LARGE-SCALE INNOVATION.

LIMITLESS CREATIVITY.

An intuitive user interface on the touch panel PC lets you access helpful features such as remote load, check print progress via webcam, change print parameters, resume print after a power failure, and many more.

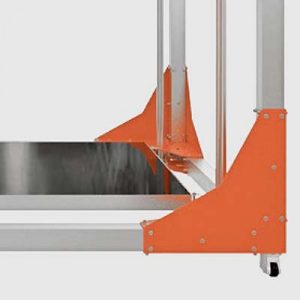

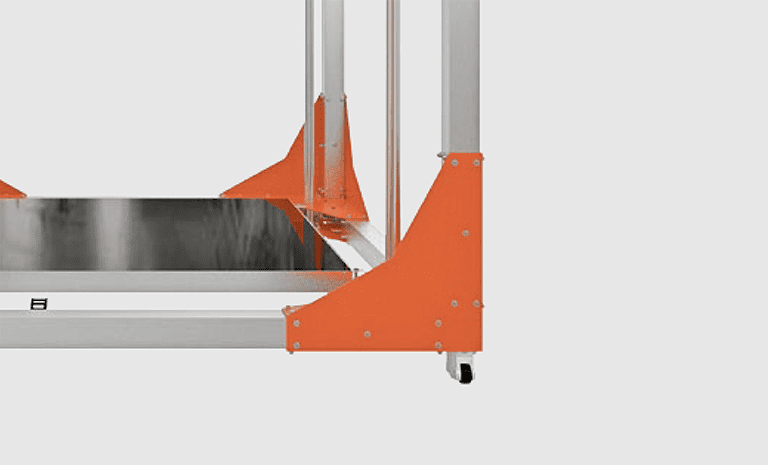

THE FRAME CONSTRUCTION

The open design ensures unobstructed print monitoring and easy access to the print bed. Check the print quality and progress at any time with access to the print bed from three sides. The optional Enclosure Add-On ensures a constant printing environment and provides CE-compliant operator protection.

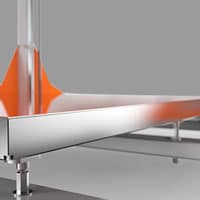

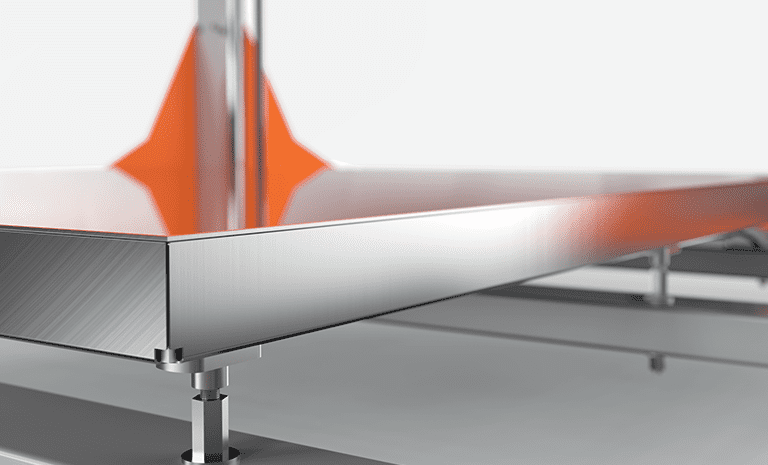

THE PRINT BED

The heated print bed is coated with a polyimide foil that provides optimal adhesion throughout the printing process. Thanks to an integrated inductive sensor, the ONE uses semi-automatic print bed leveling to streamline build platform calibration and ensure peak performance and consistent prints.

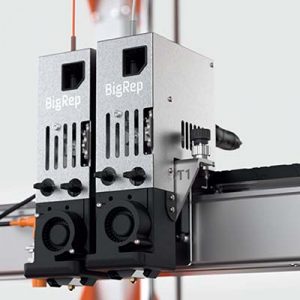

THE FIBER-READY POWER EXTRUDER

BigRep’s fiber-ready Power Extruder (PEX) is available for single or dual extrusion on the BigRep ONE. It consistently produces high-quality, full-scale parts in a range of BigRep filaments such as bio-polymers, water-soluble support, and fiber-reinforced, as well as third-party materials. Featuring interchangeable 0.6, 1.0 and 2.0 mm nozzles for maximum detail or high-flow additive manufacturing, the BigRep Power Extruder is a flexible solution for a variety of applications

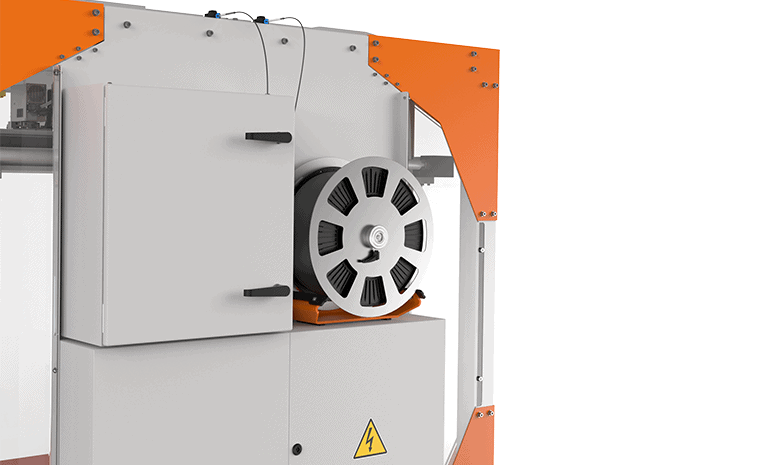

THE FILAMENT ENCLOSURE

The newly designed filament enclosure ensures optimal material handling and fits all standard spool sizes, including two spools up to 8 kg. An out-of-filament sensor pauses printing so you can replace the empty spool, which is particularly useful for very large prints. The Keep Dry Box Add-On protects the filament from moisture and dust.

LARGE-SCALE INNOVATION.

LIMITLESS CREATIVITY.

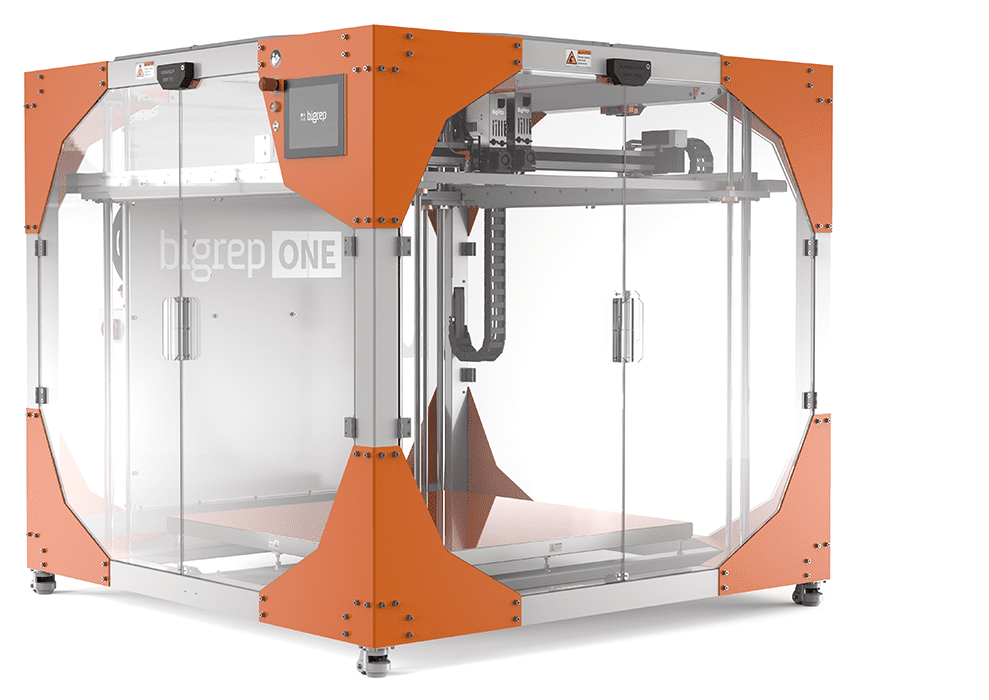

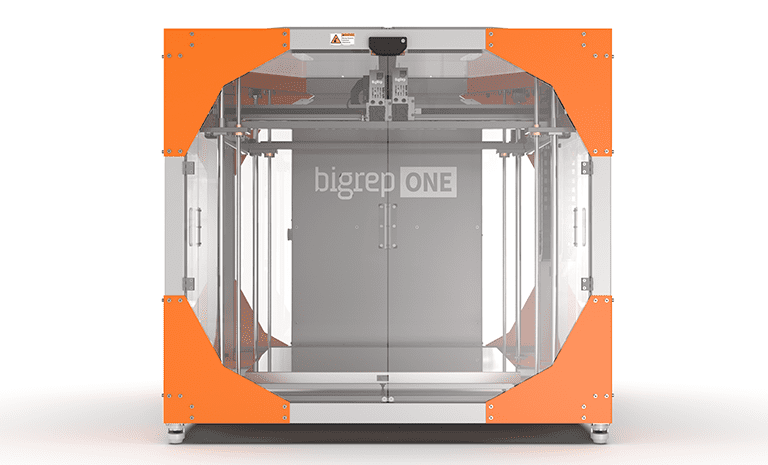

LARGE-FORMAT 3D PRINTER AT AN ACCESSIBLE PRICE

German-engineered to work around the clock

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 350 systems installed worldwide, it’s a trusted tool of designers, innovators, and manufacturers alike. Featuring a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

Perfect for prototyping, production, and a wide range of applications, the ONE comes equipped with one BigRep fiber-ready Power Extruder (PEX) that features interchangeable 0.6, 1.0, and 2.0 mm nozzles for maximum detail or high-flow additive manufacturing.

Innovative Applications with the BigRep ONE

DESIGN & ARCHITECTURE

Whether it’s fine art, museum displays, film props, or innovative installations, many BigRep customers agree that there is simply no other way to produce their large-scale creative projects. By digitizing the fabrication process, designers open a door to more possibilities.

FORMS & MOLDS

3D printed patterns and molds can replace expensive CNC milled or hand-crafted traditional forms. By modernizing the first phases of numerous casting applications, the BigRep ONE allows you to produce in-house, iterate faster, cut material costs, and streamline logistics.

PROTOTYPES

Producing prototypes quickly and cost-efficiently opens up new development and design possibilities for innovators. BigRep’s large-scale 3D printing technology enables more iterations to be manufactured simply and quickly, without increasing costs.

RESEARCH & EDUCATION

Many universities use the BigRep ONE to train their students on advanced technology to ensure quality, hands-on learning, and research. Research teams test theories with rapid iteration and avoid third-party bottlenecks that slow down innovation.

CONFIGURE YOUR 3D PRINTER

Configure your custom ONE and choose from single, dual, or twin extruder modes plus add-ons like an enclosed housing and even the printer’s color to create the perfect machine just for you. As your 3D printing needs evolve, simply upgrade your ONE with additional features to grow along with you.

Modules & Add-Ons: Benefit from packages that are tailored to your needs and applications. Only pay for what you really need for your daily work.

SINGLE MODE

Robust solution at minimal cost, perfect for beginners. Print your large-format parts using one extruder for both the model and the support!

DUAL MODE

Expand your print capabilities and get higher quality surfaces by enabling the second extruder and using water-soluble support filament or mix two filaments with different mechanical proprieties for more complex applications!

TWIN MODE

Double your production, cut cost and time-to-part by 50%! Print two same parts at a time using the two extruders simultaneously.

- ENCLOSURE ADD-ON: Our new transparent printer housing and safety concept with automatic door sensors provide a more constant printing environment.

- CAMERA ADD-ON: Monitor your print remotely via webcam from any computer or mobile device and check the progress of your print.

- KEEP-DRY ADD-ON: Our new Keep-Dry-Box protects the filament from dust and moisture for optimal printing results, particularly for filaments that are sensitive to moisture.

- CUSTOM COLOR ADD-ON: Customize your printer and replace the standard BigRep orange corners with the paint color of your choice.

COMPATIBLE 3D PRINTING MATERIALS

COMPATIBLE 3D PRINTING MATERIALS

BigRep’s HI-TEMP is an ecological engineering-grade 3D printing filament for a wide variety of industrial and general applications.

BigRep's Pro HT is a general-use bio performance material for open-environment 3D printing.

BigRep’s TPU is flexible 3D printing filament opens up a wealth of possibilities for manufacturers and customers.

BigRep PETG is ideal for 3D printing projects requiring strength, toughness, and thermal resistance in a filament.

BigRep’s BVOH support material is an ecologically friendly advanced water-soluble filament that eliminates post-processing for 3D printed parts.

BigRep PLA is an easy-to-use filament optimized for producing prototypes and pattern making, for end-use parts to the wide range of tooling applications.

BigRep's PLX filament is a PLA-derived, general-use bio performance material for open-environment 3D printing.

GET TO KNOW THE BIGREP ONE 3D PRINTER

LARGE SCALE & GERMAN ENGINEERED

LARGE-SCALE 3D PRINTING

The Massive Build Volume

With a one-cubic-meter build volume, the BigRep ONE is designed to produce massive 3D prints - over 1000x1000x1000 mm in size - for demanding and geometrically complex applications. Go beyond the limited capabilities of smaller systems and use the ONE to print your parts in full scale.

SAFE & ACCESSIBLE

The Frame Construction

The open design ensures unobstructed print monitoring and easy access to the print bed. Check the print quality and progress at any time with access to the print bed from three sides. The optional Enclosure Add-On ensures a constant printing environment and provides CE-compliant operator protection.

MODULAR & INDEPENDENT

The Fiber-Ready Power Extruders

BigRep’s fiber-ready Power Extruder (PEX) is available for single or dual extrusion on the BigRep ONE. It consistently produces high-quality, full-scale parts in a range of BigRep filaments such as bio-polymers, water-soluble support, and fiber-reinforced, as well as third-party materials. Featuring interchangeable 0.6, 1.0, and 2.0 mm nozzles for maximum detail or high-flow additive manufacturing, the BigRep Power Extruder is a flexible solution for a variety of applications.

CONSISTENT & EFFICIENT

The Semi-Automatic Print Bed

The heated print bed is coated with a polyimide foil that provides optimal adhesion throughout the printing process. Thanks to an integrated inductive sensor, the ONE uses semi-automatic print bed leveling to streamline build platform calibration and ensure peak performance and consistent prints.

SECURE & SPACIOUS

The Filament Enclosure

The newly designed filament enclosure ensures optimal material handling and fits all standard spool sizes, including two spools up to 8 kg. An out-of-filament sensor pauses printing so you can replace the empty spool, which is particularly useful for very large prints. The Keep Dry Box Add-On protects the filament from moisture and dust.

EASY & INTUITIVE

The Graphical User Interface

An intuitive user interface on the touch panel PC lets you access helpful features such as remote load, check print progress via webcam, change print parameters, resume print after a power failure, and many more.

“ I didn’t think I needed 3D printing and now I can’t live without it. ”

- Charles Boyce, President of Boyce Technologies Inc.

TECHNICAL SPECIFICATIONS

| Version | BigRep ONE.4 | |

|---|---|---|

| Build Volume | x 1005 y 1005 z 1005 (mm) / x 39.5 y 39.5 z 39.5 (inch) | |

| Layer Height | 0.3mm, 0.6mm, 1.0mmOther layer heights supported through slicer software | |

| Max. speed | Max. acceleration | 500mm/s | 400mm/s² | |

| Extruder | Fiber-Ready Power Extruder (PEX) Interchangeable nozzles with fiber-ready 0.6mm / 1.0mm nozzles and high-throughput 2.0mm nozzle | |

| Materials | BigRep HI-TEMP, BigRep HI-TEMP CF, BigRep PETG, BigRep PLA, BigRep PLX, BigRep PRO HT, BigRep TPU 98A Open for use of 3rd party materials | |

| Support Materials | BigRep BVOH Open for use of 3rd party materials | |

| Print Bed Temperature | Max. 80°C (176°F) | |

| Printer Weight | Approx. 460kg (1,014 lbs) | |

| Size | x 1850 y 2250 z 1725 (mm) / x 72.8 y 88.6 z 67.9 (inches) | |

| Power | 208V – 240V, 16A, 50/60Hz | |

| Max. temperature | 80°C | |

| Safety Certifications | CE approved (with enclosure) | |