Maximum Performance. Unbeatable Price.

FULLY AUTOMATED QUICK START

- Get started at the push of the button with auto-calibration and pre-heating.

- Advanced machine control features include out-of-filament sensors, topography measurement and compensation.

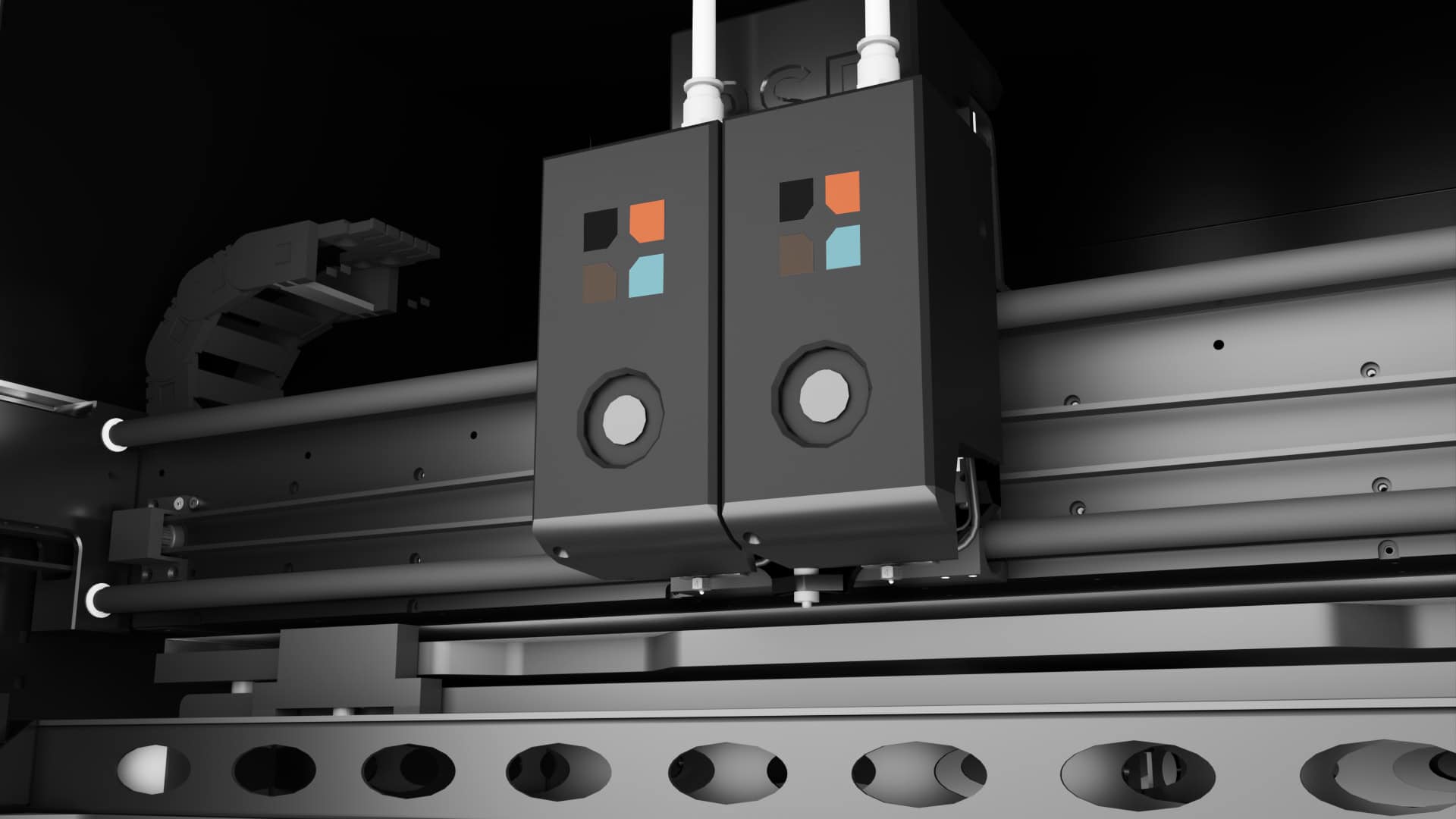

TWO DSX EXTRUDERS

- Achieve complex prints with two extruders and a backup Relay Mode.

- Each DSX is integrated with cooling channels and sensors for monitoring and control.

HIGH-TEMPERATURE CAPABILITIES

- Build chamber reaches up to 100°C

- Enables applications with high-performance materials

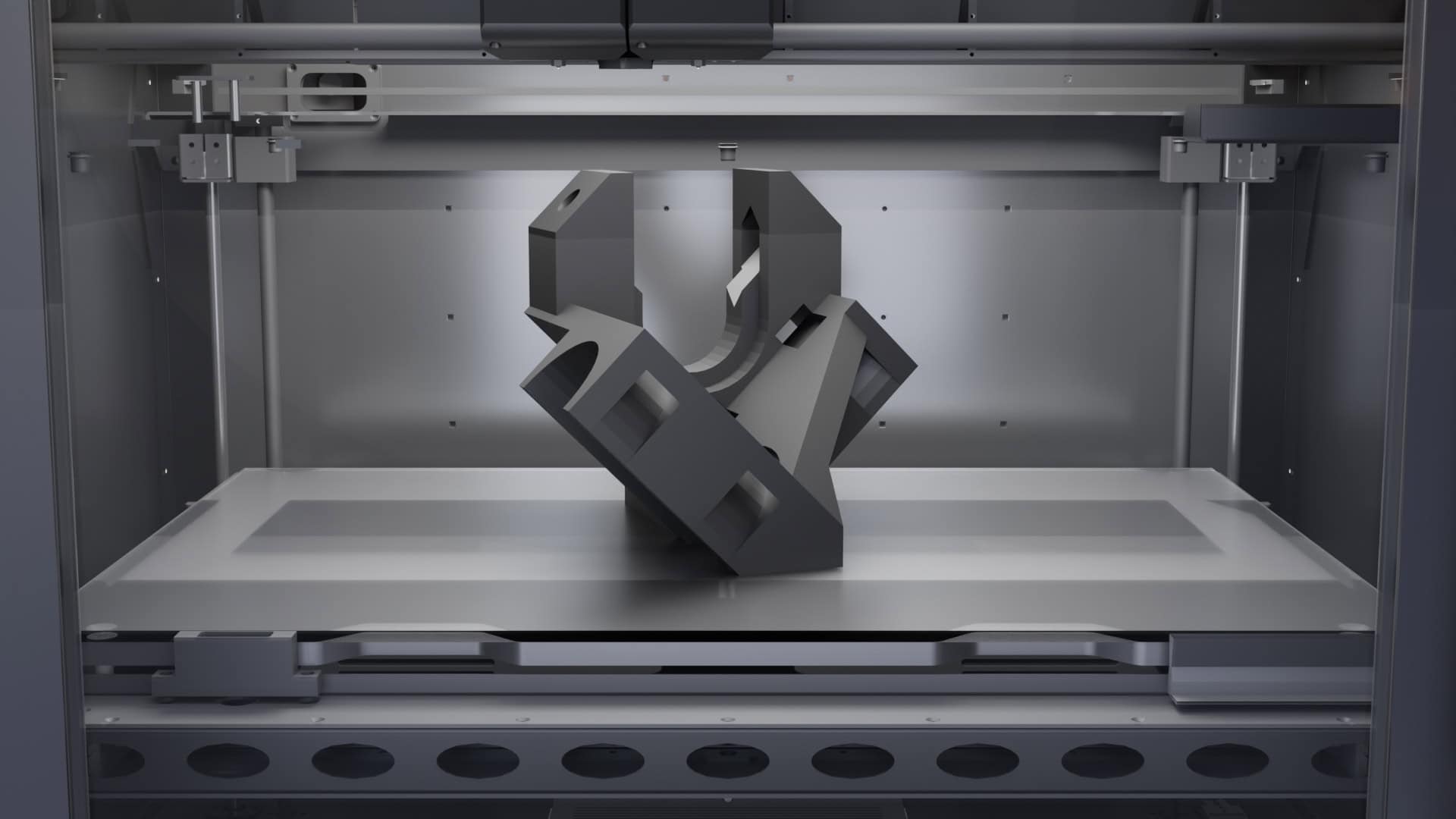

FULL-SCALE 3D PRINTING

- Build chamber dimensions: 400 mm x 600 mm x 440 m

- Build volume of 105 liters

- Produces intricate full-fledged end-use parts, tooling, and functional prototypes.

HEATED PRINT BED

- Features two evenly heated print surfaces for optimal adhesion and easy print removal.

- One print bed has a specialized tempered glass plate and experiences minimal thermal expansion.

- The second print bed is a flexible steel plate with a magnetic foil and PEI coating for easy print removal.

105 liters build chamber

heated up to 100°C

2 DSX extruders for printing complex parts

print high-performance materials up to 450°C

Industrial 3D Printer at a Competitive Price

Reliable Production of Tooling and More

The IPSO 105 is an industry all-rounder high-temp machine at an unbeatable price-to-performance ratio. It is the most automated, reliable, and fastest way to get robust, high-performance parts in the hands of industrial engineers and designers.

Aptly called the tool maker's tool, it is a blazing hot machine of 105 liters reaching 100°C with a print bed heating up to 180°C. It is built with state-of-the-art dual extruders capable of printing high-performance materials with open access to the world’s most advanced materials, including PC, PEKK, and PEKK-CF.

HIGH-TEMPERATURE FOR HIGH-PERFORMANCE

AEROSPACE-GRADE PARTS

Innovate and qualify for certifications in the aerospace industry. The IPSO 105 prints with high-performance materials creating strong, safe, light-weight parts. The high precision, repeatability, and resolution enable innovations at all stages of the design workflow.

FUNCTIONAL PROTOTYPES

Before going into final production, test designs and validate parts. The open-material system gives you the freedom to choose from a wide variety of filaments and accurately replicate the final part. Iterate quicker, slash fabrication costs, and get your products to market faster.

DURABLE TOOLING

Produce low-cost rapid tooling for your factory floor such as jigs and fixtures. Thanks to the high-temperature capabilities, you can manufacture strong and complex tooling in-house. Overcome outdated traditional techniques and print tools on demand.

FEATURES

GET TO KNOW THE BIGREP IPSO 105

PURE PERFORMANCE. MAXIMUM VALUE.

FULL-SCALE 3D PRINTING

A Tool Maker's Build Volume

With a build chamber of 400 mm x 600 mm x 440 m (build volume of 105 liters) IPSO hits a sweet spot between a desktop and a large-scale 3D printer, perfect for many tooling applications. Thanks to its made-to-last industrial components and stepper motors with encoders, IPSO 105 achieves the level of accuracy and repeatability you expect in an industrial machine.

HIGH-TEMPERATURE CAPABILITIES

High-Performance Parts

The advanced high-temperature capabilities of IPSO 105 include the build chamber reaching temperatures of up to 100°C, the print bed heating to 180°C, and the extruder temperature capability of 450°C. This versatility and precision enable the widest range of applications with unlimited materials, from engineering-grade parts to functional prototypes.

TWO RELIABLE DSX EXTRUDERS

Uninterrupted Productivity

The 2 DSX (Direct Synchronized Extruders) are capable of printing at 450°C and have integrated cooling channels and multiple sensors for monitoring and control. When filament runs out the Relay Mode kicks in and the second extruder seamlessly takes over. The DSX extruders are particularly good with soft, flexible materials (up to 70A) thanks to its short filament path and optimized feeding mechanism.

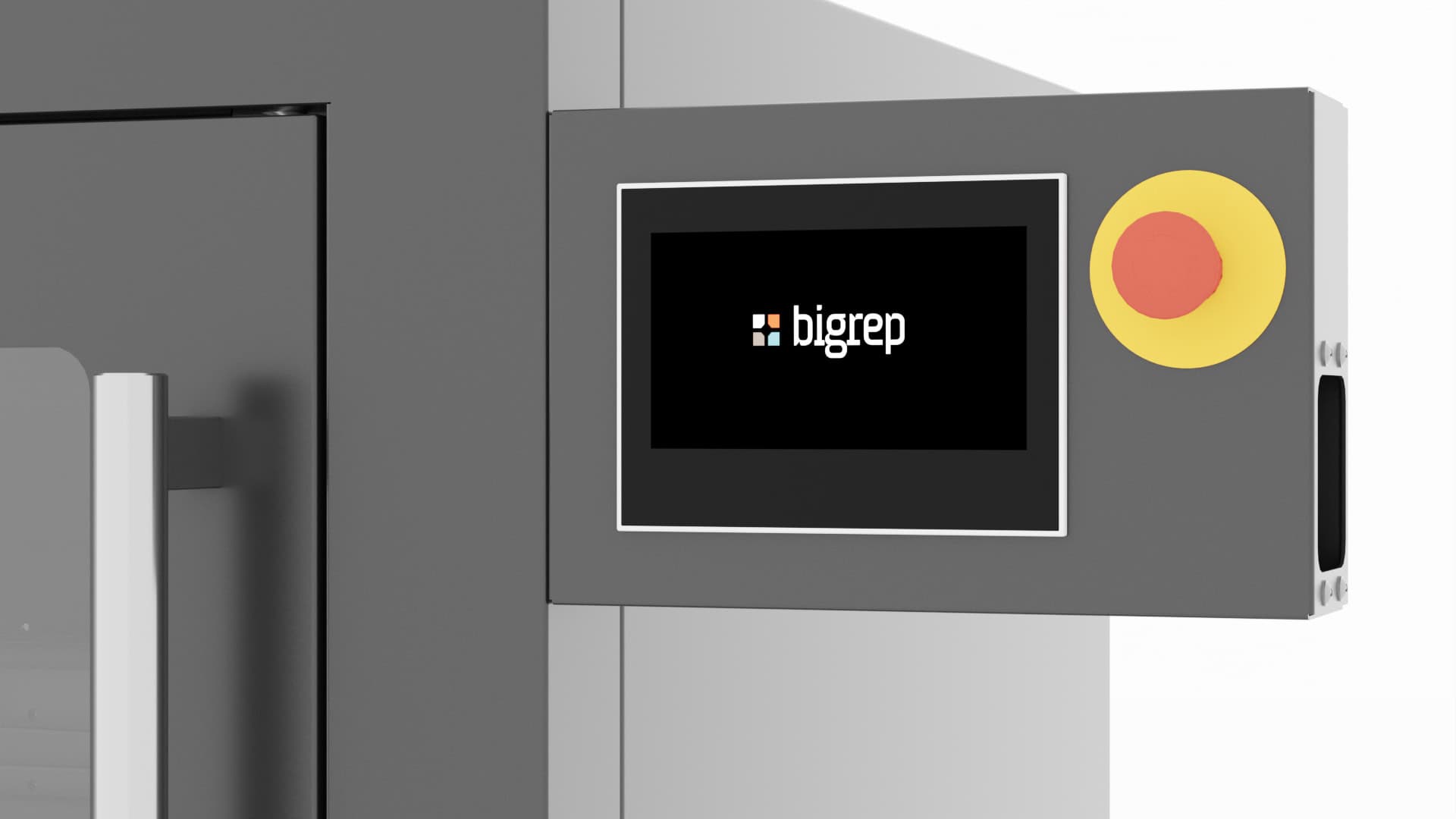

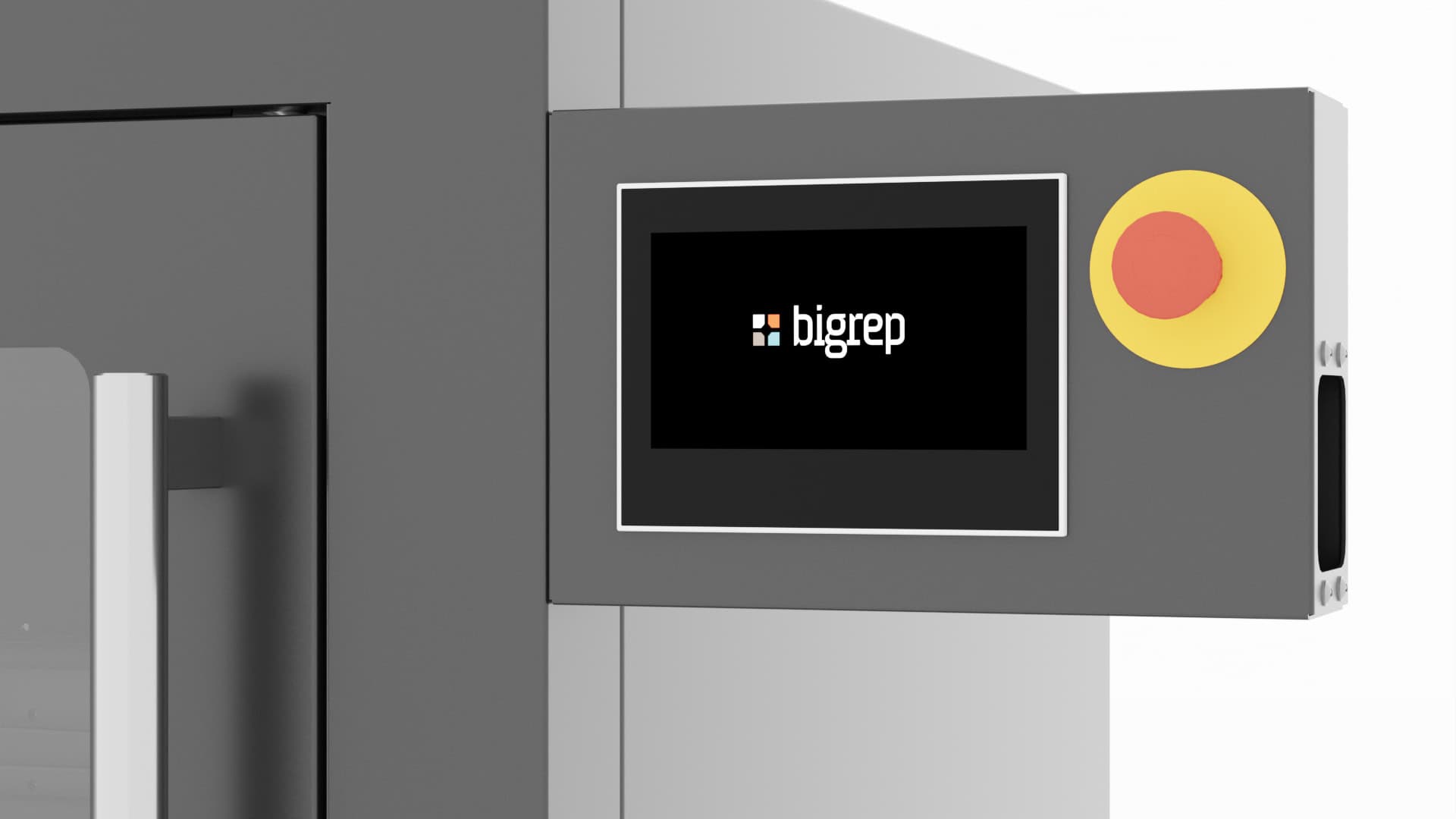

FULLY AUTOMATED QUICK START

Print at the Push of a Button

Getting started is quick and easy thanks to the numerous automatic functions like bed calibration via topology measurement and corresponding automatic compensation. After a smooth start, many built-in sensors will secure your 24/7 operation while the HD wide-angle camera enables real-time remote monitoring so you won't miss a thing.

HEATED PRINT BED

Several Options for Optimal Adhesion

Improve your print success thanks to the evenly-heated print bed offering two print surfaces. One option, a specialized tempered glass plate, displays minimal thermal expansion delivering more accurate prints with a wide range of materials. The other is a flexible steel plate with a magnetic foil and PEI coating for easy print removal.

EVEN TEMPERATURE DISTRIBUTION

Precise & Accurate Parts

Consistent temperature is key for excellent prints and a requirement for high-performance parts. Reaching temperatures up to 180°C, the IPSO 105's print bed maintains uniform heat distribution. The well-insulated build chamber circulates air heated up to 100°C assures optimum mechanical performance and print quality.

OPEN MATERIAL SYSTEM PRINTS ALL COMPATIBLE FILAMENTS

The heart of all BigRep machines is the material system that’s open for innovation. Print with any compatible filament of your choice – BigRep’s or a 3rd party’s – and unlock new applications with the IPSO 105.

BigRep's portfolio of industrial-grade 3D printer filaments ranges from affordable, general-use to technical materials for demanding industrial applications. They are created under carefully controlled conditions to guarantee uniform diameter and consistent composition ensuring reliable, even extrusion.

ABS

ACRYLONITRILE BUTADIENE STYRENE

Commonly used in electrical and electronic applications, construction materials, and automotive parts where flame resistance is crucial.

PEKK

POLYETHERIMIDE

(PEI)

Often used in aerospace, automotive, and medical applications for its high strength-to-weight ratio, thermal stability, and flame resistance.

ABS ESD

ABS - ELECTROSTATIC DISCHARGE

Widely known for its high resistance to electrostatic discharge, chemicals, impact, & high temperatures & finds applications in the electronics, aerospace, & automotive industries.

PEKK CF

CARBON FIBER POLYETHER-

KETONEKETONE

Well-suited for aerospace applications because of its lightweight, high-temperature resistance, and excellent mechanical properties.

PA12 CF

CARBON FIBER POLYAMIDE

Preferred for aerospace components, automotive parts, and sporting goods because of its high strength-to-weight ratio.

PP

POLYPROPYLENE

Ideal for consumer goods and packaging applications thanks to its lightweight, chemical resistance, and recyclability.

PA6/66

POLYAMIDE (NYLON)

Widely used in mechanical engineering, automotive parts, and consumer goods with excellent mechanical properties and chemical resistance.

PP GF

GLASS FIBER POLYPROPYLENE

Great for housings, enclosures, and connectors thanks to its light weight, chemical resistance, and glass fiber reinforcement.

PC CF

CARBON FIBER POLYCARBONATE

An ideal choice for industries such as electronics, automotive, and aerospace for its impact resistance, transparency, and heat resistance.

TPC

THERMOPOLYESTER COPOLYMER

Perfect for parts requiring elasticity and durability like shock absorbers, bumpers, protective covers, gaskets, and wearables.

PC FR

FLAME RETARDANT POLYCARONATE

Finds applications in industries demanding fire safety compliance, such as electronics, transportation, and aerospace.

TPU 98A

THERMOPLASTIC POLYURETHANE

With its flexibility, durability, & abrasion resistance, TPU is commonly used for manufacturing aids, particularly those interfacing with sensitive parts & equipment.

See the tech specs below for a full list of compatible materials.

TECHNICAL SPECIFICATIONS

| Version | BigRep IPSO 105 | |

|---|---|---|

| Build volume | 400 mm x 600 mm x 440 mm (x,y,z) | |

| BigRep materials | HI-TEMP, HI-TEMP CF, PRO HT | |

| Compatible materials | ABS, ABS-ESD, ABS-FR, ASA, HT-PETG, PA6, PA6-CF, PA12, PA12-CF, PA12-GF, PC, PC-ABS, PC-FR, PC-CF, PCTG, PEKK, PEKK-CF, PETG, PLA, PP, PP-GF, TPU, TPC (Open for 3rd party materials) | |

| Filament diameter | 1.75 mm | |

| Extruder | Direct Synchronized Extruder (DSX) | |

| Extruder configuration | Water-cooled dual DSX | |

| Hotends | Precise or Power | |

| Nozzles | Brass or hardened steel | |

| Nozzle diameters | 0.4 mm, 0.6 mm, 1.0 mm | |

| Layer thickness | From 0.05 mm | |

| Extruder temp | Up to 450°C | |

| Build chamber temp | Up to 100°C | |

| Print bed temp | Up to 180°C | |

| Max print speed | Up to 200 mm/s | |

| Max throughput | Up to 150 g/h | |

| Position accuracy | < 0.1mm in XY | |

| Movement speed | 250 mm/s in XY | |

| Drive technology | Stepper motors with encoder | |

| Air cleaning unit | Filtration system with active carbon filter and HEPA filter | |

| Safety circuit | Unmanned 24/7 operation | |

| Connectivity | USB, network | |

| Pause printing | Out-of-filament sensor with smart ʻstop and goʼ function (build chamber and print bed remain heated) | |

| Slicing software | Simplify3D, Cura | |

| Machine control | HAGE3D industrial control | |

| HMI | LED + 7” touchscreen | |

| Camera | Wide angle color HD camera for real time remote monitoring | |

| Override function | Manual override in real time | |

| User Access | Multi-level user permissions | |

| Power supply | 400 V / 16 A | |

| External dimensions | 1270 mm x 1120 mm x 1730 mm (x,y,z) | |

| Weight | Approx. 420 kg | |