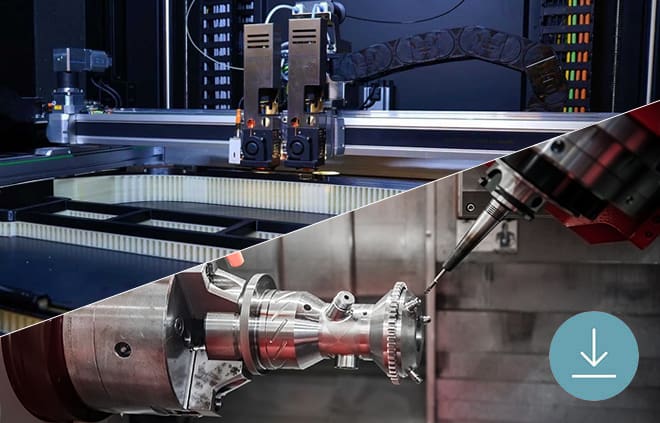

Subtractive manufacturing (computer numerical control, or CNC machining) has been one of the most preeminent manufacturing methods for the past several decades. Introduced in the 1940’s, subtractive manufacturing was used as a tool to machine highly complex parts that require optimal precision. Essentially, the process involves subtracting or cutting from a block of material to create an end product. Today, subtractive manufacturing comes in many different forms (milling, turning, laser cutting, wire EDM, and carving) and is used for a wide variety of prototyping, production and assembly line applications.

Additive manufacturing (3D printing or rapid prototyping) is a newer fabrication process, and is experiencing significant growth due to technology and material advancements. Introduced in the 1980’s as a tool for product developers to physically reproduce prototypes from their digital designs, 3D printing has become commonplace due to its speed, flexibility and cost advantages. Antithetical to subtractive manufacturing, AM deposits materials only where it is necessary on the build platform and typically does so layer-by-layer. AM comes in many different technology forms (FFF, SLA, DLP, MJF, etc.) and is capable of printing a plethora of polymer and metal materials.

Both technologies have their strengths and weaknesses when it comes to a product development and the manufacturing environment. There are certainly arguments to be made to determine which process is ideal for your business or application, but it’s important to note that these technologies are oftentimes complementary and can exist side-by-side. You can identify ways for these technologies to benefit your department by looking at several factors, such as business model, company maturity, design development or production process. For example, a machine shop will use CNC machining for voluminous production requirements and alternatively, use 3D printing to produce parts that are designed with advanced complexities or geometries that are just not possible with subtractive technology.

To better understand how your department can optimize current and new technologies, we have provided a brief guide to help discover which technology will provide the most benefit to your application. Subtractive and additive manufacturing is very broad so, for reference, this guide will compare general CNC machining vs. FFF thermoplastic 3D printing.

Prototyping

When to use subtractive manufacturing?

CNC machining equipment can be expensive and is typically reserved for production purposes. Due to setup time and operator oversight, CNC machining requires a more hands-on approach. However, if the equipment is available - subtractive technology is a viable option due to part precision and build tolerance. It’s an excellent piece of machinery but could be considered overkill due to the cost or time associated for setup.

When to use additive manufacturing?

3D printing was strategically designed for rapid prototyping because CNC equipment was either unavailable or too expensive to operate. Although some subtractive technologies are theoretically faster, additive manufacturing provides an advantage when it comes to design and cost efficiency requirements. Many product developers will create several iterations of a prototype and print them overnight for review the next day. In addition, the cost is significantly lower than subtractive manufacturing—especially when it comes to revisions.

It’s always important to compare speed, quality and cost. While the act of fabrication with CNC is faster than AM, set up time is an important consideration and holistically, will take longer compared to 3D printing. It’s possible to argue that subtractive manufacturing may produce higher tolerance parts (not always the case), but additive manufacturing is certainly the ideal choice when it comes to cost and multiple revisions. And let’s face it—no one gets their prototype perfect the first time. Check Mark Prototyping.

| Subtractive Manufacturing | Additive Manufacturing | |

| Speed to Build | ||

| Quality of Build | ||

| Cost Effectiveness | ||

| Overall |

Production

When to use subtractive manufacturing?

As previously mentioned, subtractive manufacturing technologies such as CNC are predominantly used for voluminous production. Setting up a CNC machine requires collecting stock, writing G-code, tooling and post processing so the labor time is longer compared to AM. However, once the machine is operational, it is considerably faster and part size will no longer be a factor. It’s always important to consider the breakeven cost point when it comes to technology comparison, but for the most part, CNC is a great tool for production purposes.

When to use additive manufacturing?

Material advancements in AM have led to fascinating production applications with many companies operating in the automotive, aerospace and consumer product markets. For example, the aviation industry has adopted 3D printing to print lighter weight frames, doors and brackets that capitalizes on the advantages of selective material deposition. These advantages enable the production of highly complex designs that are traditionally not possible with CNC. Customized components and short run production requests are also possible with 3D printing. However, the major limitation for high volume production with 3D printing remains to be the cost per part.

If you are looking for assistance to determine which technology is right for your production application, we recommend benchmarking your part for a cost and time analysis. This is common in the marketplace, and will help you better understand the technological and economical benefits associated with either subtractive or additive manufacturing.There are many factors such as size, quantity, time, materials and post processing that need to be accounted for and we suggest contacting the experts.

Intangibles

What is the intrinsic value of subtractive manufacturing?

Next to injection molding, subtractive machining is the most cost effective mass production technology in the industrial world. It’s been a tried-and-true method for generations. There isn’t a machine shop or service manufacturer that doesn’t either operate or outsource subtractive manufacturing for production purposes. It’s commonality within industry means that it is easier to find technically competent resources. Just by sheer volume, subtractive manufacturing is inherently more accessible.

What are the advanced benefits of additive manufacturing?

The limitless design freedom available with AM is unparalleled to any other fabrication technology. The ability to strategically deposit material and design with support structures breaths life to innovation and engineering possibilities. Working gears, complex airflow channels, lightweighting with honeycomb structures and many more applications are possible with additive manufacturing. It enables engineers to think outside the traditional box of machining and identify new ways to produce better and higher performing parts.

Conclusion

One size does not fit all when it comes to fabrication technologies. Injection molding and CNC machining have been the most cost effective mass production methods available to industry, while 3D printing adoption has grown significantly within the past decade. Amongst other variables, it’s important to compare size, quantity, functionality and purpose to establish what makes the most sense for you.

If you address these questions by industry, you may want to consider the following: The consumer product industry is experiencing massive growth with personalized footwear, accessories and electronics with the use of 3D printing. The automotive and transportation markets have invested significant time and resources to identify large format 3D printers that can replace bonding, welding and tooling requirements necessary on the production floor. Custom AM materials with superior mechanical properties have led to major advancements in biomedical and healthcare approved medical devices and applications. What industry are you in?

Want to Learn More About 3D Printing vs CNC Milling?

CNC has been the backbone of manufacturing for decades. While more recently, additive manufacturing has started to gain traction. Learn about the strengths and weaknesses of both manufacturing methods in terms of cost, materials, lead times, and more. Don't miss out, read the eBook here: