Imagine you could create thousands of options for a single design at the push of a button and then you just pick the best option! Generative design makes this possible.

Generative design is pushing the boundaries of what engineers and creators can achieve. The technology leverages artificial intelligence (AI) and machine learning to automatically generate design solutions based on design criteria.

This capability enables designers and engineers to explore geometries and forms beyond the bounds of human imagination and come up with superior solutions and products. Generative design’s potential is further unlocked using advanced manufacturing technologies, like 3D printing. In this article, we’ll take you through everything you need to know in order to understand and get started with generative design.

What is Generative Design?

Generative design is a a software-driven iterative design process in which 3D geometries are created based on goals and parameters. The software, which uses AI-driven algorithms to make optimized geometries that meet or exceed performance requirements.

In the generative design process, you are not required to upload an existing part or geometry. Instead, you input constraints and design goals for a given part, and the software will auto-generate a series of designs that meet your specifications. Inputs include dimensional and weight constraints, maximum cost, material type, necessary loads, what manufacturing technology is being used, and more. Generative design software takes all these factors into account when computing 3D models, resulting in a series of different designs that fit the parameters and goals.

From there, the various options can be further analyzed - either manually by the designer or using an automated testing program - to rank the geometries based on how well they meet the defined goals. The top choices can then be further refined and optimized until the best solution is found. Notably, because generative design is driven by artificial intelligence, the software continues to learn with every project, leading to increasingly advanced outcomes.

Difference Between Topology Optimization and Generative Design

While both are at the forefront of design processes today, topology optimization and generative design are not to be confused or conflated. One optimizes an existing CAD design to meet certain specifications, while the other creates a design from scratch using algorithms.

Topology optimization is a widely used tool in many CAD software programs. In the topology optimization process, users upload a CAD model and specify the design goals for the part including constraints, loads, etc.. The software processes this input and creates a single optimized geometry based on the original CAD model.

The generative design process, on the other hand, starts at a different point. Rather than input an existing 3D model to be optimized, you begin by setting the project constraints and goals. AI-driven software then analyzes these and generates a series of design outcomes, which you can evaluate and optimize further.

In summary, there are two important distinctions between topology optimization and generative design. First, unlike topology optimization, generative design does not require a human-designed CAD model to initiate the design process. And second, generative design offers you multiple optimized design outcomes, enabling you to explore more potential solutions and further refine the design.

Benefits and Limitations of Generative Design

There are many benefits to using generative design, including previously unimagined solutions and faster design iterations. As a relatively new software solution, however, generative design is still burdened by some limitations, which we will explore in more detail. But first, let’s take a look at some of the benefits.

Benefits of Generative Design

New design concepts: Traditionally, product designs are typically based on models that already exist. With generative design, however, geometries are not restrained by existing models. The software can therefore produce wholly new geometries that may surpass existing designs in terms of functionality and performance, often with an unexpected and novel appearance.

Faster time to market: Generative design technology can dramatically speed up product design timelines and therefore accelerate the time to market. Not only does it auto-generate multiple outcomes for a given set of parameters, it also enables you to compare the various designs and further refine them in a digital setting. This means by the time you get to physically prototyping your new product, many of the potential design flaws will have already been anticipated and avoided.

Complex design: Used in combination with advanced manufacturing processes, such as 3D printing, generative design unlocks unprecedented design freedom. Previously impossible parts, with lattices, organic structures, and complex internal geometries can be achieved to attain the best possible performance outcomes and meet design goals.

Automated assessment: Once the design outcomes have been generated the best option must be chosen. Depending on the project, this can be simply an aesthetic decision made by the designer, but more often this is a matter of part performance. Additional algorithms can be implemented to evaluate and rate the generated design in regard to parameters such as part performance, accuracy in relation to defined goals, and many more.

Limitations of Generative Design

Upskilling: To make the most out of generative design software, designers must understand how to work with machine learning and AI-driven software. This is especially true for more complex design applications. Not all designers are equipped with these skills, which creates hurdles for adoption.

Accessibility: One of the challenges facing generative design today is accessibility. The cost of using generative design software has traditionally been steep, which makes it prohibitive to certain users. Free options are available but tend to require the users to script their own algorithms. Fortunately, thanks to cloud computing solutions, the price of generative design solutions is starting to decrease. In 2021, for instance, Autodesk cut the price of its Generative Design Extension for Fusion 360 by 80% to increase access.

Generative Design Process

Once an exclusive technology, generative design software is becoming more accessible as CAD software providers integrate the process into their product offerings. Below are some of the leading generative solutions on the market:

Autodesk Fusion 360

A leading CAD software program, Fusion 360 offers users a wide selection of 3D design tools. Autodesk’s Generative Design Extension for Fusion 360 utilizes machine learning and AI to quickly iterate design solutions based on defined goals and parameter sets for various manufacturing processes, including 3D printing, CNC machining, casting, and injection molding.

Siemens NX

PLM software provider Siemens has brought generative design to market in its NX platform. Siemens NX is an integrated solution that offers a combination of intelligent design and simulation for product design. NX also integrates topology optimization powered by convergent modeling.

PTC Creo Generative Design

The Creo Generative Design solution by PTC is fully integrated into its CAD/PLM/simulation platform, enabling the seamless transition from design concept to simulation to prototype to production. The solution consists of two design extensions: the cloud-based Generative Design Extension (GDX) and the Generative Topology Optimization extension (GTO). These extensions automatically highlight the top design options for the user and are compatible with both additive manufacturing and CNC machining.

nTopology nTop Platform

nTopology’s generative design software gives the user full control over the design optimization process. With it, you can build custom workflows and utilize field-driven design, which combines simulation, experimental data, and in-house engineering knowledge to generate innovative, optimized design solutions.

3D Printing and Generative Design

3D printing, also known as Additive Manufacturing, and generative design go hand in hand. Used in combination, the advanced technologies enable engineers and producers to take their products to the next level, overcoming design limitations imposed by more traditional manufacturing processes.

3D printing is a relatively young manufacturing approach that builds parts layer by layer. This is different from subtractive manufacturing processes, like CNC machining, which creates parts by removing material from a blank. Due to the additive nature of 3D printing, the technology is capable of producing a greater range of design features, including lattices, organic structures, and internal geometries. Today, there are many types of 3D printing technology on the market, including metal, polymer, and composite systems that fall into hobbyist/industrial and desktop/large-format 3D printer categories, for example. This means additive manufacturing can be used for a broad range of applications in many industries.

Generative design gives you the tools to make the most out of 3D printing. And vice versa. In other words, 3D printing and generative design provide unprecedented design freedom, which creates pathways for more innovative product development.

In addition to the design freedom 3D printing allows, the technology also offers other benefits, including production agility. Let us elaborate. 3D printing is not bound by the same economies of scale as more traditional production methods. This means that it can cost efficiently produce a single or small series of parts. Not only does this have benefits for prototyping, where high-quality functional prototypes can be quickly iterated for testing, but also for the mass customization of end-use parts. Generative design also encourages customization in that it can quickly generate new design variations based on parameter adjustments.

There are several examples of generative design and additive manufacturing being used to enhance the performance of a part. For instance, automotive manufacturer General Motors redesigned a seat belt bracket using Autodesk’s generative design solution and metal 3D printing. Not only did the new part consolidate eight components into a single structure, but it was also 40% lighter and 20% stronger than its conventional counterpart. .

Large-scale 3D printer manufacturer BigRep has used generative design to achieve previously impossible designs. The company’s innovation consultancy NOWLAB relied on generative design software and large-format 3D printing to produce the first 3D printed green wall with built-in drainage and irrigation systems. The first installation, known as the BANYAN Eco Wall, is characterized by an organic, plant-inspired structure measuring 2000 x 2000 x 600 mm, and is designed to irrigate the living plants fitted into it. A subsequent GENESIS Eco Screen was installed outdoors in Berlin and measured 4000 x 4000 x 800 mm. Generative design was vital in creating the unique design and optimizing it for 3D printing.

Industries that Use Generative Design

Generative design is a versatile technology that offers benefits to a range of industries, from aerospace to consumer goods. Here is how the top industries that have adopted generative design are using the approach:

Automotive

In the automotive industry, generative design is being used to improve vehicle part design with the aim of enhancing performance and efficiency. Some of the most important goals in this sector are reducing weight and consolidating parts. Both are critical to improving fuel efficiency in cars.

Aerospace

Generative design is also making an impact in the aerospace industry, where new aircraft part designs are unlocking greater efficiency, performance, and safety. Like the automotive industry, aerospace is leveraging generative design to create more lightweight parts for better fuel efficiency.

Architecture and Construction

In the field of architecture, generative design allows designers and architects to conceive of new, outside-the-box solutions for architectural spaces and layouts while solving complex design problems. For example, generative design can come up with innovative and functional layouts for compact urban living spaces or offices.

Industrial Machinery

Generative design can be used with a range of manufacturing processes, including additive manufacturing and more traditional processes like CNC machining. This means industrial machinery businesses can explore new possibilities not only for AM but also for casting design. For example, industrial machinery designers can create better performing parts, such as gears, while also consolidating the number parts to lower costs, material usage, and overall risk.

Consumer Goods

Product design for consumer goods is all about innovation. Generative design is enabling product designers in this segment to bring superior solutions to market that solve complex design problems. Crucially, generative design takes out a lot of the legwork of designing by streamlining what would normally consist of multiple iteration cycles using AI-driven algorithms. This can save product design teams significant time and money.

Conclusion

Overall, generative design is changing how designers come up with solutions to complex problems. It provides an intelligent, automated pathway for conceiving new design concepts that push the boundaries while still meeting, even surpassing, the brief.

It is also worth mentioning that there are those who think generative design will make designers redundant through its use of automation and AI. This is far from the truth: the technology is not designed to replace the designer, it is built to empower them to explore wholly new design concepts that take product performance and efficiency to new levels. And as the technologies that power generative design—AI and machine learning—become increasingly sophisticated, so too will generative design solutions and outputs.

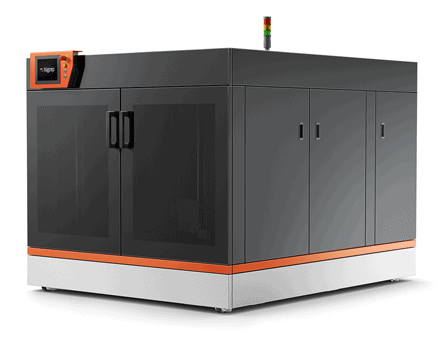

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.