It’s immediately apparent speaking to David Gurrola that he is somewhat of a guru in additive manufacturing. The Technical Director of Advanced Manufacturing at Saratech in California can boast over 15 years in the field, much of it working within the aerospace industry on projects for companies like Boeing, Lockheed Martin and Parker Hannifin. From testing different flight structures, to business development in aerospace, to starting his own service bureau, Gurrola has now built a complementary portfolio of 3D printing technologies, seeing Saratech expand into applications for additive manufacturing.

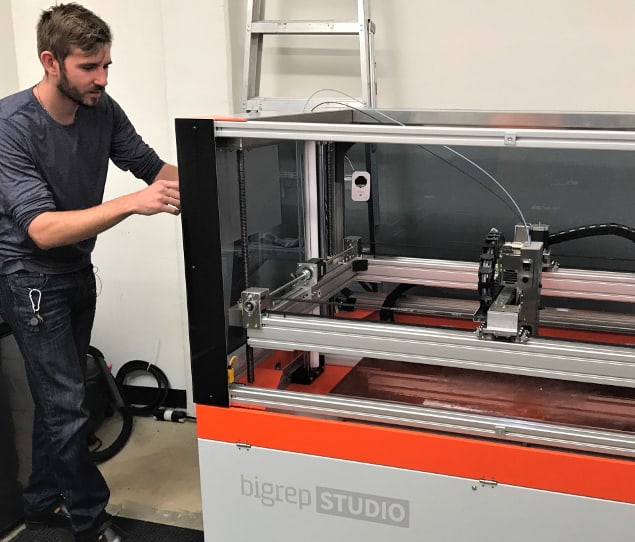

Saratech recently joined the BigRep reseller community, and is the first West-Coast-based partner for BigRep, covering 60% of the United States with their services and sales. From their headquarters in Mission Viejo, between Los Angeles and San Diego, California, they are a 3D solutions provider with a difference – their pedigree in engineering solutions consulting precedes even their sales of 3D printing equipment and machines. Saratech assists its clients with comprehensive engineering services – “Everything from napkin-sketch designs, to full analysis, design certification, method and more,” said Gurrola.

As for California, Gurrola speaks to the merits of being on the West Coast for ready access to a huge range of industries using additive technologies. “It has always been a hot-bed for 3D printing,” he said of the Golden State, where they have operated since 2004. “We work with startups, well-established medical companies, all the core design houses for automotive in Northern and Southern California.”

BigRep America President Frank Marangell says having Saratech on board as a BigRep reseller is another huge step toward reaching major players on the West Coast. “California is a state with such a broad array of industries and huge potential for additive manufacturing,” he said. “The Saratech team has such a strong track record in offering impeccable service to customers, so we’re proud to be partnering with them offering our large-scale 3D printing technology.”

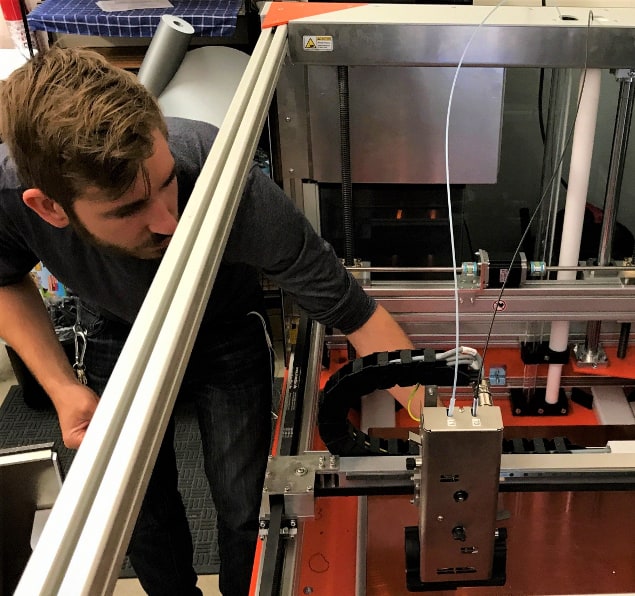

As well as scale, customers are increasingly looking for the capacity to use a range of materials. The vendor lock-in by other OEMs can be a real deterrent, says Gurrola, who thinks this has been a big part of the appeal with BigRep and its open source large-scale 3D printers. For bigger companies, especially in the aerospace industry, a vendor lock-in with materials immediately disqualifies that product from even being applicable in a lot of cases, from a risk mitigation perspective: “One of our customers has a specific custom material, which they use for their own product – they won’t share that material formulation.” Gurrola says customers like these need the capability to be able to use other materials, to retain an edge over their competitors.

Naturally, we’re always curious to know what new materials are being developed, but as BigRep develops its own 3D printing filaments – including newly released TPU-based filament PRO Flex – we understand the importance of confidentiality in development to retain competitive advantage. Furthermore, Gurrola saw the BASF investment in BigRep as a real plus, since it opens up possibilities for even more creative materials development.

Saratech’s founder Dr. Saeed Paydarfar came from an aerospace background, and worked in flight systems, so while the company has a strong track record of working with companies in automotive, medical devices and consumer products, it is aerospace that remains a core focus. Saratech is building on its various competencies to find new applications to solve manufacturers’ business challenges. Gurrola said, “We’re taking our automation skillset, and marrying it with additive to make manufacturing more efficient. We’re making it so you don’t need an operator throughout a full production run of multiple builds.”

Among the broad spectrum of cases they have worked on, Saratech has seen many a challenge presented, for which there is a perfect-fit 3D print solution. One such recent case was a customer involved in modifying aircraft with antennas. They needed to work at an extremely past pace retrofitting aircraft that were on the ground for repairs with the antennas. Time is of the essence, Gurrola says, when it’s roughly a $100,000 per-day loss that a plane is on the ground. The customer was redesigning the jigs with aluminum, but requested Saratech’s help to lightweight the jigs. When they couldn’t CNC-machine the parts quickly enough, they created a 3D-printed prototype, which turned out to be ideal for their needs. They have now produced a dozen or so of these fixtures, which the customer is using in production.

In this and other cases, Gurrola has some sage advice for customers: “Look at a design for additive from the beginning, rather than mid-way through… Understand how best to utilize additive for manufacturing or for replacing existing components.” How exactly do you do that? Well, you’ll have to talk them directly!