Would a self-assembled large-format 3D printer be worth the price tag savings?

The answer depends on a variety of factors.

The reality is there are an array of options when choosing a 3D printer, and the right system for you is going to depend on several factors, ranging from your knowledge of 3D printers, budget, and what you want to accomplish with the printer.

How much experience do you have working with 3D printers? Are you comfortably knowledgeable of every component? Can you troubleshoot most problems yourself or do you often depend on services? Even if you can troubleshoot your own printer, how large is your margin for error?

In the right situation, self-assembled 3D printers can be an affordable option. Highly experienced users who understand 3D printer construction, maintenance, and modification with a wealth of time to build and troubleshoot their new 3D printer can make use of self-assembled offerings. Unfortunately, DIY 3D printers are too often treated as a cost-saving solution and purchased without fully understanding the expertise and time they’ll likely require.

It’s important to understand what each offering includes, and weigh them against your expectations. So, in this article we’ll go over 4 key considerations when deciding if a self-assembled (DIY) 3D printer is right for you, and why we believe premium offerings like BigRep’s 3D printers are a better choice.

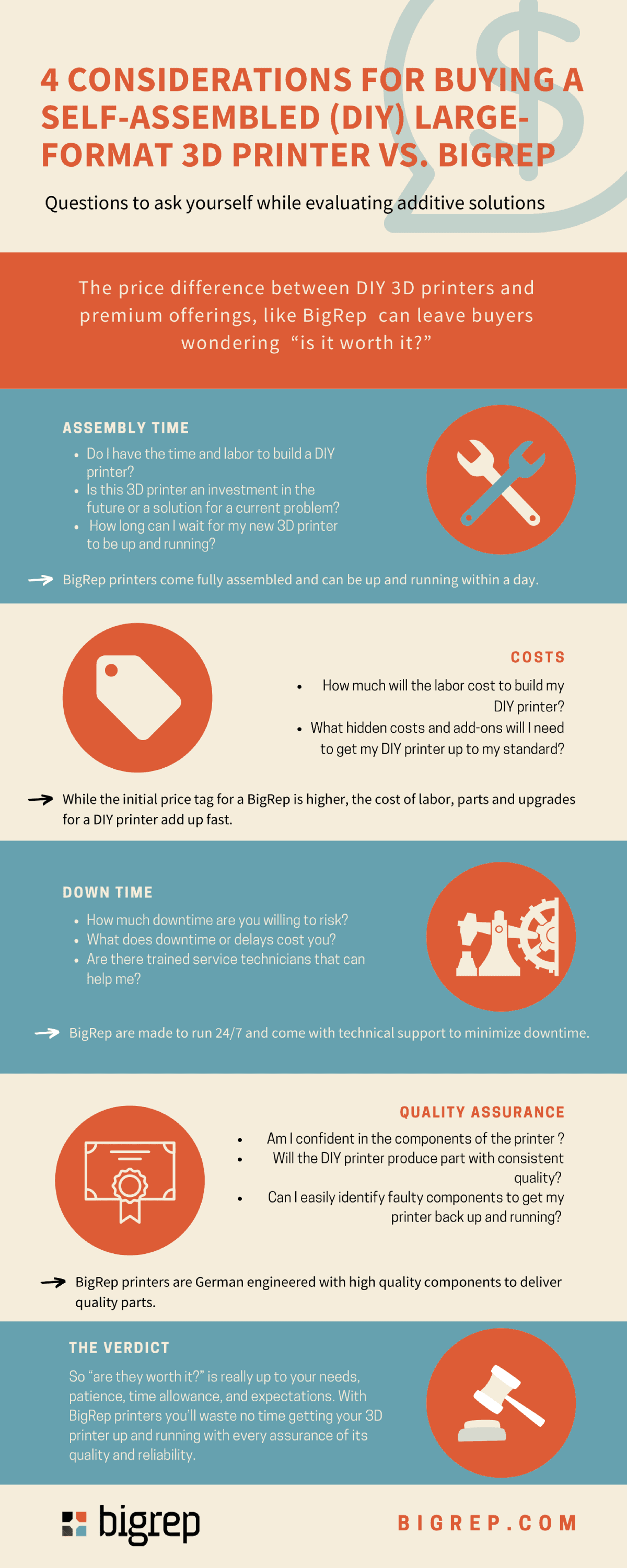

Assembly Time

Time is money and your time is extremely valuable. Assembly is one of the clearest reasons to buy a premium 3D printer, so we’ll get it out of the way first.

Many businesses invest in technologies like 3D printers with specific goals in mind. They may want to reduce the lead time on parts and tooling or decrease outsourcing expenditures. Others may need a resource for agile product development to create prototypes on demand. It’s important to consider when you want to start progressing through these goals if you’re considering a self-assembled 3D printer.

Just assembling a DIY 3D printer takes time. How much time exactly will vary from user to user depending on pre-existing knowledge and clear instructions and labeling but could take a few days up to a month or more depending on labor availability, parts and any issues that could arise.

Additive manufacturing requires high precision to function effectively. Even small imperfections – in the wrong place – can render a part useless for many applications. During self-assembly it’s easy to misalign or mistakenly construct a printer that can cause excess vibrations or other inaccuracies during operation. Experienced users may know how to troubleshoot and repair these issues if they aren’t simply the result of low-quality hardware. Less experienced users may be unable to properly assemble their new 3D printer at all. In this case, and if the manufacturer doesn’t offer onsite servicing, you would need to hire a technician for assembly – likely bridging the cost gap. Either situation, requires significant time investment to ensure a system is operating properly.

With premium 3D printers like offerings from BigRep, a highly skilled technician can install your system onsite and validate its performance in as little as one day. They’ll introduce you to your new printer, train you on typical 3D printer troubleshooting, and help you to understand large-format best practices. Better yet, should unexpected problems arise, a BigRep service technician can come onsite or through a virtual service call to remedy the problem and ensure as little productivity is lost as possible.

Costs

At first glance, the price of a DIY system might seem too good to pass up. However, what many don’t realize is the price you see for many self-assembly 3D printers are “barebone” packages. These price points offer the most basic system, and a few upgrades are usually required to bring the system to an industrial standard.

Barebone systems are typically packaged en masse straight out of an affordable manufacturer, usually in China, and come with hardware of minimal quality – depending on the specific offer. If you don’t purchase upgrades before assembly, it’s likely that you’ll feel the need to once you’re using the system regularly.

When choosing upgrades, integrations are important features to pay mind. Is your build volume’s heating integrated with the 3D printer control board? If not, you might have to manually switch the heating off before the print bed can cool down. Limitations like this can severely restrict the flexibility of large-format 3D printing, like running prints overnight.

Aside from these big quality of life upgrades, there are a lot of smaller parts – like ware components – where quality will be very important.

Industrial 3D printers come fully equipped so they are ready to perform out of the box, no upgrade costs required. So yes the price tag will be more but it also comes with the assurance there are no hidden costs or components needed to bring it up to an industrial standard for printing.

Down Time

You purchase a printer to do a job. So when the printer is down, it effects the bottom line. Most users will compare a 3D printer’s key components out the gate and upgrade self-assembly systems where they feel necessary – hot ends, filament detection, and control systems are common in the first pass. While easier to ignore, it’s essential to also examine the quality of ware components. Check various gears, bearings, and straps for quality.

All moving parts are essential to replace early on cheaper systems to ensure consistency and reliability throughout operation. Low-quality parts will ware much faster than premium industrial parts or otherwise require additional intervention when compared to parts and systems that come standard with premium industrial 3D printers like BigRep’s.

Experienced users will either upgrade low-quality moving parts from the start or when they’re skilled troubleshooters, replace them as needed. It may be difficult for less experienced users to locate these smaller components when they begin to fail and overlooking these parts can lead to serious downtime and lost business if you’re not prepared.

Keep in mind that cost-cutting doesn’t stop with the quality of a system’s parts: many DIY 3D printer manufacturers maintain their low prices by offering limited support or none at all; meaning you’ll need to hire a third-party technician if you can’t fix it yourself. That’s not a slight against the companies, their systems are made to be routinely customized and upgraded by users with extensive 3D printer knowledge and familiarity. However, given to less experienced users or placed in demanding industrial environments these concessions could mean large maintenance down times and easily bridge premium cost.

Quality Assurance

You buy a printer to produce parts – prototypes, jigs, fixtures, molds or end use parts. One expectation when producing them is that they will meet your quality expectation. The quality of parts coming off your 3D printer will be directly determined by the quality of your printer in many ways. In most cases this will be obvious parts – high-quality control boards or gantries will be pivotal to high-quality parts. Even upgrading these core components can eliminate your initial savings from many self-assembled 3D printers, but it’s important that you consider the overall quality of the system you’re purchasing.

In the wrong place even a degraded nut or bolt can lead to excess vibrations that heavily impact your production quality. While replacements for these flawed support components may be very affordable, they can be far more difficult to identify as the source of a problem. In industrial settings, those issues directly impact future revenues.

Mass manufacturing is all about cost efficiency, so many DIY 3D printer manufacturers will take advantage of these hidden concessions so they can compete better with visible features. Unfortunately, even these small components have a significant impact of the quality of your parts. If your business will be negatively impacted by reduced print quality or printer downtime, it’s vital that you consider your supplier’s commitment to their product over its lifetime. A robust service offering like BigRep’s shows that corners won’t be cut on manufacturing and assembly so your business can operate smoothly with consistent quality.

Conclusion

So the question “are they worth it?” is really up to your needs, time allowance, and expectations. If you have a dedicated technician who wants to know their machine inside and out, modify heavily, has endless time and is confident they can handle all servicing, a DIY 3D printer may be an option for you – even in large-scale. However, without the right staff, available labor, and 3D printing knowledge, they have the potential to cause more problems than they’re worth.

With an industrial large-format 3D printer like one of BigRep’s, uncertainties are taken out of the equation. Our products are carefully designed to balance cost with the performance and long-term reliability expected by industrial users. With German-engineered and validated systems installed onsite by a specialized technician, you’ll waste no time getting your 3D printer up and running with every assurance of its quality and reliability.

Not sure which solution is best for you? Talk to one of our experts and we’ll help you uncover which type of 3D printer could help you.