An investment in new technology should do more than provide a business with an immediate boost to productivity and capability. It should promise a capacity for future applications as soon as they inevitably arise. It’s a simple consideration, but it could prevent unnecessary future investments and establish an early edge in new applications.

BigRep is dedicated to pushing its technology to the limit internally with our innovation consultancy agency, NOWLAB, to ensure our reliable large-format 3D printers can handle the wealth of future-applications that regularly become realities. NOWLAB designs and creates future-ready products to inspire and aid businesses developing their own innovations around the world. Through their work, NOWLAB dispels many of the assumed limitations of additive technology and demonstrate how an investment in additive manufacturing can not only meet businesses needs today, but open doors in the future.

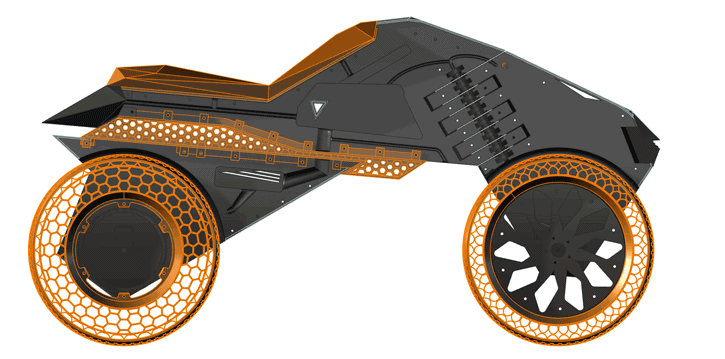

Last week, BigRep was proud to win best Creative Use of 3D Printing at the 3D Printing Industry Awards for NOWLAB’s NERA eBike, the world’s first fully 3D printed e-motorcycle. The NERA was unveiled on November 13, 2018 at Formnext and it went viral! But one impressive innovation integral to the NERA can be easily overlooked: the crucial, fully 3D printed airless tires and rims.

Airless Tires Breaching the Consumer Market

Michelin and General Motors recently unveiled their brand-new 3D printed Uptis airless tire prototype at the at the Movin’On Summit for sustainable mobility. They announced research plans to validate the design and introduce it to the consumer market as early as 2024. Michelin says the tires will combat the waste generated by the approximately 200 million rubber tires that are prematurely disposed of every year due to damage from puncture, improper air pressure and other common forms of wear.

Michelin and General Motors’ announcement is the most recent in a long line of airless tires releases, but it does mark a divergence from applications focused on lighter or slower vehicles – like all terrain vehicles or tractors – by brands like Goodyear, Bridgestone, and Hankook.

Airless tires require careful consideration from design teams to ensure the safety requirements of a vehicle’s wheels are met. Factors from weight resistance to surface grip and a variety of associated properties need to be carefully balanced to ensure such an unconventional component will work in the demanding conditions of the real world. When designing the NERA’s airless tires and rims, project lead Marco Mattia Cristofori and NOWLAB’s design team needed to consider the appropriate balance of rigidity and flexibility with respect to both components to ensure their safety and functionality. The end-use materials had to be rigid enough to keep its form but flexible enough to have shock absorbing traits on obstructed terrain.

The design goal extended beyond simple functionality, however. Airless tires have functionally existed in niche applications, like space vehicles, for years. Since NOWLAB set out with the NERA project to demonstrate realistic consumer market item, the aesthetic of the airless tire and rim had to be considered – adding an extra layer of difficulty to the product’s design.

“We realized that large-format additive manufacturing and airless tires are a powerful combination,” said Cristofori. “Full customizability is necessary to adapt different design parameters, and with additive the same machine can produce different scales, patterns and other customizations without changing settings or hardware parameters.”

NOWLAB's 3D Printed Airless Tire Design Process

NOWLAB dove into designing the airless tire's internal structure by considering biomimicry engineering. A strategy in many NOWLAB projects, biomimicry makes use of functional designs found in nature to create similar properties in human-designed products. In the case of NERA’s tires, a honeycomb design was chosen to provide the tire internal stability for its efficiency in balancing the required rigidity and flexibility. The geometry proved strong enough to take full advantage of a flexible material, BigRep’s TPU filament, which has proven capable of keeping shape under weight with the chosen geometry but maintains its properties well enough to mimic the soft function of a traditional tire.

After choosing the honeycomb pattern that would be the design’s basis, the team needed to ensure the product’s overall properties would meet their needs. Mirek Claßen, NOWLAB Head of Innovation and Generative Design Applications, helped apply algorithm-based parametric design to ensure the tire would meet its requirements for the specific customized range of weight-resistance and size that was needed for its function on the NERA, a process that also ensures the airless tire is easily adaptable for future applications with different functional requirements.

“Combining the possibilities of generative and parametric design allowed us to unlock the full potential of large-format 3D printing,” said Claßen. “Within our algorithm-based design model we could iterate unlimited design variations to find the perfect version to suit our needs and fulfill all technical requirements.”

Both the NERA’s airless tires and rims are fully 3D printed, demonstrating the functional and impressive ability of BigRep’s TPU and Pro HT materials to withstand a vehicle and driver’s weight. BigRep’s NERA was designed to hold passengers over 110 kilograms, but the design can be altered to support even more weight for heavier vehicles or heavier loads like multiple passengers.

Pro HT was an apt choice for the NERA’s rims for the same reason TPU was suited for the tire – it has the perfect balance of rigidity and flexibility for its application. Overall the rims require far more rigidity than the rubber-like tires, of course, but striking a balance ensures the rims remains solid and sturdy but aren’t so brittle as to crack under weight. The material’s marginal flexibility also adds an amount of shock absorption to the wheels, making for a smoother ride.

Beyond the airless tires, BigRep’s materials like TPU allowed for embedded functionalities in a unique way. The NERA’s bumper, seat and handles were all printed with TPU to fulfill functions that usually require complex mechanical constructions like hydraulic suspension systems.

Market-Viability of Airless Tires

To the average consumer airless tires might seem like a novelty, but beyond the innovation’s charm and environmental benefits there are practical applications that extend beyond the niche uses observed so far. For one, an average rubber tire weighs about 10 kilograms whereas the NERA’s 3D printed airless tires only weigh six kilograms, a 40% weight reduction. Complicated supply chains can make acquiring new tires an expensive challenge in remote locations, but with access to a large-format 3D printer the tires can be created locally without the costs and environmental impact of shipping.

Most concerning for the average consumer, however, is the durability and additional safety the technology provides. Removing the need for air-filled tires eliminates the risk of blow-outs that can create dangerous scenarios on the road. The exponentially improved durability of airless tires also eliminates the egregious expenses associated with regular tire changes, not to mention the fuel-economy that comes with a significantly reduced vehicle weight. Overall, airless tires on the consumer market would be a joyful innovation for all concerned.

“Coming out with the idea was pretty natural,” said Cristofori. “We researched the possibility of airless tires, read about what exists so far and their future potential. It was absurd to us that no one else had 3D printed one for bicycles or motorcycles before.”

As vehicles rapidly evolve to meet modern environmental requirements, now is the time to rethink every aspect from the ground up to redevelop everyday technology with the modern tools that enable novel designs and processes. BigRep understands the importance of the re-thinking process to innovative designers and industrial manufacturers. By taking on inspirational projects like the NERA eBike, NOWLAB not only proves the prowess of BigRep’s large-format additive technology but also gains the expertise to consult on innovations even before they’re fully realized by prominent manufacturers; ensuring our tools and training position our partners for success.

“We're happy to see that we inspired other companies,” Cristofori added. “That’s what we do at BigRep. Besides producing reliable 3D printers, we innovate and make sure their full capabilities can be taken advantage of. We research and develop innovations to inspire while we are also inspired by others.”

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.