Make it unique, make it better, with industrial 3D printing for consumer goods.

From gadgets to sports equipment – or maybe something a little more – customization and personalization are key to modern consumer goods. With industrial 3D printing, you’ll remove the constraints of traditional production and experience truly flexible manufacturing. Easily balance demand and inventory without risky investments and customize products with unparalleled simplicity. Prototype in full scale to unlock real-world insights and manufacture in-house without restriction.

Empower consumer production with true flexibility from start to finish, with BigRep’s proven industrial solutions. Modernize your production today.

CONSUMER GOODS APPLICATIONS FOR LARGE-FORMAT 3D PRINTERS

WHAT COULD YOU CREATE IN FULL SCALE?

EBOOK

HOW TO REDUCE LEAD TIME WITH IN-HOUSE SUPPLY CHAINS

Find out how designers and manufacturers across industries have created incredible efficiencies in their usual project timelines by adopting large-format 3D printing technologies.

Industrial leaders around the world like Ford Motor Company, Airbus SAS, Steelcase and more have leveraged BigRep’s large-format additive manufacturing systems to avoid the pitfalls of early stage product development, tackle traditional production bottlenecks, and create valuable opportunities for increased testing and iterating. They’ve realized massive reductions in time-to-market and increased product quality by implementing industrial 3D printing for novel manufacturing solutions.

Read this collection of industrial 3D printing case studies to learn…

- How 9 industrial leaders have effectively leveraged industrial AM

- How AM can reduce lead times by up to 94%

- How to overcome supply chain bottlenecks

- The limitations of traditional workflows

- How novel applications and workflows drive business

EBOOK

7 WAYS BIGREP 3D PRINTERS UNLOCK PROFIT INSTANTLY

Learn how world-leading companies like Ford, Steelcase, and more made instant returns on their investment in BigRep’s large-format additive manufacturing systems.

Industry leaders have modernized their businesses and created incredible cost efficiencies by introducing 3D printing to their various workflows. BigRep’s additive manufacturing systems offer reliable and flexible functionality that creates massive savings across industries and applications. The benefits of large-format additive are proven at nearly every stage in production processes: increasing opportunities for innovation, working environments, and production speed. But all these benefits serve one bottom line – creating cost efficiencies for businesses.

Find out how the world’s most experienced companies have implemented BigRep’s systems unlock unprecedented efficiency and increased margins right away.

Read this large-format additive guide to find out…

- How BigRep printers reduce traditional lead times by up to 94%

- Why moving manufacturing processes in-house secures production timelines

- How industry giants have made a return on investment from just one application

- Why any business can earn fast returns from large-format’s flexible manufacturing

EBOOK

POST-PROCESSING FOR FFF PRINTS

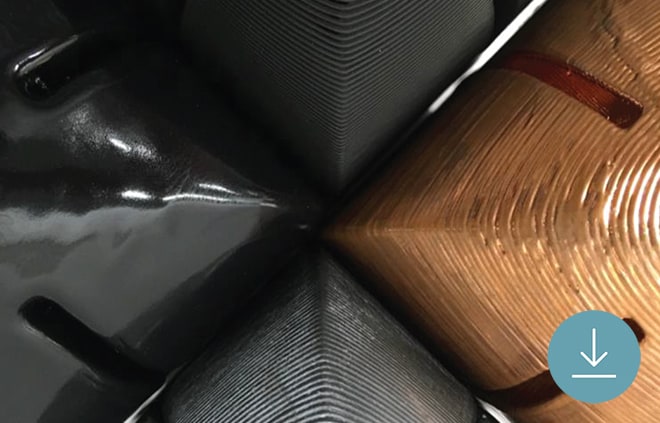

BigRep provides high-quality prints straight off the print bed, but post-processing can improve geometric and mechanical properties and creates a wowing aesthetic effect. By improving surface characteristics, post-processing widely extents the range of use cases and applications across all industries.

This eBook will explore the three types of FFF post-processing techniques: 1) Material Removal, 2) Material Addition and 3) Material Property Change. Also, learn how various techniques like high resolution tumbling, resin coating and aluminum plating are transforming 3D printed parts.

COMPLETE THE FORM TO DOWNLOAD OUR POST-PROCESSING EBOOK

START 3D PRINTING IN FULL SCALE WITH BIGREP

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

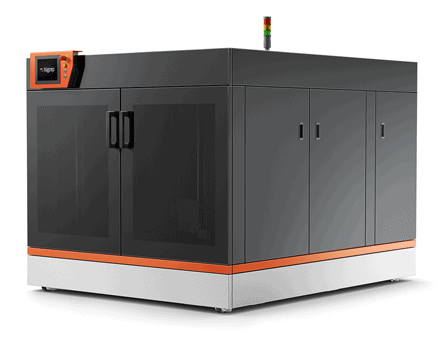

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL 3D PRINTING FILAMENTS

With BigRep’s line of affordable filaments designed specifically for large-format 3D printers, you can rely on production that is both reliable and efficient. With low-cost PLA or high-speed alternatives like PLX, you can easily balance cost and performance to suit your needs. With massive spools of up to 8 kg readily available, you’ll always be ready for the next job.

INDUSTRIAL 3D PRINTING FILAMENTS

With BigRep’s line of affordable filaments designed specifically for large-format 3D printers, you can rely on production that is both reliable and efficient. With low-cost PLA or high-speed alternatives like PLX, you can easily balance cost and performance to suit your needs. With massive spools of up to 8 kg readily available, you’ll always be ready for the next job.