China's commercial vehicle market accounts for over 40% of total global sales. Playing a key role in China’s success is the industry’s willingness to adopt new disruptive technologies like industrial 3D printing to pave the way for a new generation of production in custom commercial vehicle manufacturers such as CNHTC.

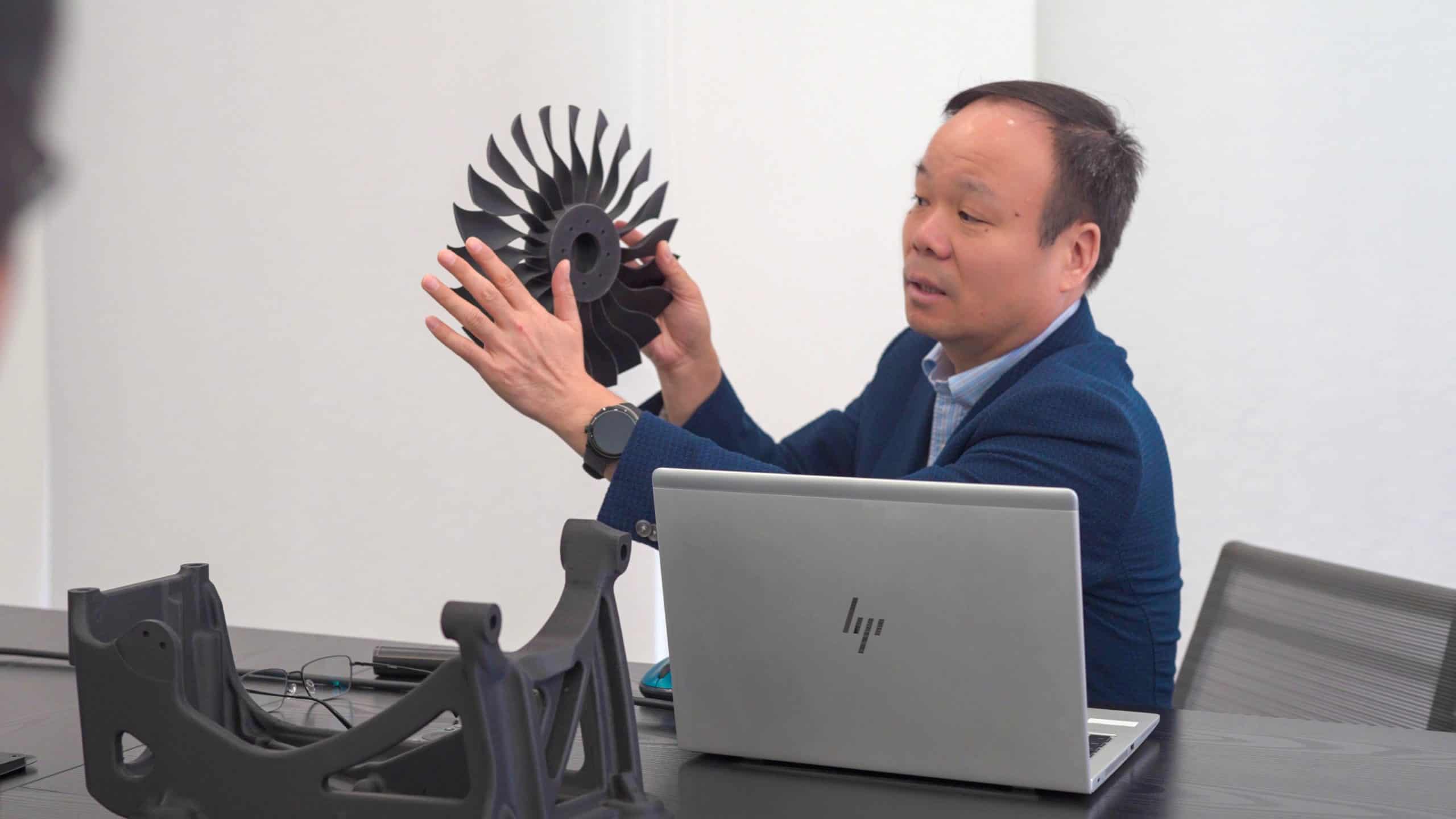

At the helm of this transformation is Dr. Dong, a visionary engineer, who established one of China’s largest 3D printing centers within CNHTC, the third-largest commercial vehicle manufacturer in the country.

With Chinese domestic demand for commercial vehicles projected to increase 10% year on year by 2028, Dr. Dong and his team could no longer exclusively rely on traditional manufacturing methods to meet the constantly evolving industry’s requirements.

Thanks to industrial 3D printing, the company has been able to advance prototyping and production processes for its heavy-duty trucks, haulage, and transport vehicles.

Embracing the Open 3D Printing System

Dr. Dong's approach to 3D printing is centered around being able to explore new applications and materials that are fundamental while innovating with the technology. While some of the 3D printer providers only sell closed material and software systems which limit application freedom, industrial 3D printers, like BigRep’s, are open for innovation. Being able to use any 3D print filament and software enabled CNHTC’s designers and engineers to leverage any technically compatible material.

It also helped CNHTC save costs as typically when companies are locked to the 3D printer provider’s materials, they’d have to forgo applications, outsource the print, or if the part warrants the investment, buy a new 3D printer that supports the material. CNHTC also had a better return on investment as they discovered the machine could be used for new applications with other materials.

Dr. Dong explains,

“Having an open-source 3D printer like the BigRep PRO is vital for our workflow. Open-source materials not only reduce production costs, they allow us to explore diverse material possibilities to achieve any number of desired outcomes”

Cost and Time Savings with Rapid Prototyping

CNHTC's traditional reliance on CNC machining and milling for prototyping translated to lengthy testing and iteration phases, often taking weeks. As a result, this slow process hurt the company’s ability to innovate within its design team.

“Since we’ve adopted 3D printing into our day-to-day work processes, we’ve witnessed a remarkable 50% reduction in both time and cost compared to traditional manufacturing methods for our projects to date.”

says Dr. Dong.

With the introduction of 3D printing, CNHTC’s workflow has undergone a total transformation. Now it takes just a few days, not weeks, for Dr. Dong and his team to turn digital designs into functional parts. "3D printing has enabled our designers and engineers to perform iterative optimizations with much faster turnaround times." Say Dr. Dong "While bypassing the mold-making stage entirely, we can directly 3D print structures that could not be created by the traditional processes.”

This kind of efficiency has allowed for the introduction of faster iteration and feedback cycles, ultimately allowing the design team to create products more in line with current market demands.

Large-Scale 3D Printing for Heavy-Duty Trucks

While previous generations and some of the current 3D printers have a smaller build limiting the size of the parts, Dr. Dong and his team have embraced industrial 3D printing with the BigRep PRO to produce large singular parts suitably sized for custom commercial trucks.

Following the same path as European commercial vehicle specialists like Zoeller Kipper, large 3D-printed parts such as customized panels and covers are being integrated as end-use components in CNHTC’s commercial trucks.

The high level of precision and dimensional accuracy in the large, robust prints meet CNHTC’s need for high-quality functional end-use parts. Printing sizable parts helps CNHTC eliminate the time-consuming and manual process of assembling smaller parts that might have errors in assembly.

He elaborates, "The quality of the larger printed parts makes it easy to integrate them directly into our vehicles. This not only increases production efficiency but also allows us to respond better to the demands of the market."

The Future of 3D Printing in Custom Commercial Vehicles

"What excites me most about the future is the possibility of using 3D printing to create more batches of end-use parts that can be directly used for manufacturing.” comments Dr. Dong.

Confident in this blueprint for the future, Dr. Dong sees even greater potential for integrating 3D-printed parts directly into CNHTC’s production facilities. He concludes,

The application of 3D printing in commercial vehicles is one of the most significant technological events to have occurred in the automotive industry. The rules of the game have changed for the better, and we are using this to our full advantage

Want to Learn More about 3D Printing for Emergency and Commercial Vehicles?

Register to watch the webinar, Improve Time to Market for Custom Commercial Vehicles

Learn how large-format 3D printers give companies the flexibility and versatility to iterate fast, produce faster, and get to market faster, all while reacting to challenging customer requirements on short notice.

REGISTER FOR THIS WEBINAR TO LEARN ABOUT

- Large-format 3D printing and customer applications

- How BigRep is supporting the trucking industry

- Customer success stories from prototyping to end use parts

- Benchmark breakdown

IMPROVE TIME TO MARKET FOR CUSTOM COMMERCIAL VEHICLES