Nova Scotia-based architect Brian Lilley is fascinated by how architecture, ecology, computation and art weave together to create solutions for communities. Now calling Halifax home, the architecture professor has honed his craft in cities such as London and Berlin, and since beginning to teach fulltime has had a focus on the potential of 3D printing. When he first began lecturing at Dalhousie University, Brian was responsible for forming a rapid prototyping lab with laser cutters, CNC milling, and depositional printers. He has worked on many collaborative projects with digital makers and thinkers across North America and Europe, one of which eventually resulted in a prototype ceramic printer.

As a jury member for the BigRep Innovation Award, we asked Brian more about his work background and for his take on integration of computation and 3D printing into design – specifically, furniture design.

Could you please tell us a bit about your background and experience as a designer?

My formative experience in Design was in London, at the Architectural Association, where exceptional projects are the expectation. Computation was just coming into play. My Tutors, Nigel Coates and Daniel Weil, both had young design firms that specialized in furniture and smaller-scale architecture.

Then, working in Berlin with sauerbruch hutton architekten, we employed a sophisticated colour sensibility meshed together with a progressive set of environmental strategies. My major project was the GSW headquarters building, including furnishing for the gardens, restaurants, and conference rooms. The use of computation as a design tool really began with forays into physical simulation (with Arup Engineers), augmented reality, and animation.

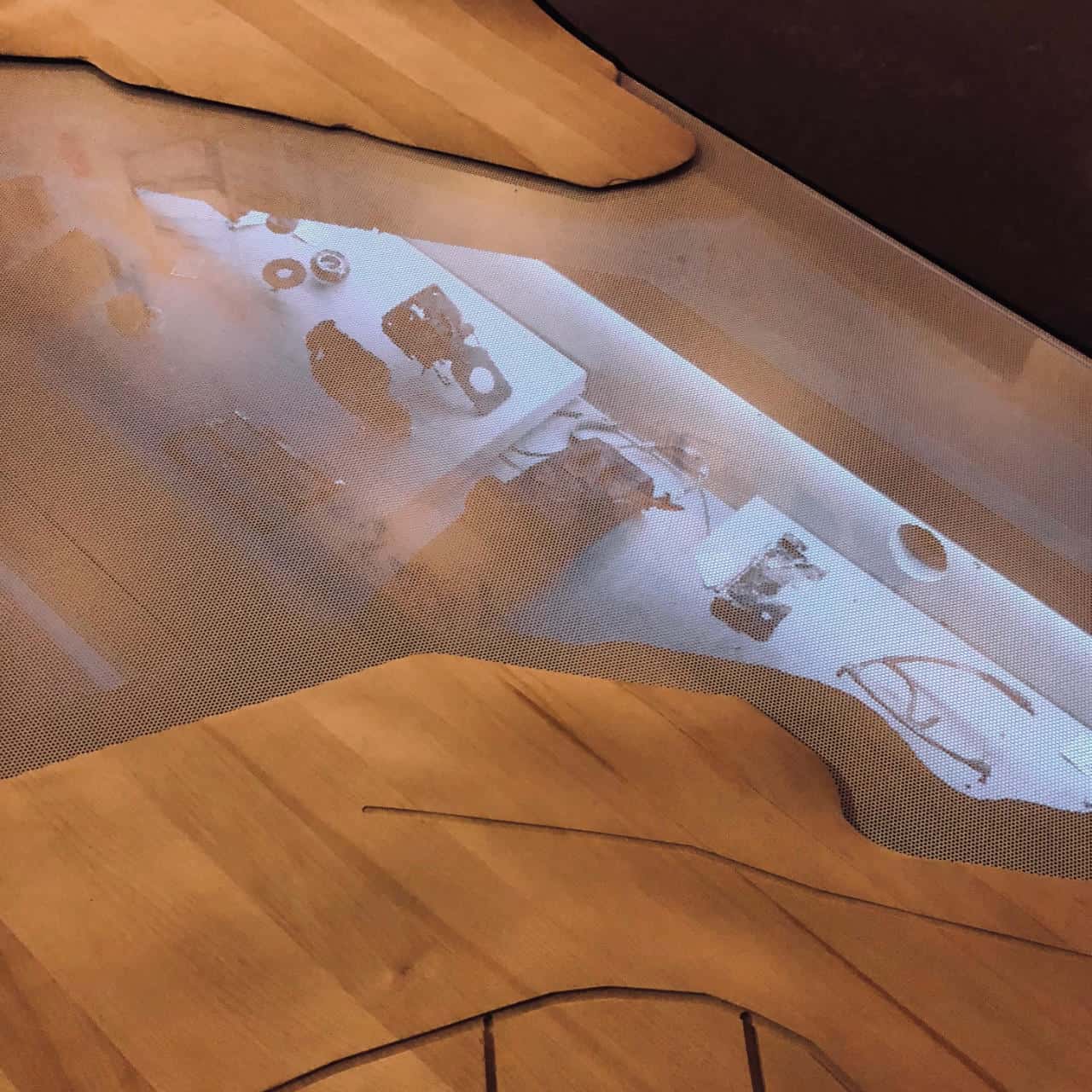

Most recently I have been working with a group named 'Narratives in Space and Time' on a series of projects related to the 100th anniversary of the Halifax Explosion. A collaborative approach resulted in an iPhone app called 'Drifts' meant to encourage story-sharing, and the 'Pyschogeographer's Table', a milled topographic tabletop that incorporates both augmented reality projections above and real physical artifacts in drawers below. Another project for the Maritime Museum of the Atlantic has focused on a digital-material-craft reproduction of a key artifact; a panel from the RMA Titanic's first-class lounge area.

You reference the Joris Laarman Lab as a key inspiration. What specifically about their approach to digital technologies and furniture design do you recommend for aspiring student designers?

Joris Laarman works in a clever way that stimulates design ideas across a range of possibilities involving character, material and production. Fabrication technologies are queried in a way that cross-pollinate with cultural expression and design constraint. For example in an iterative design series, the 'Diamond Chair' (2014), it is materially re-imagined as a magnesium mesh, a walnut maze pattern, and ultimately as a set of puzzle pieces that require assembly. His 'Soft Gradient Chair' exploits postural flexibility with a thermoplastic polyurethane mesh. A further development, the 'Adaption Chair', fuses copper plating onto a 3D-printed polyamide form. His work has been hailed as a masterpiece of digital design by the Cooper Hewitt Museum in New York.

Given the potential of large format 3D printing what do you see as the major impact for designers as it relates to structure, design and ergonomics?

From my experience, three things spring to mind: firstly, the possibilities for exploration of form and character that (perhaps) need to be tempered by concerns with materiality + elegance. Secondly, the exploration of a 'Monolithic' sculptural approach and/or the consideration of the joint detail – in allowing combination with other materials or the potential flexibility of moving parts. Thirdly, in combination with smaller prototypes, the ability to simulate a design and test aspects of both structure and ergonomics in an iterative way.

As an educator and designer, what news sources, blogs or publications do you devour for inspiration and industry news?

Certain designers and artists, for example Ross Lovegrove, Olafur Eliasson and Mark Goulthorpe, have always piqued my interest, especially in relation to architecture. The digital design communities that I value include ACADIA and Smart Geometries, for the integration of scholarship, computation and making. Social media input is sometimes useful (and sometimes not!), such as Instagram, for exposure to new ideas.

Learn about Brian Lilley’s fellow jury member Lindsay Lawson and her approach to creating art using 3D printing technology. Read here an interview with two other BigRep Innovation Award jury members, Amir Fattal and Gregor Ash, about their approach to designing furniture for 3D printing. Full competition details, including the entry form, can be found here.

Brian Lilley, Dalhousie School of Architecture. BigRep Innovation Award Judge

Connect with Brian on Linkedin HERE.