Guide to Post-Processing 3D Printed Parts: 16 Methods

Get more from your 3D prints with smoother surfaces, improved mechanical properties, enhanced aesthetics, and more.

Get an overview of 16 post-processing techniques in this guide or see some real life examples in the ebook and webinar:

SMOOTH SURFACES

Reduce the appearance of print layers and refine surfaces

Strengthen Parts

Reinforce prints for added strength and durability

ADD FUNCTIONALITY

From UV and weather resistance to conductivity and more

AESTHETIC FINISHING

Transform the surface appearance for visually striking parts

All 3D prints are produced layer by layer, which results in a notched surface texture that is more pronounced with lower print resolutions. If support structures are needed for your part, it may have additional flaws on its touch points. This guide covers the first step to part finishing, support removal, and the three categories of post-processing: Subtractive, Additive, and Material Changing.

Support Removal

Unless your print is optimized for supportless 3D printing, you’ll probably be printing with support structures. These are usually easy to snap off, but even well designed supports will leave behind imperfections where they were once attached. To smooth these areas, it is recommended to post-process the entire part by any number of methods outlined below.

With dual extrusion you can print soluble support structures that disintegrate in water and leave no trace on your part. They’re especially useful when post-processing isn’t otherwise necessary.

Subtractive Post-Processing Methods

Probably the most common post-processing category, subtractive post-processing is the act of removing some of your part’s material. Usually this is in the form of sanding or polishing a part, but there are a variety of other methods that includes tumbling, milling, abrasive blasting, and chemical abrasive dipping.

Sanding & Polishing

- DIFFICULTY

- SMOOTHNESS

Both sanding and polishing techniques remove surface layers by rubbing it with an abrasive material. Sanding requires coarser grit sandpaper and sanding tools, while polishing may use finer sandpaper, steel wool, polishing paste, or cloth.

Sanding removes larger blemishes such as support remnants or print irregularities and reduces the visibility of print layers. The sanding process will leave a gritty, although more uniform surface texture, and very course sandpaper will leave surface scratches. Polishing the part after sanding will produce an even smoother surface.

Simplicity and affordability make sanding and polishing the most common methods of post-processing, but both require labor that is time consuming for larger parts and batches. These methods may not be suited for parts with hard to reach cavities.

Tumbling

- DIFFICULTY

- SMOOTHNESS

A tumbling machine consists of a vibrating vat containing lubricating fluid and abrasive media, which are specialized stones that wear objects down according to their size, shape, and hardness as they tumble together. A 3D printed part is simply placed into the vat of tumbling abrasive media for a specific length of time. Some expertise is required to pair parts with the correct abrasive media and processing time, but when done correctly it is very effective at producing uniform finishes.

Tumbling is a largely automated subtractive method that can post-process multiple parts simultaneously, which is useful for smoothing batches of parts. Tumbling vats come in a range of sizes so larger parts can also be processed. Since the abrasive media is constantly in contact with the part, larger pieces do not require longer processing time, but only larger machines with the adequate amount of abrasive media. However, complex shapes may lose detail and sharp edges may become slightly rounded by tumbling.

Abrasive Blasting (Sand Blasting)

- DIFFICULTY

- SMOOTHNESS

Abrasive blasting, also known as sand blasting, is subtractive post-processing method where abrasive material is blasted onto 3D printed parts at high pressure. For large parts this can be done in an open environment, but smaller parts are typically processed in a containment chamber that collects and reuses the abrasive material. Like other grit-based subtractive methods, there are a range of grits available and grit must be chosen based on part geometry and desired finish. Sand is a frequently used abrasive material, but other small coarse objects such as plastic beads can be used for different results.

Since the abrasive material is smaller than that of tumbling, abrasive blasting is less effective on very rough parts or high layer heights. This method only treats surfaces reachable by the stream of blasted material, so complex geometries and cavities may not be feasible. Additionally, the blasting tool can only treat limited areas at a given time, so this method may be slower and difficult to process multiple parts simultaneously.

CNC Machining (Milling)

- DIFFICULTY

- SMOOTHNESS

CNC milling, also called CNC machining, is the inverse of 3D printing - it uses a computer-programmable drill moving (and sometime rotating) in three axes to carve out geometries. Like 3D printers, the technology uses a “G-Code” to program tool movements, in this case a milling bit rather than a filament extruder.

While CNC machining is considered highly accurate from 0.005” to 0.00005”, it cannot produce certain geometries and wastes material, which is often expensive. Conversely, large-format 3D printing cannot achieve the same accuracy, but can achieve much more complex geometries and wastes very little material.

It is typically not time or cost effective to mill the entire surface of a 3D print and it may be difficult to calibrate the milling tool to the print position. But while these two production methods are seemingly at odds, there are some situations where they may be used together. If a portion of a 3D printed part must be extremely smooth or accurate, that specific area can be milled. Alternately, manufacturers can save material by 3D printing a part in a rough finish before milling it to perfection.

Chemical Dipping

- DIFFICULTY

- SMOOTHNESS

Chemical dipping, also called aid dipping, is the process of submerging parts in a chemical bath that eats away the surface. The process involves caustic materials, such as lye, sodium hydroxide, or dichloromethan, and should only be done by experts in facilities with the requisite safety features. The appropriate chemical choice is entirely dependent on the material of the 3D print, as the chemical must be abrasive to the print material.

Some expertise is required to determine how long parts should remain submerged: too brief and the part will not be sufficiently smooth, too long and it could be ruined entirely. Some care should be taken to avoid air bubbles trapped inside the 3D print as they will prevent the chemical treatment of the surface. Typically the submerged part is gently moved to agitate the chemical bath and release any air bubbles.

The process is ideal for complex geometries as the chemical bath treats all surfaces of submerged parts simultaneously. However, the size of the chemical dipping container determines the limited part dimensions of treatable prints.

Additive Post-Processing Methods

Additive post processing puts additional material directly onto printed parts and is highly efficient for smoothing parts while adding strength and other mechanical properties. There is a wide spectrum of methods from filling to priming, coating, metal plating, and more.

Filling

- DIFFICULTY

- SMOOTHNESS

Filling is a surface treatment that uses a thick adhesive compound, typically a paste, to fill in notches like the tiny gaps between layers of a 3D print. It is commonly used as a first step before sanding or additional additive layers. A wide range of fillers from pastes to sprays are available in many materials from light spackle to 2K resins.

Paste fillers, like wood fillers or household spackle, are usually the most accessible option. They are simply spread over the part surface and can be easily smoothed with light sanding. Spray fillers are easy to apply but provide only a thin surface covering, resulting in a rougher coating. More robust, but more advanced options are resin fillers that must be cured by one of two methods: mixing with a hardener or UV exposure. Resins are available with various viscosity, cure speeds, and advanced features like UV and a high heat deflection temperature. For some UV-cured fillers leaving parts in the sun may be sufficient, but others will require a specialized UV chamber.

When using any kind of resin cover skin, wear gloves, and keep the working space well ventilated. Ensure you’re familiar with the requirements of your filler or coating before applying it to a part as this may drastically change the time or equipment required for post-processing.

For some UV-cured fillers, leaving parts in the sun may be sufficient but others will require a specialized UV chamber. Ensure you’re familiar with the requirements of your filler or coating before applying it to a part as this may drastically change the time or equipment required for post-processing.

Priming

- DIFFICULTY

- SMOOTHNESS

Primers prepare 3D-printed parts for the addition of subsequent layers by pre-treating the surface for better adhesion. They are far less viscous than fillers and may only smooth very small surface imperfections, so their main function is adhesive surface preparation. Primers are available in spray or brush form, but spray primer may produce a more even coating.

To prime a part most effectively, the imperfections and layers notches should first be reduced by other post-processing methods such as sanding or filling. Ensure that your primer is made for plastic adhesion and is suitable for additional materials you intend to apply later. Leave the primer to set for 24 hours or as otherwise directed.

Brush Coating

- DIFFICULTY

- SMOOTHNESS

Liquid coatings vary widely in material such as paint, varnish, resin, or even plastic. While there are several application methods, brush coating is the simplest way to smooth unique or small batches of 3D printed parts. Although the surface smoothness may be inconsistent due to brush strokes, choosing a material with the proper viscosity can avoid these surface irregularities.

For a robust and smooth surface apply a 2K resin, which is a two-component mixture of resin with a hardener. When combined, the mixture creates an exothermic chemical reaction that cures the resin over a given amount of time. There is a huge range of resin products for a variety of uses: laminating resins for thin surface applications, casting resins for larger volumes, fast and slow curing resins, and resins with additives (like aluminum, for example) for additional performance enhancement such as temperature, UV, or chemical resistance. To achieve the smoothest surface when brush coating, use a resin with an appropriate “self-leveling” viscosity that will even out brush strokes without material dripping off the part. There are resin products specifically formulated for 3D prints that can achieve very smooth surfaces after one coating.

When brushing other materials such as paint or varnish it may be more difficult to avoid brush strokes, but many coatings can be sanded after drying to achieve a smoother surface. It is also possible to apply an additional coating of another material, 2K resin for example, to achieve a smoother final result.

Spray Coating

- DIFFICULTY

- SMOOTHNESS

A wide-ranging and scalable post-processing technique, spray coating a offers a number of viable methods ranging from DIY projects to robotic automation at an industrial scale. Spray coatings are available in a huge variety of materials such as paint, varnish, resin, plastics, and rubbers, just to name a few.

The simple approach for DIY projects is a spray can of a chosen material applied in a ventilated/outdoor space. Since this method typically results in minimal surface smoothing, it is recommended to sand the part first and apply several spray coats. Applying a spray primer may help the spray coating adhere to the part. Spray paint can be used for aesthetic enhancements and spray varnish can protect the surface against chipping, wear, and UV damage.

For large volume or industrial spray coating applications, a robotic arm fitted with a spraying tool head can apply a wide range of coatings to a 3D printed part. The application typically takes place in spray booth with an adequate air filter. This method allows a wider range of materials, including 2K spray coatings, primers, paints, and more, and results in higher application precision and uniformity. A robotic arm will speed up the processing time and make high-volume post-processing feasible at an industrial level.

Spray coating is most suitable for finishing large parts, rather than other additive methods such as dipping, foiling, or powder coating. The later methods all require a machine or vat that can contain the entire part, whereas spray coating is only limited by the size of the room in which it is done.

Foiling

- DIFFICULTY

- SMOOTHNESS

In foiling, or vinyl wrapping, an adhesive foil made of light metals or plastic is wrapped onto an object, often preceded by priming. Commonly known for wrapping vehicles, vinyl wrapping can also be applied to 3D-printed objects with a suitable material. Depending on the material, the foil may increase heat and stress resistance but is often applied for aesthetic enhancement like smoothing and surface quality.

The difficulty of this post-processing technique varies with the size and complexity of your part. A simple geometry, like the gently curved side panel of a vehicle, is relatively easy to foil, but complex shapes are more difficult with some being impossible to foil.

Wrapping is particularly suitable to apply detailed surface designs to 3D-printed parts. Adhesive foils come in a wide range of colors and patterns, as well as custom-printed designs. Foil can be applied by hand, stretching the material over objects to ensure no imperfections like air bubbles remain. Heat guns are often used in the process to make application easier and avoid imperfections. Vacuum foiling will automate the process for faster, precise results to ensure the material wraps around the part as perfectly as possible.

Foiling is usually not suitable for complex parts as the foil will be extremely difficult to apply uniformly and inside cavities.

The difficulty of vinyl wrapping varies with the size and complexity of your part. A smooth surface – like the side paneling of a vehicle – should be reasonably simple to foil but complex shapes will become exponentially more difficult.

Dip Coating

- DIFFICULTY

- SMOOTHNESS

When dip coating, a part is submerged into a vat of material such as paint, resin, rubber, etc. and removed after a specified time, resulting in an even surface distribution. The part can be redipped multiple times for a thicker coating and smoother surface. Dipping can be used for aesthetic finishing and functional enhancement like increased strength and resistance to heat, chemicals, weather, etc.

The typical dipping process is comprised of five stages:

- Immersion: The 3D printed part is immersed in a vat of material at a constant speed.

- Start-up: The part remains submerged for a specified time for the coating to adhere.

- Deposition: The part is removed at a constant rate as a thin layer of the material is deposited.

- Drainage: Excess material will drip off of the part surface back into the vat.

- Evaporation: As the coating sets the solvent evaporates from the material, leaving a solid film.

Hydro dipping, also known as water transfer printing is a unique method for applying detailed designs onto a 3D print. The part is submerged in a vat of clean water that has a layer of material floating on its surface, typically a water soluble printed film or an oil based paint. As the part passes through the floating layer, the film or paint adheres to the part’s surface. The surface tension of the water ensures that the film curves around any shape. The best results are achieved with parts containing gently curving geometries.

Dip coating is suitable for complex geometries and requires some expertise in the coating material used. The size of the vat determines the dimension of treatable parts. Large prints may not be feasible, although batch processing is possible for smaller parts.

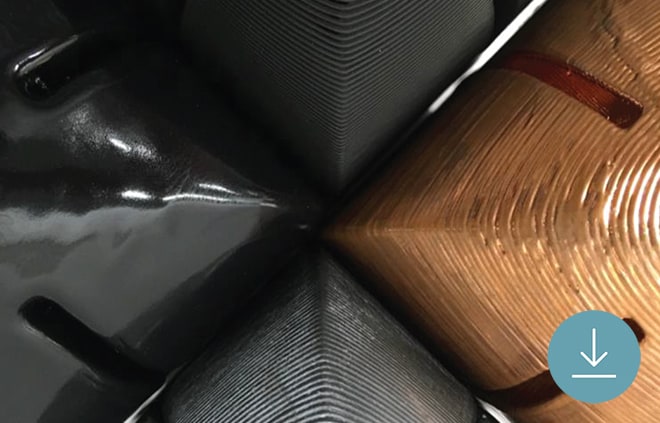

Metal Plating

- DIFFICULTY

- SMOOTHNESS

Metal plating is a chemical process where a layer of metal is bonded to a 3D printed part. It is a highly effective method to create 3D printed objects with high resistance to heat, impact, weather, and chemicals, or to create conductive parts.

The first step in metal coating plastic parts is "electroless plating" which metalizes the surface of the print, priming it for proper metal plating. This process ranges from special metal paints that are simply brushed or sprayed onto the part to industrial processes involving numerous steps of cleaning, etching, neutralizing, activating, etc. Typically, this first layer is copper or nickel, although silver and gold layers are also possible.

In the second step in metal plating, the metalized 3D print is submerged in a bath for a specific length of time to deposit a wide range of metals like tin, platinum, palladium, rhodium, and even chrome. In electroplating, the part is placed in a galvanic bath that deposits a thin metal layer from 1 - 50 microns thick. Anode and cathode ions pass through the liquid and adhere to parts in microscopically fine layers. Additional metal plating processes can build up the metallic surface thickness or deposit a different metal material.

When using a metal-acid solution, parts are submerged in the liquid solution for a specific duration, depending on the desired plating thickness. A chemical reaction attracts and adheres the metal ions to the surface of the part. Once removed from the bath, the part can receive a protective coating to prevent oxidation, corrosion, or tarnishing. Heat treatments may be used to strengthen the metal layer adhesion and prevent brittleness.

Metal plating typically works well for complex parts and can produce a range of surface qualities, smoothness, and mechanical enhancements. However, the process requires many stages and expertise.

Powder Coating

- DIFFICULTY

- SMOOTHNESS

With powder coating, also known as rotational sintering, a part is heated and rotated within a cloud of powdered plastic. As the powder compound meets the heated part, it is melted to the surface to produce a fine coating. Due to surface tension while spinning, the adhered powder produces a homogeneous, non-porous layer about 400-microns thick. The surface is typically not glossy smooth, but rather has a fine matte texture caused by the plastic cloud particle size, typically 2-50 microns.

Powder coating is a common method for protecting large metal components, but it is difficult to achieve with 3D prints. In traditional powder coating, the metal parts experience temperatures up to 200 °C, but the lower temperature resistance of most 3D printed plastics greatly limits the use of a post-processingsing method. When possible, powder coating is highly efficient for batch production with uniform surfaces, although cavities may be difficult to post-process.

Property Changing Post-Processing Methods

Neither removing nor adding material, property changing post-processing redistributes molecules of a 3D print. Smoother and stronger parts are achieved with thermal and chemical treatments.

Local Melting

- DIFFICULTY

- SMOOTHNESS

Local melting is an easy way to reduce the appearance of surface scratches from damage, support removal, or abrasive post-processing like sanding. Rough surfaces are particularly visible on dark-colored 3D prints, which appear to be a white-ish color. Using a heat gun set to high heat, quickly pass hot air over the area requiring treatment, keeping the heat gun 10-20 cm away from the part. Within seconds, the surface will melt to resemble the original print surface quality. A heat gun can also remove strings from travel moves during printing. Using the same method as described above will melt and shrink the strings. If the strings are large, small remnants may cling to the part but are often easily removed by brushing or clipping them off.

This method is not suitable for deep scratches as it is only effective for light surface roughness. It also can easily deform the part, so take care to limit the time an area is heated. The best results are achieved by sweeping hot air across the surface for several seconds. Local melting is not recommended for overall surface smoothing, but for the easy and effective smoothing of small defects and scratches.

Annealing

- DIFFICULTY

- SMOOTHNESS

Annealing is the process of heating a print to re-organize its molecular structure, resulting in stronger parts that are less prone to warping. Untreated 3D prints have an amorphous molecular structure, meaning that the molecules are unorganized and weaker. Being a poor heat conductor, the extruded plastic cools quickly and unevenly during the printing process causing internal stresses, particularly between print layers. These stress points are most prone to breakage.

To strengthen the part at its molecular level, it is heated to its glass transition temperature, but below its melting point. Achieving the glass transition temperature allows the molecules to redistribute into a semi-crystalline structure without melting the part to the point of deforming. Glass transition and melting temperatures vary between materials and some expertise is required to heat parts to the correct temperature for the proper length of time. 3D prints will shrink during the annealing process, which can be corrected by increasing the original printing dimensions accordingly.

Vapor Smoothing

- DIFFICULTY

- SMOOTHNESS

Vapor smoothing is the chemical process of smoothing 3D prints in which parts are exposed to vaporized solvents in an enclosed chamber. Similarly to chemical dipping, the correct solvent must be used in correspondence with the 3D print material. The cloud of solvent dissolves the surface of the print, while its surface tension redistributes the dissolved material, resulting in a smoother finish. Unlike chemical dipping, no material is actually removed from the part.

Solvents can either be heated to a gaseous state or vaporized by ultrasonic misting. The 3D print is exposed to the vaporized solvents for a specific length of time: too short and the part is not adequately smoothed, too long and the part can deform and become brittle. Most suitable solvents are caustic and combustible, and therefore require extreme levels of caution, adequate chemical containment, and disposal, and should only be handled by qualified persons.

Many vapor smoothing machines are available for use with a variety of solvents suitable for different print materials. These machines make the process automated and much safer, but most can only treat smaller parts due to the chamber's limited dimensions.

Post-Processing eBook

For real life industrial examples, download our free eBook Post-Processing for FFF Prints and see this webinar about post-processing techniques.

The eBook explores the three types of FFF post-processing techniques: 1) Material Removal, 2) Material Addition and 3) Material Property Change. Also, learn more about how various techniques like high resolution tumbling, resin coating and aluminum plating are transforming 3D printed parts.