Carbon Fiber 3D Printing: How to 3D Print Strong Parts

Adding carbon fiber (CF) to filaments improves both strength and stiffness. The added strength and increased stiffness provided by the addition of CF leads to a better strength-to-weight ratio, achieving lighter, stronger parts with less printing time.

Read on below to see how carbon fiber can benefit your manufacturing business and learn about the unique properties of CF filaments.

What are Carbon Fiber Filaments?

Carbon fiber-reinforced plastics (CFRP) bring together the qualities and performance properties of carbon fiber with the polymer material they are reinforcing. Printability and ease of use of a standard thermoplastic like PLA, ABS, or PET gains superior performance properties by including carbon fiber content.

Chopped fibers are mostly used for industrial production and also 3D printing. These carbon fibers come as a "filler" material in thermoplastic materials for injection molding or as carbon fiber filaments to use in 3D printers. They can be processed like any other thermoplastic material. But they have extra requirements which will be explained later on.

FFF (extrusion-based) 3D printing uses chopped carbon fibers. These small fibers are then mixed into a standard thermoplastic as a reinforcing material.

Why do you need Carbon Fiber 3D Printing?

Industrial environments often demand specific mechanical properties and finely tuned precision. Fortunately, by bringing together the capabilities of a high-strength material and the many advantages of additive manufacturing, carbon fiber 3D printing offers exceptional dimensional stability in strong, stiff parts with a fine surface finish and a high heat deflection temperature - ideal for functional, high-performance applications.

With 3D printing moving ever deeper into end-use production, the ability to manufacture both parts and tooling using carbon fiber filaments is increasing in demand.

Whether using these materials in molds, jigs, fixtures, tooling or high-performance race cars, specialty aerospace equipment, or professional cycling equipment, carbon fiber 3D printer filament enables you to create the high-strength parts you need. Of course, as a relatively new offering in the manufacturing industry, carbon fiber 3D printing may have many pros, but it's also worth being aware of the printing requirements before you get started.

Pros of Carbon Fiber 3D Printing

The advantages of carbon fiber 3D printing come down to their performance properties:

High Strength

Perhaps the most-touted property of carbon fiber 3D printer filament, high strength is key to its performance — and desirability as a 3D printing material. Carbon fiber offers a strength-to-weight ratio that enables high performance with low density.

Dimensional Stability

By lessening the tendency for part shrinkage, carbon fiber's high strength and stiffness contribute to its excellent dimensional stability upon usage, essential for parts that require precise dimensions and tight tolerances.

Light Weight

Hand-in-hand with its strength is the light weight of a carbon fiber 3D printer filament. Light weights are a key advantage of 3D printing in general, and using carbon fiber materials enables that weight reduction without a loss of performance-grade strength.

High Heat Deflection Temperature

Compared to standard 3D printing materials like PLA, ABS, and PETG, carbon fiber filaments can withstand significantly higher temperatures. Carbon fiber composite materials — such as BigRep's PA12 CF — enhance the heat deflection temperature of the base material for better performance at elevated temperatures.

LESS POST-PROCESSING REQUIRED

CF filaments make layer lines less noticeable. This gives you better surface quality and haptics, reducing the need for any post-processing operations such as sanding.

Stiffness

3D-printed carbon fiber parts maintain their shape under high stress. In contrast with other materials that trade off strength and durability for stiffness, the rigidity possible with carbon fiber ensures structural integrity.

Requirements to Work with Carbon Fiber Filaments

Carbon fiber filament is more abrasive than many other materials and has specific heat requirements. As is typically the case with engineering-grade materials, they cannot simply be swapped out for standard 3D printer filament and be expected to print with the same settings.

Heated Print Bed

Hand-in-hand with an enclosed 3D printing environment is a heated print bed, which is crucial to ensure that the first print layer adheres to the print bed. Without this strong foundation, the success of the remaining print layers may be compromised.

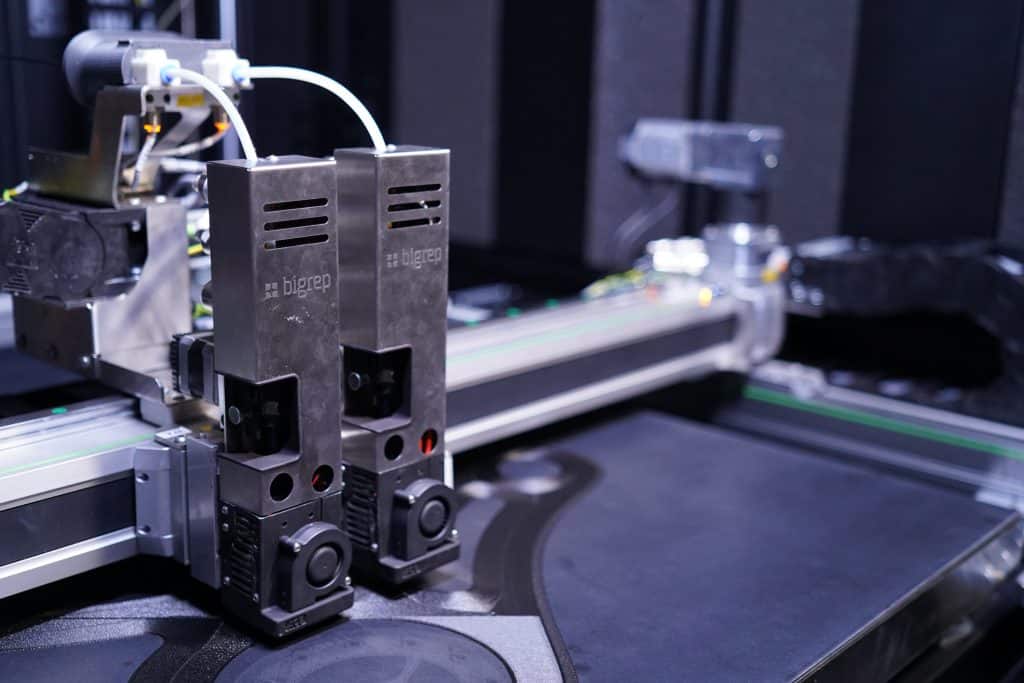

Hardened Nozzle

Over time — which can vary from one to a few print jobs — carbon fiber filament will wear down a standard 3D printing nozzle due to its abrasiveness. A brass nozzle, for example, will wear out when extruding these materials and will ultimately be rendered functionally useless. Hardened steel is a requirement for a 3D printer to handle CF filament.

Of course, designers, engineers, and operators working with any CF-inclusive project must all be well-trained in the requirements for working with carbon fiber filaments. Training and upskilling must be considered when considering bringing CF filaments into operations.

Print Orientation

The addition of CF increases tensile strength but when managed incorrectly it can lead to a reduction in layer adhesion. To compensate for the material's low ductility, orient the part in the direction of the stress or the load. This can be adjusted during the orientation of the part in a slicing software such as BLADE.

Where are CF Filaments used?

Carbon Fiber 3D printing is best put to use in manufacturing environments thanks to its high strength-to-weight ratio and overall stiffness. Among the primary uses for these materials are the creation of molds, jigs and fixtures, and tooling.

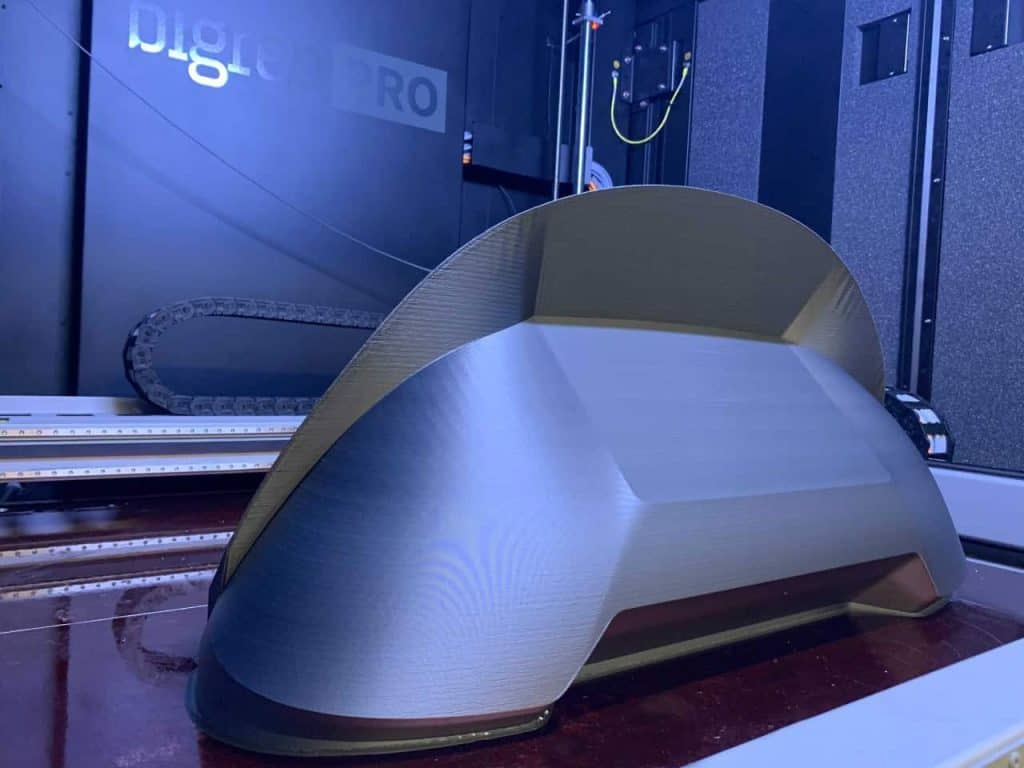

Composite Molds & Thermoforming Molds

3D printed molds are one of the most cohesive ways advanced and traditional manufacturing technologies work together in an industrial environment. 3D printed molds offer the complexities and speed of production of 3D printing to the mass production capabilities of mold-based manufacturing. When it comes to composite molds and thermoforming molds, the performance properties of CF materials are a natural fit.

Composite molds are one of the most common manufacturing methods to cost-effectively produce large batches of identical parts. As their name implies, composite molds are made using composite materials, which can be made in complex shapes and stand up to repeated use — all at a significantly lower cost than aluminum or steel molds.

Thermoforming molds use heat and pressure to shape a flat thermoplastic sheet into a form using conduction, convection, or radiant heating to warm the sheet before conforming it to the mold’s surface. Thermoforming molds must stand up to repeated high-heat usage, requiring specific performance capabilities that can be well delivered via CF materials.

Jigs & Fixtures, Tooling

Often viewed as supplemental to manufacturing processes — but vital in their own right — are jigs, fixtures, and tooling, using in milling, drilling, and other subtractive operations. Jigs and fixtures are used to hold specific parts in place throughout different stages of their manufacturing, and tooling is used throughout.

These all-important tools often perform best when customized to the application at hand and may be worn out through highly repetitive use. For these reasons, jigs, fixtures, and tooling are increasingly 3D printed on-site. They can be custom-fit to their specific need and reproduced on demand without outsourcing or waiting to be restocked.

When made of reinforced materials like CF filaments, 3D printed jigs and fixtures and tooling last longer and perform better — especially in terms of long-lasting durability. You can learn more about replacing high-cost CNC milling with agile, cost-saving solutions for low-volume production here.

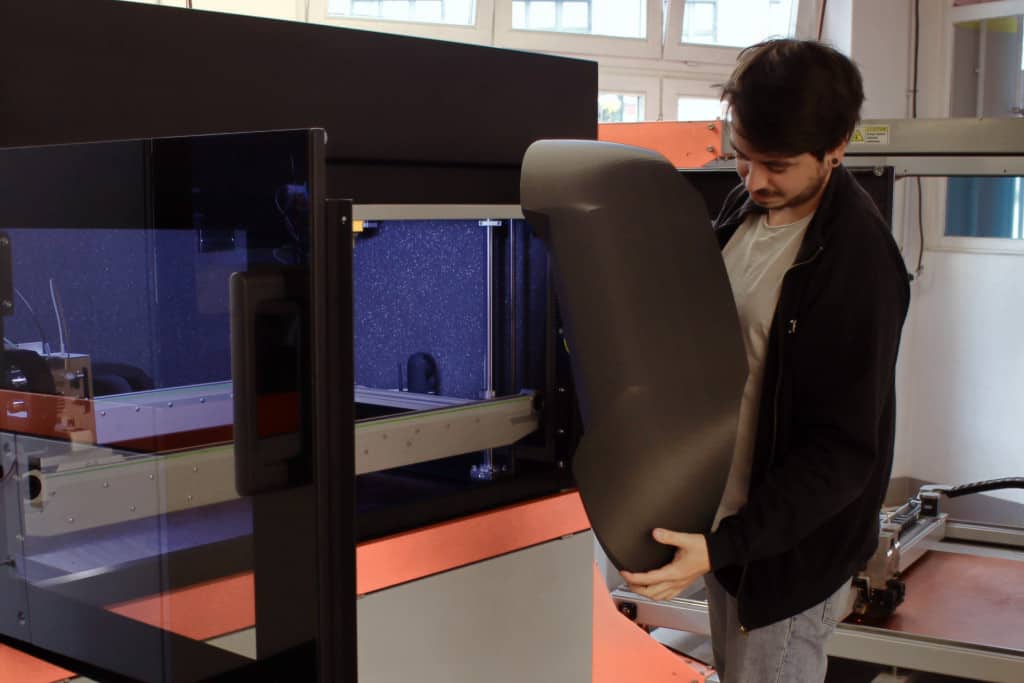

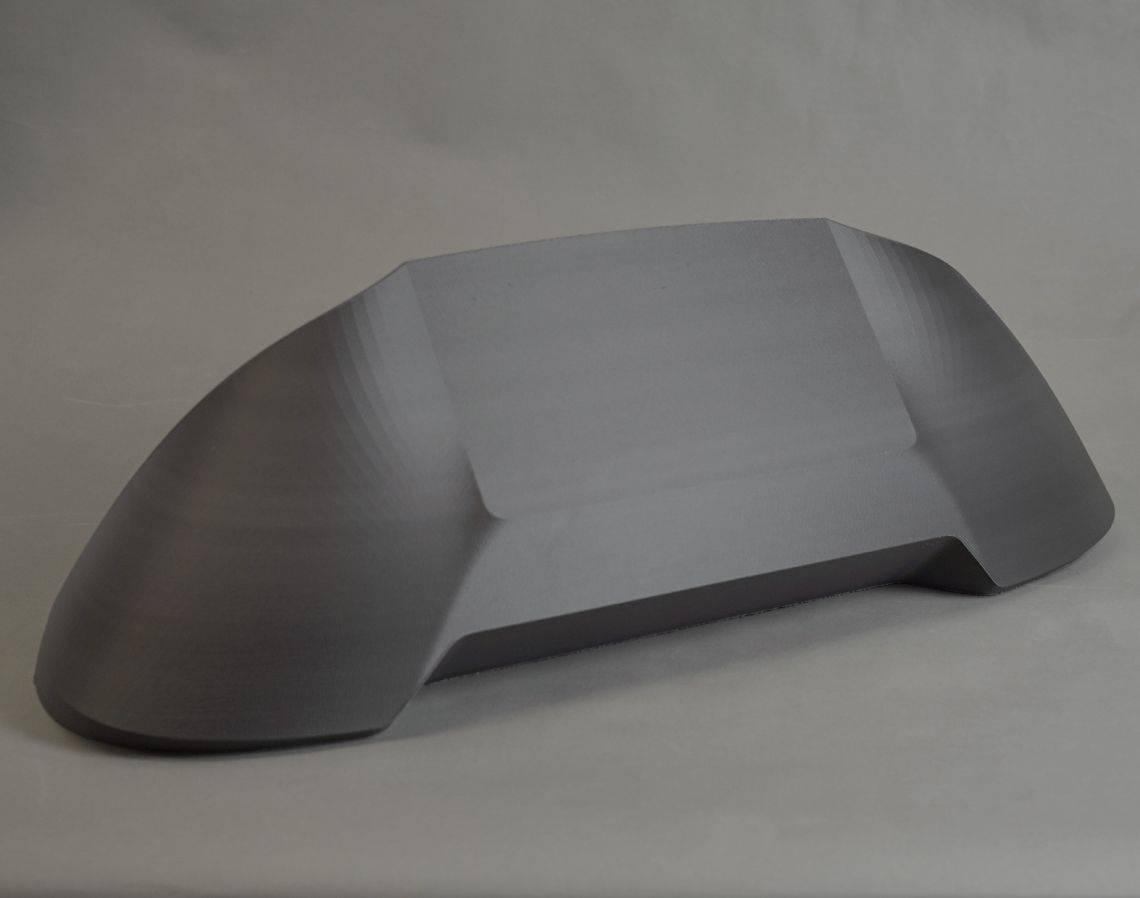

Automotive and Aerospace Industries

The design freedom of carbon fiber allows you to realize complex geometries that are not cost-effective with traditional methods. This design freedom enables you to rapidly iterate and then, due to its increased stiffness and temperature stability, create more functional prototypes. The enhanced aesthetics of the object, including complex curvature achieved with 3D printing and better surface quality with CF filaments, can open up innovation in automotive, aerospace, and other related industries.

BigRep PA12 CF and HI-TEMP CF

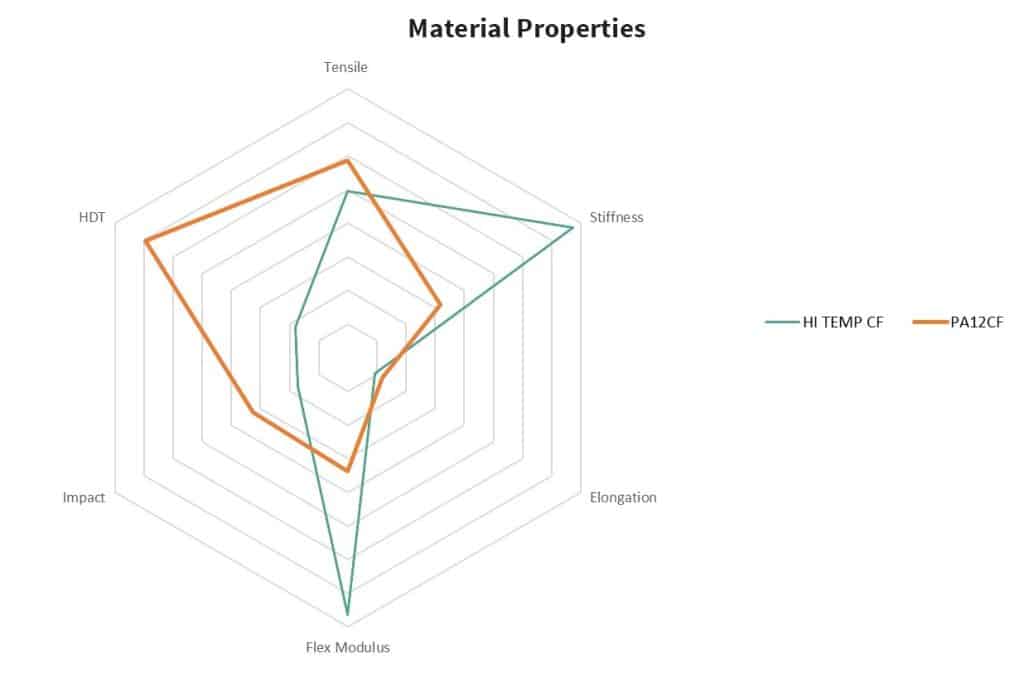

BigRep offers two carbon-filled filaments: PA12 CF, a nylon carbon fiber, and HI-TEMP CF, a bio-based, carbon fiber-filled polymer. The critical difference between these two carbon-filled filaments is that HI-TEMP CF has less demanding hardware requirements. HI-TEMP CF is applicable across multiple printers, including the ONE, the STUDIO, and the PRO, while PA12 CF is suited to industrial applications on the PRO.

If you want the best performance, then it's better to use a PA12 CF filament. PA12 CF possesses increased tensile strength, impact toughness, and heat deflection temperature, making it well suited to applications requiring superior durability and operational lifespan in challenging industrial environments.

The trade-off for HI-TEMP CF's higher stiffness, flexural strength, and less demanding printing requirements - compared to PA12 CF - is a slight reduction of impact toughness and heat deflection temperature. This makes it better suited to applications not exposed to impact but which maintain the need for dimensional stability under loading. This increased stiffness and flexural strength is provided by HI-TEMP CF.

No matter which filament you pick, taking advantage of the many benefits of carbon fiber-filled materials empowers you to increase the performance of your applications. Although specifically made for large-format printing on BigRep machines, these materials are compatible with most 2.85mm open printers with a hardened nozzle.

Conclusion

When you decide to take on carbon fiber 3D printing, you’re committing to an endeavor that requires significant attention to parameters and specialized equipment and requirements. When those conditions are fulfilled, you can produce best-in-class lightweight, durable, functional parts that can stand up to a variety of industrial uses with all the complexity in design that 3D printing has to offer. Get in touch with a BigRep expert today to learn how CF filaments can help to improve your production capabilities.

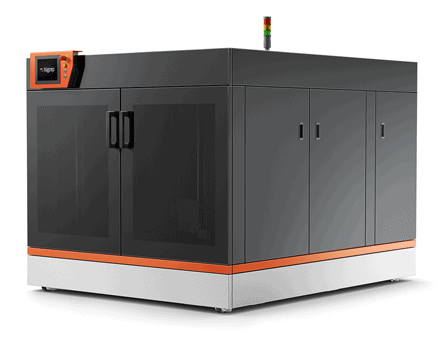

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.