Sichert, a 100-year-old Berlin-based company, integrates smart multi-tasking features into their fiber connection cabinets with the high-temp, large-volume 3D printer, the IPSO 105.

FTTH (Fiber To The Home), the future of high-speed internet in every household and company, is basically the connection where the fiber cable goes all the way to the user instead of ending at an anonymous cabinet down the street.

These outdoor cabinets (FCC), although unassuming, are a critical component in present-day telecommunication. They are designed to take on the rigors of the harshest weather conditions while ensuring seamless IT infrastructure by housing servers, networking equipment, and other essential hardware. They are equal parts of form, fit, and function while blending in with the spaces in which they are installed.

Sichert, a 100-year-old Berlin-based company, is an industry leader in producing outdoor cabinets, access chambers for fiber optic, and copper cable distribution. With innovation at the core of their offerings, 3D printing has been an integral part of their workflow for decades. While the company relied on desktop 3D printers and outsourced print projects, as their needs got bigger, they sought to invest in an in-house solution to innovate with sizable high-performance parts.

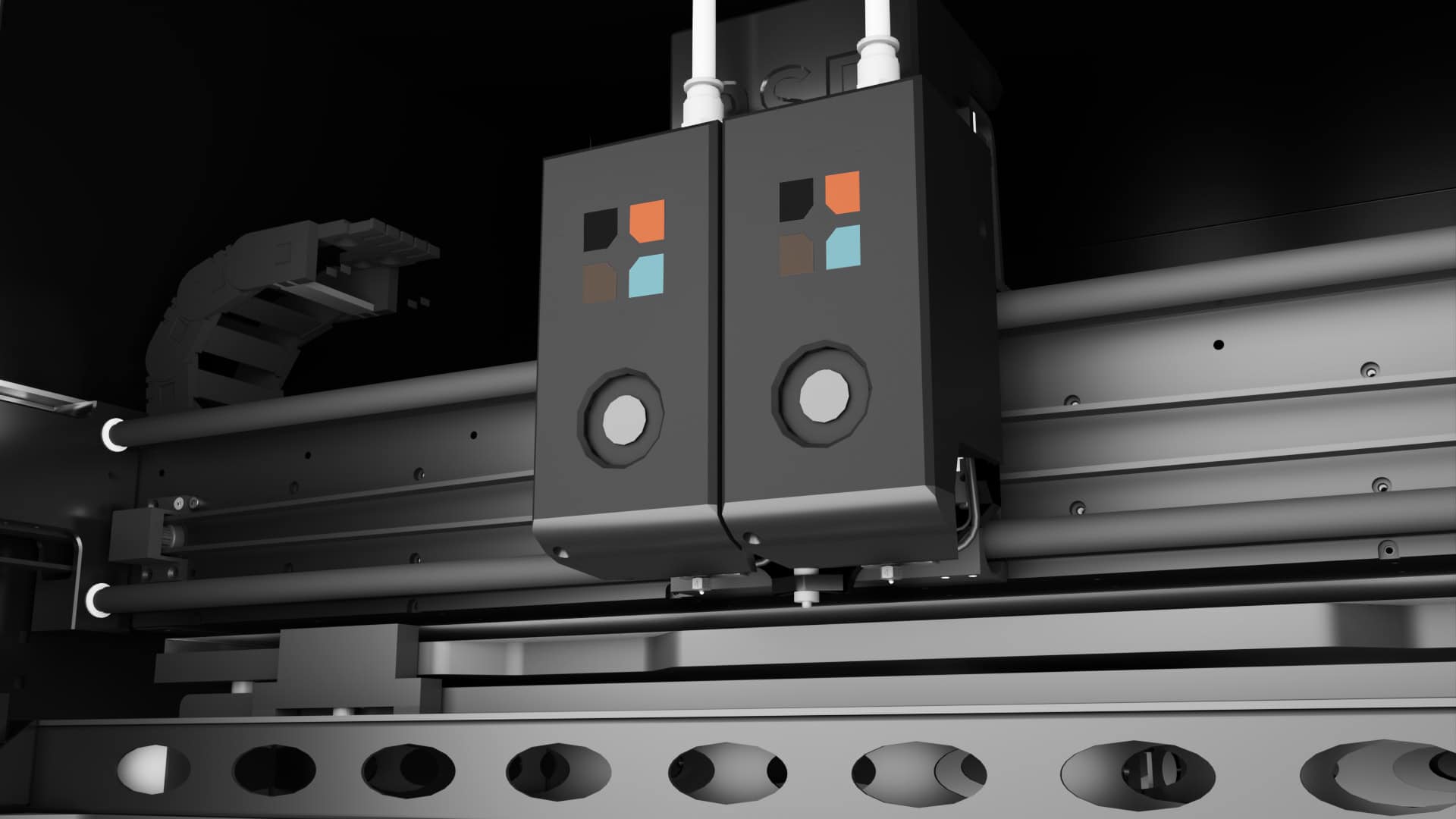

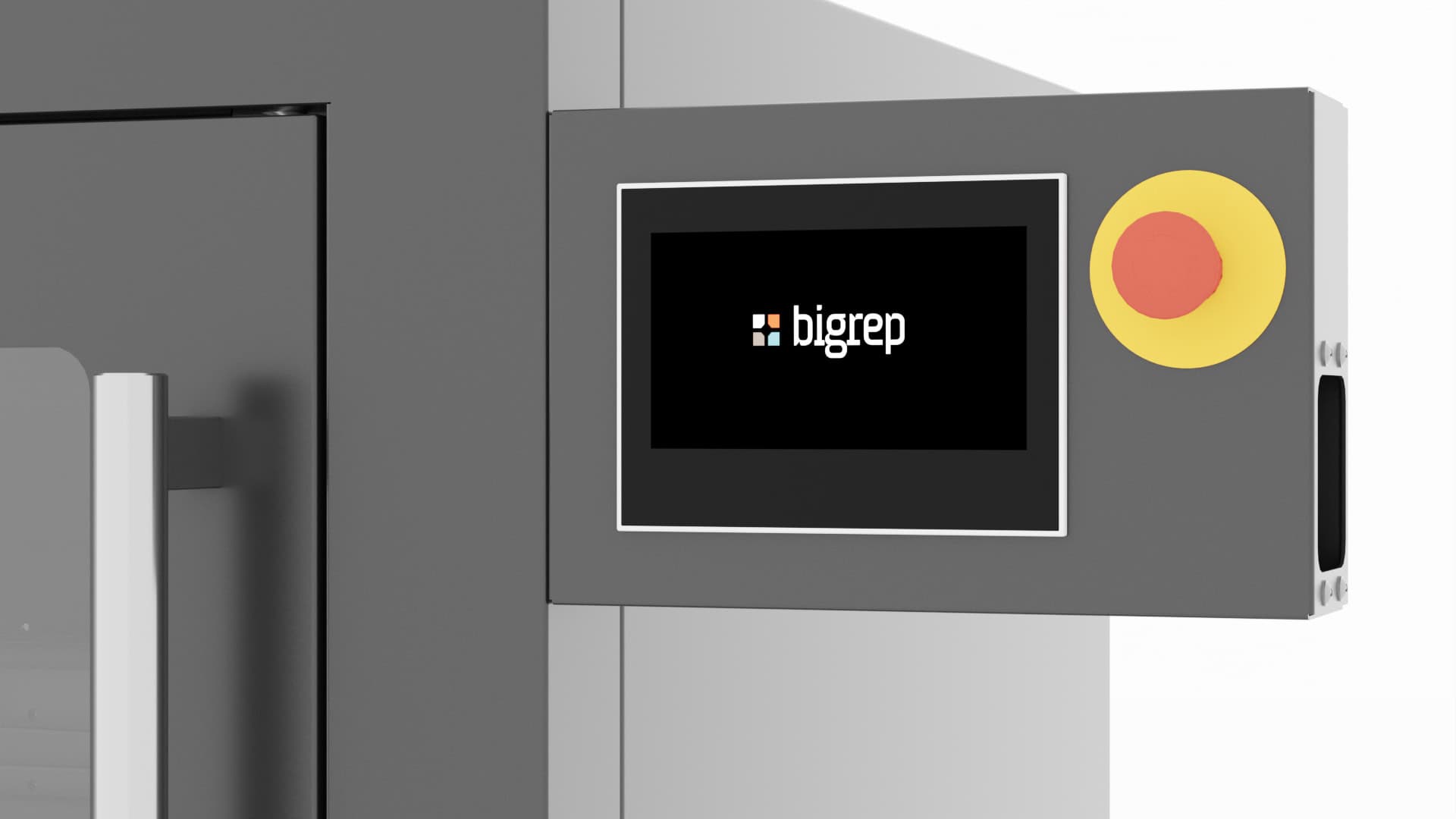

Sichert added a new player to its FFF 3D printing capabilities - the BigRep IPSO 105 - a high-temperature 3D printer, for rapid prototyping and future-proofing their products. With the 3D printer, they design cabinets that visually match their surroundings, upgrade the aesthetics, and integrate thoughtful multi-tasking features that offer smart city solutions.

What are Fiber Connection Cabinets (FCC)?

Fiber Connection Cabinets (FCC) are specialized industrial cabinets used in telecommunications to manage and distribute fiber optic cables that extend directly to households, providing high-speed internet and data services. Their core function is to also protect cables from environmental and physical damage, facilitate splicing and termination, and ensure easy access for maintenance.

Traditionally made using expensive injection molding, parts of FCCs are now increasingly produced with 3D printing technology, allowing for rapid prototyping, cost efficiency, and greater design flexibility. This supports the growing demand for reliable and scalable fiber optic connections, essential for connecting households and businesses to the gigabit age.

Challenges with Traditional Manufacturing

1. High Cost of Prototyping

Injection molding needs expensive molds which resulted in high-cost prototyping

2. Design Limitations

Metal and mold designs restrict the freedom to experiment with cutting-edge designs and structures.

3. Material Constraints

Limited range of materials that can be used, especially when it comes to high-temperature and environmentally resistant applications.

“One of the biggest challenges in developing new street cabinets is that prototypes are really expensive because of injection molding. This is where the IPSO 105 brings in the advantages - prototyping, rapid prototyping, or even small iterations. It's very fast, simple and cost-effective.”

Benefits of a Large-Scale High-Temp 3D Printer

Sichert initially used desktop 3D printers to explore the potential of additive manufacturing by printing parts of outdoor cabinets. Encouraged by flexibility and cost savings, they upgraded to the IPSO 105, BigRep’s large-format high-performance 3D printer.

SCALING UP WITH THE HIGH-PERFORMANCE BIGREP IPSO 105

Large-Scale Innovation

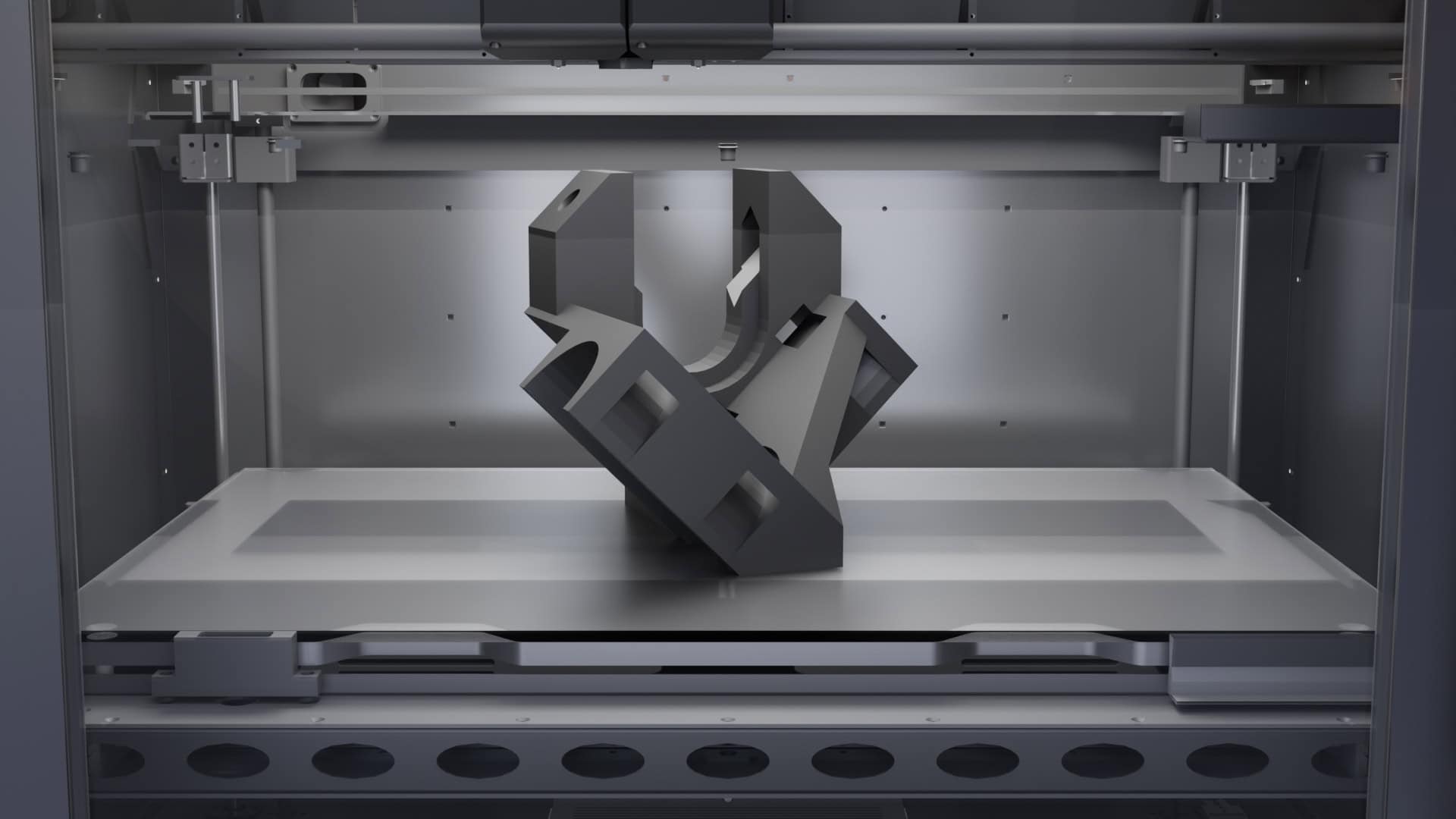

The generous build volume of 400 mm x 600 mm x 440 ensures Sichert’s design freedom to experiment with complex structures in full-scale.

High-Temperature Applications

With the build chamber heating to 100°C, the print bed reaching 180°C, & the extruder capability of 450°C,Sichert can print high-performance parts.

Open Material Platform

Capable of printing with virtually any compatible material, especially environmentally resistant filaments, is a game-changer for Sichert's R&D team.

High Cost and Time Savings

The 3D printer, IPSO 105, reduced prototyping costs and accelerated the product development cycle with quick turnaround print time.

Sichert’s Applications with the IPSO 105

1. Product Development

a. Smart Bench

Sichert designed an aesthetically pleasing outdoor fiber-cabinet bench with future cities in mind. It is fitted with a solar panel at the back, a phone charger to the side, and a fiber distribution cabinet within the bench. The 3D-printed parts were post-processed to give it a natural wood finish so it blends into environments where grey cabinets might stand out.

b. Smart Tower

Sichert’s Smart Tower was built to house 5G small cell (a small wireless device that boosts mobile network coverage and speed in busy areas), with the side panels 3D printed for flexibility in shape and design. Built to be installed in public places, it can also double as an information point in spaces such as bus or tram stops.

2. Rapid Prototyping and Design Testing

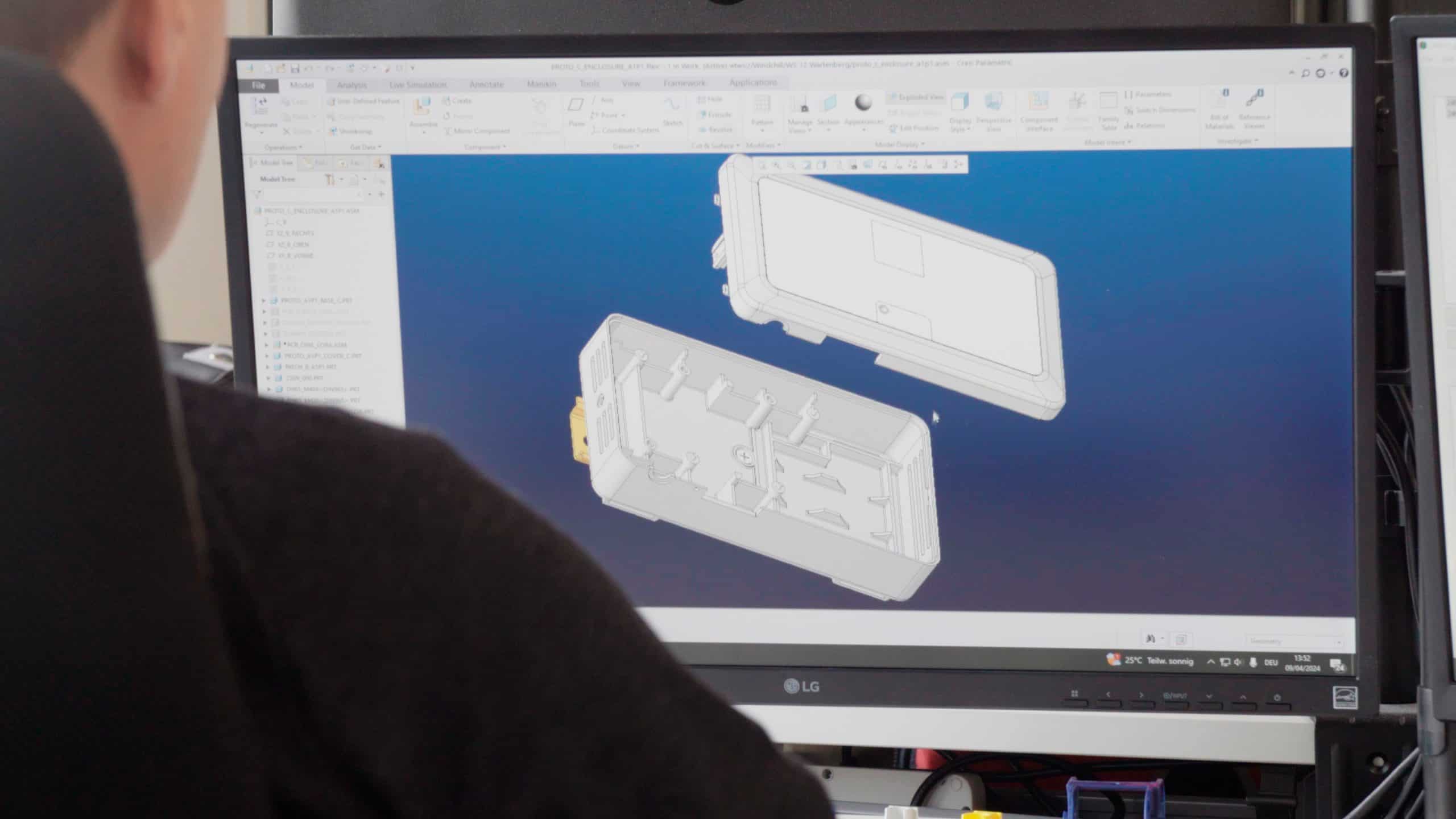

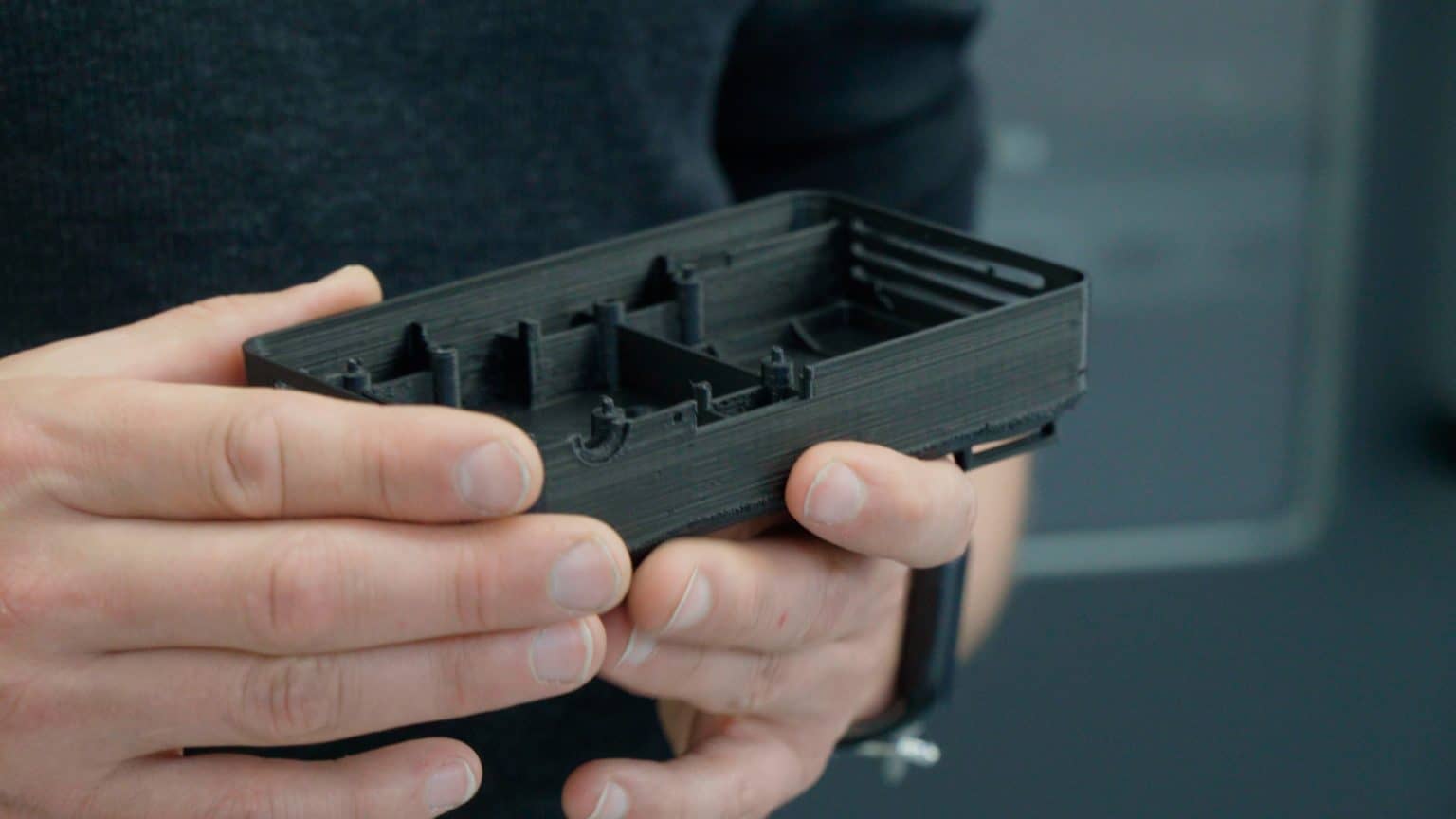

Rapid prototyping is one of the areas in which Sichert uses the 3D printer extensively, especially for all their new products, FCC cabinet series, and predominantly for their out-of-the-box designs. Prototypes of PCBs (printed circuit board) and cabinet parts are often printed and tested for tolerance, design fit checks, and stability. The printer’s capability to handle large parts without the need to cut and reassemble them ensures structural integrity and saves time.

3. Material Testing and Validation

The IPSO 105’s open material system which allows for printing with any compatible 3D print filament enabled Sichert to test a range of 3D print materials like BigRep’s environmentally resistant ASA, high-strength Polyamide with carbon fibers, and the durable Polycarbonate filament. This ensured the final part met all environmental and operational requirements.

“The IPSO 105 gives us the freedom to choose any material range from low to advanced materials like PEEK which we use in high-temperature use cases. We used to face challenges in picking the right materials which meet specific needs and with this 3D printer, we can explore our options.”

4. Trade Fair Samples

Sichert often takes part in trade shows and showcasing high-quality, visually appealing prototypes are an integral part of keeping the industry updated with their latest offerings. These 3D-printed parts are post-processed with varnish or undergo structural reinforcing treatments to give potential customers a realistic idea of what the final product would look and feel like.

Future-Proofing Outdoor Cabinets

The freedom to print in true scale, unlimited choice of material, high to low-temperature capabilities, and cost and time efficiency delivered by the 3D printer have enabled Sichert to expand the functionality and experiment with the design of their fiber cabinets.

With the IPSO 105, Sichert not only weatherproofs but also future proofs their outdoor cabinets by making them smarter and ahead of their time.

Want to learn how Industries are expediting Product Development with 3D Printing?

Reduce Cost and Lead Time with Industrial 3D Printing in Product Development.

Design Prototypes for Industrial Production

- Prototyping design iterations is faster and easier as part of a seamless digital workflow

- Get better-informed feedback regarding part fit, function, aesthetics, and more with full-scale prototypes

- Accelerate time to market with 3D printed prototypes produced in a fraction of the time

Maximum Performance. Unbeatable Price.

The IPSO 105 is an industry all-rounder high-temp machine with an unbeatable price-to-performance ratio. It is the most automated, reliable, and fastest way to get robust, high-performance parts in the hands of industrial engineers and designers. Aptly called the tool maker's tool, it is a blazing hot machine of 105 liters reaching 100°C with a print bed heating up to 180°C.

Maximum Performance. Unbeatable Price.

The IPSO 105 is an industry all-rounder high-temp machine with an unbeatable price-to-performance ratio. It is the most automated, reliable, and fastest way to get robust, high-performance parts in the hands of industrial engineers and designers. Aptly called the tool maker's tool, it is a blazing hot machine of 105 liters reaching 100°C with a print bed heating up to 180°C.