From its humble beginnings as a niche technology for rapid prototyping to its current spectrum of capabilities to create forms that are virtually impossible to build any other way, 3D printing has spawned a brand-new generation of manufacturing.

In this article, we’ll take a look at the origins of 3D printing, its big moments in history, applications, and explore the future it holds.

Table of Contents

1. The Basics of 3D Printing

What Is 3D Printing and How It Works

3D printing, also known as additive manufacturing, is a process of building a physical object from a three-dimensional digital model. It creates an object by laying down successive thin layers of a material such as plastic, metal, resin, or even biomaterials—based on a digital design created using computer-aided design (CAD) software.

The process begins with the digital 3D model sliced into numerous thin layers. The 3D printer then follows these instructions, precisely depositing material layer upon layer, gradually constructing the physical object. This technology has found applications across a gamut of industries, including aerospace, healthcare, automotive, fashion, architecture, and more.

Types of 3D Printing Materials

3D printing materials can be categorized under:

- Plastics (PLA, ABS, PETG, nylon)

- Metals (stainless steel, titanium, aluminum, copper)

- Resins (standard, flexible, tough, castable)

- Ceramics (porcelain, stoneware, earthenware)

- Wood pulp with a binding polymer (Bamboo, Birch, Maple, Cherry)

- Composites (carbon fiber, fiberglass)

- Paper-based (cardboard and paper)

- Food-based (chocolate, dough, sugar)

- Bio-based (living cells and tissue)

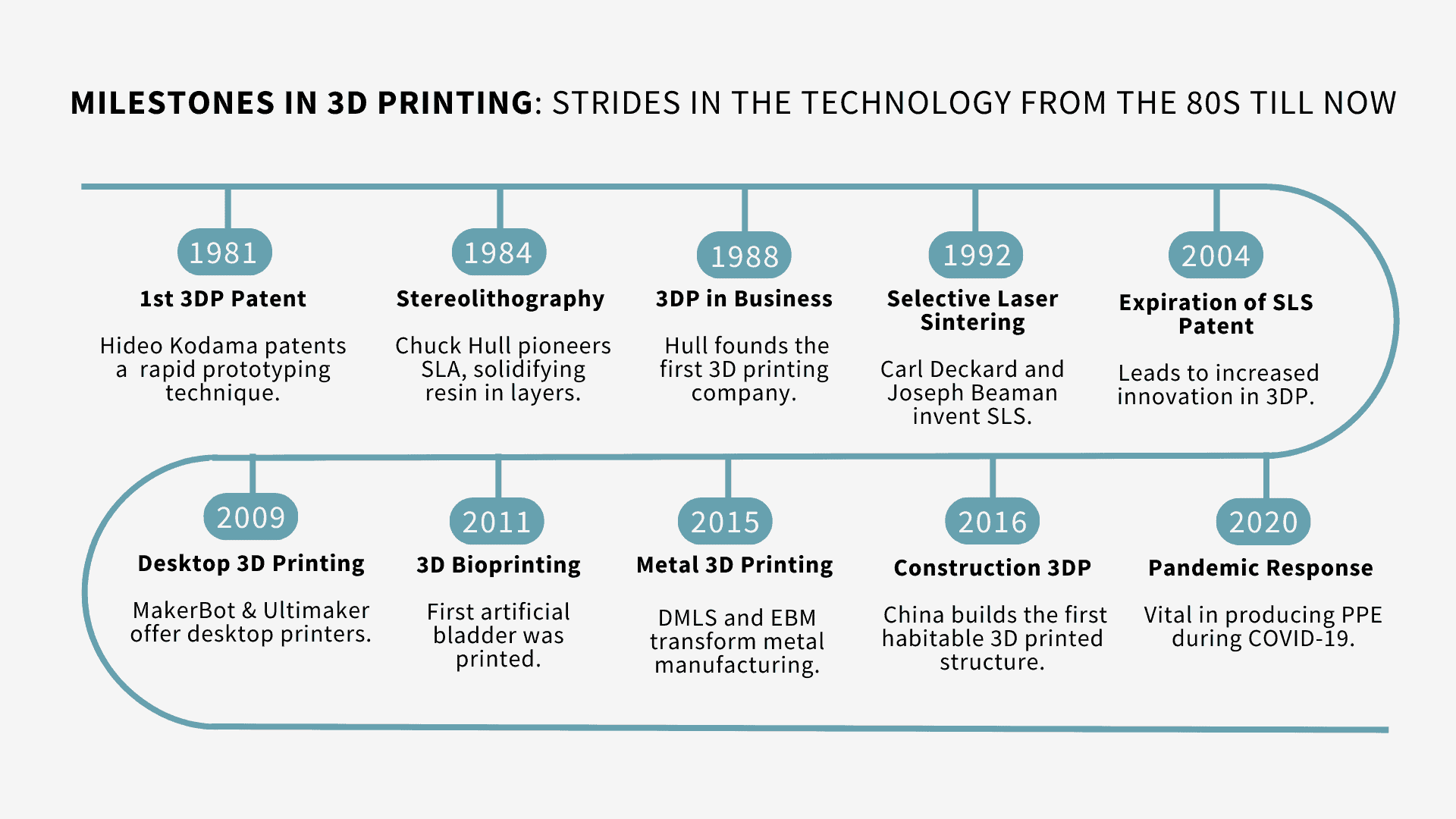

The History

The roots of 3D printing go back to the 1980s when visionaries like Hideo Kodama proposed methods for fabricating three-dimensional models using photopolymers solidified by UV light. Around the same time, Charles Hull pioneered stereolithography, patenting the concept in 1986. This technique employed UV light to solidify layers of liquid photopolymer resin, laying the groundwork for additive manufacturing. Subsequent decades saw the evolution of various printing methods like Selective Laser Sintering (SLS) and Fused Filament Fabrication (FFF), expanding material options and applications.

By the 2010s, 3D printing had become more accessible, integrating into industries such as aerospace, healthcare, and automotive manufacturing. Bioprinting also made strides, enabling the printing of living tissues and organs. Today, 3D printing stands as a transformative force, reshaping manufacturing, rapid prototyping, and medical advancements through its capability to produce intricate designs with precision and speed.

The advantages

Benefits of 3d printing Across Industries

3D printing enables quick and cost-effective prototyping, allowing designers and engineers to iterate designs swiftly, reducing time-to-market for new products.

Highly individualized products can easily be produced catering to specific needs and preferences without significantly increasing production costs.

Unlike traditional manufacturing methods, 3D printing can create intricate geometries and complex designs that would be challenging or impossible to achieve otherwise.

Additive manufacturing is inherently more efficient, as it typically uses only the materials necessary for the object being printed, minimizing waste.

On-demand production enabled by 3D printing reduces the need for large inventories and streamlines the supply chain by producing parts as needed.

For small batches or low-volume production, 3D printing can be more cost-effective than traditional manufacturing methods due to lower setup costs.

Creating patient-specific implants, prosthetics, and medical models for surgical planning requires precision and customization which 3D printing delivers effortlessly.

3D printing has become an invaluable tool allowing students and researchers to visualize concepts and create prototypes to test theories in various fields.

2. Common Types of 3D Printing Technologies

Fused Filament Fabrication (FFF)

FFF is one of the most common 3D printing methods. It works by melting a thermoplastic filament and depositing it layer by layer through a heated nozzle onto a build platform. As each layer cools, it solidifies, gradually building the object. FFF is known for its simplicity, affordability, and versatility, making it popular for hobbyists and prototyping.

Stereolithography (SLA)

SLA employs a vat of liquid photopolymer resin and uses a UV laser to solidify the resin layer by layer, building the object from the bottom up. The UV laser traces the shape of each layer onto the surface of the liquid resin, solidifying it. SLA is known for producing high-resolution, detailed prints, making it suitable for applications requiring precision, such as dental and medical prototypes.

SELECTIVE LASER SINTERING (SLS)

SLS uses a high-powered laser to selectively fuse powdered material, typically nylon or other polymers, into a solid structure layer by layer. Unlike SLA or FFF, SLS doesn't require support structures as the unsintered powder acts as a support. SLS offers design flexibility and can produce complex geometries and functional prototypes with robust strength, making it common in the aerospace and automotive industries.

POLYJET PRINTING

PolyJet technology operates similarly to inkjet printing but with layers of liquid photopolymer cured by UV light. Tiny droplets of liquid photopolymer are instantly cured by UV light, solidifying it, layer by layer, onto a build tray. PolyJet printers can produce multicolor, multi-material parts with high accuracy and fine details. It's often used in industries requiring high-resolution models, such as product design and architectural prototyping.

3. Real-World Applications Across Industries

1. Aerospace and Defense

Lightweight yet durable components are the lifeblood of the aerospace and defense industry. Components like turbine blades, fuel nozzles, brackets, and even entire rocket engines can be 3D printed. This results in reduced component weight, improved fuel efficiency, and enables rapid prototyping for testing different designs.

2. Automotive

In the automotive industry, 3D printing is used for rapid prototyping, and creating functional prototypes for testing and validation before mass production. Additionally, it's utilized for manufacturing parts like engine components, interior elements, custom tooling, and even entire vehicle bodies. The technology allows for quicker design iterations and the production of complex parts, enhancing overall efficiency in the automotive manufacturing process.

3. Medical and Dental

3D printing has transformed the medical and dental fields by enabling the production of patient-specific implants, prosthetics, and surgical tools. In dentistry, it's used to create crowns, bridges, and dental models tailored to individual patient needs. In medicine, it's utilized for creating anatomical models for surgical planning, prosthetic limbs, customized orthopedic implants, and even bioprinting tissues and organs for transplantation and research purposes. These offerings deliver personalized solutions and improve patient outcomes.

4. Consumer goods

Embraced by leading companies across sectors like consumer electronics and sportswear, 3D printing has democratized manufacturing processes with the accessibility of industrial 3D printers. This accessibility empowers designers and engineers to delve into its immense potential. Its benefits include expediting product development through rapid prototyping, accelerating time-to-market, and enabling mass customization by efficiently catering to individual consumer preferences.

5. Industrial Applications

The industrial goods sector, pivotal in machinery and equipment production, grapples with the need for agility and cost-effectiveness amid escalating costs and digital advancements. To address these challenges, manufacturers turn to 3D printing for its agility, responsiveness, and innovation. Its advantages lie in rapid prototyping, on-demand production, slashing design change times, and cutting lead times by eliminating tooling requirements.

4. Seven Steps to Find the Right 3D Printer

Building on the foundation of 3D printing basics, types, and applications, you can now quickly narrow down the vast choice of 3D printers by considering factors like:

1. Type of Printer

Consider various technologies such as FFF (also called FDM), SLA, and SLS. Inexpensive desktop FFF printers may suit hobbyists, while SLA and SLS offer higher accuracy at a higher cost.

2. Cost of the Printer

Entry-level printers cost less than $500, while industrial-grade printers can go up to hundreds of thousands of dollars. Also, factor in maintenance and filament costs.

3. Printer Size and Volume

Evaluate available space and print size needs. Beginners may opt for smaller, faster printers while for industries it’s recommended to invest in large-format 3D printers.

4. Print Quality and Speed

Take resolution, layer height, and print speed into consideration. Higher resolution often means slower speed and vice versa.

5. Ease of Use

Look for user-friendly interfaces, easy calibration, automation, and reliable performance. Consider reviews for insights into reliability.

6. Support and Maintenance

Check for maintenance instructions, available replacement parts, and technical support. Some companies offer less expensive, build-your-own 3D printers while others offer a full-service package. Also look for community support as it can be a holy grail in troubleshooting your 3D printer.

7. Additional Features

Consider extras like multiple extruders for varied prints, auto-calibration, built-in cameras, touchscreen displays, proprietary 3D software, and internet connectivity based on personal needs and budget considerations.

5. The Future Of 3D Printing

3D printing holds vast unexplored potential to reshape our everyday lives by offering innovation, customization, sustainability, and efficiency through:

- Diverse Use of Material

Expect a widening array of printable materials, including advanced polymers, metals, ceramics, and bio-compatible substances, expanding the scope of applications. - Accessibility

As technology progresses, 3D printing might become more accessible, affordable, and user-friendly, potentially integrating into everyday homes and workplaces. - Sustainable Manufacturing

Efforts towards eco-friendly printing using recyclable materials and reducing waste during the printing process are gaining traction, contributing to sustainable manufacturing practices. - Bioprinting and Healthcare

Advancements in bioprinting may revolutionize healthcare by facilitating the creation of tissues, organs, and medical implants, leading to personalized healthcare solutions. - Integration with AI and Robotics

The fusion of 3D printing with AI and robotics could streamline and automate the entire printing process, enhancing efficiency and precision. - Space Exploration

3D printing's potential for on-site construction using locally available materials might revolutionize space missions and support off-world colonization.

Past production advancements were typically gradual, building upon iterations by refining production lines and inventory systems. In contrast, 3D printing reimagines production at a fundamental level. It simplifies, accelerates, and streamlines the creation process using a single machine, deviating from the reliance on a string of machines.

This paradigm shift is why most industries invest in this technology, firmly believing in the promise 3D printing holds in exploring untapped industrial applications in the manufacturing sector. From the invention of the telephone to the personal computer, there have been milestones in human history when a technology has completely transformed society. Now is one of those times.

Want to learn more about Large-format Additive Manufacturing?

Download the eBook Guide to Integrate Large-Format Additive Manufacturing.

Explore how increasing the build size increases the possibilities for builds, why size matters, how to integrate, 4 applications that benefit from large-format additive, case studies from industry-leading companies like Ford, Steel Case, and more.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

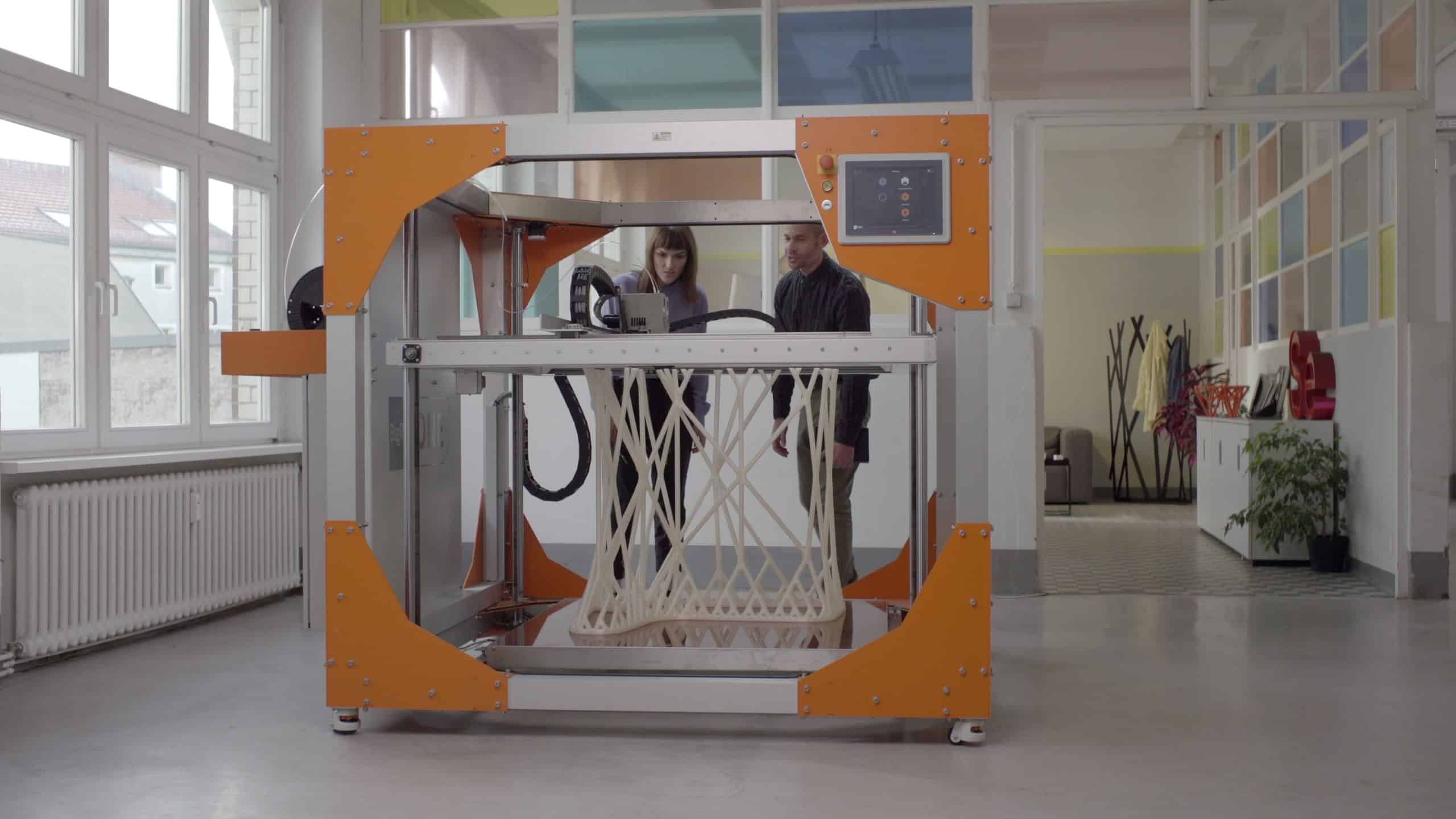

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.

INDUSTRIAL QUALITY MEETS COST EFFICIENCY.

COMPLEX PARTS IN LARGE SCALE.

The BigRep PRO is a 1 m³ powerhouse 3D printer, built to take you from prototyping to production. It provides a highly scalable solution to manufacture end-use parts, factory tooling or more with high-performance, engineering-grade materials. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs.