Trucks Customization with 3D Printed Parts and Tools

Reduce development time and costs of parts and tools for customized trucks and other commercial vehicles.

REDUCE PRODUCTION TIME

Reduce lead times, avoid outsourcing, cut logistics, and save time with streamlined processes.

REDUCE COSTS BY UP TO 80%

Bypass expensive machining or injection molding by directly printing prototypes, end-use parts, and tools.

RETHINK DEVELOPMENT PROCESS

Leave conventional ways of manufacturing behind and take the chance to design smarter.

Commercial vehicles like refuse collection trucks and fire engines place high demands on their components and, therefore, on the methods employed to produce them. Maximum reliability, extreme toughness, and the need to replace parts quickly are vital factors for choosing the proper manufacturing process for truck parts. Also, due to the customers varying expectations and the resulting need for customization, parts are produced in small numbers only. Many iteration cycles are necessary on the way to the final design. BigRep 3D printers give companies worldwide the flexibility and versatility to fulfill all these requirements and react to challenging customer requirements on short notice.

Fast Product Development with 3D printing

ZOELLER Group uses BigRep printers to develop customized panels and covers for refuse trucks and lifts. Development times for customer-specific parts for commercial vehicles are drastically reduced by using 3D printers:

- design parts according to customer requirements

- print parts with realistic material properties

- assemble parts and do field testing

- get fast and reliable feedback

- discuss results with the customer

From Prototyping to End-Use Parts in Fire Engines

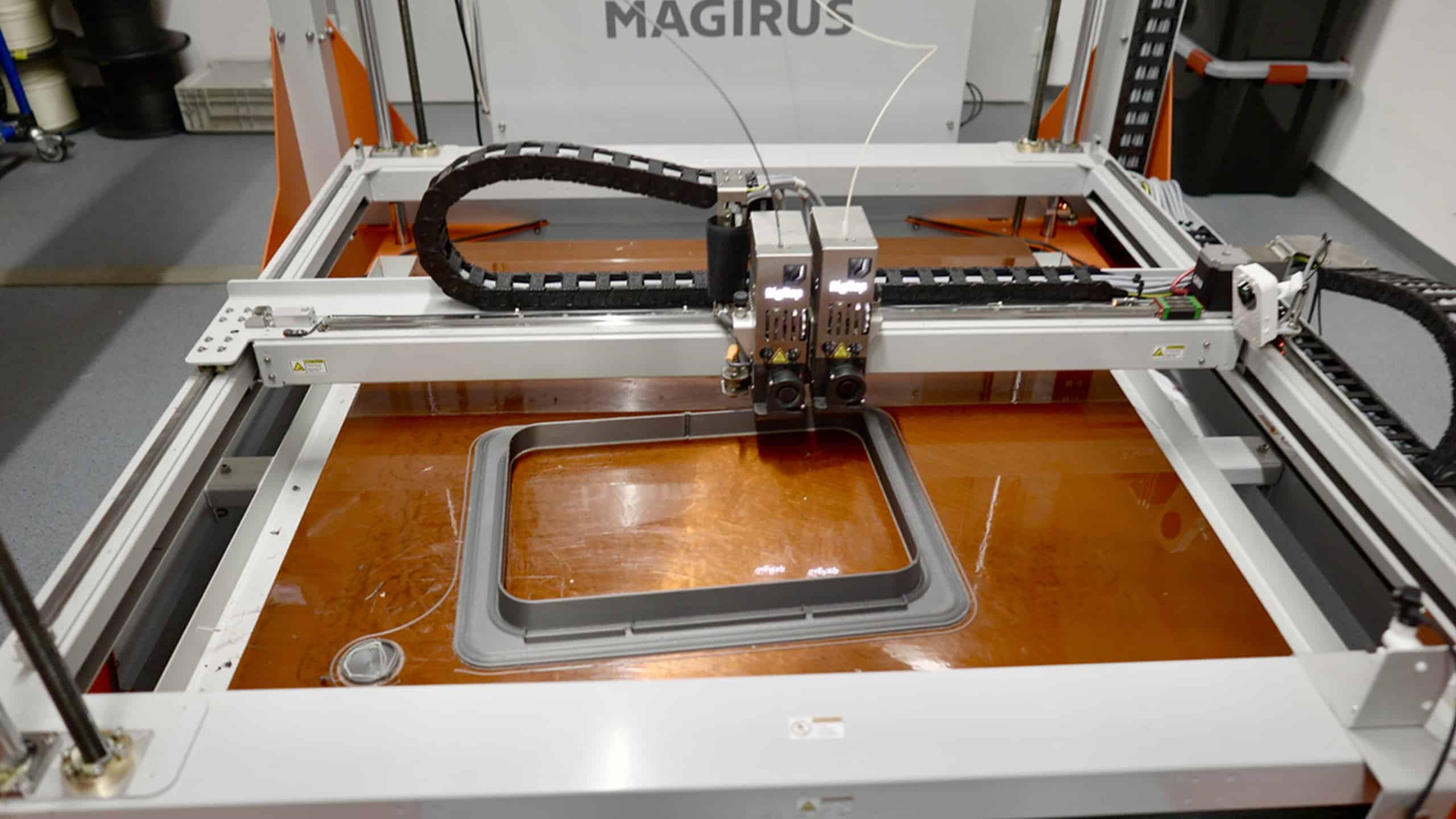

Magirus bought a BigRep ONE 3D printer to speed up prototype production and reduce costs. Previously, making a prototype by hand lamination or CNC machining took about 3-6 months, depending on the part size and capacity of the workshop.

A part can be 3D printed within days, making customization more accessible and faster. Costs could be reduced by at least one order of magnitude. After the good experiences Magirus had with prototyping, they decided to qualify the process and materials for making end-use parts. The frame for an additional window in one of the cabin doors is now in pre-series production.

The 3D printer is used for prototyping and end-use parts. Here, a window frame that will later be an integral and load bearing part of a door is printed.

Because no significant number of the window frame are required, it is more financially reasonable to 3D print it instead of making a mold for injection molding or similar processes.

After validation and extensive testing, it is then installed in the door of the fire engine.

Custom made tools and fixtures for electric trucks

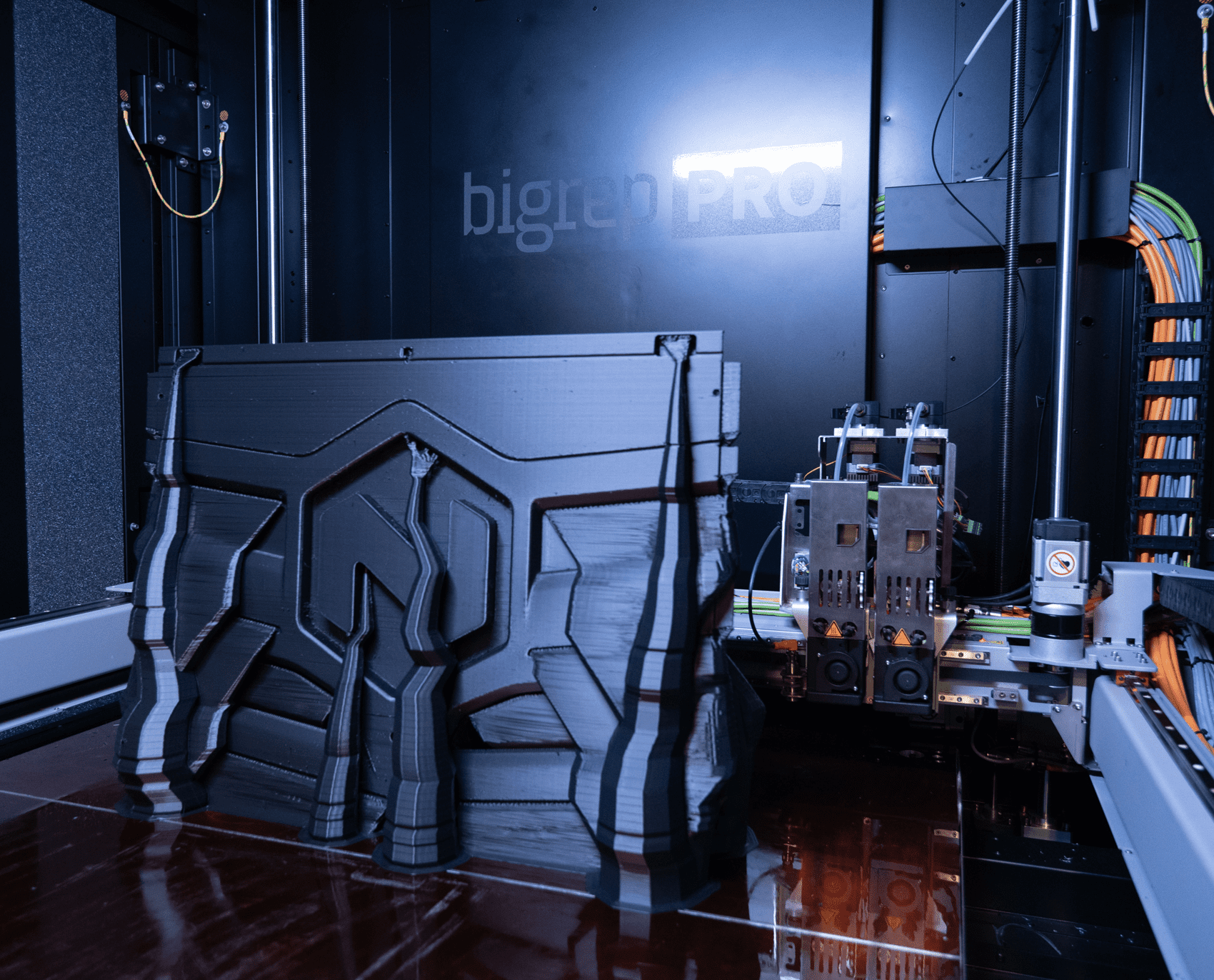

Nikola Motor Company designs and produces battery and fuel-cell driven trucks.

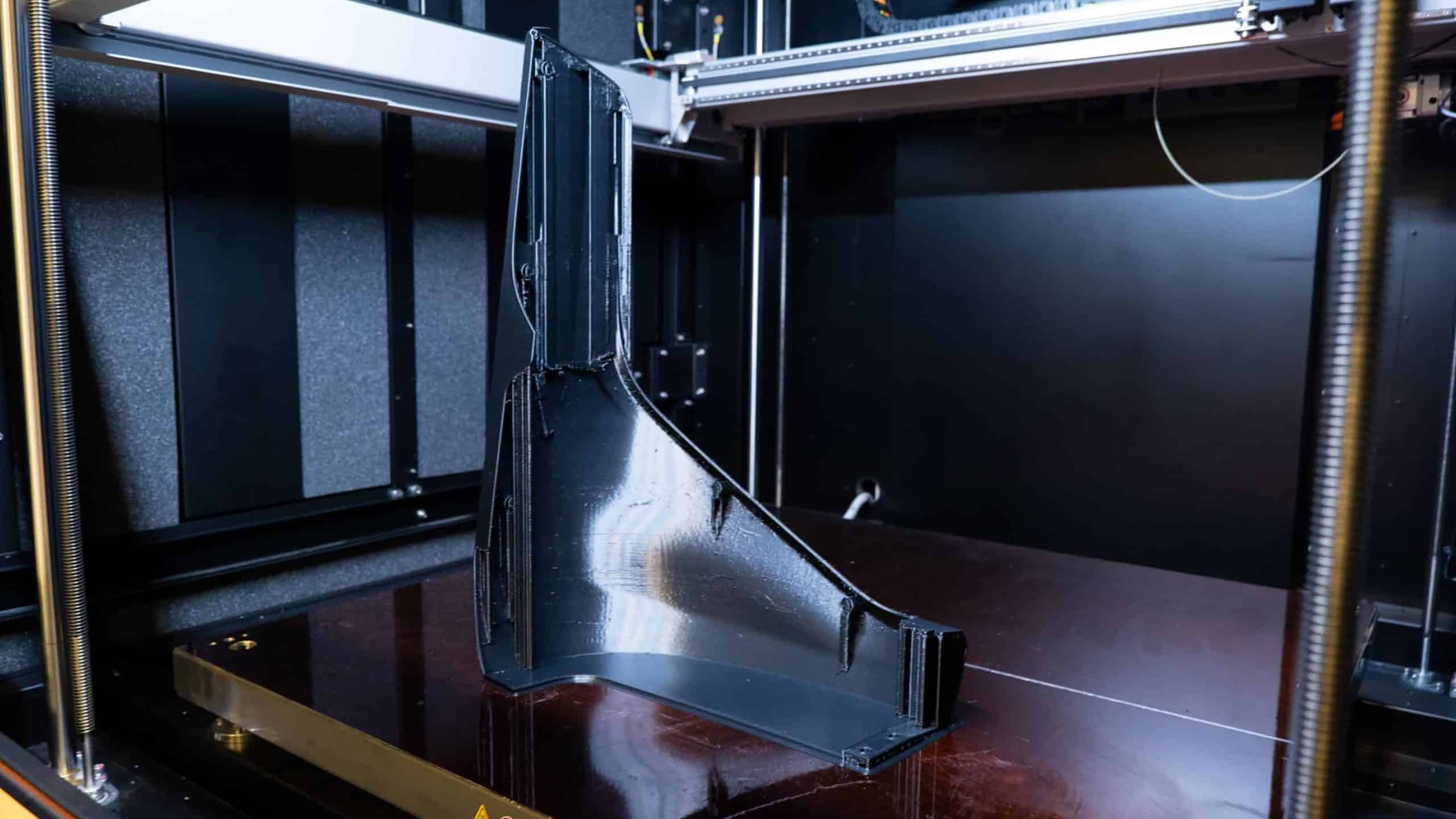

With their BigRep PRO they manufacture models of parts for their trucks for design and development purposes, but also jigs and fixtures to help in production. By printing these parts instead of CNC milling them or outsourcing their manufacturing, Nikola saves time and money and gains flexibility.

Also the freedom given them by the new technology and the large print volume of one cubic meter allows engineers to rethink the whole product development process.

Nikola Motors Company uses 3D printing to produce tools for production as well as prototypes and fixtures.

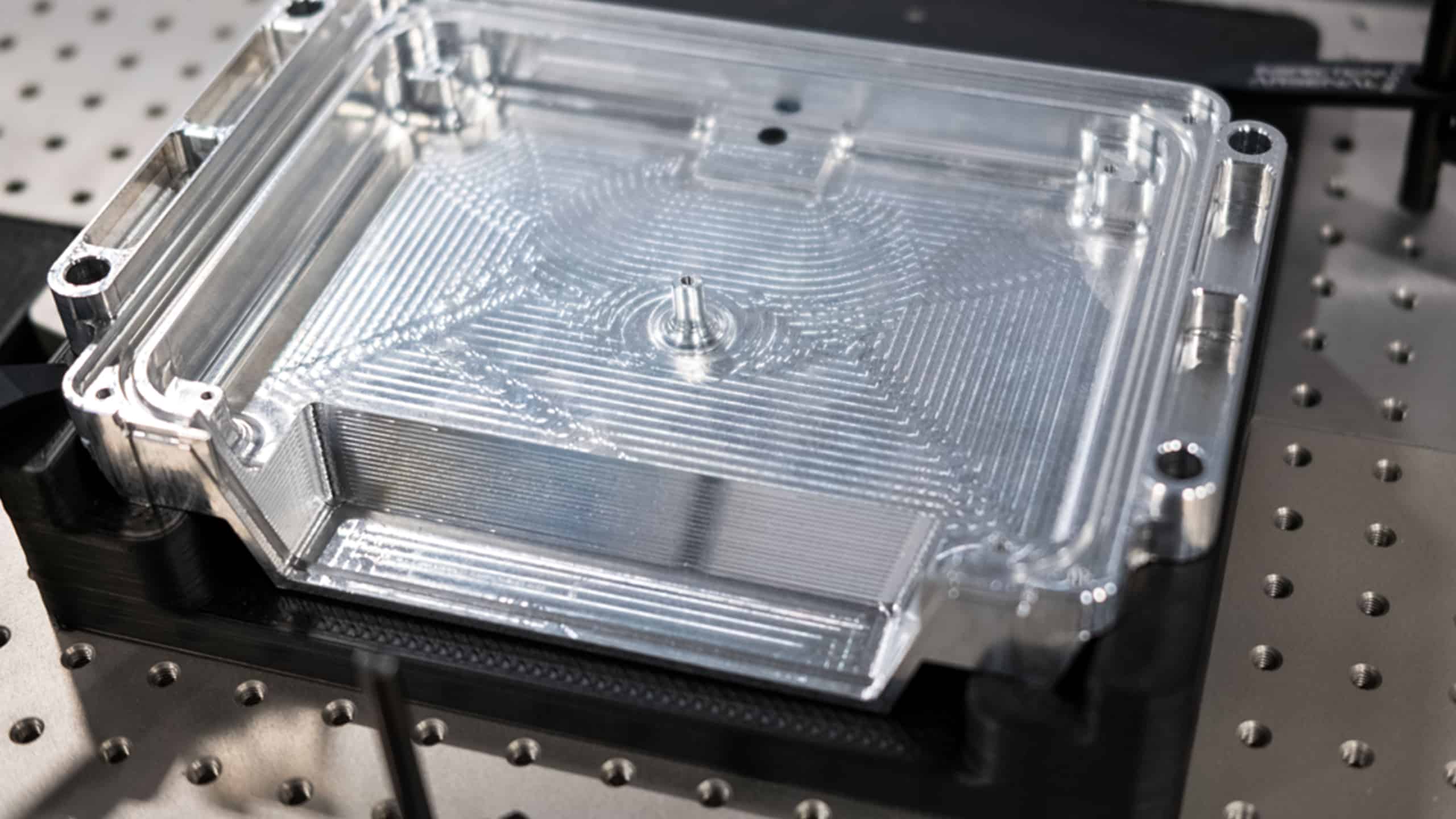

A positioning tool helps to keep the CNC part in place on a CMM.

Being able to produce large truck parts in real scale in-house allows for more and faster iteration cycles and so accelerates development.

Talk to an Expert

We have a team of experts ready to answer all your questions. Do not hesitate to get in touch to get more information about Additive Manufacturing, best materials for your application, and how to implement it in your business!

You THINK BIG, we'll help you get there!