“We are currently in the fourth industrial revolution."

If you are into production somehow, statements like this one come from every direction: "We're in the middle of the transformation from the non-connected to a connected industrial world. Machines are no longer isolated systems. Connectivity enables machine to machine and machine to human communication. Getting convenient and constant access to data is one driver for machine connectivity.”

At the same time you hear about data security problems and you may wonder: Why is the whole industrial world in the wake of Industry 4.0 opening up their machines and systems for communication with the outside world, may it be with the internet or just local factory floor network zones?

The Basics of Digital Machines:

3D Printers are by nature digital machines. So other than conventional machines, which need to be equipped with additional sensors to get data about the process, every 3D printer from the very beginning is filled with data.

They know their state. They know in which phase of the print process they are. They know their next steps, their upcoming axis’ movements and extrusions. There are commands decoded in a G-Code and there are manual commands from the 3D printer operator, all collected in printer log files. Professional printers get additional data on their actions from sensors (e.g. closed-loop-control actuators tell the control system that they reached a certain location and monitor the forces they needed on the way), they know temperatures of components and spaces. And sometimes even have webcam footage.

This data is there. It can be used far beyond just controlling the print process in that very moment. It can give tremendous benefits not only to machine manufacturers, but to printer owners, operators, production floor planners & managers, service engineers and in the end the maturity of the printing process itself. Let’s see how:

Level 1: Monitoring & Notifications

The first benefit of getting a 3D printer connected, is being able to monitor it. Data streaming over accessible interfaces lets you gather information on printer’s states and print progresses. This makes centralized visualizations over all your connected printers possible.

This adds a great level of convenience, even efficiency: You can see which of them are currently idle, heating up, printing or paused. You can see which of them are healthy and which are not. You can see how far into the print process each of them already is, which layer is currently being printed and what is the remaining print time which is especially important in large-format 3D printing.

Apart from actively monitoring machines, getting access to live printer data also enables alerting and notifications. Being immediately notified, when a print unexpectedly stops, the printer runs out of filament or the current print is about to finish, boosts efficiency and reduces unplanned idle time to a minimum.

Level 2: Machine Analytics

Printer data can not only be used to indicate the current state of the machine, but it can also be collected centrally to enable analysis over time. The collection of printer states data and visualization of print statistics lets you easily see how your printer capacity usage has developed over time. The same can be done with filament usage or print success rates. Having a good understanding of the current situation as well as the development until now is the basis for planning. And a great fact base to trigger constant improvement in your organization.

Bringing different data sets together for cross-data analysis lays the groundwork for pattern and anomaly detection. A database with slicer, extruder and printer settings, temperature sensor data and material data can be a good foundation for print part optimization, where for different print iterations of one part all data are compared and patterns for quality are identified.

With recording all process-relevant parameters throughout the whole print, this data can be turned into a high-level quality assurance. Giving you more information and so better confidence than any conventional quality inspection method (remember: for 3D printed part, you should check the inner structures as well).

And again: It does not need to be rocket science. With simply setting up algorithms to compare the dataset of the latest print to a previous one (where the part came out in specs) your production can tell you on the spot and fully automized if your part will be in specs or if deviations were found.

Level 3: Prediction

When patterns and anomalies are identified and a sufficient amount of data is being considered, future prediction is nothing but the next natural step. When you know the indicators of optimized print parts and the combination of settings, material etc., you will be able to predict the quality of a print part in advance, without the need for print iterations. You will get the first print right.

The same can be done with printer capacities. If you know the evolution of printer usage capacity, you will likely be able to plan capacities and make data driven decisions. You will be able to predict the exact point in time when a new printer is needed and when the invest is returned. Maintenance can be predicted when the indicators of a part’s nearing end of life are identified.

Level 4: Smart 3D Printing

At the end of the process stands its supreme discipline: smart printing. When adjustments to the print are being done during the print by the printer based on sensor and prediction data. When the machine itself learns from past’s faults, the technology will finally fully mature. When all print process related know-how and data interpretation ability is transferred from human to machine, people can finally concentrate on the parts they want to print and not on how to print them.

Until then there are a few steps still to go technology wise. But companies are pushing the development here with every new machine and software generation.

3D printing is by nature the most digital manufacturing process of all. So, to connect and to smarten up this technology can push the efficiency, the quality, the costs and even the convenience of 3D printing to higher levels than what most other production processes can do.

Want to Learn More About 3D Printer Connectivity?

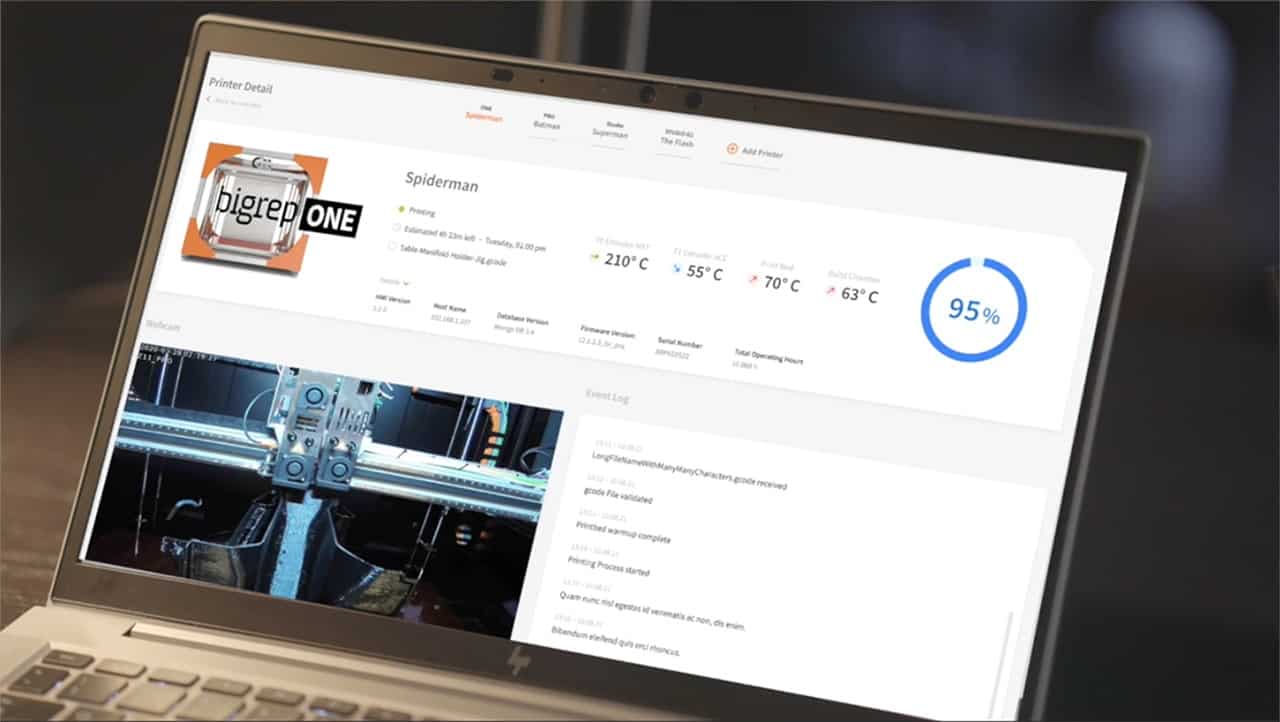

Learn how BigRep CONNECT, a one-stop platform connecting you with your BigRep 3D printers, can boost productivity with remote monitoring and data analytics. It's fully web-based, giving you access no matter where you are or what device you use. Don't miss out, watch the webinar now:

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

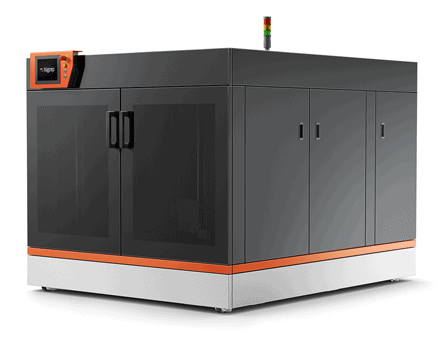

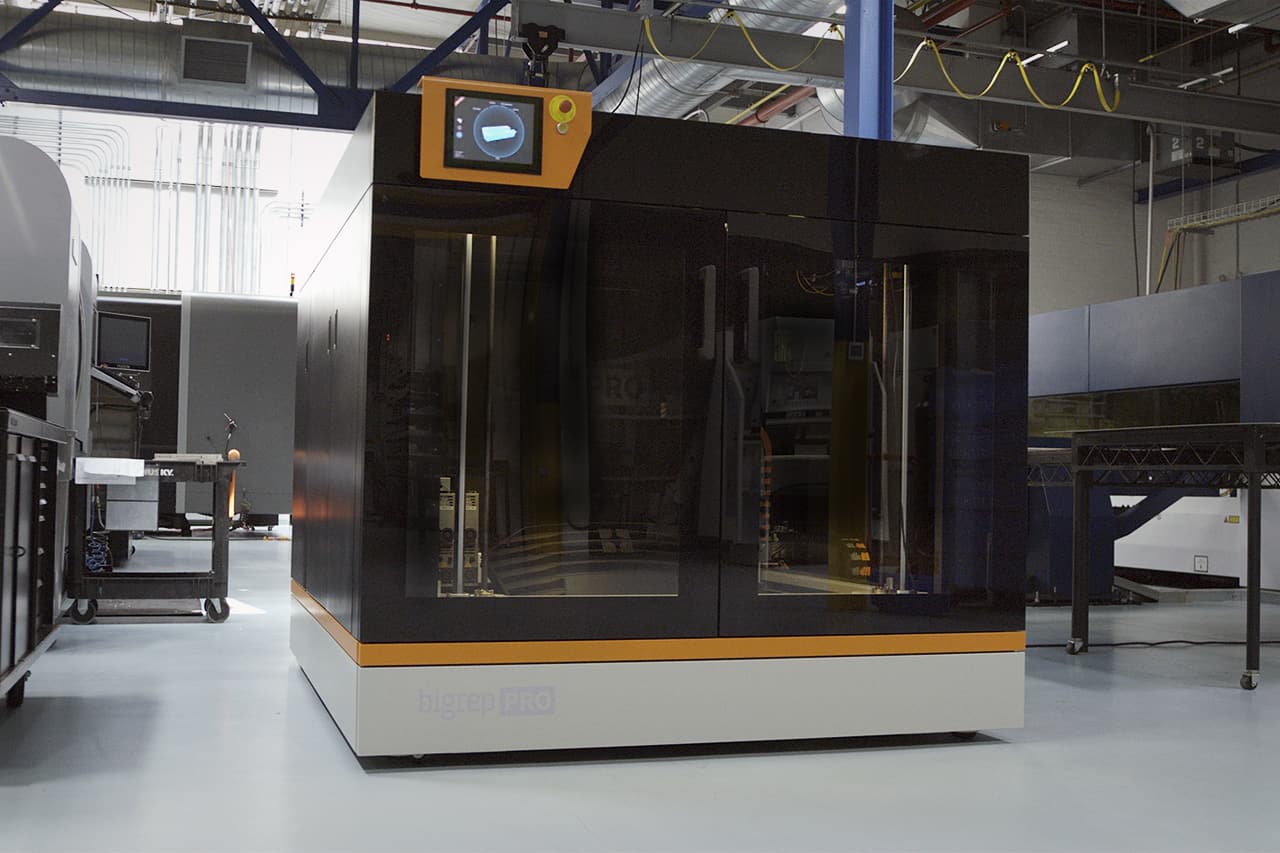

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.