Improve your 3D prints with gyroid infill, a structure that strengthens, lightens, and enhances design. This guide covers benefits, strategies, and applications to help you achieve the best results.

You'll learn:

- What is gyroid infill?

- Advantages of gyroid infill

- How to use gyroid infill

What is a Gyroid?

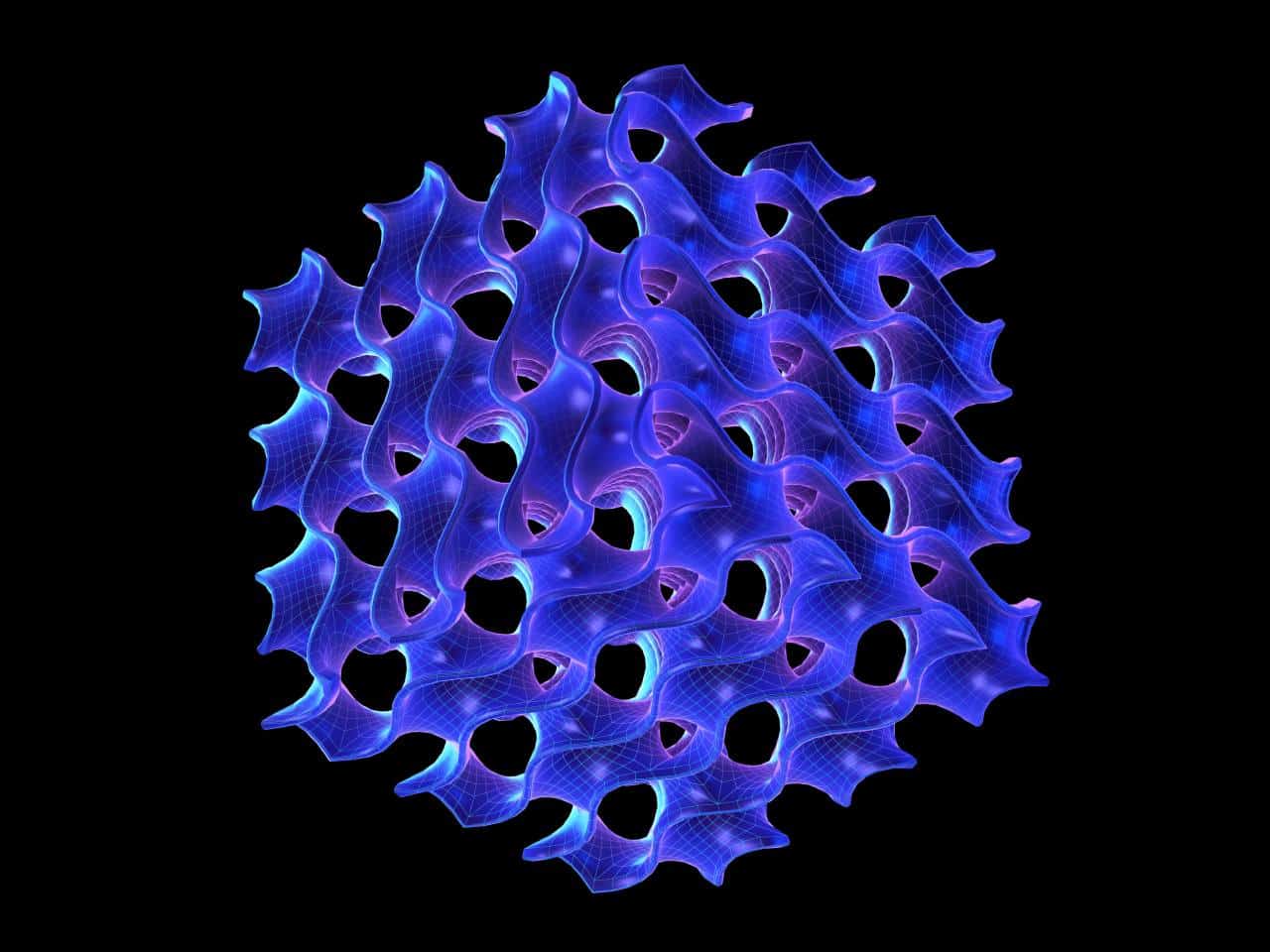

A gyroid is a fascinating mathematical shape known as a triply periodic minimal surface. It was discovered by physicist Alan Schoen in 1970 and has since become a popular infill pattern in 3D printing.

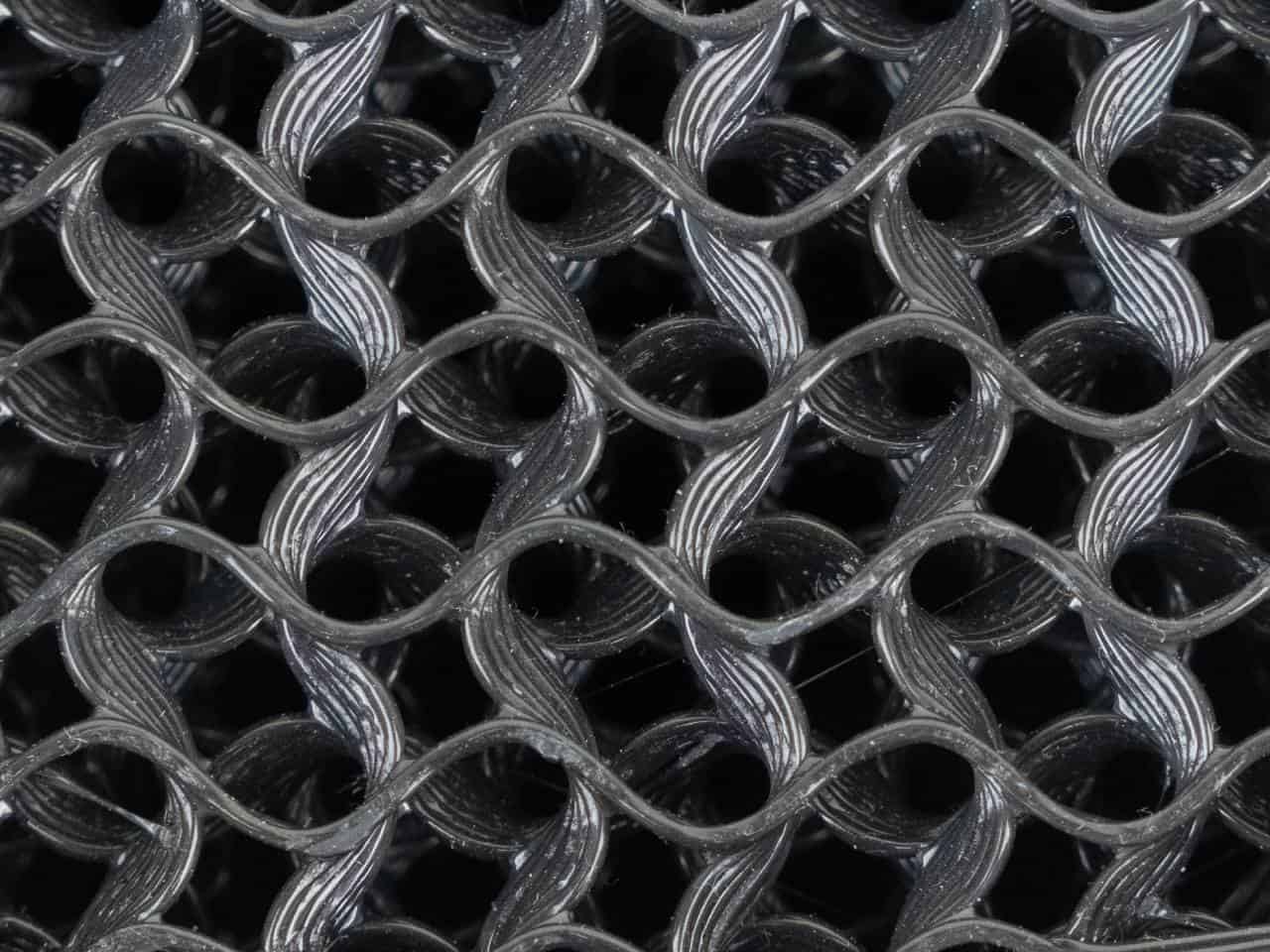

To understand a gyroid, imagine a complex network of twisted and interconnected tubes. These tubes form a repeating pattern that extends infinitely in all directions without intersecting or overlapping. The result is a continuous lattice structure that fills up space in a unique and captivating way.

The gyroid pattern exhibits a remarkable balance between complexity and symmetry. It features self-replicating motifs that create an intricate and interconnected lattice. This intricate geometry is what gives gyroid infill its exceptional properties.

While understanding the mathematical intricacies of a gyroid can be complex, 3D printing software simplifies the process of creating this pattern automatically. By leveraging the power of intelligent 3D printing software, you can easily implement gyroid infill and harness its unique properties for your 3D prints.

Understanding Gyroid Infill:

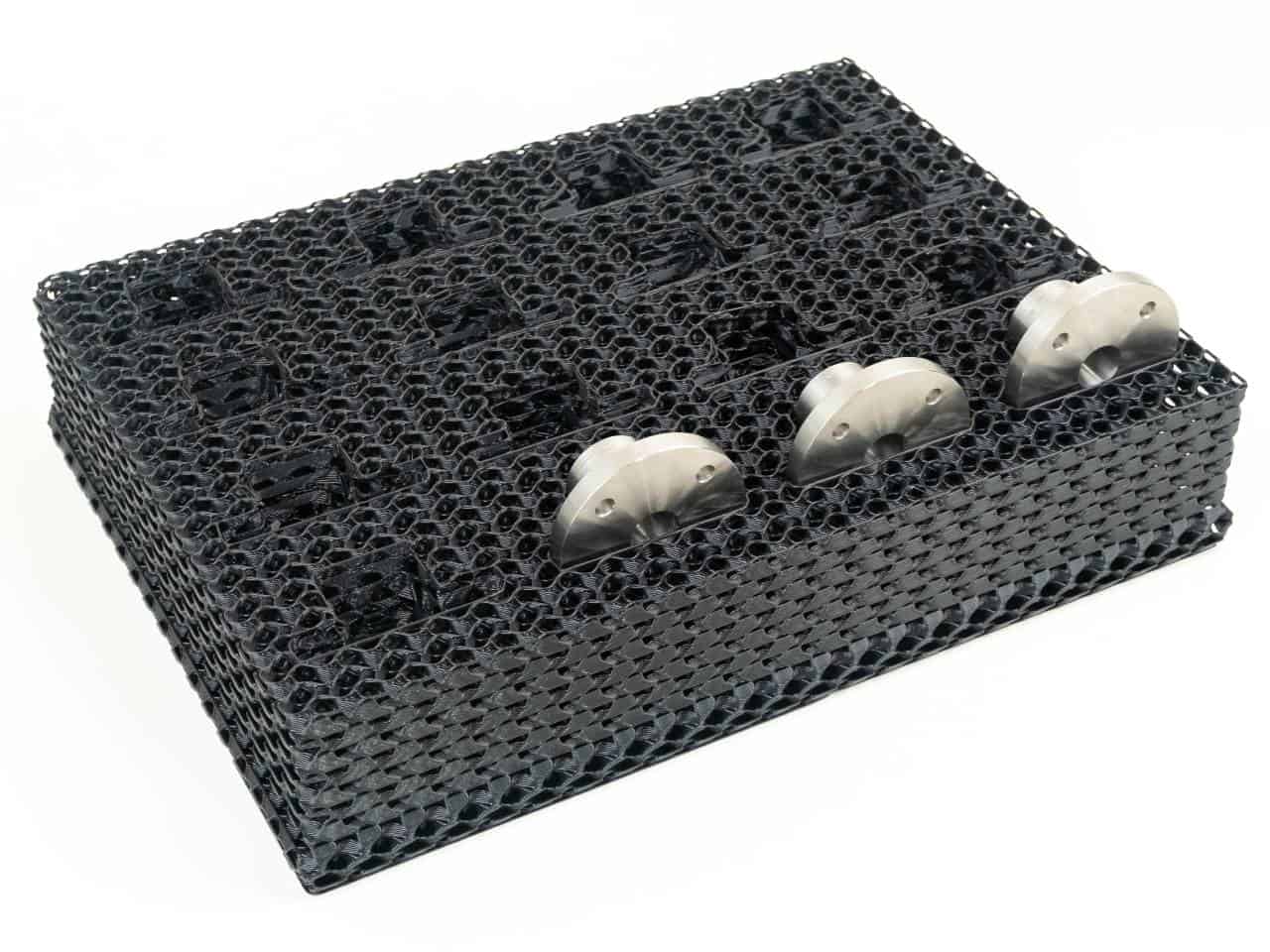

The gyroid infill pattern is renowned for its exceptional strength-to-weight ratio. Due to its intricate interlocking geometry, it provides excellent load-bearing capabilities, making it ideal for parts that require durability and resilience. Whether you're prototyping functional components or creating intricate art pieces, gyroid infill ensures that your prints can withstand the test of time.

In addition to its strength, gyroid infill is known for its material efficiency. By utilizing its interconnected channels, it reduces material usage without compromising structural integrity. This characteristic is particularly advantageous when printing larger objects that can become overly heavy and use large amounts of material or when cost-effective production is a priority. With gyroid infill, you can achieve lightweight 3D prints while minimizing waste, making it an eco-friendly choice for sustainable manufacturing practices.

Gyroid infill is a great choice for creating visually appealing 3D prints, thanks to its intricate and organic pattern. The interlocking tubes create a mesmerizing visual effect that adds a unique touch to your 3D prints. This can be particularly striking in 3D prints that are sliced without perimeter walls, making the gyroid infill fully visible.

Advantages of Gyroid Infill in 3D Printing:

Low warping:

Unlike other infill patterns, the curved lines of the gyroid infill do not provide a specific direction for plastic shrinkage. This unique characteristic helps to distribute the stresses and forces evenly throughout the print, reducing the likelihood of warping. Eliminating the directional bias enhances the overall stability and dimensional accuracy of 3D printed objects.

Enhanced Strength and Structural Integrity:

Gyroid infill exhibits exceptional strength and structural integrity due to its interlocking lattice structure. The complex network of interconnected channels distributes forces evenly throughout the print, minimizing the risk of failure and improving overall stability. This makes gyroid infill suitable for load-bearing applications that require durability and resistance to external forces.

Significant Weight Reduction:

One of the standout advantages of gyroid infill is its ability to achieve significant weight reduction in 3D printed objects. The intricate lattice structure optimizes material usage, creating a lightweight yet robust internal framework.

Material Efficiency and Cost Savings:

Gyroid infill is highly efficient in terms of material usage. The interconnected channels and intricate lattice pattern reduce the volume of material required for the infill, minimizing material waste and lowering costs. This is particularly valuable when working with expensive or high-volume materials, as gyroid infill maximizes material efficiency without compromising strength or structural integrity.

Improved Heat Dissipation:

The gyroid lattice structure provides excellent heat dissipation properties. The interconnected channels allow for efficient airflow, aiding in the cooling process during printing. Improved heat dissipation helps prevent warping, deformation, or other thermal issues, resulting in more reliable and dimensionally accurate prints.

Enhanced Flexibility and Impact Resistance:

The intricate lattice structure of gyroid infill offers a unique advantage in terms of flexibility and impact resistance. The interlocking nature of the lattice allows for controlled flexing and absorption of energy upon impact, making 3D printed parts more resistant to breaking or cracking. This property is beneficial for parts that undergo stress or require a certain degree of flexibility, such as protective cases, sports equipment, or wearable accessories.

Excellent Filament Flow:

The gyroid infill pattern facilitates smooth and consistent filament flow during printing. The continuous, interconnected channels enable efficient material distribution, reducing the chances of clogs or inconsistent extrusion. This results in improved 3D print quality, accuracy, and reliability, contributing to successful prints with fewer defects or issues.

By leveraging these advantages, gyroid infill unlocks new possibilities in 3D printing, allowing for stronger, lighter, more cost-effective, and visually appealing prints.

Disadvantages of Gyroid Infill in 3D Printing:

While gyroid infill offers numerous advantages, it is important to consider its potential disadvantages as well:

Longer Slicing Times

Each layer must be meticulously computed and mapped to the interlocking channels of the gyroid infill. Consequently, the slicing software needs to process more data and perform additional computations, resulting in longer slicing times.

Limited Control Over Internal Geometry:

The complex nature of the gyroid grid can make it difficult to incorporate specific internal features or structures into the print. Unlike lattice infill patterns, gyroid infill may limit the ability to create precise internal geometries or incorporate functional features such as internal channels or compartments. If your print requires precise internal designs or specific functionality, gyroid infill may not be the best option.

Reduced Transparency and Visual Clarity:

If transparency or visual clarity is desired in your print, gyroid infill may not be the best choice. The complex structure of gyroid infill can obstruct light transmission and result in reduced transparency. This limitation may not be suitable for applications that require optical clarity or the ability to see through the 3D printed object.

Understanding these potential disadvantages will help you make informed decisions when choosing infill patterns for your 3D prints.

Applications and Use Cases:

The versatility of gyroid infill opens up a wide range of applications and use cases where its unique properties shine. Here are a few areas where gyroid infill has proven to be particularly advantageous:

Functional Prototypes:

When creating prototypes for functional testing, gyroid infill offers the perfect balance of strength, weight reduction, and material efficiency. It ensures that prototypes can withstand rigorous testing while minimizing material costs.

Mechanical Components:

Parts that require durability, stability, and resistance to external forces benefit greatly from gyroid infill. Whether it's gears, brackets, or structural supports, gyroid infill enhances the overall performance and longevity of these components.

Lightweight Structures:

Industries such as aerospace, automotive, and robotics often require lightweight components to improve performance and efficiency. Gyroid infill helps achieve these goals by reducing weight without compromising strength or structural integrity.

Artistic and Decorative Prints:

The visually captivating nature of gyroid infill makes it an excellent choice for artistic and decorative prints. From intricate sculptures to visually appealing art pieces, gyroid infill adds a unique aesthetic dimension to the finished prints.

Implementation and Tips for Using Gyroid Infill:

Now that we have explored the advantages and disadvantages of gyroid infill, let's delve into its implementation and some tips for achieving the best results:

- Software and Slicer Settings:

To utilize gyroid infill effectively, ensure that your 3D printing software and slicer support this infill pattern. Most popular slicing software, such as Cura, Simplify3D, or BigRep BLADE, provide gyroid infill as an option. Select the gyroid infill pattern and adjust the infill density according to your requirements. Experimenting with different densities can help find the optimal balance between strength and material usage. - Print Orientation:

Consider the orientation of your print when using gyroid infill. The orientation can affect the strength and overall performance of the 3D printed object. For parts that require enhanced strength in a specific direction, orient the print accordingly. Testing and analyzing the load-bearing capabilities in different orientations can help optimize the performance of your prints. - Infill Density:

The density of gyroid infill determines the amount of material used and impacts the structural integrity of the print. Higher infill densities result in stronger prints but require more material. Conversely, lower infill densities reduce material usage but may sacrifice some strength. Finding the right balance between infill density and material efficiency is crucial. Consider the specific requirements of your print to determine the optimal infill density. - Experiment and Iterate:

As with any 3D printing technique, it is essential to experiment, iterate, and test your prints. Adjust the infill density, print orientation, and other parameters to find the optimal settings for your specific application. This iterative approach will help you fine-tune your prints and achieve the desired balance between strength, weight reduction, and aesthetics.

Conclusion:

Gyroid infill offers a multitude of advantages in 3D printing, including

- enhanced strength,

- significant weight reduction,

- material efficiency,

- improved print quality,

- and versatile applications.

Its interlocking structure provides superior structural integrity, making it ideal for functional prototypes, mechanical components, and lightweight structures.

To leverage gyroid infill effectively, ensure that your software and slicer support this infill pattern, and adjust the infill density and print orientation to meet your specific requirements.

Experimentation, testing, and iteration are key to achieving optimal results with gyroid infill.

Utilizing gyroid infill can significantly enhance the strength, efficiency, and appearance of your 3D printed objects. Regardless of whether you are a hobbyist, engineer, or designer, incorporating gyroid infill in your 3D printing process can unlock new opportunities and enable innovative applications.

Want to Learn More About Gyroid Infill?

Explore the innovative use of gyroid structures in wind turbine manufacturing and biomedical applications with expert Jörg Alber from TU Berlin. Don't miss out, watch the webinar now:

THE 3D-PRINTED GYROID: IMPROVING STRUCTURALLY DEMANDING APPLICATIONS