INTRODUCING THE NEW

INDUSTRIAL QUALITY

MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

INTRODUCING THE NEW

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

There was an opportunity to not only fill SAS's need for this tool they couldn't acquire through the normal supply chain, but we also saw the opportunity to make it better.

Nathan Brown, Managing Director at CNE Engineering

INDUSTRIAL 3D PRINTERS FOR LARGE-FORMAT ADDITIVE MANUFACTURING

BigRep makes big, industrial 3D printers for big, full-scale parts (and even big batches of smaller parts). Our commercial 3D printers are up to 1 m3 in build volume, which in fact is big enough to hold 2 baby elephants or equals the build volume of about 40 desktop printers!

With a large 3D printer, you can advance your manufacturing capabilities with 3D printed prototypes, jigs and fixtures, patterns and molds, and end-use parts. Where size isn’t a limiting factor, BigRep industrial 3D printers are built to make you faster and more agile, getting your products to market ahead of the competition.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

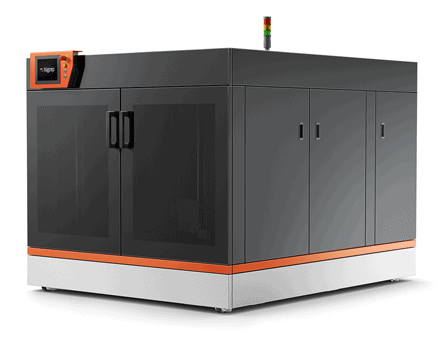

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

INDUSTRIAL 3D PRINTING MATERIALS

BigRep's portfolio of industrial 3D printing filaments are created under carefully controlled conditions to guarantee uniform diameters and consistent composition. They are sealed in controlled, low-humidity conditions for safe storage and transportation - ensuring reliable, even extrusion regardless of whether they're used today or after a reasonable shelf life.

With a wide variety of offerings from affordable, general use filaments to high-quality, engineering-grade materials for demanding industrial applications, BigRep has what you need - specialized for large-format 3D printing to bring your designs to life in full scale.

INDUSTRIAL 3D PRINTING MATERIALS

BigRep's portfolio of industrial additive 3D printing filaments are created under carefully controlled conditions to guarantee uniform diameters and consistent composition. They are sealed in controlled, low-humidity conditions for safe storage and transportation - ensuring reliable, even extrusion regardless of whether they're used today or after a reasonable shelf life.

With a wide variety of offerings from affordable, general-use filaments to high-quality, engineering-grade materials for demanding industrial applications, BigRep has was your need - specialized for large-format 3D printing to bring your designs to life in full-scale.

INTRODUCING

A new customizable SaaS solution that makes application engineering for 3D printed jigs, fixtures, and manufacturing aids easier than ever, with no design skills or 3D printing experience required.

INTRODUCING

A new customizable SaaS solution that makes application engineering for 3D printed jigs, fixtures, and manufacturing aids easier than ever, with no design skills or 3D printing experience required.