PROve it

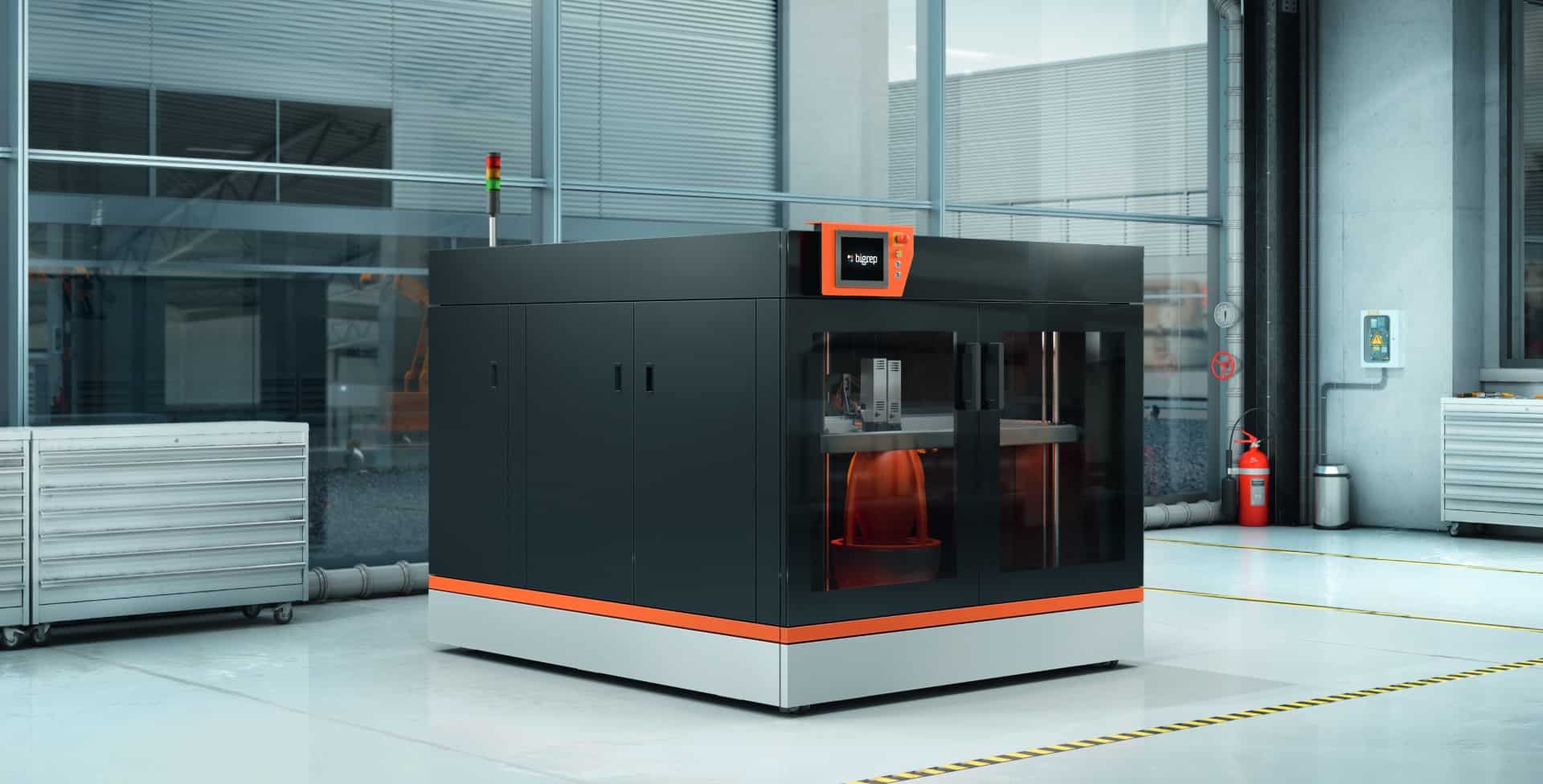

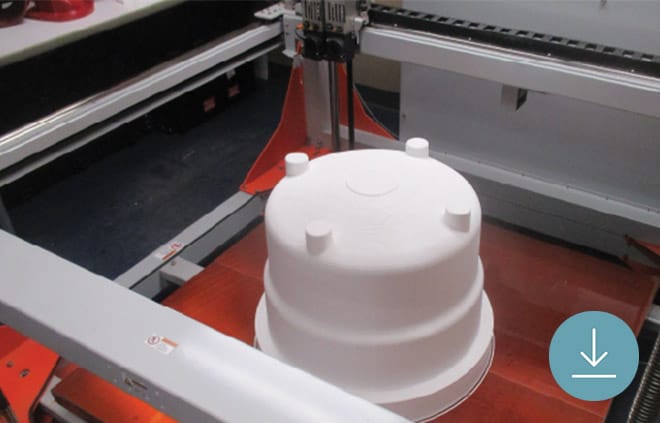

The BigRep PRO will increase your productivity while keeping your costs down. LET US PROVE IT TO YOU. GET YOUR FREE REPORT 1. UPLOAD You send us the 3D model of your part 2. ANALYSIS We analyze your part and calculate Cost Per Part 3. PROOF See the savings in your custom report BigRep … Read more