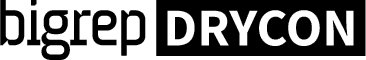

Industrial Filament Dry Cabinet

Your 3D printer's reliable partner to dry, store, and anneal for maximum part performance.

Active Air Exchange Cycles

The periodic air cycles eliminate moisture by replacing humid air with fresh air, enabling high energy efficiency.

Up to 36 kg Filament Storage

The chambers house up to 16 spools of 1 kg, 8 spools of 4.5 kg, or 4 spools of 8 kg filament.

Siemens LOGO! control systems

Intuitive user interface thanks to the Siemens LOGO! control systems.

Heats up to 180°C

Both chambers have customizable temperature settings that heat to 180°C, creating uniquely optimal conditions for your high-performance materials.

DRY

Dual chambers perfect for customized drying settings for different materials.

STORE

Locks out the moisture and heat so your material is ready for print when you are.

ANNEAL

Makes your prints robust, heat resistant and enhances mechanical properties.

MAXIMIZE YOUR PART'S PERFORMANCE

The DRYCON is the only dual-chamber machine on the market that has three things at once - a dryer, storage, and an annealing system. It is engineered to be the perfect partner for your 3D printer, so you can unlock the full potential of your additive manufacturing workflow.

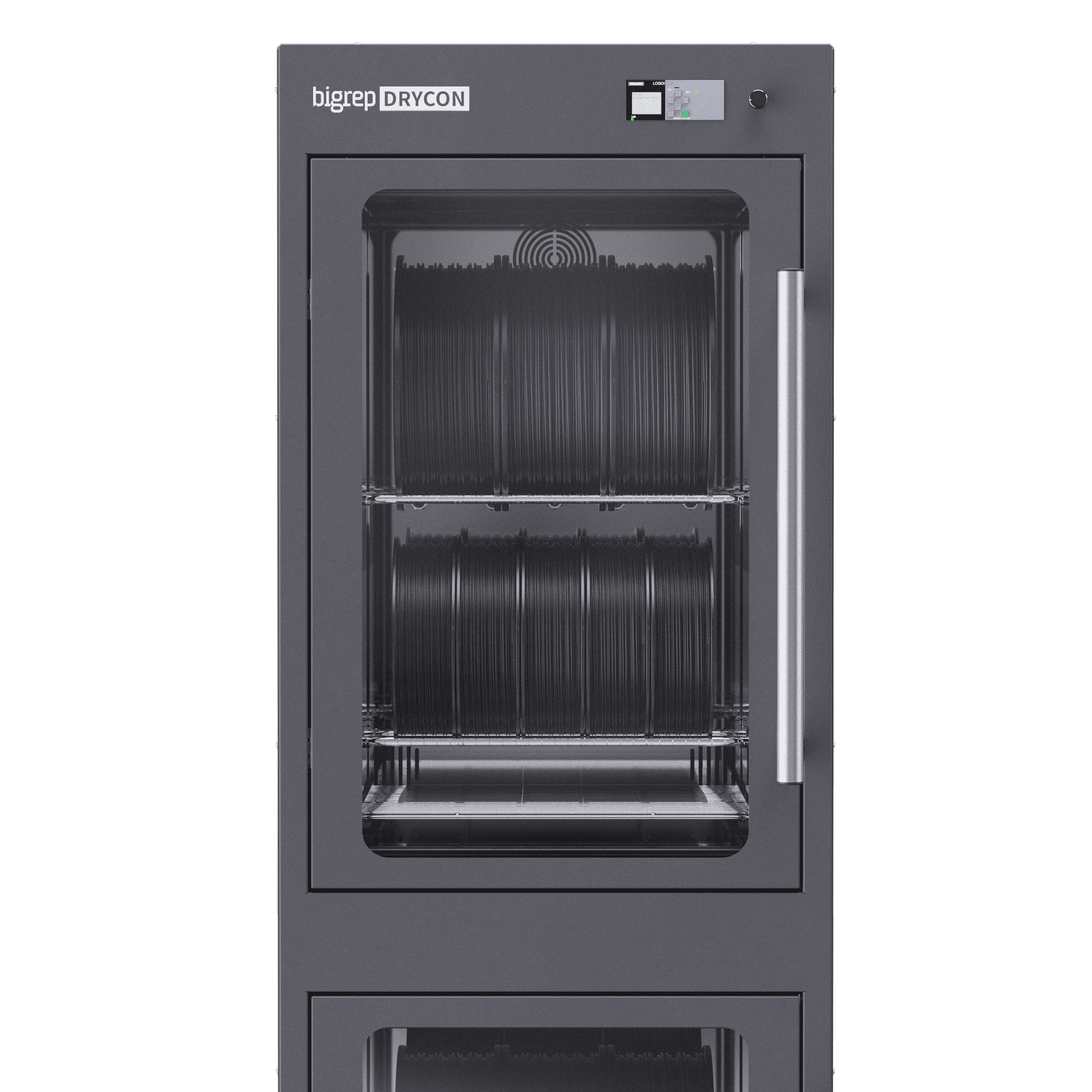

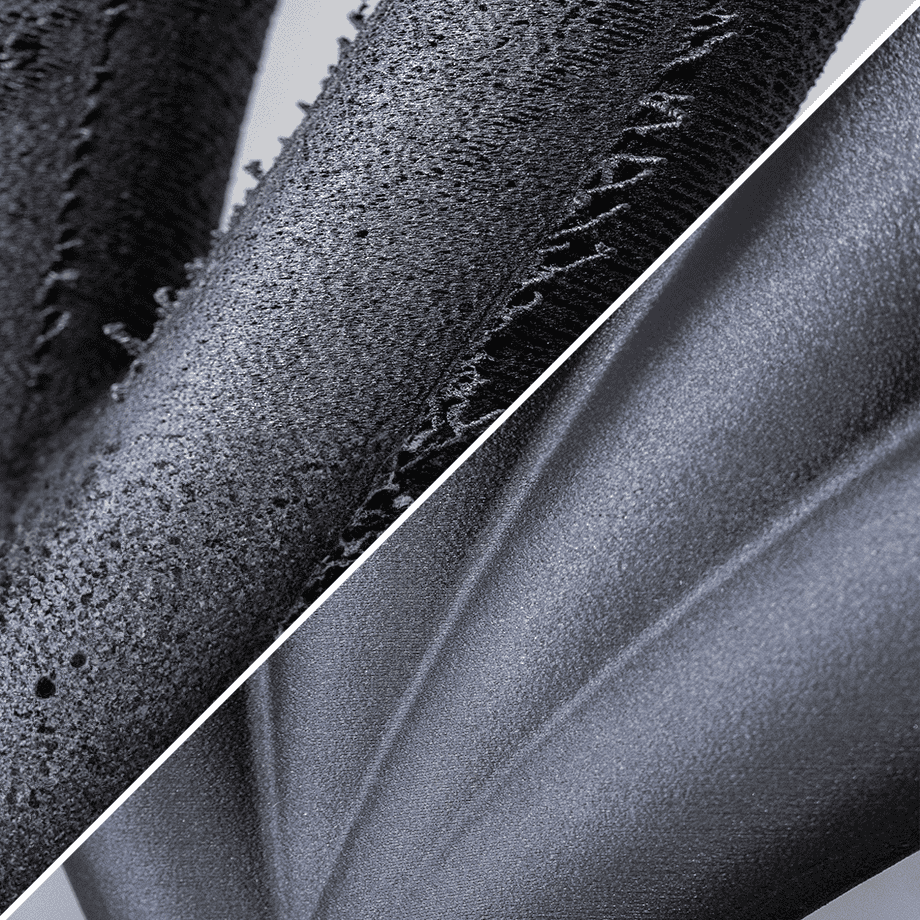

DRYCON delivers quality.

See the difference for yourself.

Improve your 3D print's quality, strength, and resistance. Drying, optimal storage, and annealing ensure your parts perform at their best and withstand the test of time.

DRYCON delivers quality.

See the difference for yourself.

Improve your 3D print's quality, strength, and resistance. Drying, optimal storage, and annealing ensure your parts perform at their best and withstand the test of time.

WHY DRY FILAMENTS

Enhances Print Quality

Hygroscopic filaments absorb moisture, resulting in bubbles, holes, and poor layer bonding. Drying it ensures a smooth finish and higher print quality.

Increases Print Success Rate

Moisture in filaments causes inconsistent flow, leading to under- or over-extrusion, stringing, and oozing. You can reduce print defects and failures by drying it.

Keeps Filaments Print Ready

Fully dried and optimally stored filaments save valuable time. Drying eliminates time spent during pre-printing steps so you can start printing right away.

Ensures Dimensional Accuracy

Wet filaments expand unevenly during a print, causing warping and inaccuracies. Drying it gives you precise prints by maintaining the material's original shape.

Improves Mechanical Strength

Wet filament prints are weaker and prone to cracking. Printing with dry filaments creates stronger layer adhesion and more durable prints.

WHY ANNEAL 3D PRINTED PARTS

Improves Mechanical Properties

Annealing 3D printed parts involves heating them to a controlled temperature and then slowly cooling them which rearranges the internal structure of the print. This helps release internal stresses that cause warping and distortion, ensuring the part retains its dimensional accuracy. The process also improves inter-layer bonding by fusing the layers more tightly, resulting in greater tensile strength, durability, and functionality.

Enhances Thermal Stability

Increase a part’s resistance to high temperatures by annealing. The process alters the material’s crystalline structure, making it less prone to deformation when exposed to heat. This improves the part's ability to maintain its mechanical properties in fluctuating or extreme temperature environments, ensuring long-term durability and performance in demanding applications.

Enhances Thermal Stability

Increase a part’s resistance to high temperatures by annealing. The process alters the material’s crystalline structure, making it less prone to deformation when exposed to heat. This improves the part's ability to maintain its mechanical properties in fluctuating or extreme temperature environments, ensuring long-term durability and performance in demanding applications.

Features

Your Printer’s Reliable Partner for Industrial Strength Prints

Two Chambers, Three Functions.

The 2-chamber system delivers optimal performance with three essential functions ensuring high-quality, reliable prints for even the toughest applications.

Dual Chamber Capacity

The DRYCON is equipped with two chambers (396mm X 455mm X 478mm each) that heat up to 180° C. They are both engineered to dry, store, and anneal parts to perfection.

The chambers house up to 16 spools of 1 kg, 8 spools of 4.5 kg, or 4 spools of 8 kg filament with custom temperature control. They can be set to different conditions to treat filaments with their ideal environment requirements. Both chambers operate independently, allowing for multiple functions simultaneously—such as drying or storing filaments in the upper chamber while annealing parts in the lower chamber.

Active Air Exchange Cycles

During the filament drying process, air is periodically exchanged to efficiently remove moisture by replacing humid air with fresh air. This air exchange system ensures consistent drying conditions throughout the process and is more energy efficient than other filament drying methods.

Active Air Exchange Cycles

During the filament drying process, air is periodically exchanged to efficiently remove moisture by replacing humid air with fresh air. This air exchange system ensures consistent drying conditions throughout the process and is more energy efficient than other filament drying methods.

Annealing for Superior Parts

Both chambers heat to 180° C, ideal for annealing parts exposed to heat and mechanical stresses. Annealing significantly improves part accuracy, heat resistance, stiffness, dimensional stability, and other mechanical properties. The process also enhances the aesthetics of the part by giving it a smooth and even finish.

Streamlined DRYCON to 3D Printer Filament System

The DRYCON features four filament outlets that feed the material directly into your 3D printer. This eliminates the need for separate storage or manually transferring the filament to the 3D printer, making it a stream-lined drying, storage, and hassle-free printing process.

Streamlined DRYCON to 3D Printer Filament System

The DRYCON features four filament outlets that feed the material directly into your 3D printer. This eliminates the need for separate storage or manually transferring the filament to the 3D printer, making it a stream-lined drying, storage, and hassle-free printing process.

Materials that Need Drying to Achieve Superior Quality Prints

Technical, flexible, high-performance materials deliver high-performance parts with the DRYCON.

PA 12 CF

CARBON FIBER POLYAMIDE

Preferred for aerospace components, automotive parts, and sporting goods because of its high strength-to-weight ratio.

PA6/66

POLYAMIDE (NYLON)

Widely used in mechanical engineering, automotive parts, and consumer goods with excellent mechanical properties and chemical resistance.

TPU 98A

THERMOPLASTIC POLYURETHANE

With its flexibility, durability, & abrasion resistance, TPU is commonly used for manufacturing aids, particularly those interfacing with sensitive parts & equipment.

BVOH

BUTENEDIOL VINYL

ALCOHOL CO-POLYMER

Created for use with dual-extruder printers, BigRep BVOH is compatible with a wide range of materials to provide efficient support during the printing process.

ULTEM® 9085

POLYETHERIMIDE (PEI)

Often used in aerospace, automotive, and medical applications for its high strength-to-weight ratio, thermal stability, and flame resistance.

PEKK-A

POLYETHER-ETHERKETONE

Predominantly used for applications that need exceptional mechanical, thermal, and chemical resistance in aerospace, automotive, and medical industries.

3D Printers Recommended with DRYCON

The DRYCON integrates seamlessly into your new or existing additive manufacturing workflow with its direct dryer-to-3D printer filament feed system.

The ultimate high-performance machine with maximum reliability and an expansive build volume.

An industry all-rounder high-temp machine with an unbeatable price-to-performance ratio.

Industries that Benefit the Most from the DRYCON

Filament drying and print annealing are vital for industries with demanding applications where parts need to be strong, durable, and heat resistant.

Technical Specifications

| Chamber Dimensions (W x D x H) | 455 x 478 x 396 mm | |

| Spool Sizes per chamber | 16 spools of 1 kg 8 spools of 4.5 kg or 4 spools of 8 kg |

|

| Volume Flow | 200 m³/h | |

| Power | 230 - 240 VAC, 50/60 Hz | |

| Power Consumption | Maximum 3 kW | |

| Device Dimensions (W x D x H) | 620 x 750 x 1970 mm (depth without handles) | |

| Door Dimensions (W x H) | 540 x 1100 mm | |

Ready for a conversation?