With a wide range of industrial 3D printers available in the market, evaluating machines for your production floor that fulfill your manufacturing needs entails considerable factors. Understanding your 3D print applications, the space it would need, the conditions to house the machine in, material and software requirements, and the budget are some of the important parameters to take into account before investing in the machine.

To filter down the vast array of industrial 3D printers available in the market, we deep dive into the top 7 questions to consider while buying a large-format industrial 3D printer.

1. What Applications Would You Use the 3D Printer for?

The first question to ask yourself is - what do you want to 3D print and why?

This question lays the groundwork to help you create a list of the applications the machine can be used for and in which part of the production line it can be implemented.

For example, if you are looking to print prototypes, will they be for functional roles like performance testing and fit checks or are they geared toward design approval? Similarly, for tooling applications, would the printed tools be deployed on the production line or used for specialized tasks like CMM inspection? If 3D printing end-use parts, what would the operating environment be like, and the requisite tolerances?

The next question is the dimensions – how big are the parts you intend to 3D print?

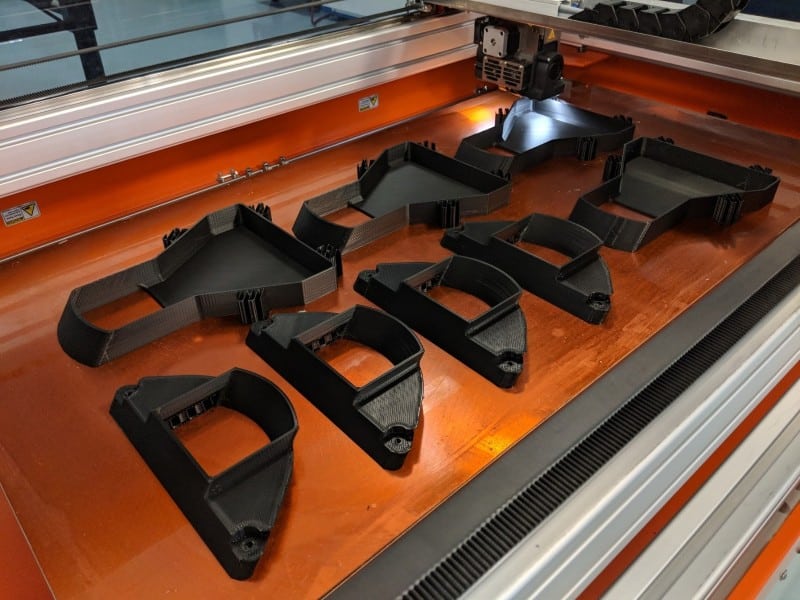

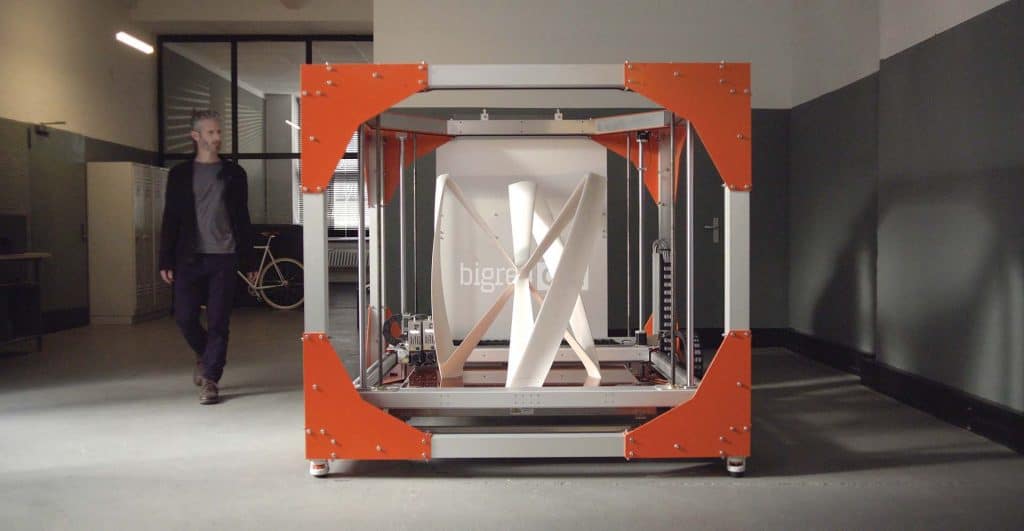

The key advantage of a large-format 3D printer is its capability to produce sizable components or batch print smaller parts in a single print job. Smaller printers face a limitation where they cannot accommodate large parts within a single print session, requiring the assembly of individual components post-printing.

In practice, the applications of 3D printing extend across almost all industries. AM can cut tooling costs and reduce lead times, especially for manufacturing industries by maintaining a digital inventory and manufacturing on-demand. It can reduce external dependency and minimize logistics by printing lightweight, strong, and ergonomic jigs and fixtures in-house. In the vehicle after-market customization sector, it can manufacture individualized 3D printed parts and patterns and also molds for a variety of components. For the aerospace industry, it’s used extensively to build low-volume MRO tools that meet the highest standards and certification set by the tightly regulated sector.

2. Which are the 3D Print Materials You Would Use?

The next aspect to consider would be whether you prefer a restricted or open material system. Closed material 3D printers restrict you to using only the printer's proprietary products, while open systems, like BigRep’s machines, allow you the freedom to use any compatible 3rd party filaments. Closed material 3D printers restrict you to using only the printer's proprietary products, while open material systems, like BigRep’s machines, allow you the freedom to use any compatible 3rd party filaments.

When choosing a filament, consider mechanical properties such as surface quality, sustainability, ease of use, printing speed, post-processing requirements, UV, temperature, and chemical resistance, as well as strength, stiffness, and flexibility. BigRep offers a comprehensive range of industrial-grade 3D printer filaments, from cost-effective materials to high-performance options tailored for demanding applications.

To set you up for success with every 3D print, we have profiles for all BigRep filaments. These material profiles have been meticulously created by our experts and are optimized for BigRep’s machines. They streamline your printing process by eliminating the need for you to manually adjust settings such as print temperature, bed temperature, print speed, layer height, and so on for each material. Just select the relevant material profile and hit print, and you are set up for optimal printing results.

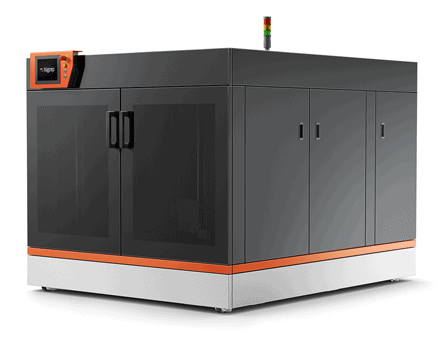

3. What is the Space, Ventilation, and Electricity Requirements for the 3D Printer?

Evaluate the available space for the large-build volume 3D printer on your production floor. With dimensions ranging from x 1950 y 2500 z 2105 mm / x 77 y 98 z 83 inches (with tower) for our largest machine, BigRep PRO to x 1715 y 1170 z 1765 mm (x 67 y 46 z 69 inches) for the smaller BigRep STUDIO, our printers are suitable for different spaces, including shop floors, labs, and offices.

The environmental conditions you are housing the 3D printer also play an important role. Factors such as humidity levels, airborne particles from nearby equipment, and also the storage condition of the 3D printing filament can significantly impact print quality. For enclosed lab environments, an open-frame system may suffice, but climate-controlled rooms might be necessary for more demanding conditions.

Given the high power consumption of industrial 3D printers, you must also consider the electrical requirements of large-format 3D printers. Make sure there’s sufficient electrical output while deciding the printer's location on the production floor. BigRep’s machines have relatively lower power consumption as compared to other industrial 3D print machines in the market. The BigRep STUDIO and ONE can run with standard power outlets while our biggest machine, the BigRep PRO, needs an industrial power socket.

4. Which 3D Print Software Would You Use?

Nearly every 3D printer manufacturer offers its proprietary software for setting up and slicing parts, but some companies embrace an open-source approach, allowing you to select your preferred slicing software. You might opt to stick with familiar software or use the pre-loaded profiles and settings from the printer manufacturer.

When assessing software options, consider the expertise level of the people operating the machine. Whether experienced or newbie operators, some systems demand more technical proficiency, while others, like the BigRep’s, are more plug-and-play. Regardless of the printer, opting for software installation and training from your provider helps you learn the optimal settings, part orientation, and materials for successful prints.

With BigRep’s 3D printers, we have an open-source approach where you can use external software or our suite of intelligent solutions. With our software—FLOW, BLADE, and CONNECT, you have complete oversight from design to print monitoring.

FLOW is customizable software that makes application engineering for 3D-printed jigs, fixtures, and manufacturing aids easier than ever. No design skills or 3D printing experience are required.

BLADE is an easy-to-use slicing software that allows for greater control of printing parameters on all BigRep large-format additive manufacturing systems.

CONNECT is a one-stop platform connecting you with your BigRep printers to boost productivity with remote monitoring and data analytics.

5. Does Your 3D Printer Provider Deliver Local Support?

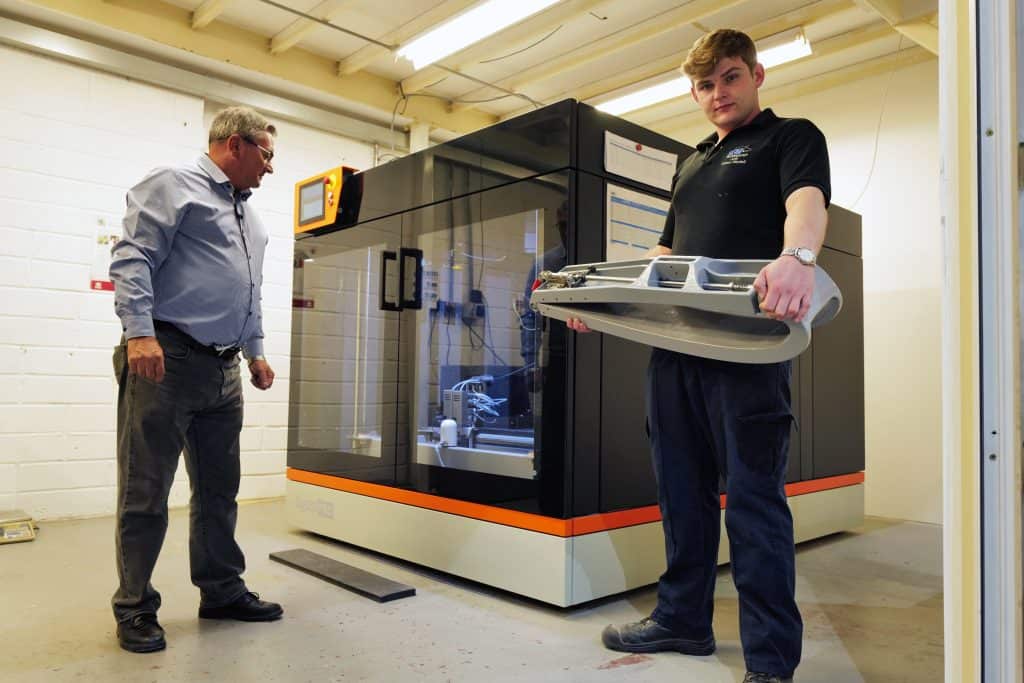

Having local support is often an invaluable asset to any business embracing 3D printing. Ask for references, talk to customers who are using the printers, and understand their experience working with the company and if the level of service meets or exceeds your expectations. When you invest in an industrial large-format 3D printer, you expect the level of support to match the price tag of the printer.

BigRep provides local support through our global and regional headquarters (Berlin, Boston, and Singapore), as well as a network of reseller partners around the globe. We offer three levels of support beyond our standard on-demand service, so your 3D printer is tuned for optimal performance and has minimum downtime.

Our support options include access to:

1. A knowledge base for 24/7 troubleshooting through the BigRep HUB

2. On-demand service with an online ticket system for additional support

3. Service contracts for scheduled maintenance to prevent issues and ensure your peace of mind

6. Does Your 3D Printer Provider have eLearning and Training Resources?

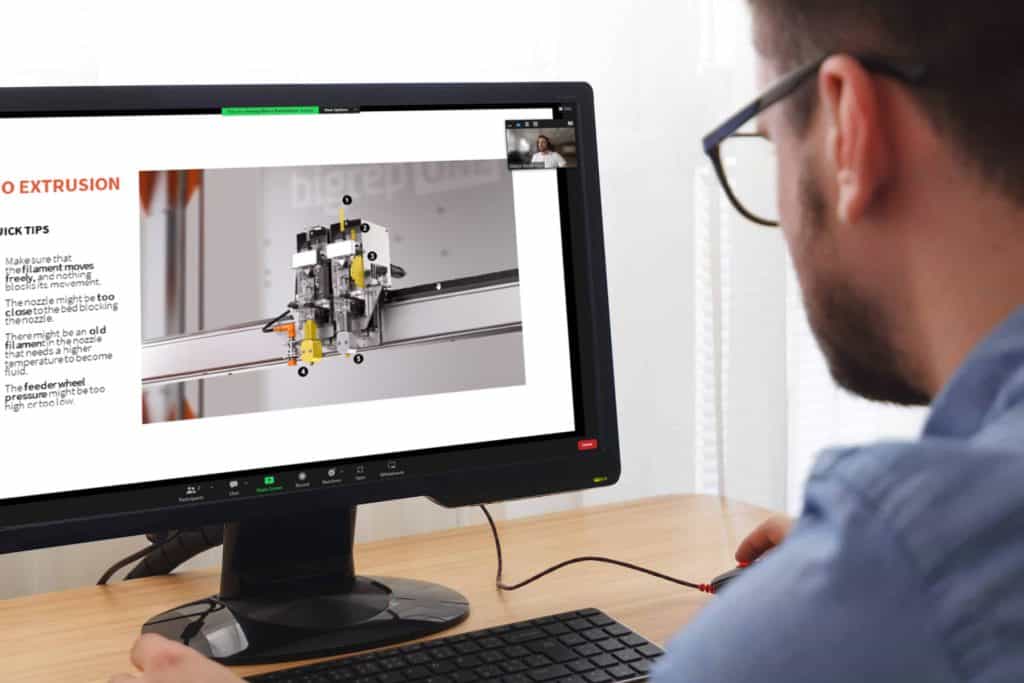

If you are new to 3D printing and want to learn more about the machine or are a seasoned operator trying to troubleshoot an issue, where would you start? While the internet has a wealth of information, it may lack the specifics to train you on the intricacies of a particular industrial 3D printer. If your 3D printer provider has eLearning courses, hands-on training, and learning resources, it can significantly improve your knowledge and ability to efficiently operate a 3D printer, troubleshoot issues, and maximize its capabilities.

BigRep's eLearning platform, Academy, offers comprehensive courses from fundamentals to expert-level, spanning all aspects of large-format 3D printing. Whether you're delving into design, slicing, printer operation, troubleshooting, or beyond, the platform has you covered. For specific projects and topics, we provide custom training through remote conferencing or in-person sessions where a BigRep expert will guide you through the course while giving you real-time feedback.

Advanced and custom courses can be hosted in the BigRep offices if you prefer to learn hands-on with the machine. For your company’s on-site training, experts from the BigRep Academy can also come to your location.

7. What’s Your Budget?

We recommend taking the time to develop an ROI calculation while budgeting for a large-format 3D printer and truly assess every aspect of the purchase. How expensive is the annual service contract? If you find less expensive materials, does the 3D printer have an open materials system that can run it? Is safeguarding intellectual property a consideration? Will the printer be reliable enough to become profitable for your business?

Bringing manufacturing capabilities in-house gives you more control and flexibility in the design and production process, potentially resulting in significant cost savings over time. A reliable 3D printer can deliver consistent performance, minimize operational costs, and adapt to evolving manufacturing needs offering a lifetime value.

Often BigRep customers realize a positive ROI more quickly than they expected. Industrial giants like Ford Motor Company found their investment in a BigRep additive system returned in less than a financial quarter. “After two or three successful prints, the BigRep printer was already paid for,” said Lars Bognar, a research engineer at Ford.

Go BIG with Industrial 3D Printers

By integrating 3D printers into your production workflows, you can explore new applications and make the most of your investment. The latest versions of industrial printers are much more affordable and offer intuitive user experiences making it easier than ever to adapt AM technologies on the factory floor.

With a line-up of large-format industrial printers, engineering-grade materials, intelligent software, an eLearning platform and exceptional customer service, BigRep offers a holistic ecosystem that enables a wide range of professional applications. If you’re ready to leverage 3D printing in your business, get in touch with our experts and find the right BigRep 3D printer for your needs today.

Want to learn more about how Industry Giants made Instant Returns on Investment with BigRep 3D Printers?

Register to download the eBook, 7 Was BigRep 3D Printers Unlock Profit Instantly

Find out how industry-leading companies such as Ford and Steelcase implemented BigRep’s 3D printing systems and unlocked unprecedented efficiency and cost savings.

Read this large-format additive guide to find out:

- How BigRep printers reduce traditional lead times by up to 94%

- Why moving manufacturing processes in-house secures production timelines

- How industry giants have made a return on investment from just one application

- Why any business can earn fast returns from large-format’s flexible manufacturing