NERA: the first fully 3D printed Motorbike in the World

NERA. A new era in 3D printing.

With Additive Manufacturing and rapid prototyping, you can get from the first idea to a fully functioning motorcycle in just 12 weeks.

NERA is fully 3D printed. Only 15 parts.

Discover how you can save time and money with 3D printing.

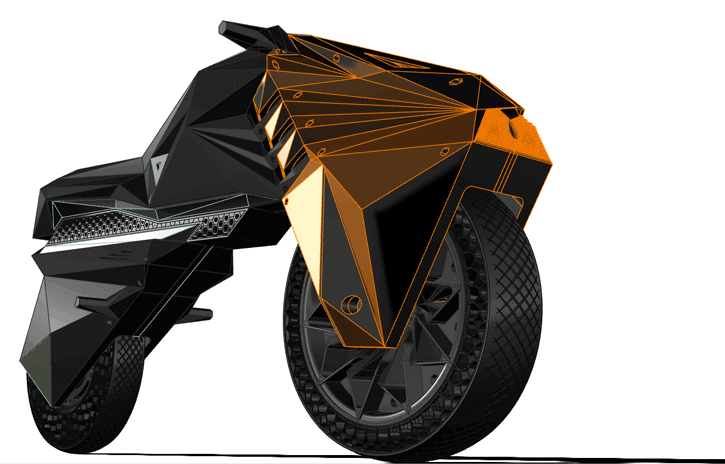

The NERA motorbike started with an idea: create a functional prototype that revolutionizes mobility and can be produced entirely with 3D printing.

Lets look at the complexity of the process:

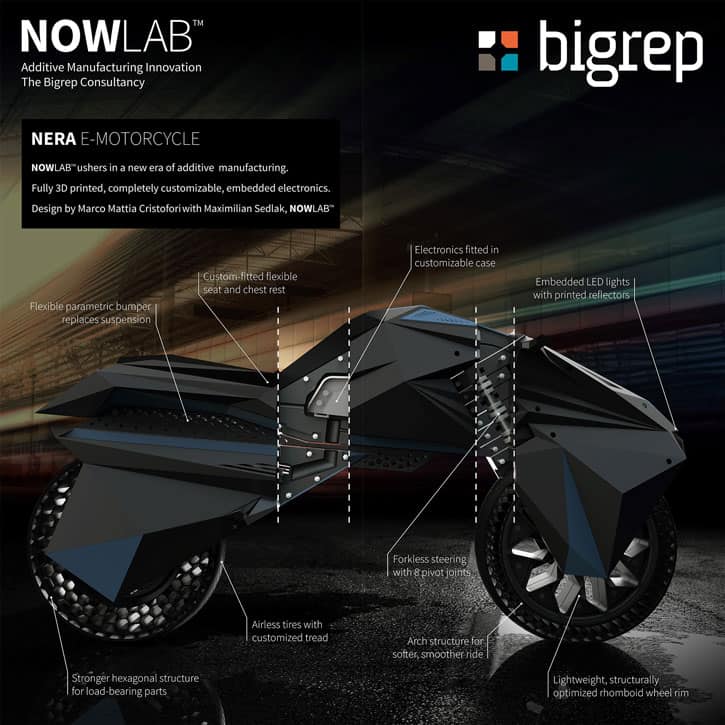

With Marco Mattia Cristofori in the design lead, we engineered NERA e-Bike from the ground up, disrupting traditional design, engineering and production in every aspect. The result is a 100-percent, customizable, functional prototype, designed and produced with more time- and cost- efficiency than previously imaginable.

In building NERA, our designers and engineers didn’t simply adapt existing motorcycle designs; instead they envisioned a bike designed for large-format FFF 3D printing, setting a benchmark for truly creative design and breaking the limits of traditional mindsets.

To hear more about the design process behind the NERA, watch our OnDemand webinar Optimize your Design Process with 3D Printing hosted by Daniel Büning, BigRep's Chief Innovation Officer and one of the NERA's creators:

How Additive Manufacturing technologies disrupt existing possibilities:

- Ideation: First, we worked on the basic bike aesthetics. From the basic mechanical functionality to a unique design language, we started sketching in five design iterations.

3D printing changes the perception of design language and allows total freedom in terms of design: bionic, organic, edgy – any designs are only one thought from reality. - FFF-based Design: We ideate especially for the FFF technology with its unique possibilities: design and functionalities are exclusively FFF-based and don`t work with any other production technology. Prototyping for standard manufacturing methods has extremely limited design possibilities when it comes to mechanical functions, as well as to the design language of objects.

- Design process: First, we arrange the functionally relevant core parts, then design the outer shell translating the chosen design language into the functional parts. We decided to pursue a low polygon/ stealth design language, which allowed us to avoid top layers that can be a weakness of FFF printing.

- Embedded Electronics: Battery, motor, cable and control systems are not printed. The motor is electric since traditional combustion engines cannot be embedded in polymer objects. The electronics can be adjusted individually and are integrated as a modular system that allows individual settings.

- Materials: NERA is printed with BigRep TPU, BigRep ProHT, BigRep PLA, and BigRep PETG materials. While we use ProHT for rigid parts, PLA for color details and PETG for the light reflectors, TPU allows us to embed functionalities in a unique way. Tires, bumper, seat and handles are printed with the flexible material and fulfill functions that usually require complex mechanical constructions such as hydraulic, shock absorbing suspension systems.

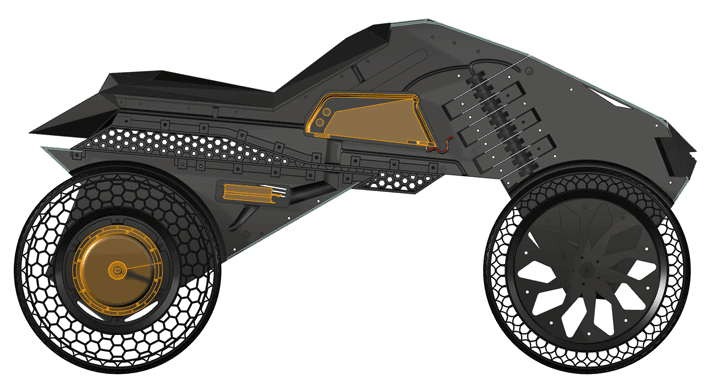

The strength and elasticity of the material allowed us to come up with completely new design approaches that replace the traditional mechanical components. A horizontally embedded TPU suspensor with honeycomb structure, for example, replaces a traditional hydraulic system integrated in metal fork steering systems for motorcycles. - Forkless steering: Instead of a fork steering, NERA has eight pivot points, clamping vertically instead of assembling the fork to rotate the wheel on a horizontal axis.

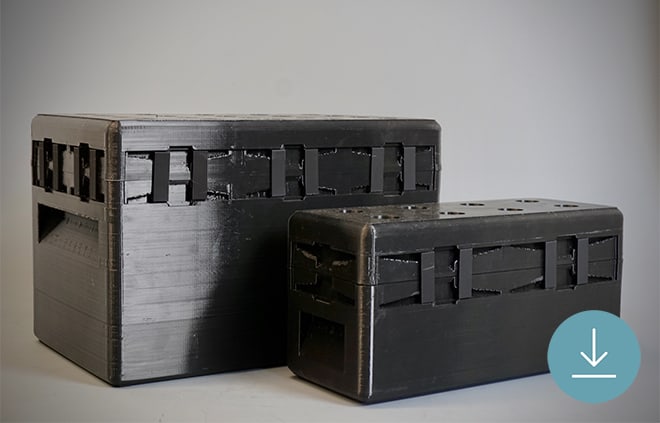

- Print parameters: Our design team used 12 percent infill almost everywhere. This was determined by testing several small portions and then determining that 12 percent is the perfect fit for structural stability.

In total, the design features include 15 fully 3D printed parts:

- Fully-functional, full-scale 3D printed prototype

- All parts printed with BigRep printers (except electronics), including body, rims, tires, steering, seat, headlight and shocks

- Flexible parametric bumper replaces suspension as a shock absorber

- Custom-fitted seat and chest rest printed with flexible thermoplastic

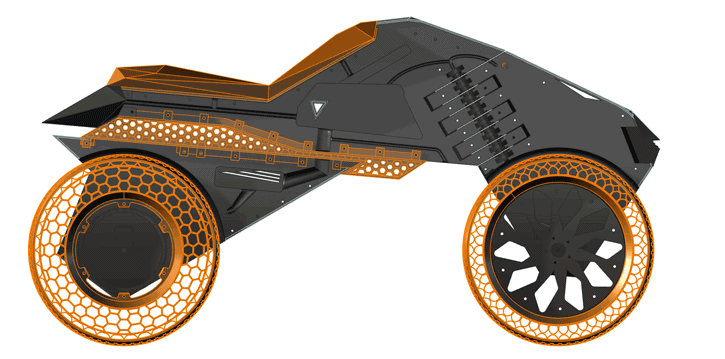

- Airless tires with customized tread printed with flexible thermoplastic

- Front tire has an arch structure for a softer, smoother ride

- Back tire has a stronger hexagonal structure for load-bearing parts

More than just an exercise in what can be achieved with 3D printing – and specifically FFF printing with BigRep technology – the NERA shows that the low cost and fast results of additive manufacturing allow designers to immediately test prototypes and rapidly produce iterations of experimental engineering. The NERA also illustrates the massive benefits that 3D printing offers to produce functional parts, particularly for unique- to small-series production, by reducing lead times and costs, optimizing supply chains and limiting dependency on supplier networks.

Daniel Büning, Co-Founder and Managing Director of NOWLAB, explains, “Our NERA E-Motorcycle is the perfect example of the disruptive capabilities of additive manufacturing in the mobility sector. The bike is the result of a radical new approach to product development, seamlessly spanning digital simulation to custom manufacturing. Therefore, NERA combines several innovations developed by NOWLAB such as the airless tire, functional integration, and embedded sensor technology. We push the limits of engineering creativity to reshape additive manufacturing technology as we know it.”

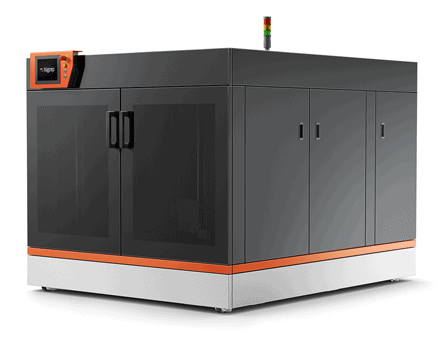

A truly industrial 3D printing experience

The BigRep PRO is a large-format 3D printer designed for high productivity in industrial manufacturing environments. It provides engineers and manufacturers with a highly scalable solution, able to efficiently manufacture end-use parts and products or factory tooling with high-performance, engineering-grade materials. With a generous 1m3 build volume, it's an industrial 3D printer with the speed and reliability to supercharge your production.