The Next Level of Automated Production

INTUITIVE USER INTERFACE

- Multi-lingual menu and guides

- Animated guides walk you through processes

- Easy-to-use print queue and job history

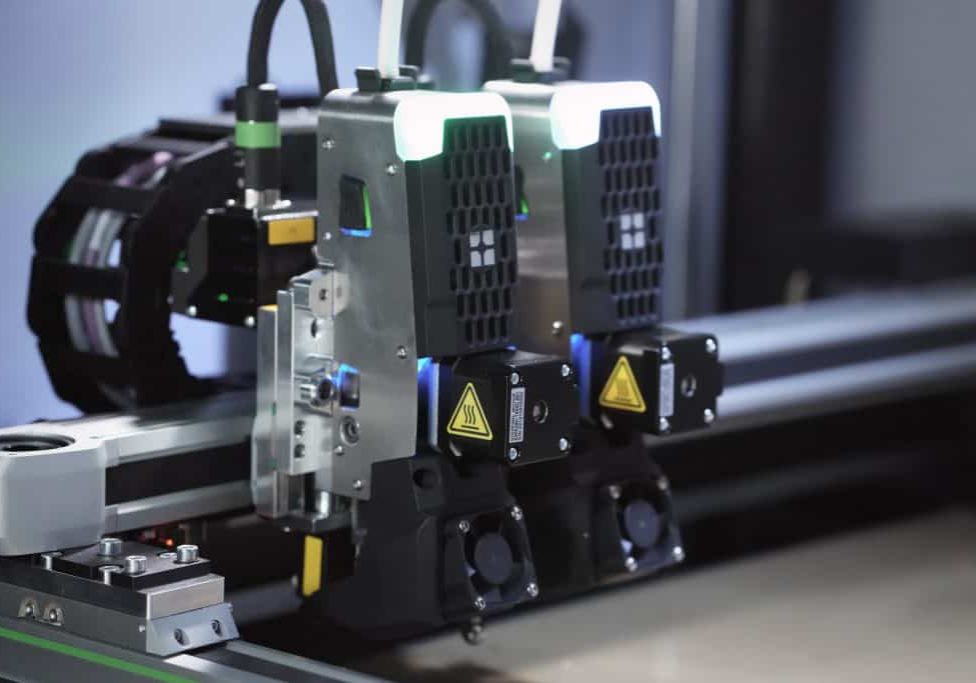

DUAL SMX EXTRUDERS

- Print up to 350°C with engineering-grade and carbon-fiber materials

- Reliable extrusion thanks to embedded sensors for monitoring and control

- 3 nozzle sizes - 0.4mm, 0.6mm, and 1.0mm

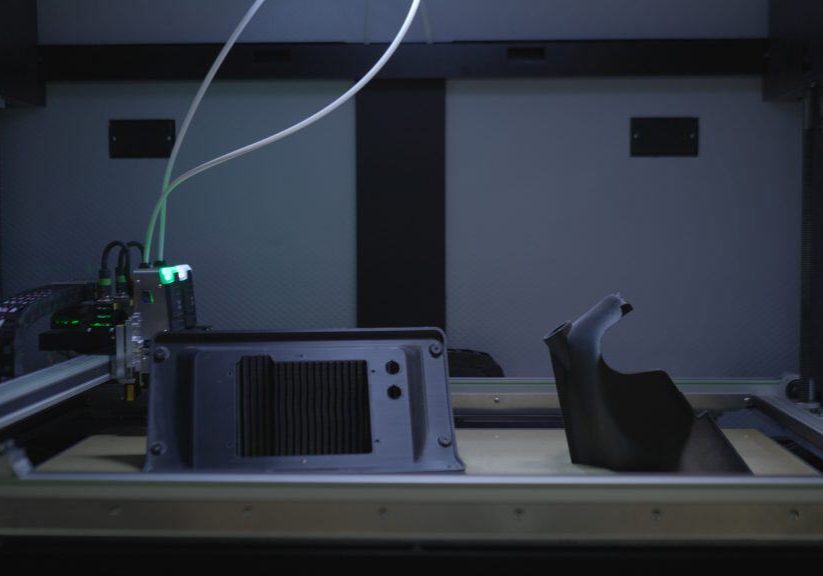

LARGE-SCALE 3D PRINTING

- Build chamber dimensions: 1000 mm x 500 mm x 500 mm

- Build volume of 250 liters

- Produces small serial production, jigs & fixtures, and prototypes

HEATED PRINT BED

- Print bed temperature of up to 120°C

- Flexible SWITCHPLATE® removable print bed surface

- 2 SWITCHPLATE® surface coatings for different sets of materials

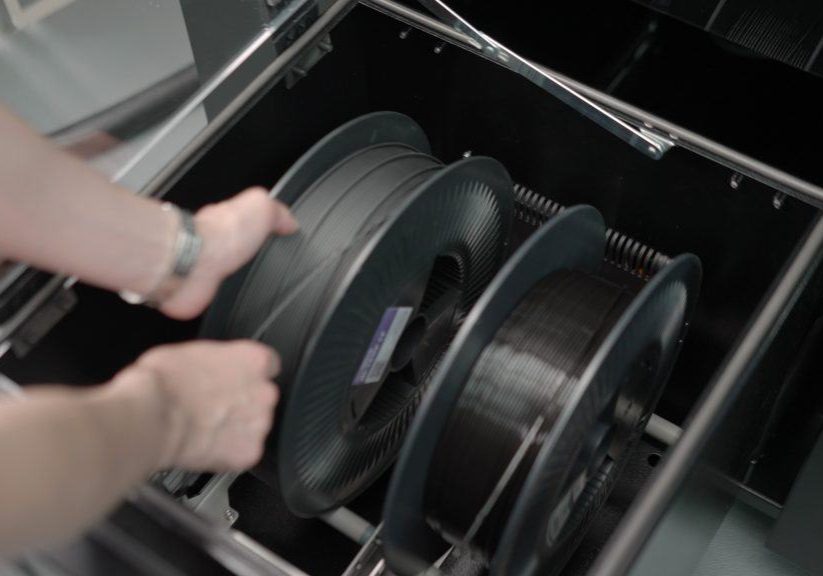

INFINITY BOX

- Automatic filament handling for continuous printing without intervention

- 2 filament bays hold up to 4 spools totaling 32 kg

- Functions as an active keep dry box to maintain optimal material condition

250 liters build chamber

heated up to 50°C

QUALITY IN LARGE-FORMAT

With a robust frame and components, plus an actively heated build chamber, VIIO 250 delivers industrial quality in large scale.

Dual SMX extruders for

precision and speed

LARGE & COMPLEX PRINTS

Dual SMX extruders tackle complex geometries, while continuous printing features can process up to 32 kg with hands-off production.

print engineering

materials up to 350°C

ENGINEERING MATERIALS

Thanks to precisely controlled SMX extruders, VIIO 250 reaches up to 350°C for complex prints with engineering-grade materials.

Industrial Automation Made Easy

Non-Stop High-Resolution Prints

The large-scale BigRep VIIO 250 is a fully automated 3D printer for reliable continuous industrial manufacturing.

To achieve this, the machine is built with breakthrough automation features: a backup extruder function - Relay Mode, auto print bed calibration, auto-sequential printing, and the automated filament handler - Infinity Box. Featuring dual Smart Manufacturing Extruders and an intuitive user machine interface with animated guides, using an industrial 3D printer has never been this easy. These combined automation features deliver a big impact: maximized machine efficiency.

Designed for high efficiency, the VIIO 250 enables affordable production of functional parts with reduced energy consumption. 3D print more quality parts in less time so you can save costs and get production off your hands. With the VIIO 250, spend less time printing and more time doing.

FULLY AUTOMATED PRODUCTION FOR EVERY INDUSTRY

AUTOMOTIVE-GRADE PARTS

Produce durable parts for a range of applications in the automotive industry. The VIIO 250 prints with engineering-grade materials creating strong, light-weight parts. The high accuracy, repeatability, and resolution enable innovations at all stages of the design workflow.

FUNCTIONAL PROTOTYPES

Before going into final production, test designs and validate parts. The open-material system gives you the freedom to choose from a wide variety of filaments and accurately replicate the final part. Iterate quicker, slash fabrication costs, and get your products to market faster.

DURABLE TOOLING

Produce low-cost rapid tooling for your factory floor such as jigs and fixtures. Thanks to the automation features, you can reliably manufacture geometrically complex tooling in-house. Overcome outdated traditional techniques and print tools on demand.

FEATURES

GET TO KNOW THE BIGREP VIIO 250

WORRY-FREE AUTOMATION. MASSIVE BUILD VOLUME.

HUGE HIGH-RESOLUTION PARTS

Large-Scale Build Chamber

Achieve maximum geometric accuracy with VIIO 250's actively temperature-controlled build chamber of 1000 mm x 500 mm x 500mm (build volume of 250 liters) that heats up to 50°C. The compact design offers large-format printing capabilities in a robust, sleek frame that fits in any workspace. If you move the machine to a different space, the automatic portal leveling fully recalibrates even after relocation so you can enjoy consistent print quality wherever you go.

MAXIMIZED EFFICIENCY

24/7 Automation

Enjoy the comfort features of a desktop 3D printer at an industrial level with automated bed mapping, filament flow rate adjustment, and x/y calibration. Enabling unattended production, the VIIO 250 comes with groundbreaking fully automated features: the Infinity Box and Relay Mode.

The Infinity Box loads new filament automatically when the material runs out during a print job without any intervention. Ensuring reliable non-stop printing, the VIIO 250 has Relay Mode, an auto-backup extruder functionality. It also has a new controls platform delivering industrial CNC quality and the convenience of instant over-the-air software updates of every new feature we release.

ADVANCED PRINT CONTROL

Dual Smart Manufacturing Extruders (SMX)

The VIIO 250 is equipped with dual Smart Manufacturing Extruders (SMX) capable of printing up to 350°C with engineering-grade and carbon-fiber materials. The extruders have LED light indicators to signal different statuses so you stay updated in a single glance.

Consistently achieve quick high-resolution complex 3D prints thanks to the intelligent embedded sensors and 3 nozzle sizes - 0.4mm, 0.6mm, and 1.0mm.

ENHANCED USABILITY & WORKFLOW MANAGEMENT

Intuitive Machine User Interface

The new multi-lingual user interface is designed to make the 3D printer operation feel as natural as possible. Animated guides walk you through each step with clear information, statuses, alerts, and warnings, making it easy to understand and intuitively manage your print job.

Additionally, the Print Queue feature allows you to easily check and assign the order of your prints, ensuring efficient workflow management and maximum productivity.

CONTINUOUS FILAMENT HANDLING

The Infinity Box

You can press print and walk away without worrying about the filament running out thanks to the add-on feature - the Infinity Box.

The automatic filament handler detects when the material runs out during an active print job and loads new filament without anyone stepping in. It also doubles as an active keep-dry box to store filament in optimal conditions and holds 4 spools of up to 8kg each.

SECURE PRINT BED ADHESION

Precise Prints With Any Material

With a print bed temperature of up to 120°C, the VIIO 250 maintains uniform heat distribution for consistently robust parts. The print bed's temperature also enables strong part adhesion thanks to the flexible SWITCHPLATE® print bed surface. The heat keeps the print fixed in place, and when the printer cools down, you can easily pop the part off in seconds.

The removable magnetic SWITCHPLATE comes in different coatings for different materials so you can explore more applications.

SUPERIOR REMOTE MONITORING & MANAGEMENT

The BigRep CONNECT Software

A true industrial IoT machine, the VIIO 250 fully integrates CONNECT, a 3D printer management platform that offers seamless remote control and monitoring of your BigRep printer.

The multi-functional IoT platform boosts productivity by displaying real-time printer status updates and allows you to efficiently manage print jobs by uploading files and organizing queues. The platform also provides live video streaming, detailed analytics, and visualized historical data in easy-to-understand charts, enabling you to make informed decisions and optimize production.

OPEN MATERIAL SYSTEM PRINTS ALL COMPATIBLE FILAMENTS

The heart of all BigRep machines is the material system that’s open for innovation. Print with any compatible filament of your choice – BigRep’s or a 3rd party’s – and unlock new applications with the VIIO 250.

BigRep's portfolio of industrial-grade 3D printer filaments ranges from affordable, general-use materials to technical materials for demanding industrial applications. They are created under carefully controlled conditions to guarantee uniform diameter and consistent composition ensuring reliable, even extrusion.

BigRep ASA is an engineering-grade UV-resistant filament for high-strength and environmentally exposed applications.

BigRep’s TPU is flexible 3D printing filament opens up a wealth of possibilities for manufacturers and customers.

BigRep PETG is ideal for 3D printing projects requiring strength, toughness and thermal resistance in a filament.

BigRep's Pro HT is a general-use bio performance material for open-environment 3D printing.

BigRep PRO is now compatible with PA12-CF, carbon fiber reinforced PA12 filament.

BigRep's PLX filament is a PLA-derived, general-use bio performance material for open-environment 3D printing.

BigRep’s HI-TEMP is an ecological engineering-grade 3D printing filament for a wide variety of industrial and general applications.

BigRep’s BVOH support material is an advanced water-soluble filament that eliminates post-processing for 3D printed parts.

BigRep PLA is an easy-to-use, cost-efficient filament optimized for producing prototypes and suitable for many applications.

TECHNICAL SPECIFICATIONS

| Version | BigRep VIIO 250 | |

|---|---|---|

| Build volume | 1000 mm x 500 mm x 500 mm (x,y,z) | |

| Compatible materials | BigRep ASA, BVOH, HI-TEMP, HI-TEMP CF, PA12 CF, PA6/66, PETG, PLA, PLX, PRO HT, TPU 98A (Open for 3rd party materials) | |

| Support materials | BigRep BVOH (Open for 3rd party materials) | |

| Filament diameter | 2.85 mm | |

| Extruders | Dual Smart Manufacturing Extruders (SMX) | |

| Nozzles | Tungsten carbide (0.4 mm, 0.6 mm) or polycrystalline diamond (1.0 mm) | |

| Nozzle diameters | 0.4 mm, 0.6 mm, 1.0mm | |

| Layer thickness | 0.2 mm, 0.3 mm, 0.6 mm (Other layer heights supported through slicer software) | |

| Extruder temp | Up to 350°C | |

| Build chamber temp | 30-50°C | |

| Print bed temp | Up to 120°C | |

| Removable print surface | SWITCHPLATE prime, SWITCHPLATE select | |

| Max print speed | Up to 200 mm/s | |

| Max throughput | g/h (115 cm³/h) with PLA | |

| Position accuracy | ±0.2 mm ±0.002 mm/m in XY, ±0.1 mm ±0.001 mm/m in Z | |

| Drive technology | Stepper motors with steel reinforced belt drive in XY, Spindle with self-lubricating nut in Z | |

| Connectivity | 10/100/1000 Base T Connection Ethernet Protocol, USB Port, BigRep Connect Ready with remote monitoring/control features | |

| Slicing software | BigRep BLADE | |

| Machine control | BigRep Kreuzboard | |

| HMI | 12.1” touchscreen | |

| Camera | Built-in chamber camera for real time remote monitoring | |

| Power supply | 208-240 V, 50/60Hz, 16 A | |

| Power consumption | Average (while printing): 660W, Peak: 3200W | |

| External dimensions | 1715 mm x 1170 mm x 1765 mm (x,y,z) | |

| Weight | 560 kg printer in base configuration, 62 kg Infinity Box | |