“Made like a Swiss watch,” says Daniel Broglie, CEO of Chromos AG to us when we call for a chat. “Right on time, 2PM!” It’s immediately reflective of the value the Swiss CEO – and indeed, perhaps Swiss businesses more broadly – place on precision and timing. As Broglie explains, Swiss companies across industries put huge emphasis on being the best in their field.

They tend to have strong research and development foundations and a lot of companies are highly specialized in what they do – they’re proudly niche, specialized. There’s the material competence, combined with the fact that many of companies do highly specialized tooling for automotive and other core traditional industries. Broglie explains of Swiss industry, “On the one hand, we have to think about production. But on the other side, we have to be thinking about how we can adapt for future success.”

With its beginnings as a 2D printer supplier and ink distributor, the Zurich-based Chromos AG may not have seemed like a clear contender to be a leader in the Swiss 3D printing field. Though it was the company’s philosophy of helping customers to transform their businesses that had them put on their large 3D glasses, so to say.

“We help our customers to find new ways of working – to move from conventional ways of working into the future. It’s not just the printing or the hardware, it has to do with change,” said Broglie. It is this deep knowledge about the ways businesses can shift, strong partnership network and a robust contact base across Switzerland, that formed the basis for a powerhouse cooperation in the field of additive manufacturing.

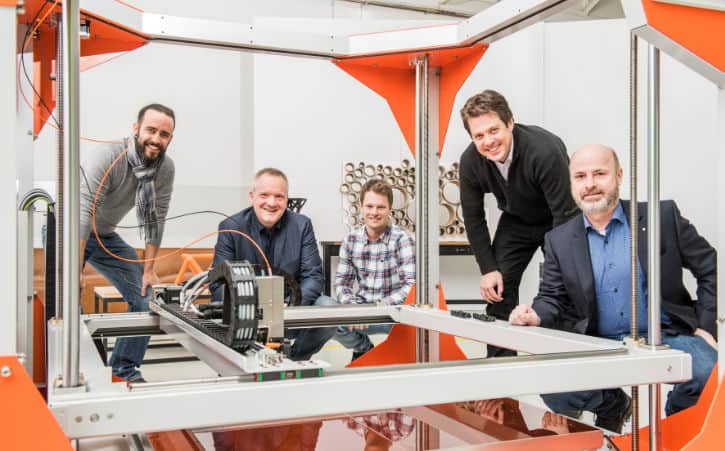

Chromos AG has a history with Bern-based 3D printing experts Form AG, as supplier for them. It turned out the two companies had a mutual interest in BigRep machines and were brought together by BigRep’s Sales Director EMEA & LATAM, Ingolf Nachtigall. They decided to cooperate – finding Form’s strength in applications and using the machines, to be a good fit with Chromos’ customer consulting, sales and after-sales experience (provided by service division Imsag). “We were convinced that this is a really perfect match,” said Broglie. “We can benefit from each other and learn.”

Chromos AG and Form AG have gone on to found Plattform3, which is a 3D-printing-focused venture to consult Swiss companies on using large-scale BigRep technology to improve their production. Form AG is a pioneer of new technologies in a range of fields, including 3D modelling. Recently they worked on a fascinating advertisement project for the Samsung SSD 850 Pro internal storage device, in which they designed the Samsung Robot ‘Victo’ (watch the robo-battle ad here) and also printed a full-scale example of it on the BigRep ONE.

Stefan Ingold, CEO of Form AG, is thrilled with the partnership with Chromos and BigRep and believes it can further convince Swiss companies that it is crucial to engage with large-scale 3D printing technologies as soon as possible. “Ensure your finger is on the pulse, and benefit from the sheer unlimited possibilities of 3D printing,” said Ingold. “3D is also about implementing visions: using technology to develop something unprecedented, exploring new horizons, reinventing oneself, and surprising and inspiring customers.”

Education is a big part of this, because additive manufacturing technologies are an investment for the long run, not a fad. Many Swiss industries are listening closely, but perhaps just not yet sold on the benefits for their business. BigRep is a proud partner with Chromos AG, Form AG and their Plattform3 in this process. “BigRep shares cool applications, and if this helps our industries to see the potential, then that is a great thing,” said Broglie of BigRep’s resources, such as blog articles, videos and use case e-books. “We feel BigRep really wants to understand what customers are doing. We like their partnership approach as well.”