Vacuum forming has been used for nearly a century to make many of the products we see and use daily. From grocery store items to car parts, vacuum formed components are all around us. But how are they made - and how is 3D printing making them better?

What is Vacuum Forming & Thermoforming?

Vacuum forming is a type of thermoforming: heat used to form a design. Thermoforming processes include vacuum forming, pressure forming, and twin sheet forming. Each of these processes uses a mold or molds to shape heated sheets of plastic into the desired form.

Pressure forming methods require that the plastic sheet be pressed between two molds and then heated to assume the shape. In twin sheet forming, two plastic sheets are heated and fused together to form double-walled or hollow parts.

Vacuum forming is the simplest of the thermoforming methods, using only one mold at a time. As the name might indicate, vacuum forming relies on a vacuum, as suction applied to the heated plastic sheet will draw it around the mold to create the appropriate contouring.

How Does Vacuum Forming Work?

The vacuum forming process comprises a few relatively straightforward steps:

- Clamp a plastic sheet in a frame

- Heat the plastic sheet to the point the plastic is workable - soft enough to take on a new shape, but not heated to the point of melting or losing its integrity.

- Apply vacuum to pull the plastic around the mold, shaping the heated sheet to the desired contours.

- Allow the plastic to cool before removing from the mold. This may be expedited for large pieces, using fans or cool mists.

- Trim excess plastic and smooth edges to final part quality.

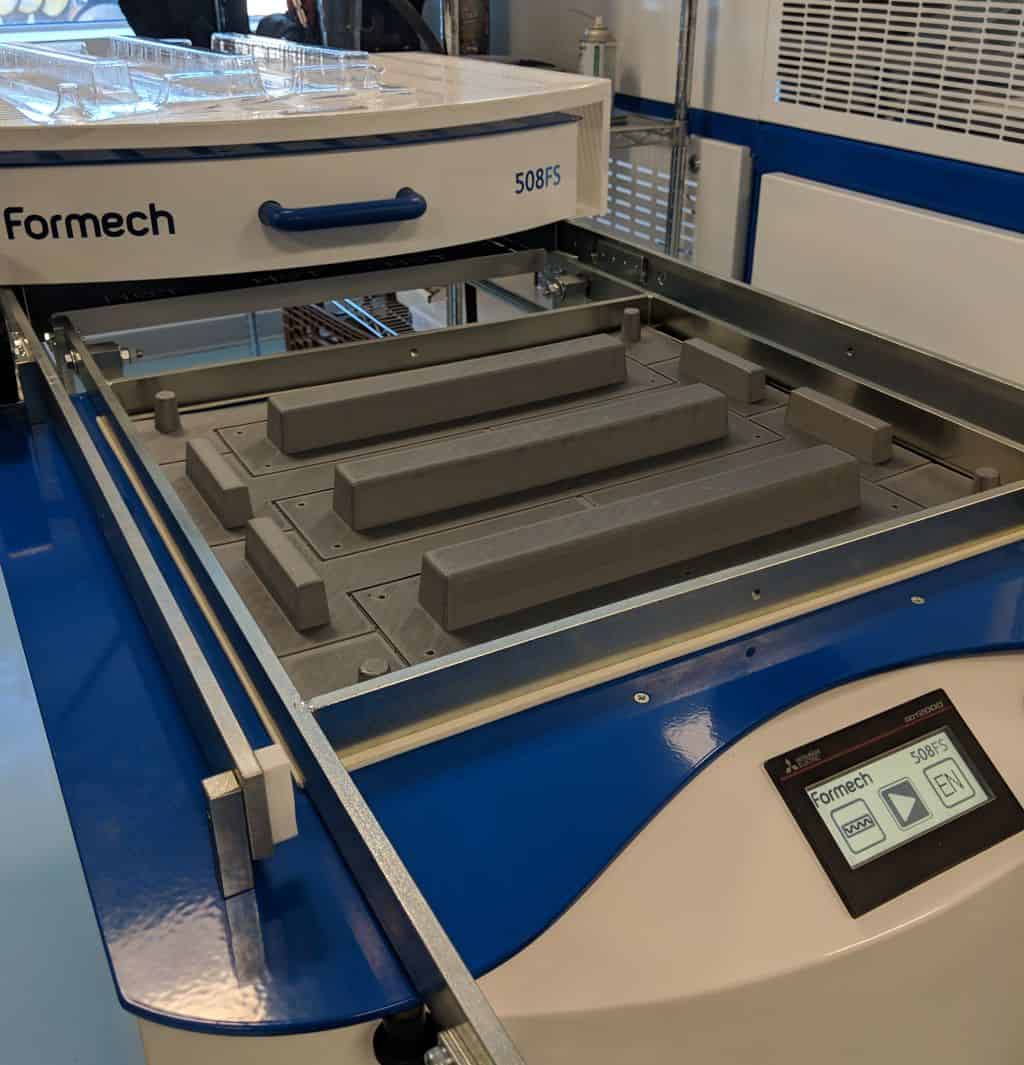

See how the process works on a Formech vacuum forming machine:

Types of Plastic for Vacuum Forming

The ultimate result of a successful vacuum forming operation is creating a shaped plastic part. But what type of plastic should be used? That depends on what you want from the product; different plastics are applicable for different uses. For a clear plastic salad box, you wouldn’t need the same high impact strength as you would for an outdoor sign, for example, while a car bumper needs still more durability.

When choosing a plastic, considerations that should come into play include:

- Strength

- Rigidity

- Chemical/impact/UV resistance

- Specific gravity

- Formability

- Colours

- Hygroscopicity

- Temperature range for pliability

- Availability/cost

Further, you’ll need to take into account the look and feel of the plastic for the end-use application you have in mind. A strong plastic may not be usable if it offgasses volatile organic compounds (VOCs) when subjected to high temperatures, for instance.

Among the most popular plastics used in vacuum forming are:

- ABS - acrylonitrile butadiene styrene)

- Acrylic - PMMA - Poly(methyl methacrylate)

- HDPE - high density polyethylene

- HIPS - high impact polystyrene

- PC - polycarbonate

- PET - polyethylene terephthalate

- PETG - polyethylene terephthalate glycol

- PP - polypropylene

- PS - polystyrene

- PVC - polyvinyl chloride

Each option has its pros and cons. As with any end-use material choice, you’ll need to weigh the cost and ease-of-working of a given material with its strength and performance.

How to Create Molds for Vacuum Forming

The molds used for vacuum forming are critical to the process: they form the basis of the actual shape for the end product. How you choose to create your molds will depend on the precision, complexity, and timing of your project.

While wood, aluminium, and structural foam are among the conventional options for mold making, 3D printed molds are becoming more popular. These newer options enable more complex geometries to be made and can significantly speed up the process of mold making.

3D Printed Molds

The benefits of 3D printing are many. 3D printing can reduce the time and costs needed to make items like vacuum forming molds, as well as improve the geometric complexities possible. Faster turnaround and lower costs can be a major incentive when it comes to adopting a new way to create molds, forms, and rapid tooling.

In-house 3D printing can substantially shorten timelines when it comes to producing new molds and tooling. Without the need to outsource mold production, wait for turnaround is limited only to how fast a 3D printer can bring a CAD design to life - which can be as short as a matter of hours. Only the material needed to produce a given design need be used, eliminating waste and additional material costs. Furthermore, small features - think textures or even text - can be added without increasing the cost of a design. Customization and rapid prototyping of designs are also big benefits, getting unique designs to customers who need them quickly and for lower cost.

Working with the right 3D printing equipment is of course key to producing the best results. Industrial equipment offers professional quality, as well as the opportunity to work with heat-resistant materials like carbon fiber 3D printing filament. Furthermore, large-format 3D printers enable faster production of either large parts or several small parts in a single build job.

Wood, Aluminium and Structural Foam Molds

Traditional vacuum forming molds are formed by subtractive processes, such as carved wood or structural foam, or by metal casting processes. While each of these processes when leveraged appropriately will produce workable molds, their use is subject to the wait times of casting and high costs of milling.

Wooden molds are well-known to be durable for vacuum forming. Strong wood choices can lead to molds that can be used for hundreds, if not thousands, of vacuum forming runs. Eventually, though, most wood molds will splinter or warp. The best usage of wooden molds is when little detail is required or a thicker mold is desirable.

Cast aluminum molds are among the most durable types, best-suited for scale production of 100,000+ parts. Costs of both material and production -- which can take up to a few months -- make aluminum molds infeasible for shorter production runs.

Structural foam molds are durable and can also be used for larger production runs. These molds are lightweight yet extremely durable, and are often a lower-cost alternative to aluminum options. Many plastics are viable, as a chemical blowing agent is used to makes the plastic’s internal walls thicker for longer-lasting molds.

Applications for Vacuum Forming

Vacuum forming is often used to create parts we interact with every day. Lightweight packaging, securely fit coffee cup lids, and car parts are just a few of the places we often encounter vacuum formed parts.

Aerospace

Aerospace applications for vacuum forming can range from specialty packaging to keep tools in one place to massive parts. Cabin components like large bulkhead dividers and seating needs like arm rests, footwell trays, seat backs, and tray tables are increasingly produced via vacuum forming.

Automotive

In the automotive industry, both internal and external components are often vacuum formed. From relatively small cabin structures like the grate on an air conditioning vent to a full bumper, shaped plastics help to shape our automotive experiences.

Packaging

Salad containers or sushi boxes, razor packaging, and sterilized medical device packages are just a few of the packaging uses for vacuum forming. The plastic sheets used in this process can be shaped to precisely house a premium product or made more generally to hold whatever we need to carry.

Consumer Goods

Toys, musical instrument cases, helmets, luggage, barware -- you name it and the plastics we use every day often come about through vacuum forming. From the outer housing on a bicycle helmet to the body of an RC car, vacuum formed products keep us all rolling.

Conclusion

When it comes to vacuum forming, the sky is the limit. Heated plastic can be exactly shaped to match a custom mold for one or thousands of parts. When the molds are 3D printed, they can be made with more complexity, more detail, more options -- and less cost.

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.

GRADUATE FROM DESKTOP. GET INDUSTRIAL.

The BigRep STUDIO G2 gets 3D printing off your desk and takes it to the next level. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact “fits everywhere” build.