To achieve the best possible results, 3D printers must be calibrated before printing. That includes the correct positioning of the print bed and the extruder(s) to eliminate dimensional deviations of the 3D print as much as possible. At the same time, correctly adjusting the distance between the nozzle and the print bed ensures good adhesion resulting in better overall quality, less warpage, and fewer failed prints.

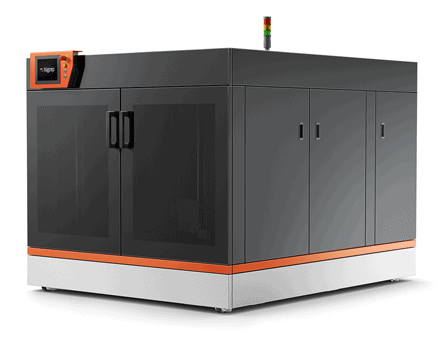

The complexity of calibration depends on the type of printer, machine equipment, and application used. It requires knowledge and experience with the machine and is time-consuming and costly. Calibration can also become a significant time factor in the case of frequent material changes or a switch between an operation with and without dual extrusion. To address this, the new BigRep PRO offers autocalibration, taking this task off your hands and saving you time and money.

Autocalibration on the PRO - How Does It Work?

The first step to ensure a properly calibrated BigRep PRO is bed leveling. This can be done by running the 'bed level' function, which initiates the ball sensor to scan a number of points on the print bed. The PRO's user interface will report which areas are not level within an acceptable tolerance and then you simply adjust the bed screws. Bed leveling does not need to be done frequently, but only after initial installation or semi-annual check ups.

The BigRep PRO performs several calibration tasks before each print. The first is bed mapping, which is also used during the bed leveling process. In this case, a sensor ensures that the distance between the print nozzle(s) and the bed is the same over the entire surface of the print bed.

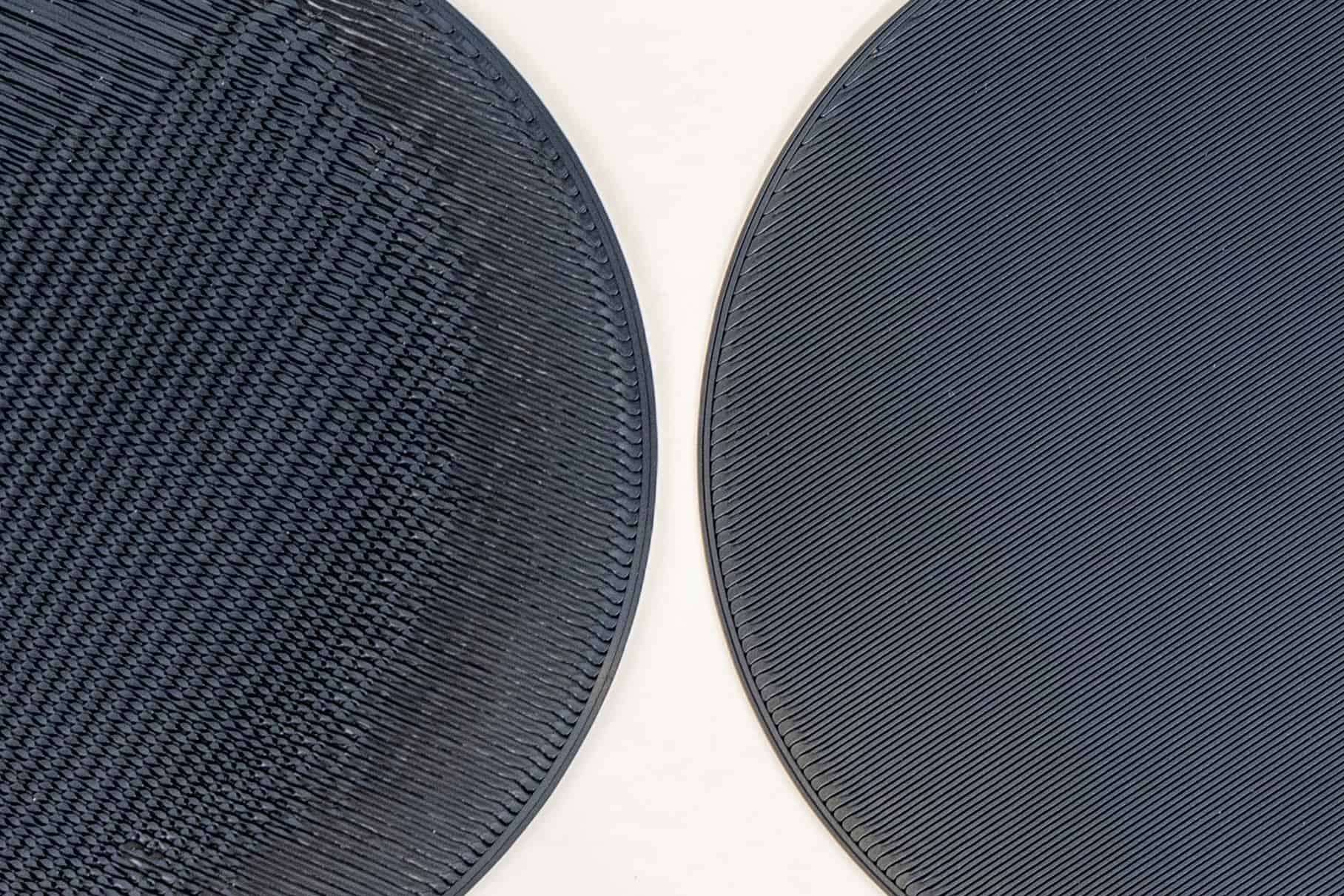

If inconsistencies are measured, the PRO can automatically adjust the thickness of the print layers to compensate for differences. This is particularly crucial for the first print layer, which is essential for successful adhesion between an object and the print bed. This can save you a lot of time on the BigRep PRO. Without precise calibration, the first layer is typically over-extruded to ensure that the print sticks on the printer bed, but this results in sub-optimal quality, as seen in the image below.

Secondly, the PRO calibrates the distance between the two extruders. This alignment is paramount when bringing out the full benefit of dual extrusion. Only when the control software knows the exact distance between extruders can perfectly aligned structures be printed. Doing this step manually can take a lot more time. Automatic calibration also enables a superior level of precision to manual calibration.

How Does Bed Mapping Work?

The flatness of a print bed, which usually consists of a solid aluminum plate, is an approximation as the surface may slightly deform when heated. This is the case with everything on the FFF printer. However, the larger the print bed, the greater the deviation from the ideal flat surface. Since 3D printers from BigRep - such as the BigRep PRO - are among the largest machines available on the market, a perfect calibration is crucial.

With the aid of the sensor, a network of measuring points is recorded over the entire surface of the print bed. The relative height of each measuring point above an ideal theoretical surface is automatically stored in the software. This enables the printer to adjust the size of the print head—the result is a perfect first layer with a constant material thickness and ideal material adhesion.

The principle used for distance measurement has a direct influence on calibration precision. BigRep decided to use mechanical-inductive surface scanning for the BigRep PRO. Compared to purely inductive or optical methods, it is independent of surface conditions or appearance and allows the detection of printed structures.

How Does Extruder Calibration Work?

There are some scenarios when dual extrusion is beneficial - or even necessary.

- When printing several identical parts at the same time. Both extruders move in parallel, cutting production time per part in half and increasing productivity.

- When printing a part using a support material. Since different extruders process both primary and support materials, they can use other materials. For example, they can combine a stable primary material with a water-soluble support material.

- When printing two different primary materials in the same component. This procedure allows chemically identical materials to be combined with other colors to achieve visually desirable effects. Alternatively, materials having different mechanical properties can be combined.

In the first case, the exact alignment of the extruders to each other still plays a minor role, as it only influences the position of two parallel created objects on the print bed. These are usually made with sufficient spacing, while exact compliance does not affect print quality.

In cases 2 and 3, extruder calibration is very important. Since printing occurs in the same component, any offset of the extruders is immediately visible and noticeable on the print surface. Support material misalignment results in inadequate support functioning, causing unclean overhangs and concave horizontal surfaces. If different materials are used to print a single part, incorrect extruder calibration can lead to poor material bonding. There are also adverse effects on appearance and dimensional accuracy. The larger the print, the bigger the deviations, resulting in more sunk costs.

At the push of a button, the BigRep PRO measures printed test lines and uses them to calculate the relative positions of the extruders. In this way, measurement errors are avoided.

Extruders 1 and 2 create two patterns that are offset from each other. The sensor scans the printed structures and determines their distance. These values are now stored in the machine control system and are used to achieve maximum accuracy during dual extrusion. Once the calibration is complete, your BigRep PRO is ready for precise printing.

Get in touch with us to learn more!

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.