FROM CONCEPT TO FUNCTIONAL PARTS

When it comes to printing large, affordable parts for concept modeling and basic functional testing, PLA is the most common material used to achieve a good result. PLA has a low-cost entry point and is easy to handle on any FDM 3D printer. But what happens when there is a need to print large functional parts with a material that has much better temperature and impact resistance properties? For this purpose, ABS would be a good choice for many closed platform printers. BigRep offers another option at a price from €52.50/kg, its high-performance PRO HT filament, which is suitable for open machines. PRO HT has various advantages over ABS which make it a candidate for closed-platform environments too.

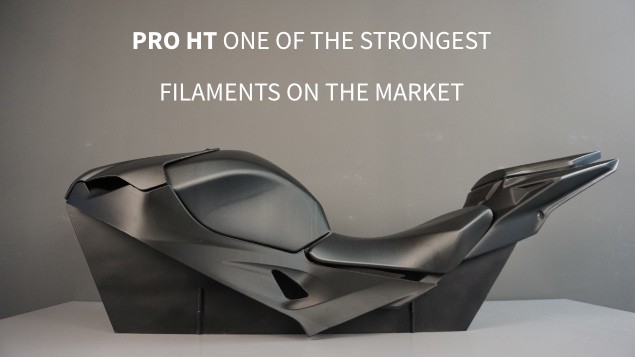

BIGREP PRO HT

With 3D printers that have an open or otherwise unheated build chamber, low printing temperature is the limiting factor when it comes to producing heat-resistant prints. PRO HT was developed by BigRep and our filament producers to answer the need to produce large parts with improved mechanical properties for functional testing on such machines. PRO HT is composed of 100% renewable and naturally pure raw materials, is CO2 neutral, and exhibits excellent adhesion to the print bed.

Key Points - BigRep PRO HT

- • Meets all requirements of European regulation for food contact

- • Extrudes very well between 195°C and 205°C

- • Has very low “warping effect”

- • Withstands temperatures of up to 115°C

- • Is compatible with BigRep’s Power Extruder with 0.6, 1 and 2 mm nozzles

- • Produces no smell issues during extrusion

- • Price from €52.50/kg

PRO HT vs ABS

Since it’s considered as an ABS alternative, one should ask about the differences between these two materials. Before we compare their performance, it’s important to mention a significant difference in their make-up: PRO HT is a Biopolymer while ABS is an oil-based plastic, making PRO HT in a basic sense more environmentally friendly and sustainable. Turning then to performance: PRO HT and ABS share similar tensile and flexural strength characteristics; in terms of impact strength, ABS shows good results, but PRO HT is much stronger still; finally, PRO HT can withstand a 15°C higher temperature than ABS.

A separate, important difference is in surface quality. PRO HT has a matt finish which is an increasingly valued property in the added manufacturing industry, while ABS has a gloss surface finish. Overall then, for open platform printers for which ABS is not usable PRO HT represents an excellent alternative to it. For closed platform machines PRO HT’s better impact strength and environmental credentials, greater temperature resistance, and matt finish will make it more desirable for many applications.

Learn About BigRep 3D Printers

Key Characteristics of BigRep PRO HT, BigRep PLA and ABS

| Characteristic | PRO HT | PLA | ABS |

|---|---|---|---|

| Temperature Resistance (VST) | 115°C | 60°C | 100°C |

| Material | BioPolymer | BioPolymer | Oil-based |

| Tensile Strength | 44 MPa | 60 MPa | 44 MPa |

| Impact Strength | 216 KJ/m2 | 7.5 KJ/m2 | 58 KJ/m2 |

| Flexural Modulus | 2600 MPa | 3800 MPa | 2030 MPa |

| Density | 1.3 g/cm3 | 1.24 g/cm3 | 1.1 g/cm3 |

| Finish | Matt | A range: from Matt to Gloss | Gloss |

| Price/kg | From €52.50 | From €28.12 | N/A for BigRep machines |

Summary

BigRep PRO HT seems to be the perfect, cost-effective solution for printing large parts with high performance characteristics on an open platform machine. It may also often be the optimal material to carry out similar tasks on closed platform machines as well. It has great environmental features, a great matt finish available in several colorways, and is easy to print with on the BigRep ONE and BigRep STUDIO 3D printers, as well as many others.

With over 22 years in the printing industry, Gil Lavi is a Sr. 3D-Printing Specialist with vast experience in implementing diverse 3D-printing technologies in design and manufacturing processes.

Connect with Gil on Linkedin HERE.