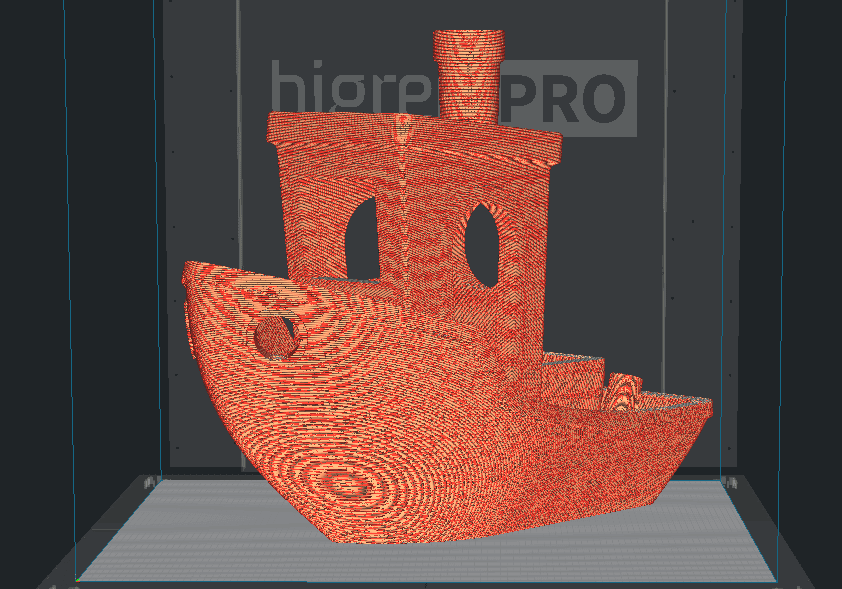

The most frequently 3D-printed object in the world, 3D Benchy, is a 3D model in the shape of a boat that was designed as a benchmark to test all sorts of 3D printing parameters. BigRep put its large-format 3D printers to the test by producing the world's largest Benchy, measuring at 816 mm tall. Let's have a close look at this giant Benchy and what its features can show about BigRep 3D printers' capabilities.

What is a 3D Benchy?

A 3D Benchy is a computer model that is specifically designed to test the capabilities of a 3D printer. Its name derives from "benchmark," which reflects its relevance in 3D printing. The Benchy was first released as an STL file in 2015 and is often the first thing one prints with a new 3D printer it has a set of features that determine the printer's capabilities and possible limitations.

Benchy Features

The most common Benchy features include overhangs, bridges, surface finish, and dimensional accuracy. These features are all important in 3D printing, and help evaluate the printer's ability to produce intricate designs, handle complex geometries, and maintain precise measurements. By looking closely at the quality of Benchy prints, one can identify issues or limitations with their 3D printer and make necessary adjustments for better results.

Overhangs

Overhangs are horizontal or inclined surfaces extending beyond more vertically oriented parts of a 3D print. Successful overhangs showcase the printer's ability to handle complex geometries and maintain structural integrity without supports.

Dimensional Accuracy

The 3D printed Benchy's dimensions can be compared to the 3D model's original specifications. Accurate dimensional reproduction is an important indicator of a printer's ability to maintain precise measurements and avoid scaling issues.

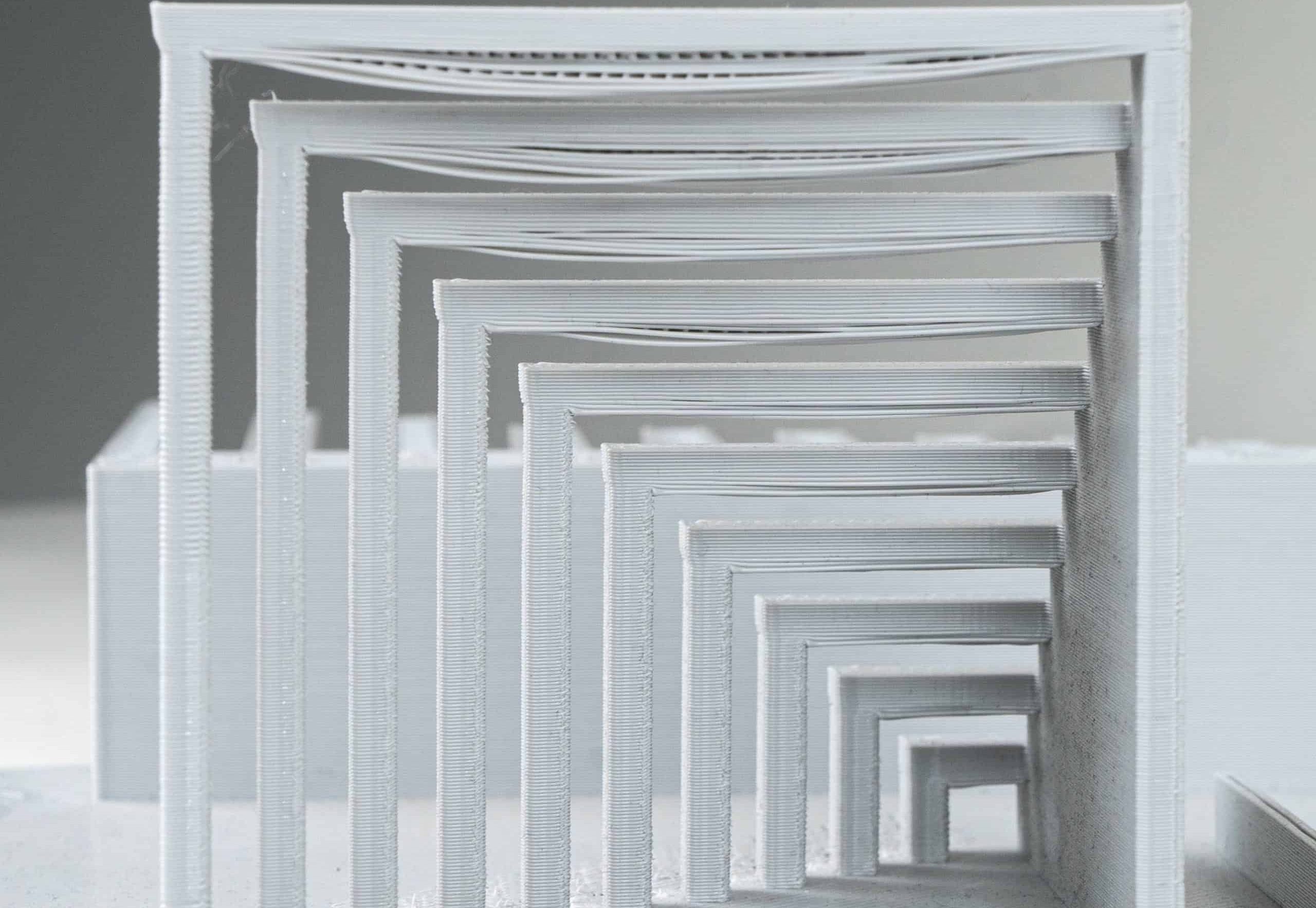

Bridges

Bridges are horizontal gaps between two vertical structures. Bridges demonstrates the printer's ability to create even and sturdy horizontal spans, without sagging or drooping in the middle. The length of possible bridges depends on a printer's capabilities, slicing settings, and material used.

Surface Finish

The surface finish of the Benchy model is an essential feature to evaluate. The smoothness, texture, and overall appearance of the 3D printed Benchy can be examined for any imperfections such as layer lines, warping, or inconsistent extrusion, which can affect the final print quality.

Advantages and Challenges of Printing 3D Benchy

The Benchy is widely recognized in the 3D printing community for its successes and challenges. One of its major strengths is its ability to assess various 3D printing technologies and how they work with various materials. This versatility allows users to evaluate the capabilities and performance of different printers and materials, providing a first-hand understanding of their strengths and weaknesses. Another advantage of using the Benchy is its focus on evaluating print quality and accuracy. By using it as a test model, users can assess the level of detail, dimensional accuracy, and surface finish achieved by their 3D printers. This information is crucial for ensuring the desired level of quality in the final printed objects.

However, where there are opportunities, there are also challenges. One of the major challenges is the time-consuming nature of the test. The benchmark requires printing a complex model, which can be lengthy, resource-intensive, and particularly demanding for users who need quick results or have limited resources at their disposal.

Another limitation of the Benchy is that it may not fully represent real-world printing scenarios. While it is designed to incorporate various features and geometries to challenge printers, it may not capture all the complexities and nuances of real-world objects, potentially leading to limitations in its usefulness as a benchmark for real-world applications.

BigRep Benchy Specs

The world's largest Benchy was printed at the BigRep headquarters in Berlin. And while it is definitely a huge 3D print, it was not BigRep's biggest, heaviest, or longest running print.

Here are the printing specs for the BigRep Benchy:

- Printer: BigRep ONE

- Material: BigRep PLA

- Nozzle Diameter: 1.0 mm

- Layer Height: 0.6 mm

- Dimensions: 864 x 864 x 816 mm (x, y, z)

- Printing Time: 121 hours

- Material Weight: 11.1 kg

How Does the BigRep Benchy Measure Up?

While it's a beloved and whimsical 3D model, Benchy does also function as a useful benchmark to evaluate a wide range of 3D printing parameters. Let's have a closer look at the giant Benchy results.

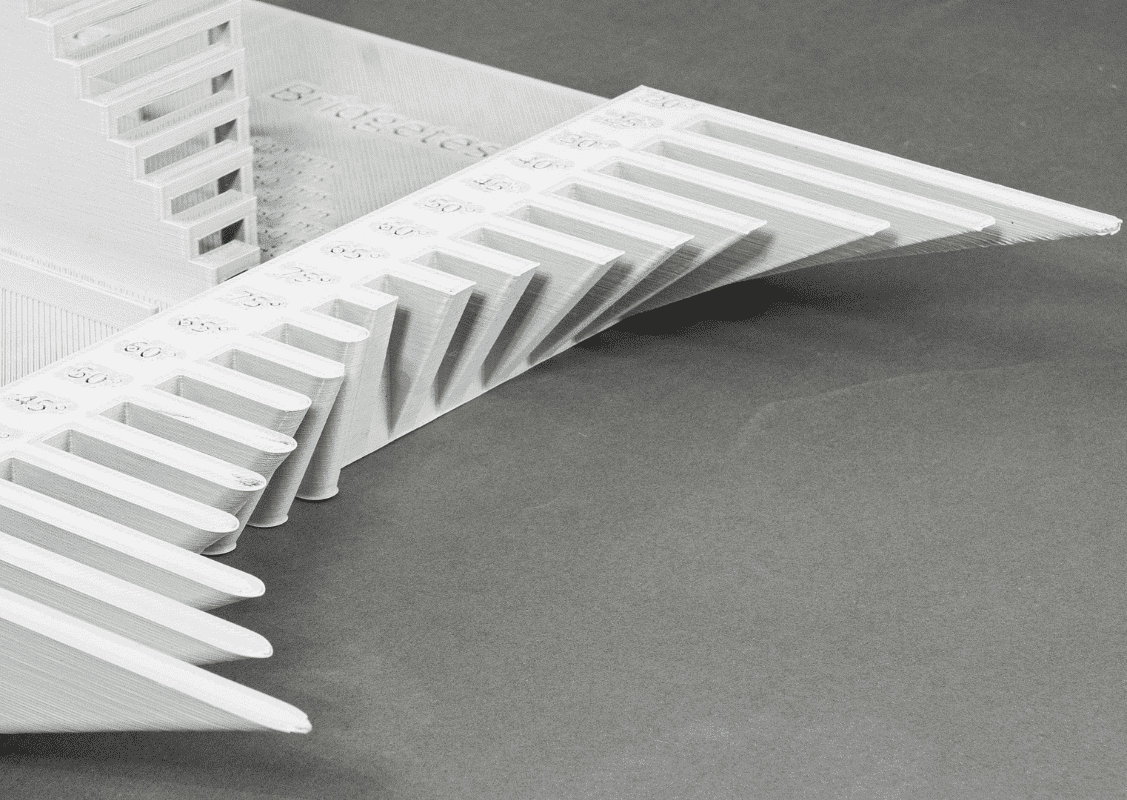

Overhangs

The layer height, nozzle diameter, and overall 3D print dimensions greatly effects the quality of overhangs. This gigantic Benchy has large overhangs spanning ranges up to 50 mm long. They were not printed with support to help demonstrate the limits of the printer's capabilities. The BigRep ONE achieved an even, consistent quality with minimal deviations in layer appearance.

Dimensional Accuracy

Accuracy is highly dependent on what tolerances are required for a part to be acceptable for its use case. There is no noticeable warping of this giant Benchy and only small deviations in layer quality in the most challenging aspects of the print. For a real-world accuracy analysis, a 3D scan of the print can be compared to the original design to determine tolerance.

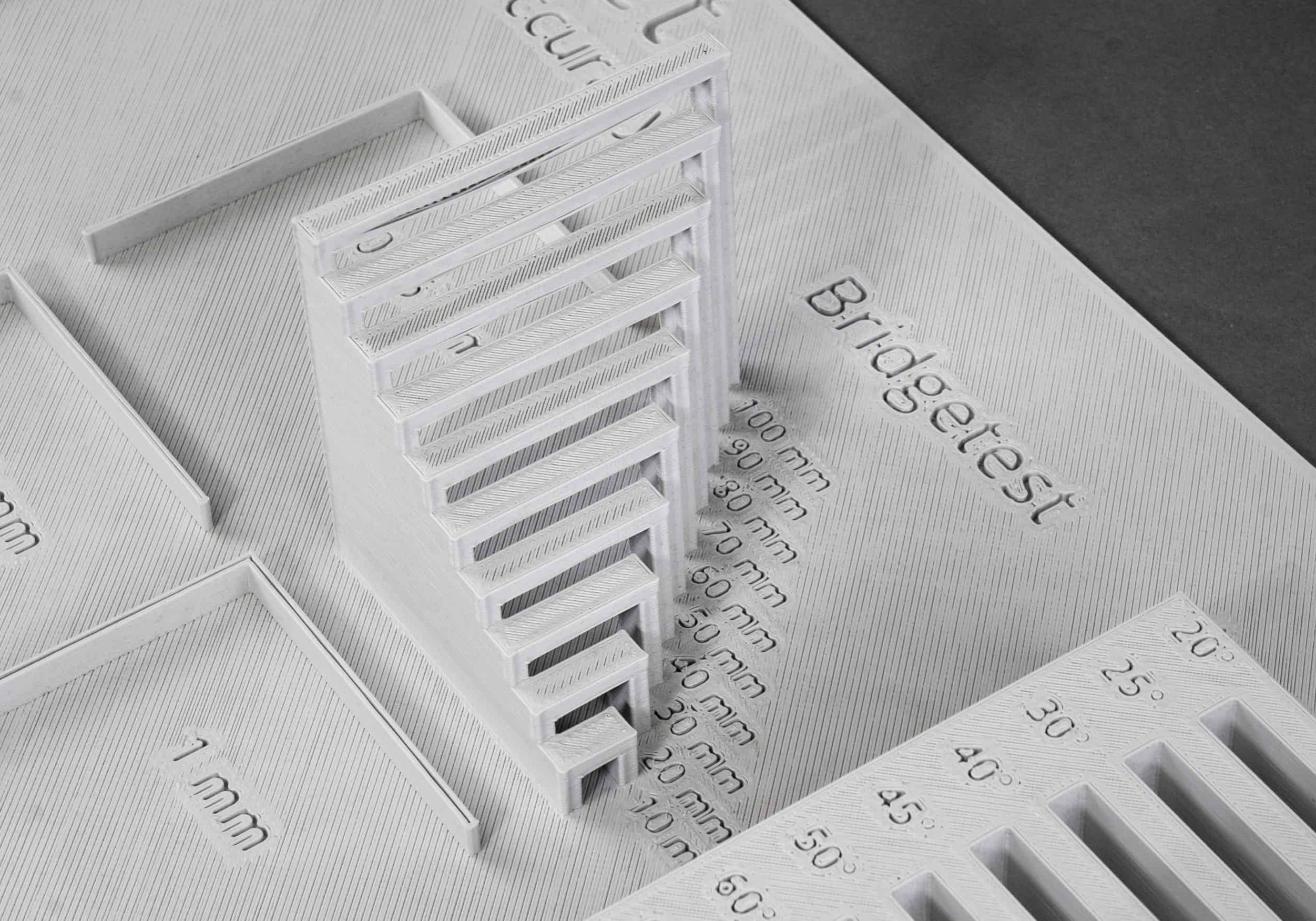

Bridges

Some of the bridges in Benchy are too long - in this case, up to 180 mm - to be printed without sagging, and therefore required support. The image above shows the top section of some circular cutouts which were printed without support. There are some slight imperfections, but the overall quality is surprisingly good at such a large scale.

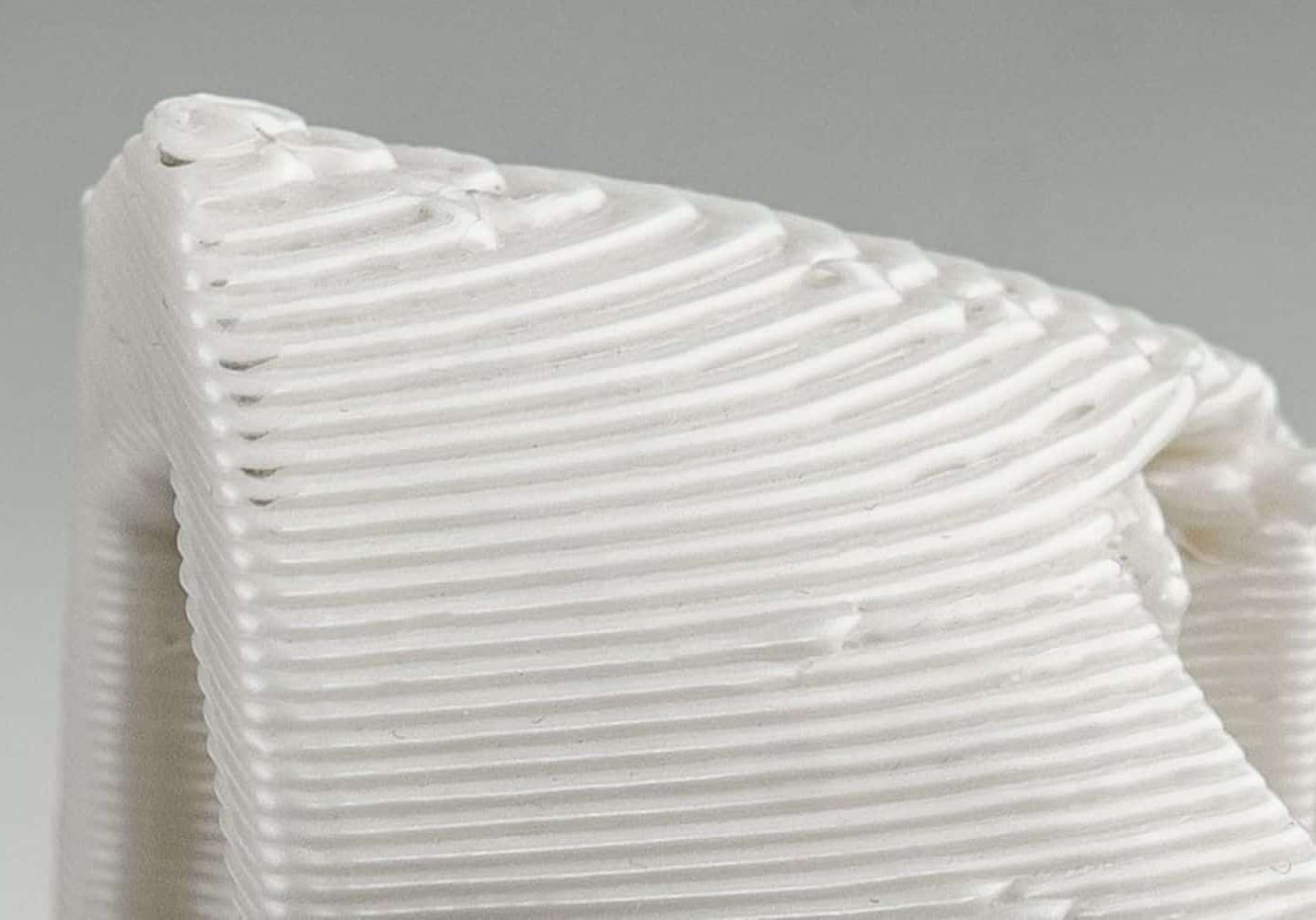

Surface Finish

The more vertically oriented the surface, the smoother the appearance of the layer lines. As a surface is more horizontal, the layers become more pronounced with the appearance of the staircase effect. With a relatively large layer height of 0.6 mm, the differences between vertically and horizontally oriented surfaces is visually apparent.

Conclusion

The Benchy 3D model has become a cornerstone in the world of 3D printing, serving as a reliable benchmark for evaluating the capabilities and limitations of different 3D printers. Its various features, such as overhangs, bridges, surface finish, and dimensional accuracy, provide valuable insights into the printer's ability to handle complex geometries and produce high-quality prints. By closely examining the quality of Benchy prints, users can identify issues with their 3D printers and make necessary adjustments to achieve better results.

However, it is important to acknowledge possible challenges with using the Benchy. The test can be time-consuming and resource-intensive, which may not be ideal for users who require results very quickly or have limited resources, such as filaments. Moreover, the model may not fully capture the complexities and nuances of real-world printing scenarios, potentially limiting its usefulness in certain applications.

Nevertheless, the Benchy remains a valuable evaluation tool within the 3D printing community. It provides a comprehensive assessment of printer capabilities, highlights potential areas for improvement, and allows users to make informed decisions when selecting printers and materials for their projects. By understanding its strengths and limitations and using it with other evaluation methods, users can maximize the benefits of the Benchy for their specific printing needs and applications.

Want to learn more about large-format additive manufacturing?

Register to download the eBook, Guide to Integrate Large-Format Additive Manufacturing.

Learn how Increasing the build size increases the possibilities for builds: users can create larger parts, removing the constraints of more standard sizes of build envelopes. 3D printing a large part all at once means less time is spent designing around multiple print jobs, less time assembling multiple parts, and more time getting those parts to work for you. Don't miss out, download the eBook today:

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.