In the heart of the art district in Tampa, Florida, Artistic Spaces is a design studio known for its avant-garde sculptures and large-scale installations. While the studio specializes in creative custom fabrications, some of its major projects faced significant challenges with scalability, materials and labor costs, complex geometries, and time constraints.

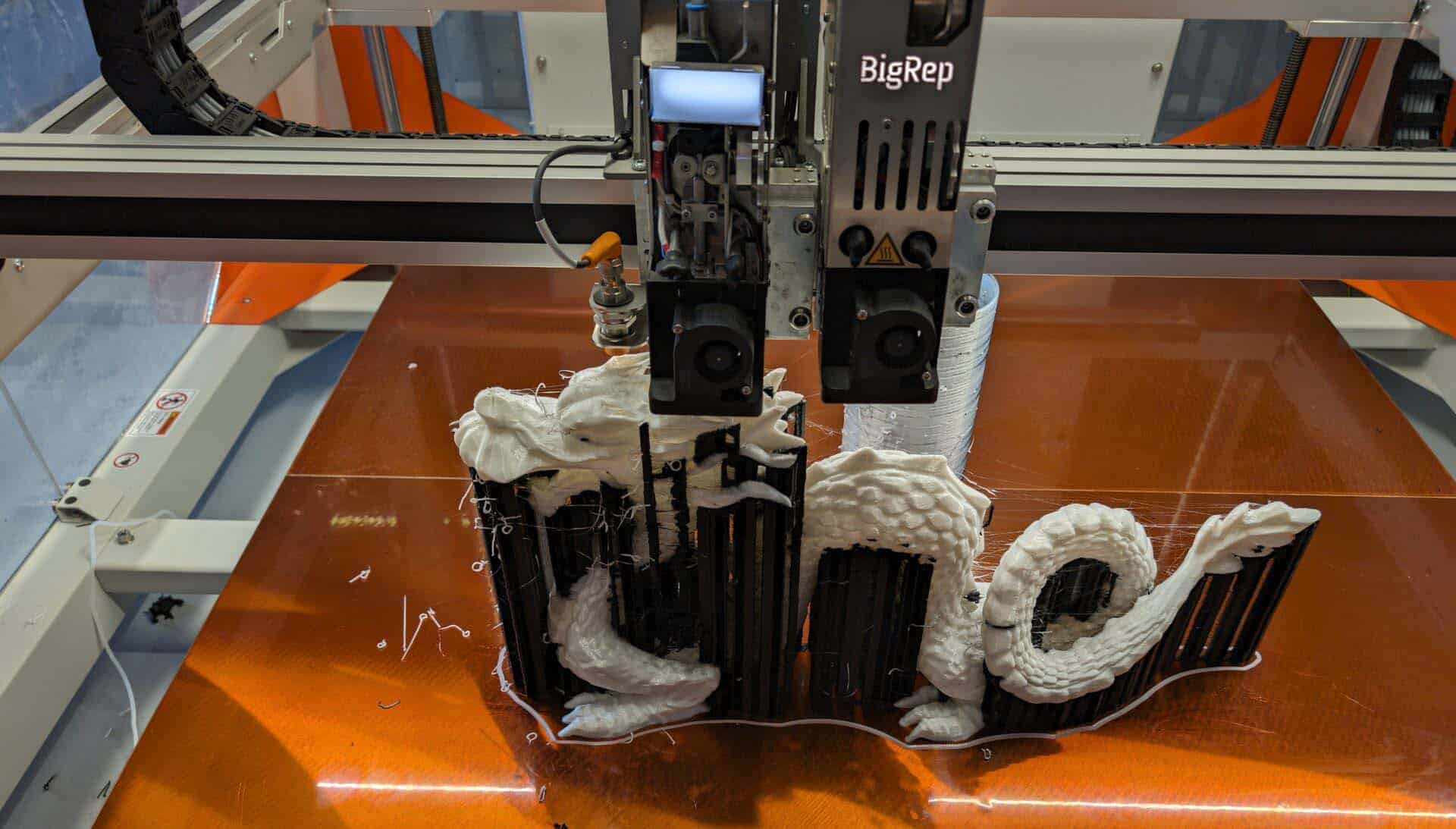

The owner of the studio, James Murray, recognized that to maintain their competitive edge and meet growing demands, he needed to upgrade their fabrication to more technologically advanced methods. His journey towards overcoming these obstacles began in December 2023 when he purchased the BigRep ONE 3D printer from a local reseller, ELK3D, a veteran-run partner specializing in advanced 3D printing solutions.

The Challenges Artistic Spaces Faced

James and his team had challenges with:

- Scalability: Traditional methods couldn't easily scale to larger projects.

- Cost: The expenses involved in traditional sculpting materials and labor were skyrocketing.

- Time: The time required to produce large art pieces hindered their ability to take on more projects and meet client deadlines.

- Geometric Complexity: Traditional manufacturing methods were too labor-intensive and produced lower-quality results for intricate geometries.

BigRep's Solution

Artistic Spaces was introduced to BigRep’s catalog of large-scale industrial 3D printers, specifically the BigRep ONE, by ELK3D. James Murray from Artistic Spaces said,

“This was our first experience working with a large-scale 3D printer, and the entire process exceeded our expectations. Once we had the model in the slicer, it was easy to write the code and watch it print.”

Artistic Spaces ordered the BigRep ONE with ELK3D in mid-December, and it was delivered on the 28th, a couple of weeks later. BigRep printers are manufactured in Germany and have a facility in Boston, Massachusetts. Thanks to meticulous planning, efficient logistics, and the ability to maintain stocked inventory in the USA, ensuring (JIT) just-in-time delivery, ELK3D, and BigRep delivered the machine to Artistic Spaces in Tampa within a few weeks.

The BigRep ONE offered:

- Massive Build Volume: Can produce pieces up to one cubic meter or 31 cubic feet, perfect for large installations.

- Cost Efficiency: The open material system, flexible scale and design capabilities, and automated production reduced costs significantly.

- Speed: Drastically cut down delivery time through automated production and fewer failed prints allowing Artistic Spaces to take on more projects and deliver them quicker.

- Geometric Precision: Enabled the creation of complex geometries with high precision and quality.

- Reliability: Ensured consistent performance and high-quality output, minimizing downtime and enhancing productivity

ELK3D's technical leader, Taylor Hardy, was on-site to oversee the delivery and installation of the printer. The team efficiently unboxed, assembled, and calibrated the BigRep ONE in less than two days. As part of the ELK3D’s Assurance program, Taylor ensured the Artistic Spaces team received thorough training, and was well equipped to operate the printer confidently.

James Murray from Artistic Spaces said,

“The BigRep ONE ran nonstop for three days without any issues. Thanks to ELK3D's onsite training, our team confidently use the machine, we simply hit the start button and get on with our tasks while the machine takes care of the part.”

This Assurance Program and rapid setup included:

- Detailed Guidance: Taylor provided step-by-step instructions for every function of the BigRep ONE, covering everything from basic operations to advanced settings. This included practical demos of how to use the machine efficiently, along with best practices to ensure longevity and consistent performance.

- Test Prints: Taylor facilitated initial test prints to verify the machine's calibration and optimize printing These test prints were essential in fine-tuning the printer's settings, ensuring that the output was of the highest quality and that the machine was running at peak efficiency.

- Comprehensive Training: Taylor and the ELK3D technical team conducted in-depth training sessions with James, the lead artist at Artistic Spaces which included flow rate calibrations tailored to different materials, enabling him to adjust the printer settings for different filaments. Taylor also covered troubleshooting techniques and routine maintenance procedures to ensure long-term performance and minimize downtime.

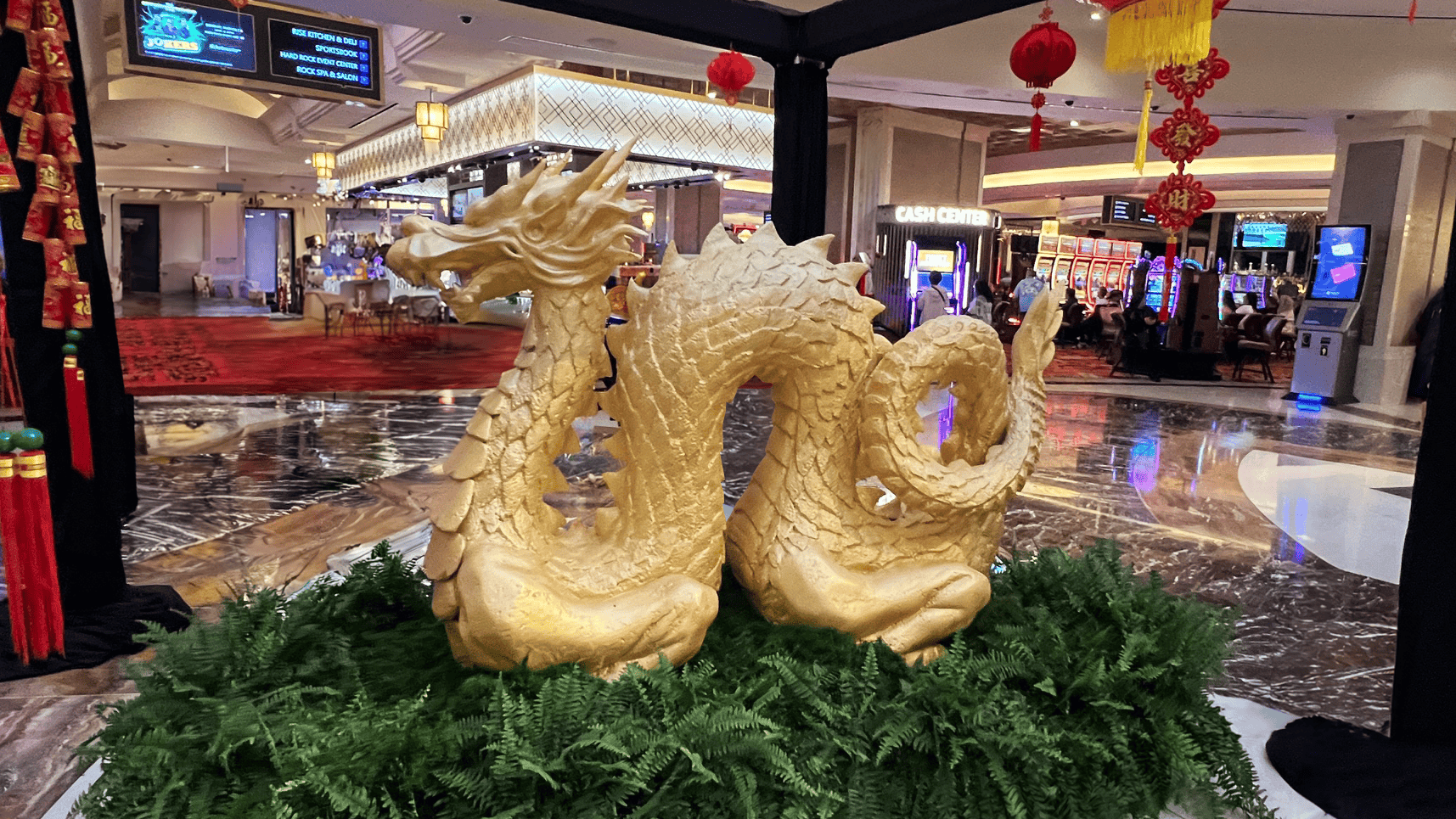

Over the next few days, the team printed several sample pieces to understand the machine's capabilities. One of the first large-scale projects was a dragon sculpture for the Chinese New Year celebration at the Hard Rock Hotel in Tampa.

Chinese New Year and the Dragon Project

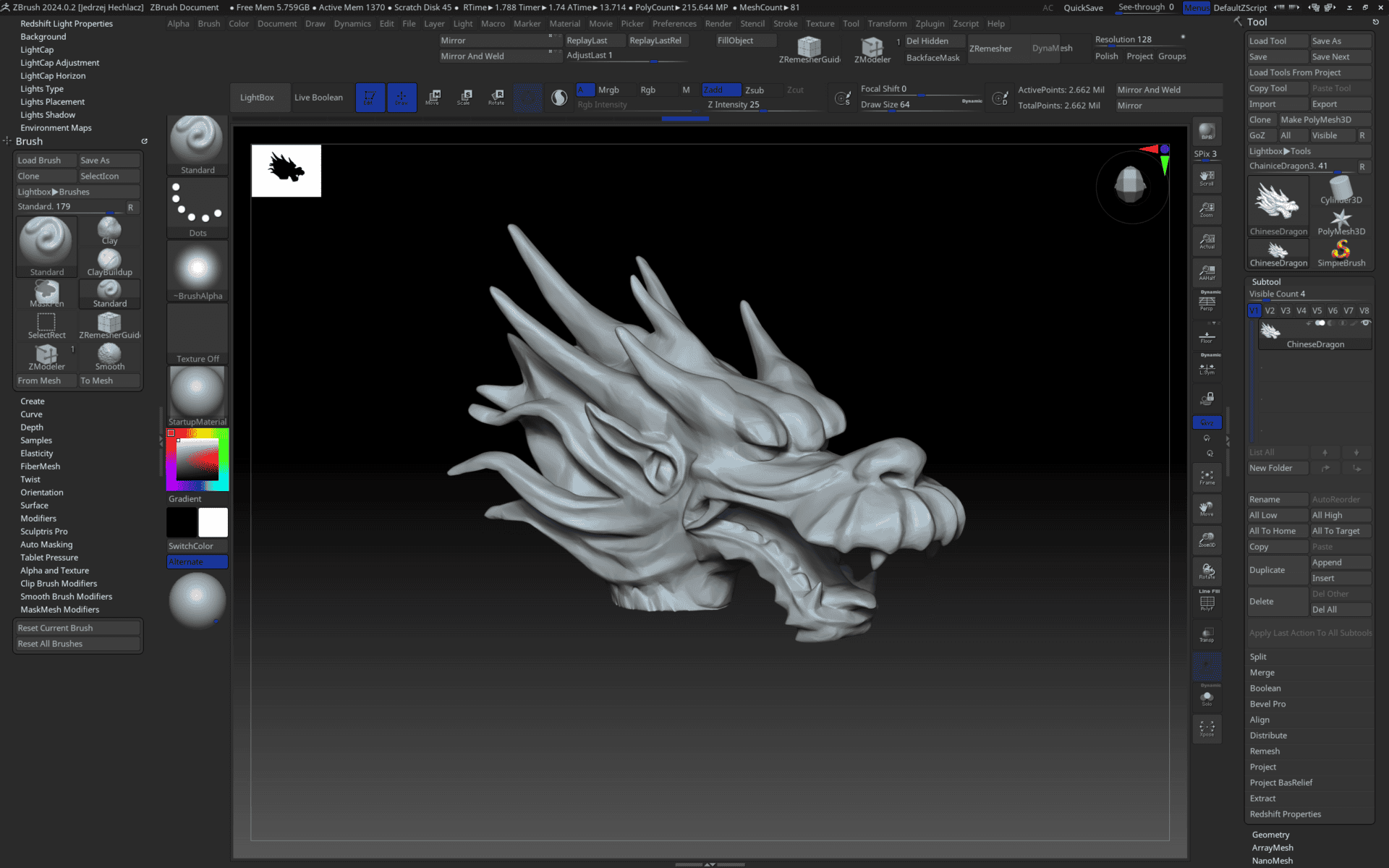

Chinese New Year, or the Spring Festival, is China’s most important traditional celebration, marking the start of the lunar new year. For the occasion, Artistic Spaces was commissioned to create a dragon sculpture for the Hard Rock Hotel in Tampa. Despite initial challenges with print settings, the team, with support from BigRep's engineers, successfully printed the dragon's head in 3 ½ days.

The combination of 3D printed precision and hand-carved craftsmanship resulted in stunning dragon sculptures in a large and smaller scale that seamlessly blended tradition with technology.

Technical Training for the Dragon Sculpture’s Execution

ELK3D Assurance Program included:

- Project Consultation: In-depth discussions on project requirements and strategic advice on dividing the dragon project into manageable parts.

- Technique Exploration: Methods for merging printed parts seamlessly post-production and applying specialized coatings to enhance durability and aesthetics.

- Printing Setup and Support: Collaboration on slicing the dragon model file, ensuring precise settings for dual-material printing, and providing real-time assistance through screen-sharing sessions.

- Material Selection and Configuration: Recommendations for PLX as the model material and PRO HT for breakaway supports, optimizing print quality, ease of post-processing, and structural integrity.

Taylor Hardy from ELK3D said,

“We partnered with BigRep because of their reliability, quality, advanced technology, and the dedicated team behind it. This collaborative environment enabled us to achieve success with Artistic Spaces, James, and his team.”

The Transformation

Within 20 days of installation, Artistic Spaces had monetized their investment by successfully completing the dragon sculpture project. They were now able to:

- Expand Creativity: The freedom to experiment with new designs and scales without worrying about the constraints of traditional methods.

- Increase Productivity: With reduced production times, they could take on more projects and increase their revenue.

- Enhance Quality: The precision of the BigRep ONE ensured that every piece of art printed met the highest standards of quality.

The Results

- Revenue Growth: In 2024, Artistic Spaces experienced an increase in revenue within the first year of using the BigRep ONE with customers asking for new concepts. New projects were rolling in, allowing them to capitalize on their new capabilities.

- Project Capacity: They are able to take on more projects, thanks to the reduced production time.

- Cost Savings: Material and labor costs were cut by 30%, significantly improving their profit margins.

Limitless Creativity

Given the tight timeframes and budgets, the BigRep ONE was able to accommodate large-scale projects quickly and deliver results faster than traditional methods. The digitized fabrication process opened doors to a much wider spectrum of possibilities, unlocking new dimensions of creativity and business success.

Large-Scale Innovation. Limitless Creativity.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. It's the trusted tool of designers, innovators, and manufacturers alike.

- Open 1000 Liters Build Chamber: Large 1 cubic meter build volume for creating big, complex objects in a single print.

- Dual Extrusion (Up to 250°C, 72 g/h): Multi-material printing capability with a dual-extrusion system, supporting a wide range of materials and a print rate of up to 72 grams per hour.

- Heated Print Bed (Up to 80 °C): A heated bed with a polyimide surface that enhances print adhesion for a range of materials and minimizes warping.

- Fine Detail or Fastest Printing: Layer heights from 0.3 to 1.0 mm let you achieve fine detail on large prints or extra fast prints when surface texture is less important.