Hailing from Beijing, China, Xuberance is a product design firm that leverages 3D printing technology to create unique furniture pieces and accessories. By embracing BigRep’s large-scale 3D printers, Xuberance is writing a new design narrative that combines sustainability and unparalleled design freedom.

From steam-bending woodworking techniques in the 19th Century to injection molded plastics in the 20th Century, advances in production technologies have continually reframed the creative possibilities. Product designers are looking to innovate and push the boundaries of their craft with cutting-edge technologies that allow them to support their vision.

In the 21st Century, design firms such as Xuberance are proving that there is scope for an entirely new conversation - one that empowers the unbound imagination of the product designer thanks to 3D printing technology.

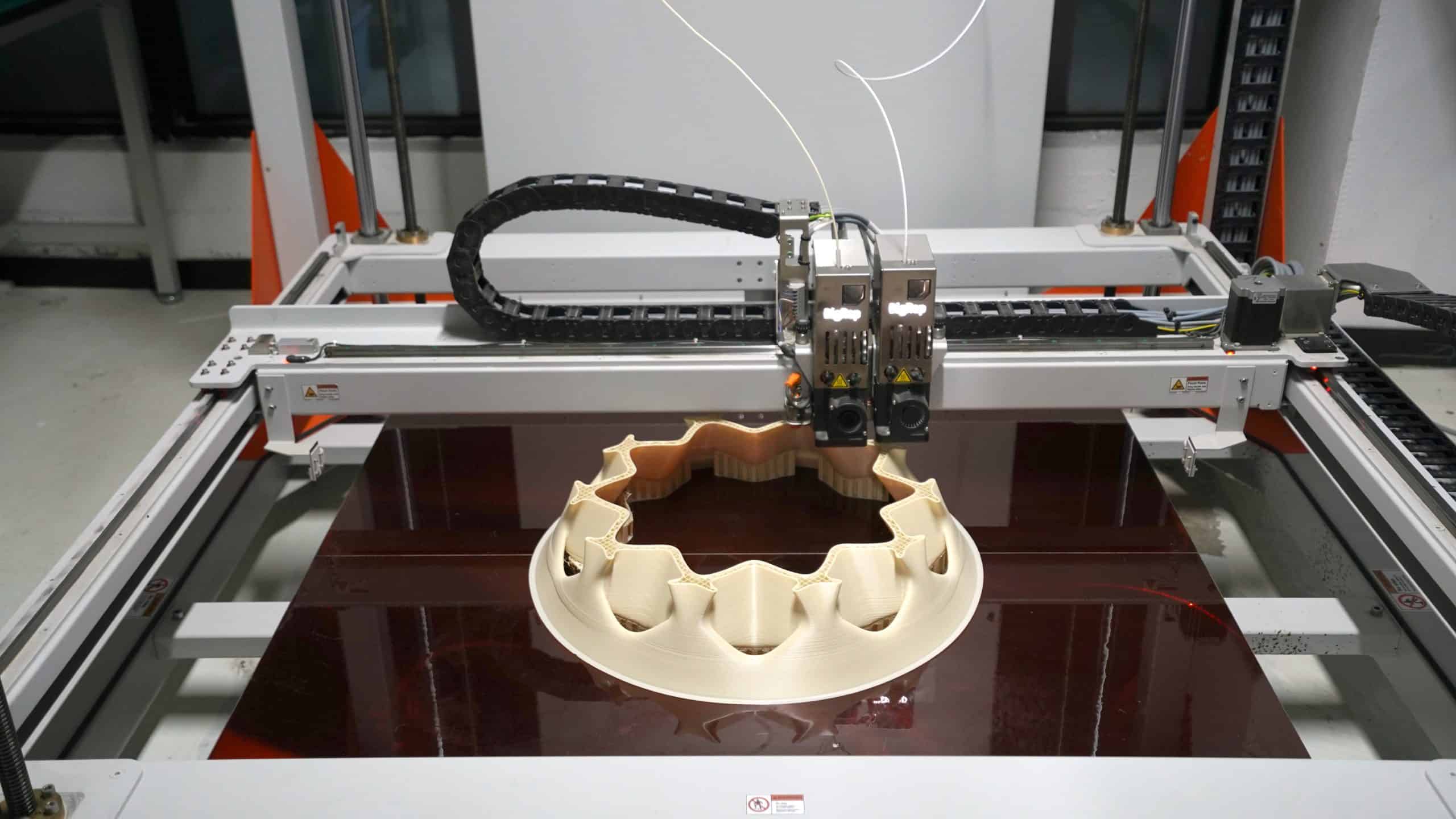

Xuberance is making complex, intricate, and lightweight structures made possible by 3D printing objects from digital designs. The design ranges from furniture pieces to wearable fashion accessories and has become a symbol of a new age of digital expression.

The Form is More Than Function

With products such as the 3D printed Cloud Lamp, a luminaire that garnered the team the prestigious SaloneSatellite Award at the Milan Design Week in 2015, Xuberance has developed a distinctive design language; a language inextricably bound to the digital process of 3D printing.

The resulting intricate, organic forms of its 3D printed products are so unique, that they are virtually impossible to reproduce with conventional production methods such as molds.

“3D printing forms the backbone of our entire design and production process,” comments Leira Wang, Managing Director of Xuberance.

“Our designers can fully translate their digital designs into physical products using 3D printers such as BigRep’s. It offers unparalleled design freedom while pushing the boundaries of what’s technically possible.”

Large Scale Printing Creates Unique Design Possibilities

Although 3D printing was traditionally utilized by manufacturers to produce specific parts, Xuberance was one of the pioneers to embrace the medium as its primary tool to produce entire products from the ground up.

Having the ability to print larger single products such as chairs and stools with 3D printers such as BigRep’s ONE and STUDIO has enabled Xuberance to focus on building its product design niche.

The resulting products are not only strong, durable, and lightweight, but also unique in their form.

“Large-scale printing has had a transformative effect upon our overall ability to create distinctive designs,” continues Wang. “The BigRep large scale printers are instrumental in this, and unlock new possibilities by reducing time and costs.”

As evident with Xuberance products such as the Madame Butterfly chair - a single-piece 3D printed chair consisting of ethereal, organic, and intricately printed patterns, BigRep’s 3D printers allow the production of larger objects while retaining the intricate design.

“BigRep's dual extrusion printing offers a crushing advantage with its super accurate printing quality. We’re now able to faithfully translate our designer’s compositions into finished Xuberance products without losing any of the intricacies of the original design.”

says Wang.

Responding to Customer Demand

Unlike traditional manufacturing, where modifications require mold changes or adjustments to tooling, Xuberance has built its business around the flexibility of 3D printing, which allows for quick iterations to final product designs.

Not only has this allowed the team to eliminate the time and cost associated with physical adjustments in texture, structure, or color gradients can also be quickly executed depending on the customer’s requirements.

3D Printing in a Circular Economy

Product design and furniture industries have been plagued by non-sustainable practices, especially with nonbiodegradable plastics and other materials. But Xuberance is proving that 3D printed products have earned their place within the circular economy with their choice of materials.

With BigRep’s open material system, Xuberance can select the appropriate materials according to the requirements of each design, and set up printing parameters for each geometric model.

In addition to citing BigRep’s PRO HT and ASA filaments as exceptional with regards to their material composition and heat resistance qualities, Wang also highlighted the importance of their biodegradability in underlining the ethos of the company.

A Future Filled with 3D-Printed Possibilities

By embracing 3D printing technology, Xuberance has proven that it’s possible to create stunning, customized products whilst paving the way for a more sustainable future in design. Key to achieving this are the BigRep large format printers, which Wang believes are fundamental to achieving the company’s vision.

"There is an ancient Chinese saying," concludes Wang, "' When brothers are united in purpose, their strength can cut through metal.' We believe in the future of large-scale printing, and we will work together with BigRep to achieve this greater development."

As Xuberance continues to explore the unprecedented creative possibilities of 3D printing, its designers are forging a radical new language formed around the desire to celebrate form and organic beauty.

This approach echoes a historical truth: form isn't dictated by function, but rather, by the tools and technology available to the designer at any given time. With the tools of 3D printing at its disposal, Xuberance is at the very cusp of redefining the possibilities of product design.

Want to Learn More about 3D Printing Bespoke Furniture?

Download the eBook, RH-Engineering & manoFigura 3D Print Luxury Furniture.

Find out how RH-Engineering and manoFigura design and create custom furnishings. Deep dive into their breakthrough product, the Magna Patero Ortus – a 3D-printed end-use sink.

Read this additive manufacturing case study to learn:

- How businesses are manufacturing custom products with 3D printing

- Why additive manufacturing is the perfect solution for custom and low-volume production

- How large-format 3D printers unlock creativity and opportunity

- Unique post-processing systems for end-use products

HOW RH-ENGINEERING & MANOFIGURA 3D PRINT LUXURY FURNITURE