In the competitive arena of product development, rapid prototyping is the cornerstone of innovation. 3D printing is at the forefront of this process, transforming ideas into tangible realities with unprecedented speed and precision. This synergy of technology and creativity not only enhances the design process, it redefines it.

Engineers and designers now have a powerful ally in 3D printing that streamlines the path from concept to prototype.

Find out how this rapid prototyping not only accelerates development cycles, but opens up new ways to design and excel.

Understanding Rapid Prototyping

Before delving into the benefits and challenges of rapid prototyping, it is important to first define what it is. Rapid prototyping is a methodology that involves creating physical models of designs or concepts using computer-aided design (CAD) software and usually 3D printing. The goal is to produce a tangible representation of an idea that can be tested and refined before committing to large-scale production.

What is Rapid Prototyping?

Rapid prototyping, also known as additive manufacturing or 3D printing, is a process that builds up layers of material to create a three-dimensional object. It has revolutionized the product development cycle by significantly reducing the time and cost traditionally associated with creating prototypes.

Is Rapid Prototyping the Same as 3D Printing?

When the technology was first developed, 3D printing was so synonymous with rapid prototyping that the two terms were interchangeable. Whether referencing “3D printing,” “rapid prototyping,” or “RP,” the conversation generally all referred to the same thing. Today, 3D printing has developed into end-use production capabilities as well and is more commonly synonymous with “additive manufacturing.”

Still, rapid prototyping was the first and remains the largest application for 3D printing. Iterations from proof-of-concept through to functional prototype can all be 3D printed. Whether outsourced or in-house, using 3D printers speeds up the rapid prototyping significantly through removing traditional bottlenecks in tooling and/or shipping. Rapid prototyping can also increasingly be done using the same 3D printing technology as will be used for the final product.

The Importance of Rapid Prototyping in Innovation

One of the main reasons why rapid prototyping is vital in the innovation process is its ability to accelerate the design cycle. In the past, creating physical prototypes required specialized equipment and often took weeks or even months to complete. With rapid prototyping, businesses can quickly produce multiple iterations of a design and test their feasibility in a matter of days.

Rapid prototyping not only speeds up the design process but also allows for more creativity and experimentation. Designers and engineers can easily explore different ideas and concepts by quickly producing physical prototypes. This iterative approach encourages innovation and pushes the boundaries of what is possible.

Also, rapid prototyping enables effective communication and collaboration among team members. Instead of relying solely on 2D drawings or verbal descriptions, stakeholders can interact with a physical prototype, providing valuable feedback and insights. This enhances the decision-making process and ensures that everyone involved is on the same page.

In addition to its role in the design and development phase, rapid prototyping also plays a crucial role in marketing and sales. By creating realistic and visually appealing prototypes, businesses can showcase their products to potential investors, customers, and partners. This helps in securing funding, generating interest, and gaining a competitive edge in the market.

Rapid prototyping allows for early detection of design flaws and technical issues. By physically testing a prototype, engineers can identify and address any potential problems before moving forward with production. This saves time, resources, and prevents costly mistakes down the line.

Another advantage of rapid prototyping is its ability to facilitate customization and personalization. With the flexibility of additive manufacturing, products can be easily tailored to meet individual customer requirements. This opens up new opportunities for mass customization and niche markets.

Overall, rapid prototyping is a game-changer in the world of product development. Its speed, cost-effectiveness, and ability to foster innovation make it an indispensable tool for businesses across various industries. By embracing rapid prototyping, companies can stay ahead of the competition, deliver better products, and drive continuous improvement.

The Process of Rapid Prototyping

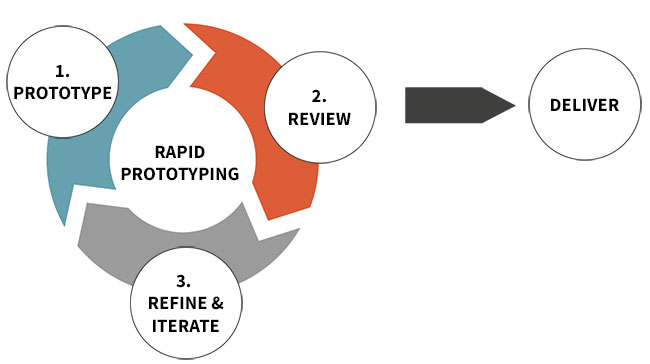

Now that we understand the concept of rapid prototyping, let's explore the steps involved in the process and the tools and techniques used to bring ideas to life.

Steps Involved in Rapid Prototyping

Rapid prototyping typically involves the following steps:

- Design: The first step is to create a digital 3D model of the idea using CAD software. This model serves as the blueprint for the physical prototype.

- Printing: Once the design is finalized, it is sent to a 3D printer. The printer uses a variety of materials, such as plastic or metal, to build up the prototype layer by layer.

- Post-processing: After the printing process is complete, the prototype may require some post-processing, such as sanding or polishing, to achieve the desired finish.

- Testing and Iteration: The final step involves testing the prototype to evaluate its functionality and gather feedback. Based on the results, the design can be refined and further prototypes can be created.

Design is a crucial step in the rapid prototyping process. It involves translating an idea into a digital 3D model using computer-aided design (CAD) software. This step requires careful consideration of the desired functionality, aesthetics, and manufacturability of the prototype. Designers must ensure that the model accurately represents the intended product, allowing for a realistic evaluation of its feasibility and potential improvements.

Once the design is complete, the next step is printing the prototype. This is where the magic happens! The digital model is sent to a 3D printer, which brings it to life layer by layer. The 3D printer uses various materials, such as plastic or metal, depending on the requirements of the prototype. The choice of material can greatly impact the final product's strength, durability, and appearance.

After the printing process is finished, the prototype may undergo post-processing. This step involves refining the prototype's surface finish and texture to achieve the desired look and feel. Techniques such as sanding, polishing, or applying a protective coating may be employed to enhance the prototype's aesthetics and functionality. Post-processing is crucial for creating prototypes that closely resemble the final product, allowing for a more accurate evaluation and feedback.

Testing and iteration are vital components of the rapid prototyping process. Once the prototype is complete, it is subjected to rigorous testing to evaluate its functionality, performance, and user experience. This step helps identify any design flaws or areas for improvement. Feedback from testing is then used to refine the design and create further iterations of the prototype. This iterative process allows for continuous improvement and optimization of the product, ensuring that it meets the desired requirements and objectives.

Tools and Techniques for Rapid Prototyping

Several tools and techniques are used in rapid prototyping, each with its own advantages and limitations. Some of the most commonly used methods include:

- Fused Deposition Modeling (FDM): This technique involves extruding thermoplastic material through a heated nozzle to build up the prototype layer by layer. FDM is known for its affordability and versatility. It is widely used in various industries, including product development, engineering, and architecture.

- Stereolithography (SLA): SLA uses a laser to solidify liquid resin, creating the prototype layer by layer. This method provides high levels of detail and accuracy, making it suitable for creating intricate and complex prototypes. SLA is commonly used in industries such as jewelry, dentistry, and automotive.

- Selective Laser Sintering (SLS): SLS utilizes a laser to fuse powdered material together to form the prototype. This technique is particularly suitable for creating prototypes with complex geometries and functional parts. SLS is widely used in industries such as aerospace, automotive, and medical.

There are various other tools and technologies available for prototyping, such as CNC machining, vacuum casting, and laser cutting, but rapid prototyping always refers to 3D printing. The choice of tool or technique depends on factors such as the desired material properties, level of detail required, and budget constraints.

Rapid prototyping has revolutionized the product development process, enabling faster and more efficient iteration and innovation. By allowing designers and engineers to quickly transform ideas into tangible prototypes, it accelerates the development timeline and reduces the risk of costly errors. With the continuous advancements in technology and materials, the possibilities for rapid prototyping are expanding, opening up new avenues for creativity and problem-solving.

The Benefits of Rapid Prototyping for Businesses

Rapid prototyping offers numerous benefits that contribute to accelerated innovation. Let's take a closer look at two key advantages: time and cost efficiency, and enhanced design and functionality.

Time and Cost Efficiency

In traditional product development cycles, creating physical prototypes can be time-consuming and expensive. The process typically involves multiple iterations, which can lead to delays and increased costs. However, with rapid prototyping, businesses can significantly reduce both the time and cost associated with developing new products.

One of the main reasons for the time and cost efficiency of rapid prototyping is the ability to quickly iterate and test designs. Unlike traditional methods, where each iteration requires significant time and resources, rapid prototyping allows for rapid design changes and modifications. Designers can quickly create a new prototype, test it, and make necessary adjustments in a matter of hours or days, rather than weeks or months.

This accelerated iteration process not only saves time but also reduces costs. By identifying and addressing any potential issues early in the process, companies can avoid costly mistakes and rework later on. This proactive approach helps streamline the overall product development cycle, leading to faster time-to-market and increased competitiveness in the industry.

Decrease Time to Market

The time it takes an idea to move from concept to deliverable should be as short as possible. Replacing months or years of traditional wait times in the iterative prototyping process with days or weeks is an easily apparent benefit of rapid prototyping. A 3D printer can precisely create the next iteration from a slightly tweaked design file much faster than could any traditional tooling-based prototyping process. Speeding the design cycle inherently improves time-to-market for a new product.

Enhancing Design and Functionality

Rapid prototyping enables designers and engineers to explore complex designs and functionalities that may be difficult or costly to achieve with traditional manufacturing methods. By creating physical prototypes, they can test the design's functionality, ergonomics, and aesthetics, and make necessary improvements before moving forward with production.

With rapid prototyping, designers have the freedom to experiment and push the boundaries of what is possible. They can easily create multiple iterations of a design, allowing them to explore different concepts and variations. This flexibility not only leads to better design outcomes but also encourages innovation and creativity.

Furthermore, rapid prototyping allows for a more iterative and collaborative design process. Designers can share physical prototypes with stakeholders, such as clients, investors, or end-users, to gather feedback and make informed design decisions. This iterative feedback loop ensures that the final product meets the needs and expectations of all stakeholders, resulting in a more successful and marketable product.

In addition to design improvements, rapid prototyping also enables the testing of functionality. Engineers can simulate real-world conditions and evaluate how the product performs under different scenarios. This testing phase helps identify any flaws or limitations in the design, allowing for necessary adjustments and refinements.

Improve Effective Communication

The fast turnaround of rapid prototyping eases communication gaps by opening up the conversation. It’s much easier if every engineer on your team has the same understanding of a process, and quickly getting a next physical prototype in hand offers a clear point of reference. As each prototype becomes closer to the feel and performance of the final design, small tweaks and large adjustments both become easier to understand for your entire team.

Overall, rapid prototyping enhances both the design and functionality of products. It empowers designers and engineers to create innovative and user-centric solutions, while also reducing the risk of costly design errors and production issues.

How to Use Rapid Prototyping in the Engineering Process

Rapid prototyping sounds great, but where can it be used in the engineering process? The answer may not be wholly surprising at this point: from initial proof-of-concept to final-look-and-feel prototype, rapid prototyping can come into play across the entire process.

Concept Prototypes

The earliest prototypes are often conceptual. Proof-of-concept prototypes serve as physical validation of the ideas that may have emerged as a sketch on a napkin. Taking an idea into the three-dimensional real world is the best way to prove viability. Getting hands-on with a concept model can help your engineering team understand their next steps at the same time as it may encourage management to simply move forward with a project.

These early prototypes are often the roughest, as they are the lowest-risk representations made in the rapid prototyping cycle. These prototypes are made quickly and generally in different materials and colors than later-stage prototypes, much less final designs.

Aesthetic or Industrial Design Prototypes

Once a design is validated in its roughest form, it moves next into an aesthetic or industrial design step. These next prototypes begin to hone in on how the design should look and feel, with the thought process beginning to turn toward usability and functionality -- without necessarily being fully functional quite yet. To ensure a new part will fit into a greater whole, or a new product will fit with your brand’s existing aesthetic or functional line, these prototypes more accurately look like something that is moving toward a final design. These prototypes also enable engineers to consider how exactly to best manufacture the eventual final design.

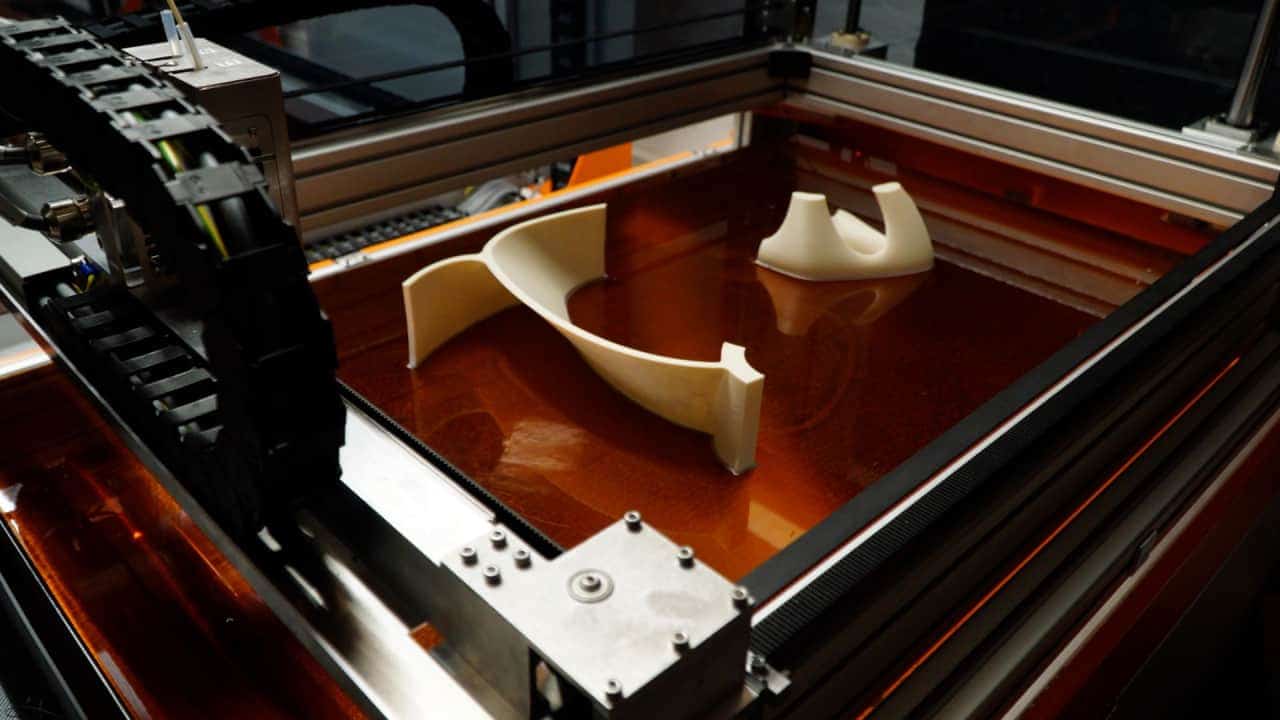

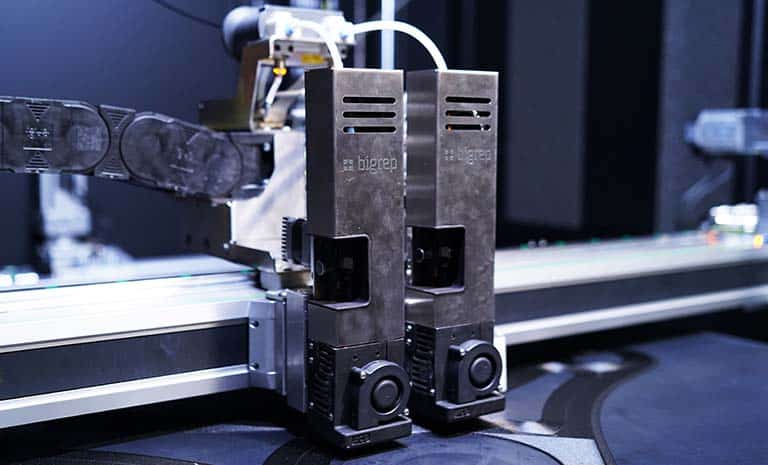

Especially when working with life-sized, larger designs like furniture, having life-sized prototypes to fit to spaces and users becomes ever more important as designs move through the prototyping cycle. Large-scale 3D printing can bring these large-scale designs to life, allowing for a full iteration to be made and tested in less than the time it would take for a traditional tool to be made. Furniture maker Steelcase experienced this benefit first-hand as they use their large-format BigRep 3D printer to create new furniture designs:

Functional Prototypes

A functional prototype does just that: it functions. These later-stage prototypes are often made of materials similar to what will be used in a final product, to validate that everything will work as intended. Engineers at this stage pay attention to performance: does it fit, does it function, do load-bearing parts bear loads?

Attention must be paid to detail, to how the final part will be manufactured (especially if this will be done in a different process than the prototype; for example, 3D printing a prototype for a part that will ultimately be injection molded) as well as how the final part will be post-processed/finished.

Test Serial Production

Many products bound for the mass market are bound for mass production, and this may mean in a different manufacturing process. While 3D printing may be the right technology for both rapid prototyping and serial production of the final part - consider, for example, cases of mass customization - this will not always be the case.

Prototyping must take into account the eventual manufacturing process to be used, and later-stage prototypes should use the same materials and fit into the appropriate manufacturing parameters as the final parts will be. Consideration for traditional production processes comes more into play here, for example for tooling, jigs and fixtures, or any other necessary implements. Design for additive manufacturing (DfAM) may move toward traditional design for manufacturing (DFM) thinking.

Demonstration or Presentation Model Prototypes

The final look is the final stage in prototyping, the last step before full production begins. At this stage, a prototype should not only feel and operate like the final product, but needs to look like it, too. This prototype can be used for marketing materials while production ramps up, for convincing investors of final viability and feasibility, for final field testing, or for any other demonstration or presentation needs. The goal of rapid prototyping is to reach this stage faster than ever before using conventional prototyping workflows.

Challenges in Rapid Prototyping

While rapid prototyping offers many advantages, it is not without its challenges. Let's discuss potential limitations and risks, as well as strategies for overcoming obstacles in the rapid prototyping process.

Rapid prototyping, also known as 3D printing, has revolutionized the manufacturing industry. It allows for the quick and cost-effective production of prototypes, enabling designers and engineers to iterate and refine their designs at a much faster pace. However, there are certain limitations and risks associated with this process that need to be addressed.

Potential Limitations and Risks

One of the main limitations of rapid prototyping is the material selection. While rapid prototyping supports a wide range of materials, including plastics, metals, and ceramics, the selection may not be as extensive as with traditional manufacturing methods. This can be a constraint when trying to replicate the exact properties and characteristics of the final product.

Additionally, the strength and durability of prototyped parts may not match those of the final manufactured product. This can be a limitation when testing for functionality and reliability. It is crucial to keep in mind that prototypes are not always a perfect representation of the end product, and adjustments may need to be made during the manufacturing process.

Another risk associated with rapid prototyping is the potential for design flaws to go unnoticed until the final product is manufactured. Since the prototyping process is relatively fast, there may not be enough time for thorough testing and evaluation. This can result in costly rework and delays in production.

Overcoming Obstacles in Rapid Prototyping

To overcome these challenges, it is important to carefully consider material selection during the design phase. By understanding the limitations of the available materials and their properties, designers can make informed decisions and choose the most suitable material for their specific application.

Additionally, testing the prototypes under realistic conditions and conducting thorough performance evaluations can help identify and mitigate any potential issues before production. This includes subjecting the prototypes to various stress tests, simulating real-world scenarios, and gathering feedback from end-users. By thoroughly evaluating the prototypes, designers can gain valuable insights and make necessary improvements to ensure the final product meets the desired standards.

Furthermore, collaboration between designers, engineers, and manufacturers is crucial in overcoming obstacles in rapid prototyping. By working together and leveraging each other's expertise, it becomes easier to address any challenges that arise during the prototyping process. Regular communication and feedback loops can help streamline the process and ensure that all parties are aligned towards achieving the desired outcome.

In conclusion, while rapid prototyping offers numerous benefits, it is important to be aware of the potential limitations and risks associated with the process. By understanding these challenges and implementing strategies to overcome them, designers and engineers can maximize the potential of rapid prototyping and accelerate the innovation and development of new products.

Future of Rapid Prototyping

Rapid prototyping continues to evolve, presenting exciting opportunities for the future of innovation. Let's explore some of the emerging trends in rapid prototyping and its role in shaping the future of the industry.

Emerging Trends in Rapid Prototyping

One key trend is the integration of rapid prototyping with other advanced technologies, such as artificial intelligence (AI) and virtual reality (VR). This combination allows for even faster and more accurate prototyping, as well as enhanced visualization and user experience.

With the integration of AI, rapid prototyping can now generate intelligent designs based on user requirements and preferences. This not only speeds up the prototyping process but also ensures that the final product meets the specific needs of the target audience. Additionally, AI-powered rapid prototyping can analyze vast amounts of data to identify potential design flaws or areas for improvement, leading to more refined and successful prototypes.

Virtual reality is another technology that is revolutionizing rapid prototyping. By creating virtual environments, designers and engineers can test and experience their prototypes in a simulated setting, allowing for better evaluation of form, fit, and functionality. This immersive experience enables early identification of design flaws and facilitates iterative improvements, ultimately resulting in more robust and user-friendly products.

The Role of Rapid Prototyping in the Future of Innovation

Rapid prototyping will play a crucial role in the future of innovation by enabling businesses to swiftly adapt to changing customer demands and market dynamics. As the technology continues to advance, we can expect to see even greater speed, precision, and customization in the prototyping process, further empowering businesses to bring their innovative ideas to life.

One industry that is benefiting from rapid prototyping is aerospace. With the ability to rapidly produce and test complex components, engineers can iterate designs and optimize performance, leading to lighter and more fuel-efficient aircraft. Rapid prototyping also enables the production of intricate and customized parts that would be difficult or costly to manufacture using traditional methods.

In the consumer electronics sector, rapid prototyping allows companies to quickly bring innovative products to market. By rapidly iterating designs and incorporating user feedback, businesses can stay ahead of the competition and meet the ever-changing demands of consumers. This agility in product development is crucial in an industry where trends and technologies evolve rapidly.

Conclusion

In conclusion, rapid prototyping is a powerful tool that accelerates innovation by allowing businesses to quickly iterate, test, and refine new ideas. Through the use of advanced technologies and manufacturing processes, companies can bring innovative products and services to market faster than ever before. While there are challenges in the rapid prototyping process, the benefits far outweigh the limitations. As we look to the future, rapid prototyping will continue to redefine the way we bring ideas to life and shape the landscape of innovation.