In the last article we discussed the use of large-scale 3d printing in design and concept modeling processes. It is now time to examine more advanced applications. As heavy industries look for ways to save costs by implementing 3D-Printing in short run production/manufacturing, we turn to the question of whether and how large-scale 3dp solutions can face this challenge.

"But large-scale FDM 3d-printing is not there yet," you might say. "How can one use this technology to produce end use parts?" Well, not only is it possible, but it also has the potential to solve unique challenges manufacturers are facing today with production of large objects.

All parts below were printed with the BigRep Large Scale 3D-Printing Technology

MOLDS AND PRODUCTION TOOLING

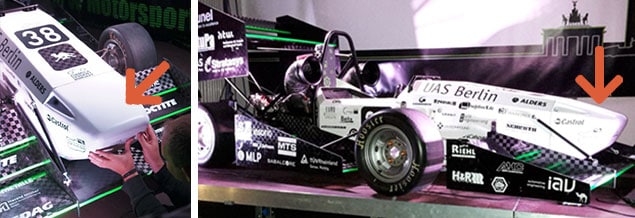

3d-printing provides developers and manufacturers with an efficient way to produce one or several custom design products. In the following example, a large mold was printed and was used as a lay-up tool for a composite structure to produce the final part. Here's an overview of the process:

Step 1 – Printing a large-scale mold

Step 2 – Coating & post-processing

Step 3 – Carbon fiber sheet coating

Step 4 – Resin injection (vacuum infusion)

Initial production was completed with injection of the resin into the mold. After post-processing and finishing it was installed on a racing car as a fully functional end use part:

THE BENEFITS

- Achieving higher accuracy compared to non-3D printing methods when working with wood and foam

- Drastically shortening the production time of an end-use part

- Making considerable cost savings compared with producing the same part with a CNC machine.

ANOTHER GREAT EXAMPLE

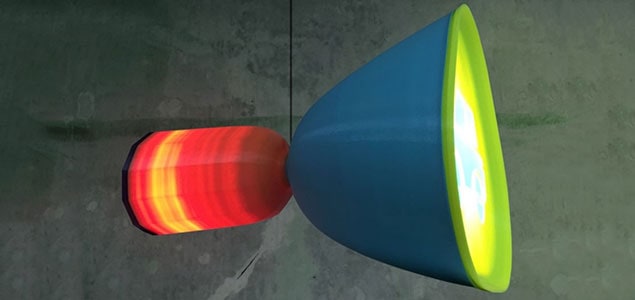

A fabricated forming mold to produce a new bus lighting panel design, using a similar process:

Step 1 – Printing a large-scale mold

Step 2 – Producing the end use part

THE BENEFITS

- Shortening production time by 50% compared to working with CNC

- Costs lower than they would be using alternative techniques or other more expensive 3D printing technologies

Learn more about modeling, building and testing custom products fast and cost-efficiently.