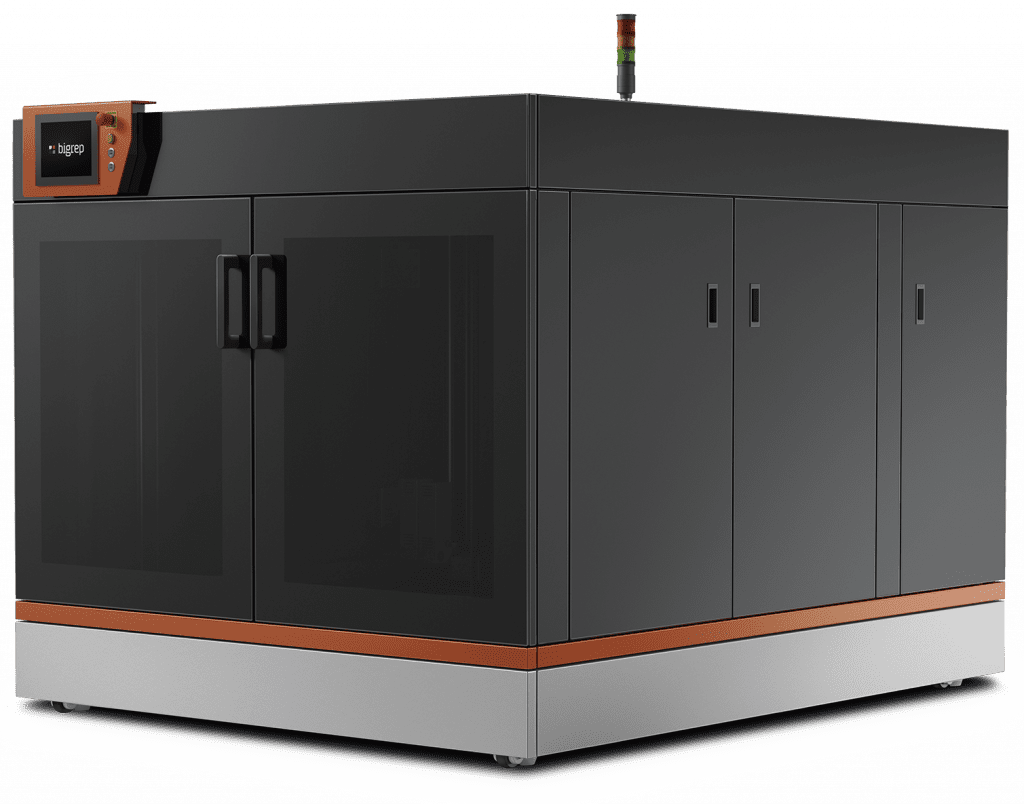

With a 1 cubic meter build volume, the BigRep PRO is a fully enclosed industrial 3D printer for producing fullscale, large parts including functional prototypes, factory tooling, patterns and molds, and end-use parts. Built for productivity throughout all stages of manufacturing, the PRO provides designers, engineers, and manufacturers with an easy-to-use, agile solution to produce faster and cheaper.

Supported by its Precision Motions Portal, a durable, custom-built gantry, along with Bosch Rexroth CNC components, the PRO consistently delivers on speed, precision, and quality. Now thanks to JUMPSTART, a new BigRep hybrid software-hardware solution that lets you skip the hassle and just start printing, the PRO is easier than ever to use.

Why Carbon Fiber 3D Printing?

High Strength

Perhaps the most-touted property of carbon fiber 3D printer filament, high strength is key to its performance — and desirability as a 3D printing material. Carbon fiber offers a strength-to-weight ratio that enables high performance with low density.

Light Weight

Hand-in-hand with its strength is the light weight of a carbon fiber 3D printer filament. Lightweighting is a key advantage of 3D printing in general, and using carbon fiber materials enables that weight reduction without a loss of performance-grade strength.

High Heat Deflection Temperature

Compared to standard 3D printing materials like PLA, ABS, and PETG, carbon fiber can withstand significantly higher temperatures. Carbon fiber composite materials — using a carbon fiber-reinforced polymer — enhances the heat deflection temperature of the base material for better performance.

Stiffness

3D printed carbon fiber parts maintain their shape under high stress. In contrast with other materials that trade off strength and durability for stiffness, the rigidity possible with carbon fiber ensures structural integrity.

JUMPSTART

SKIP THE HASSLE. JUST PRINT.

Using the latest PRO 3D printer is easier than ever thanks to BigRep JUMPSTART, a hybrid software-hardware solution that lets you skip the hassle and just start printing. It includes the SWITCHPLATE, a removable and flexible print bed surface, the LOCKSTAGE for easy and secure extruder mounting, and the MXT® Control System that bypasses manual calibration ensuring crucial first print layers are optimal every time.

SWITCHPLATE

MXT® CONTROL SYSTEM

The MXT® Control System employs proprietary algorithms that improve your gcode print file. The result is better quality, higher accuracy, and all-around consistent results. MXT® is the brain powering JUMPSTART, which simplifies the user experience, bypassing the need for manual calibration for the print bed, extruder, and dual extrusion.

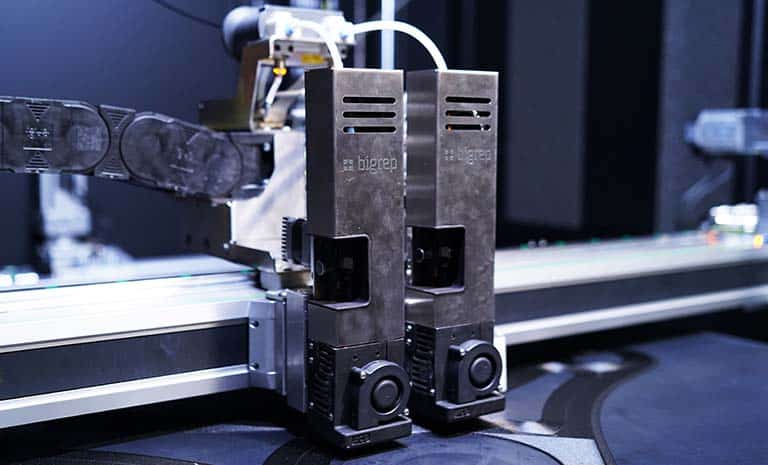

LOCKSTAGE

The LOCKSTAGE allows simple and secure extruder mounting without the need for manual position calibration. Extruders easily snap into place and provide consistent precision throughout your entire print.

“The first prints that we ran lasted 17 days. Since then, we have been running the PRO non-stop to print parts and components using its large capacity, high resolution and accuracy throughout the entire process. ”

- Riley Gillman, Technical Operations Manager of Nikola Corporation

Get to know the BigRep PRO 3D Printer

LARGE-SCALE & GERMAN ENGINEERED

High Accuracy at High Speeds

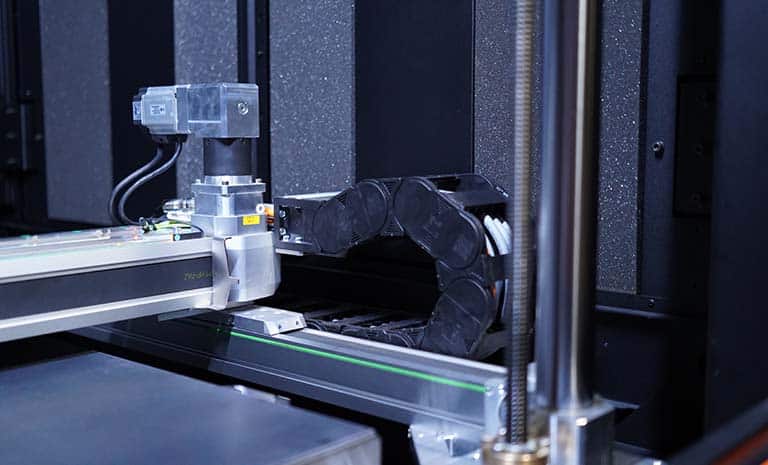

The Precision Motions Portal

The PRO's massive 1m3 build volume is supported by a durable, custom-built gantry engineered for high speed, fast acceleration, and accuracy. The robust frame eliminates vibrations during 3D printing assuring fast, yet precise movement gliding the extruders along a reinforced carriage system. Powered by Bosch servo motors with integrated encoders, the PRO calculates the real-time location of the print head to self-monitor for position accuracy.

Fast, Precise & Fiber-Ready

The Advanced Capability Extruder

BigRep’s Advanced Capability Extruder (ACE) expands the material capabilities of the PRO while still reliably delivering quality 3D prints with speed and precision. ACE is a direct drive extruder, perfectly equipped for fiber-reinforced materials such as BigRep’s HI-TEMP CF. With ACE you can print large-format, strong parts 50% faster than other large-scale printers.

Airtight Filament Chamber

The Dry Material Storage