Carbon Fiber Parts with

3D Printed Molds & Patterns

Replace high-cost CNC milling with agile, cost-saving solutions for low volume production

You can't wait to find out, how you could use 3D printed carbon fiber molds and patterns in your production?

SAVE TIME

Drastically reduce lead times and speed up design iterations

5x CHEAPER

3D printing molds costs a fraction of the price of CNC milling aluminum

AGILE ITERATION

Adapt, test, and produce parts in-house with ease

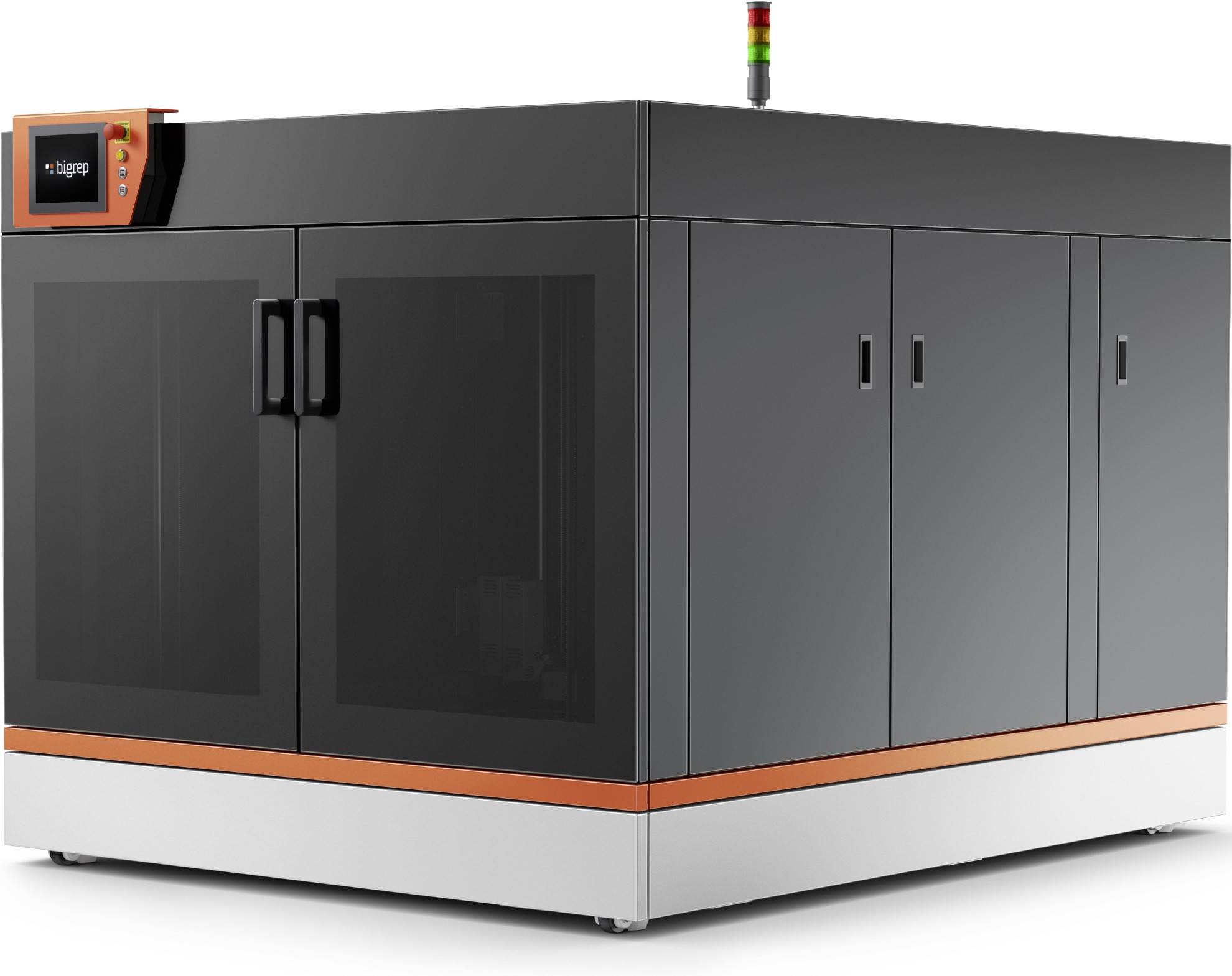

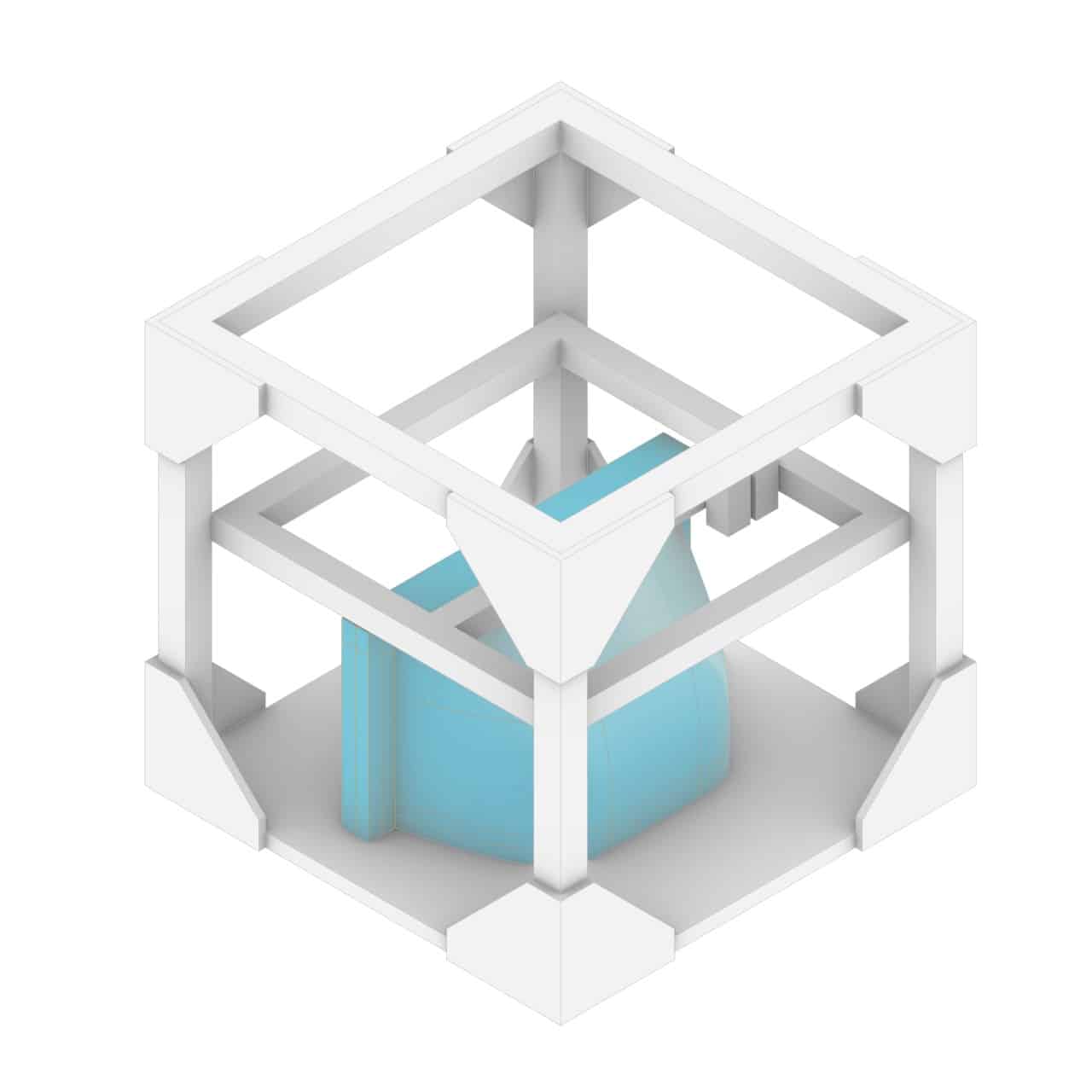

Large-scale patterns and carbon fiber molds are expensive, slow to produce, and complex shapes may not be feasible. Typical CNC milling of patterns wastes material and design iterations are expensive and time-consuming. Therefore, 3D printing can play a huge role in producing high-quality carbon fiber parts while reducing costs and lead times. BigRep machines deliver cost-saving solutions to produce large-scale carbon fiber molds.

How to Mold Carbon Fiber with Additive Manufacturing

Airflight uses prepreg carbon fiber parts to build their human-sized drones. See how they use BigRep machines to produce 3D printed molds for faster, cheaper carbon fiber fabrication

Two Methods of 3D Printing for Carbon Fiber Molding

Method 1:

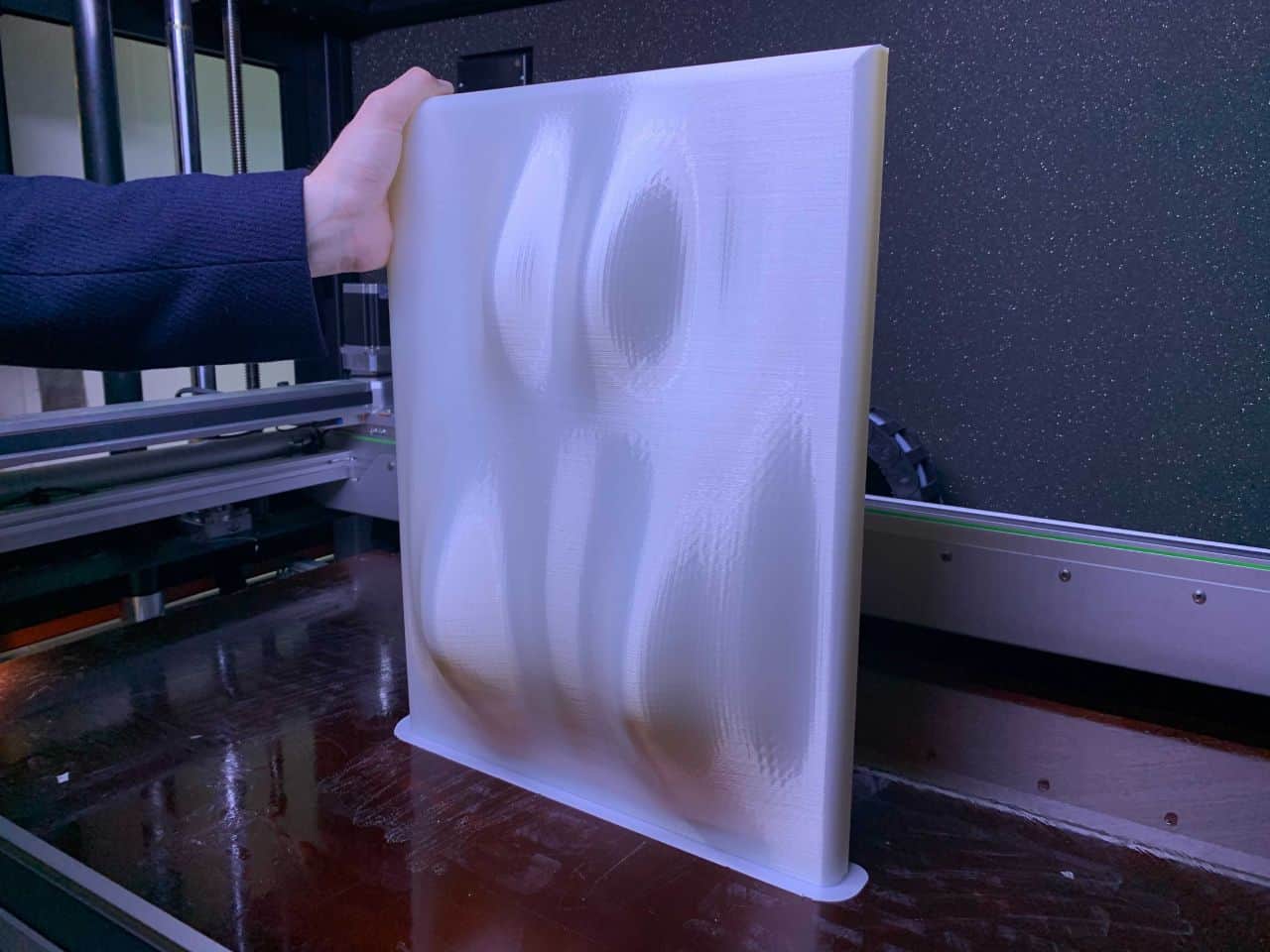

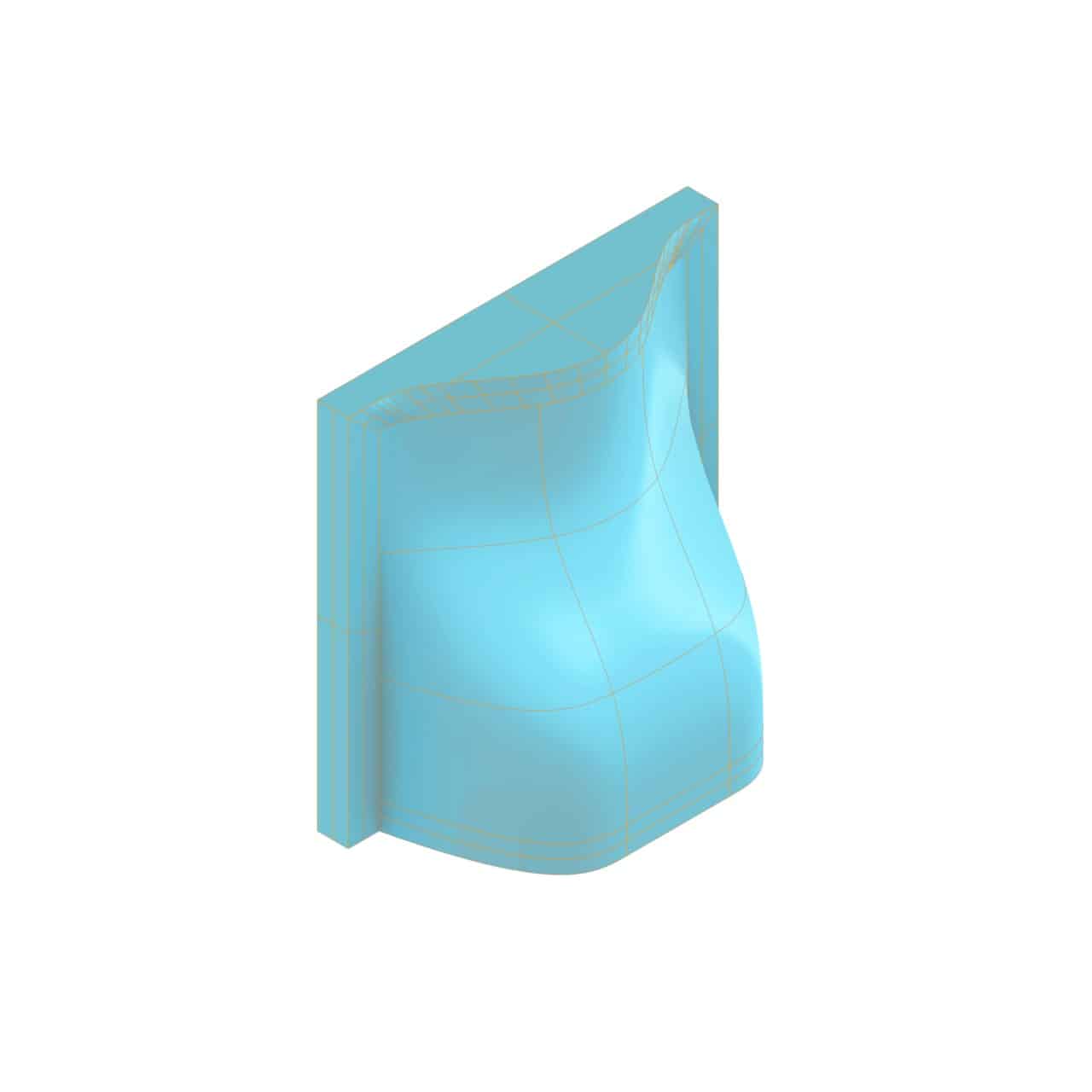

3D Print the Carbon Fiber Mold

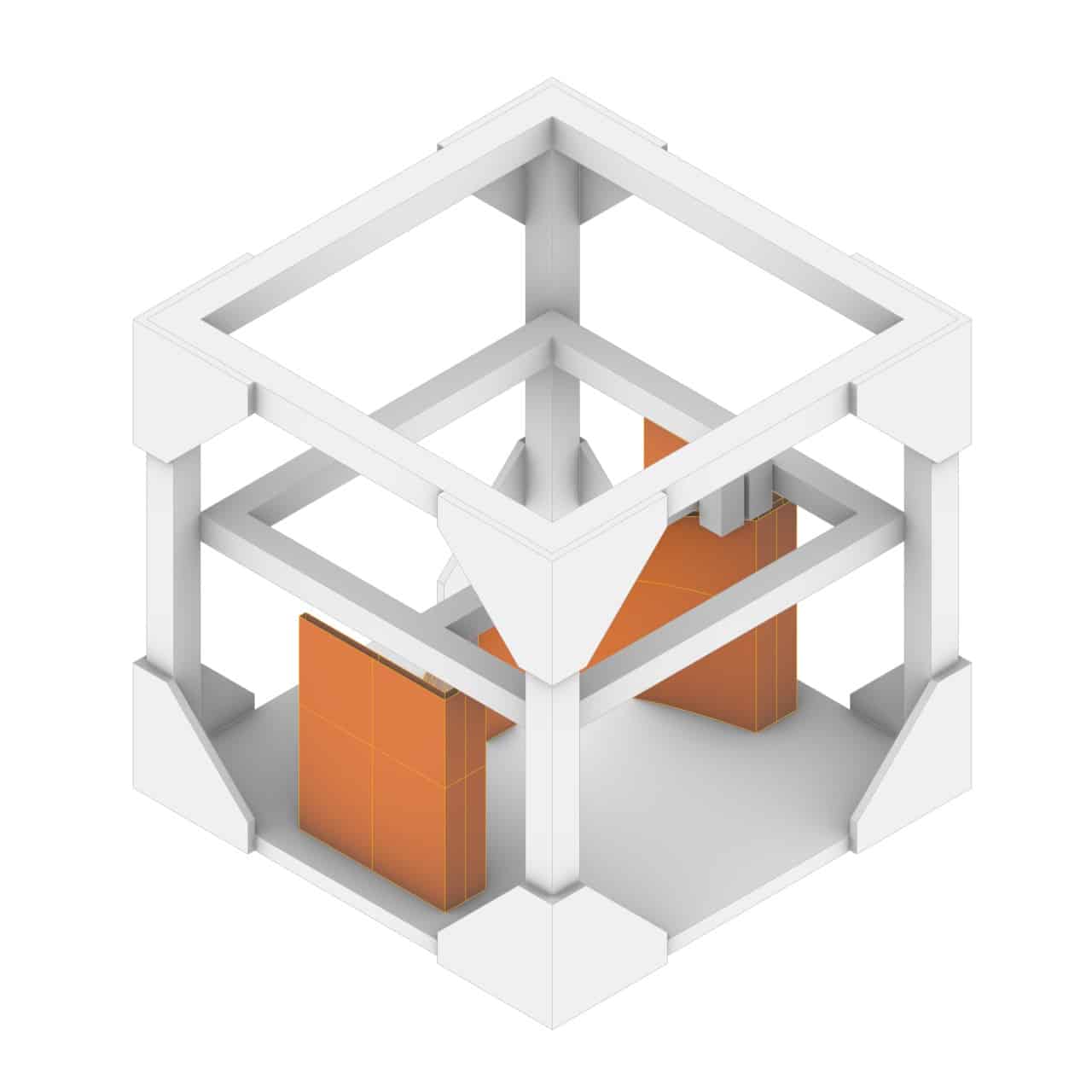

If the part design still needs iterations, the part is intended for small batch production, or the carbon fiber prepreg requires lower temperature / pressure resistance, then 3D printing the mold is recommended.

The mold is 3D-printed and post-processed to required surface quality. If needed, the mold can be designed with inlets to pour in reinforcement filler so the mold can withstand pressure in the autoclave. Carbon fiber prepreg is laid into the mold, placed in a vacuum bag, and cured in an autoclave at the required temperature and pressure settings.

Step 1

3D Print the mold

Step 2

Post-process the mold

Step 3

Use mold to create CF part

Step 4

Post-process the CF part

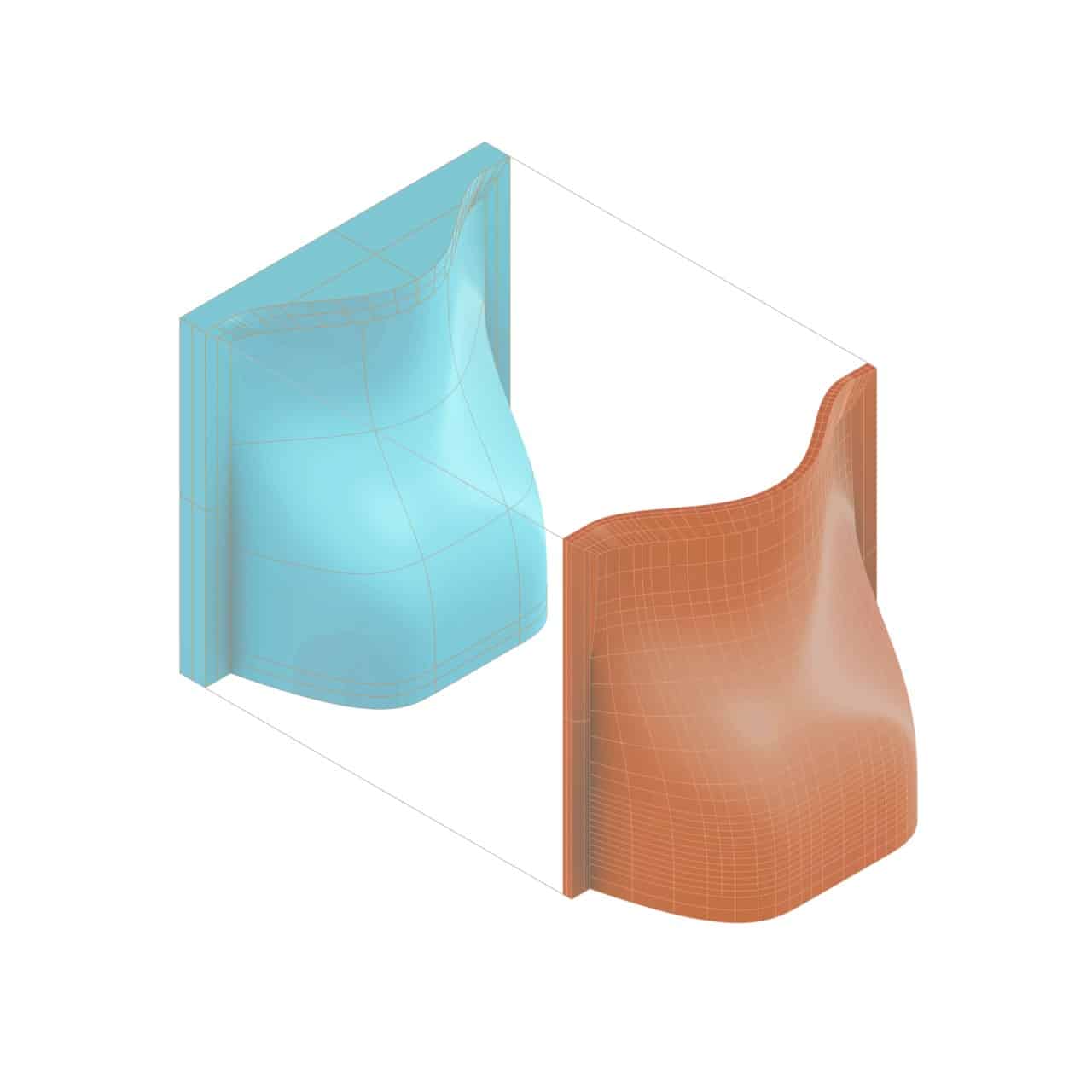

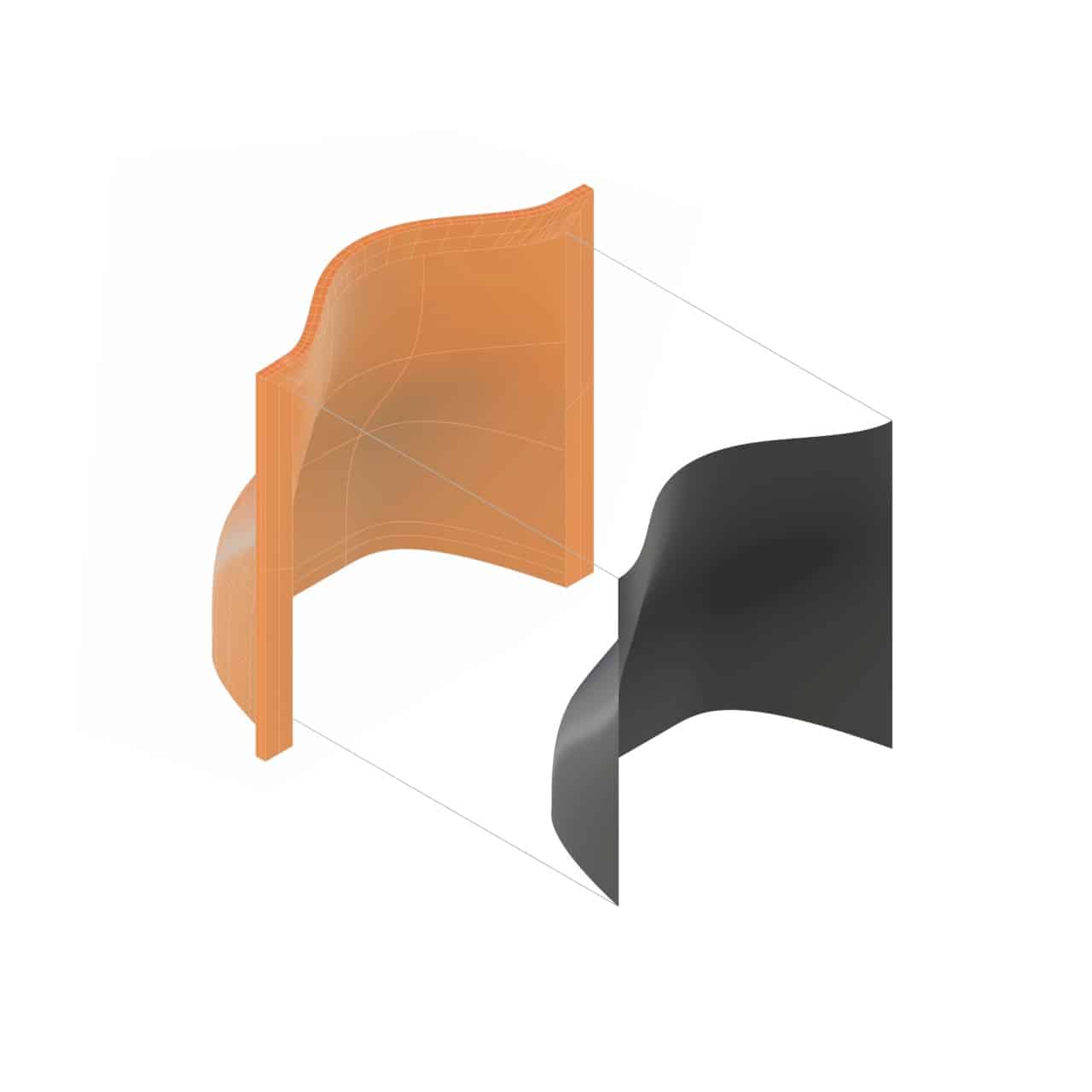

Method 2:

3D Print the Pattern

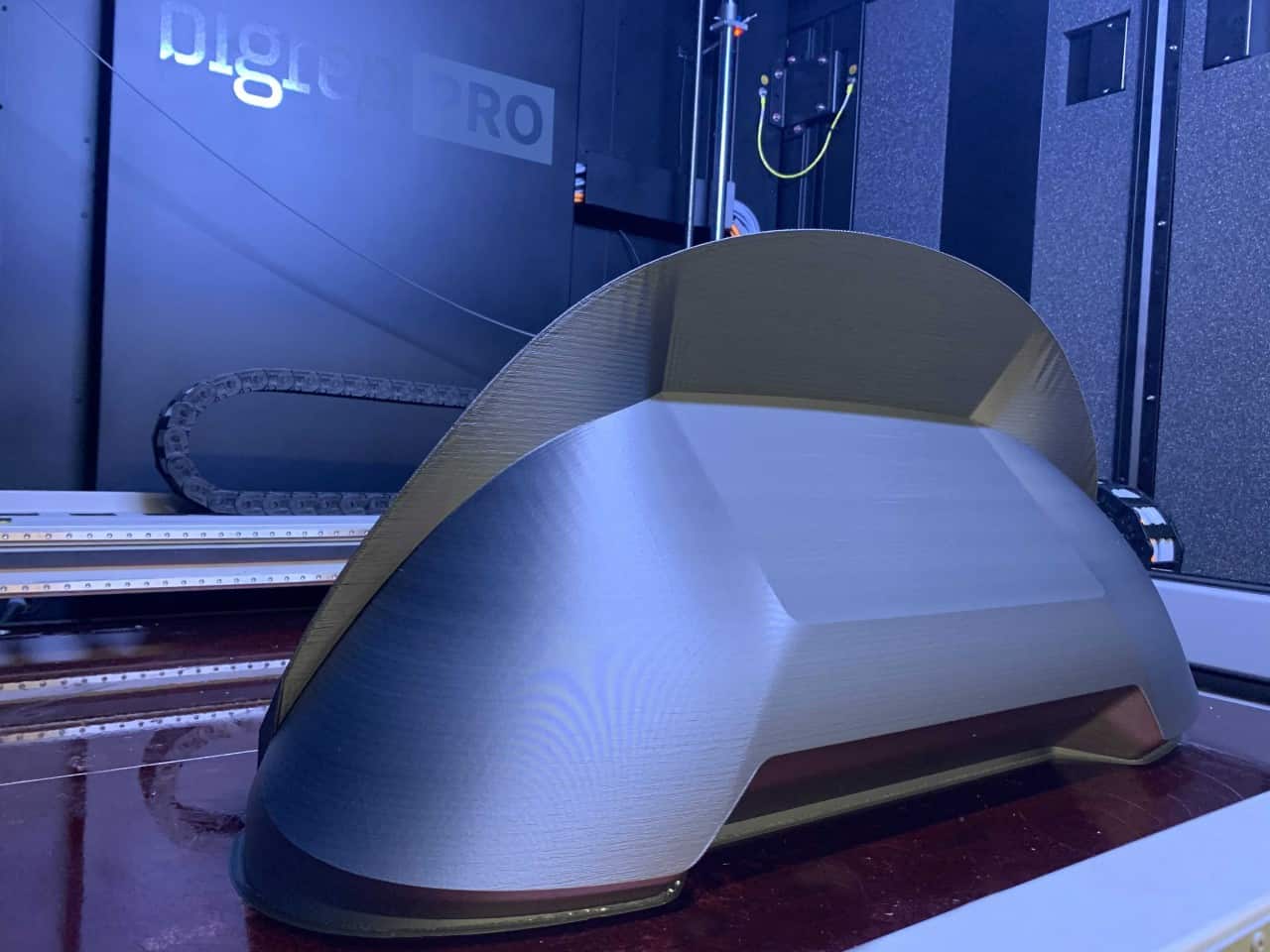

If the part design is finalized, the part is intended for series production, or the carbon fiber prepreg requires higher temperature / pressure resistance, then 3D printing the pattern is recommended.

The pattern is 3D-printed and post-processed to required surface quality. Then a carbon fiber mold is produced from the pattern, typically using glass fiber or high temperature epoxy molding paste. Carbon fiber prepreg is laid into the mold, placed in a vacuum bag, and cured in an autoclave at the required temperature and pressure settings.

Step 1

3D Print the pattern

Step 2

Post-process the pattern

Step 3

Create mold from pattern

Step 4

Use mold to create CF part

Step 5

Post-process the CF part

Talk to an Expert

We have a team of experts ready to answer all your questions. Do not hesitate to reach out to us to get more information about Additive Manufacturing, best materials for your application, and how to implement it in your business!

You THINK BIG, we'll help you get there!