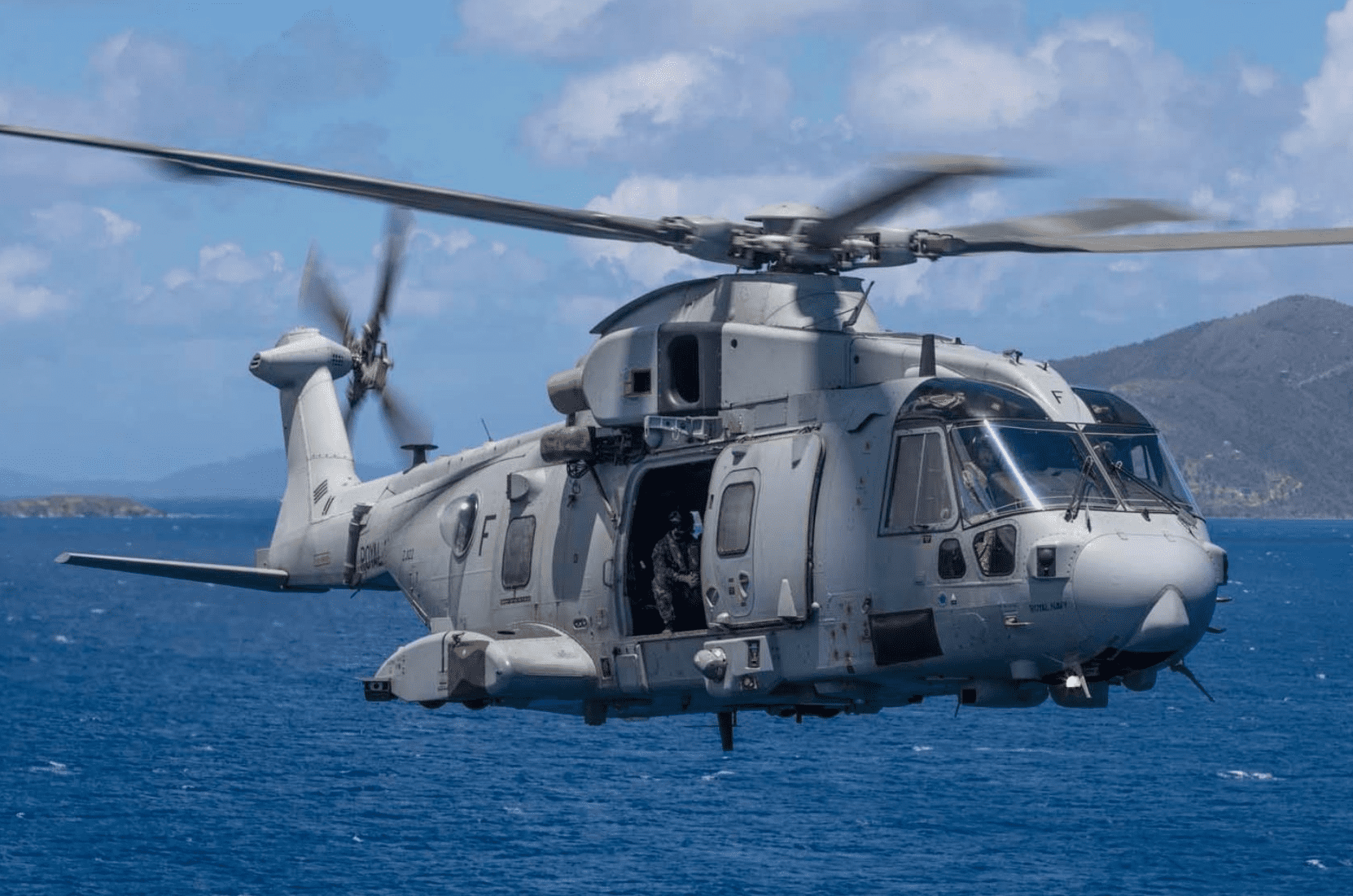

When tasked with creating restraint cradles that allow helicopters to load safely, SFM Technology turned directly to the BigRep PRO.

Rough seas not only make smooth sailors, they also make smooth engineers who can find innovative solutions to choppy conditions. This is especially true when it comes to aviation, as helicopters are frequently tasked with embarking onto ships during all different types of weather conditions.

Once helicopter flying operations have ceased, they will either stay on the flight deck or be stowed in the ship’s hanger. They use an automatic folding system, folding in their blades like a bumblebee. The issue of stabilization remains a key priority when it comes to the smoothest embarkation possible. This is achieved by using a main rotor blade restraint cradle.

As Gary Wilson, head of Technical Sales at SFM's AeroAdditive division tells us: "When a helicopter is on board a ship, it can fold its helicopter blades back. But at sea it's still windy, and the blades can flap. These blades must be restrained so flapping doesn't occur."

Aerospace and defense giant Leonardo - tasked by the Ministry of Defence to provide AgustaWestland AW101s for the Royal Navy - found that their pre-existing main rotor blade restraint cradles were not living up to their standard. They turned to SFM Technology's AeroAdditive department for the solution, resulting in the first 3D-printed main rotor blade restraint cradle, measuring 900 x 230 x 160mm. Gary Wilson explains how they created the cradle and why he believes this is just the start for additive manufacturing within the aerospace industry.

3D PRINTING PROVIDES THE SOLUTION

As a solution had to be found very quickly, SFM relied on the speed of innovation possible with additive manufacturing.

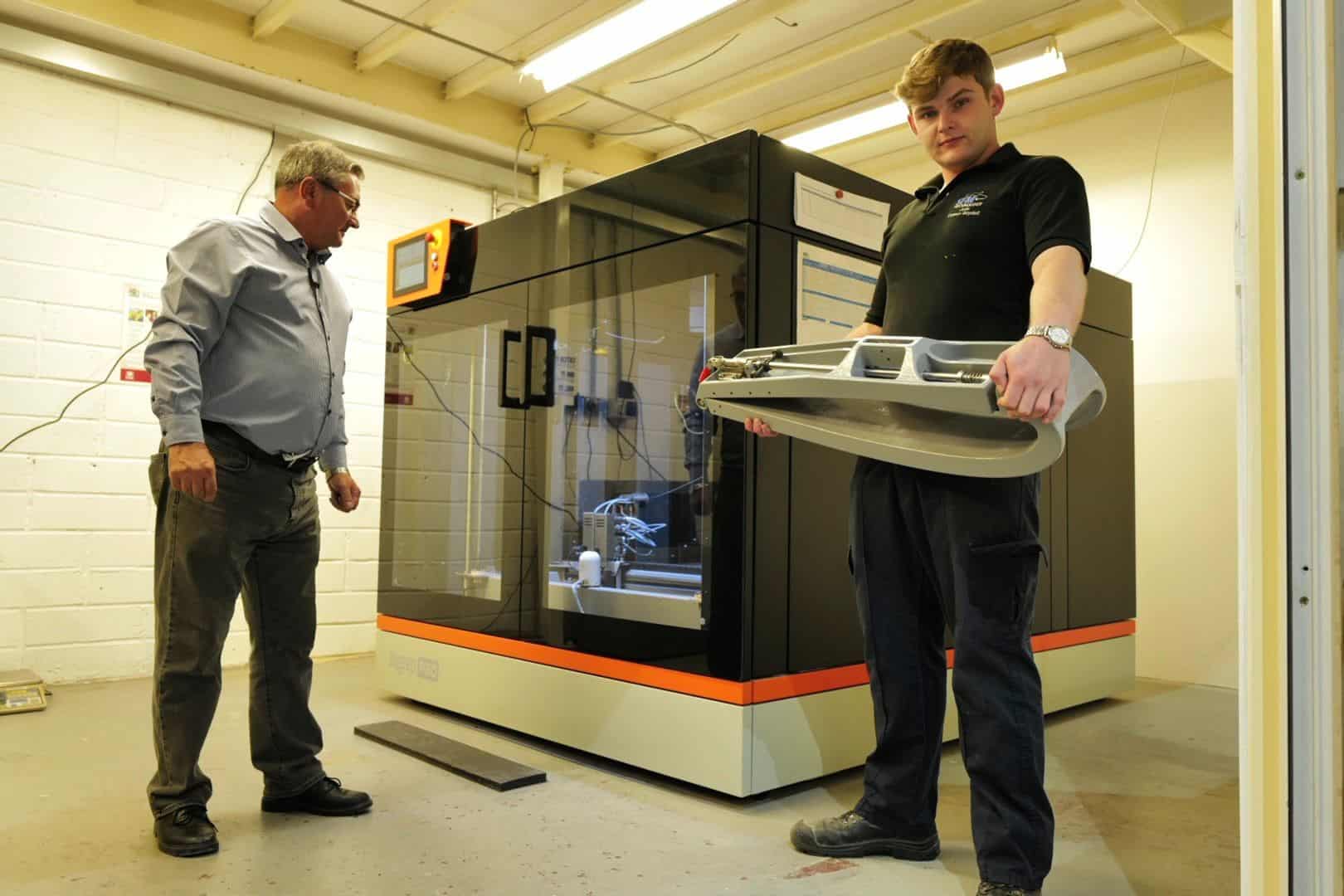

"We had to look at many aspects of 3D printing, including cost, efficiency, and of course, size. Eventually, we looked at the BigRep PRO as we had to look at a production 3D printer. The machine is used as a production machine, so every rotor blade restraint cradle goes to the end customer."

3D PRINTING MORE VERSATILE THAN TRADITIONAL METHODS

In the aerospace industry, lightweight yet strong parts are essential. After stress-testing their 3D printed parts, SFM Technology found that they performed better than original, non-printed parts. By using Hi-Temp CF – a carbon fiber reinforced material with versatile, high-strength properties – the blades are extremely durable and weather resistant.

The benefits have been manifold.

“To date, we have printed 30 cradles, consisting of 60 halves, since January. If we were to do that in a traditional way, we would have done about a quarter of that. So, you can see that 3D printing is far quicker, as we don’t have any adjustments to make, or if we do, they’re very minor and can be quickly overcome. And the material is just as strong.”

THE ADVANTAGES OF HI-TEMP CF

Choosing the right material was crucial in SFM’s choice.

“We carried out many tests to establish which was the most suitable material within the budget given. Having looked at the data sheets, we felt that BigRep's HI-TEMP had a slight advantage over the other BigRep materials.”

Once they remove the support material, sandpaper is used to smooth the surface. Bushes - a type of fixed or removable cylindrical tube - are inserted in the hinges, before using threaded helicoil inserts for fastening when required. After the cradle is painted to the customer's specification, the remaining hardware is embedded along with a protective foam on the inside of the cradle, preventing it from scratching the blade surface.

THE START OF 3D PRINTING IN THE AEROSPACE INDUSTRY

With the main rotor blade restraint cradles already in use, Mr. Wilson attests that this experience shows what 3D printing can achieve in the aerospace industry and that it's only a matter of time before additive manufacturing becomes the norm.

"In the aerospace industry, there are many designers nervous about 3D printing. We've demonstrated that 3D printing can be used in the aerospace industry quite comfortably from a strength, repeatability, and quality side. I know for a fact that as the industry moves forward on 3D printing, there will be more and more accessible paths to use."

SFM Technology are using the BigRep PRO as a batch 3D printer, sequencing production and creating improved results across the board. This follows more aerospace designers discovering the benefits of 3D printing and adopting it in due course.

Want to learn more about 3D printing and aerospace. Learn about how 3D printing saved Airbus time and money!

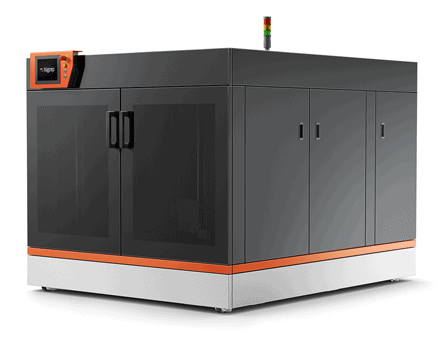

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.