BigRep Introduces a New Generation of Large-Format 3D Printers Tailored to Their Users’ Applications

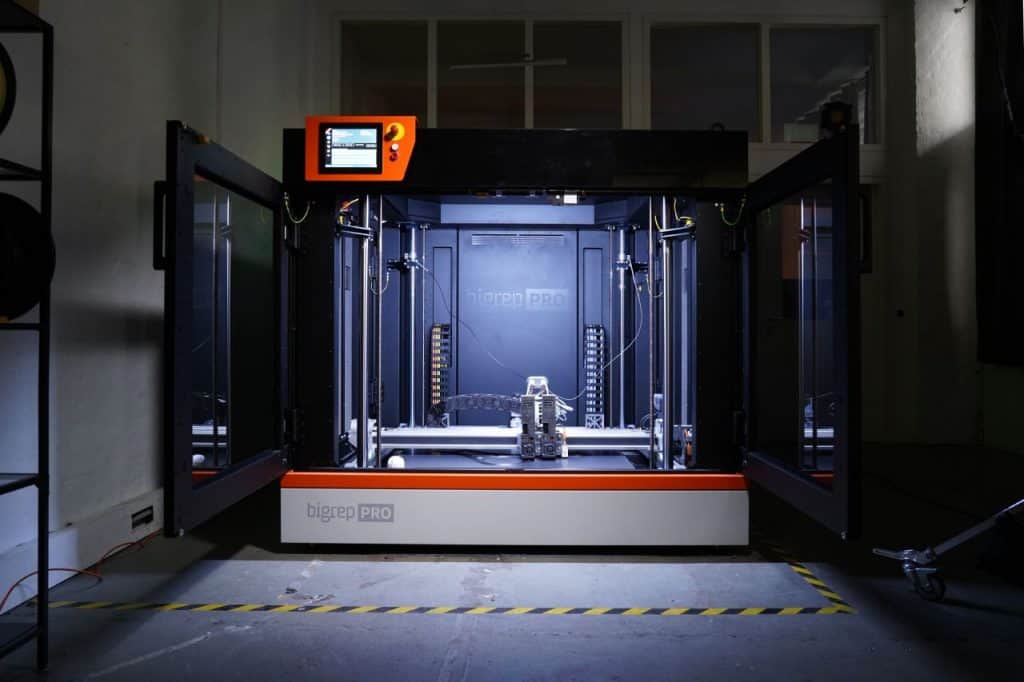

The new and improved BigRep PRO, a meter cubed powerhouse 3D printer, is designed with the industrial user’s needs in mind. Its versatility allows for full-scale, large parts including functional prototypes, factory tooling, patterns, molds, and end-use parts.

Large-Format 3D Printing Unlocks New Frequencies for Bell Casting

Australian Bell turns to FEA software and 3D printing to bring bell production into the 21st century.

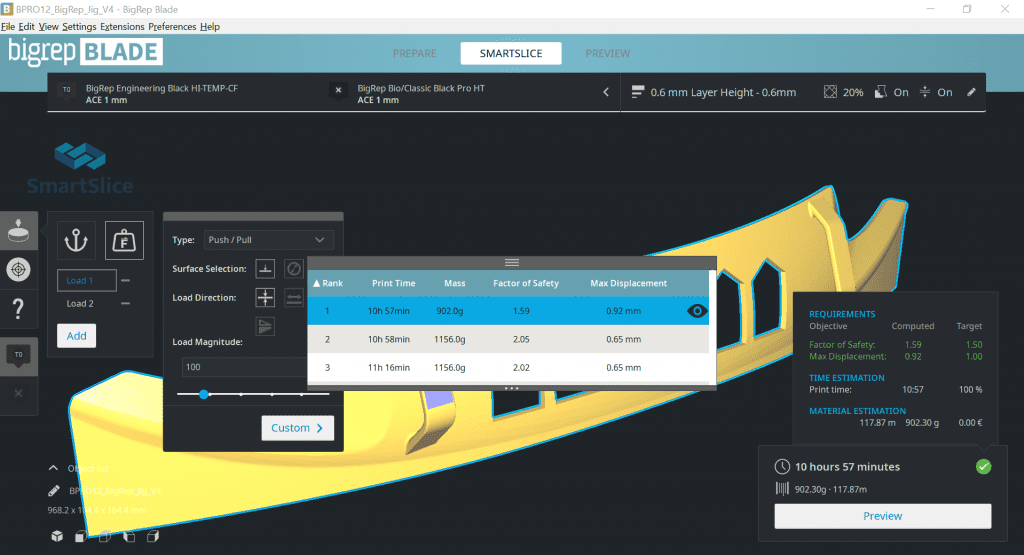

BigRep and Teton Simulation establish a Partnership to Integrate SmartSlice™ into Large-Format 3D Printing

SmartSlice™ helps industrial users to quickly define load cases for parts they intend to print and validate the as-printed performance of these parts against mechanical limits of the material but also against part deflections.

3D Printing Creates Mixed Reality Worlds

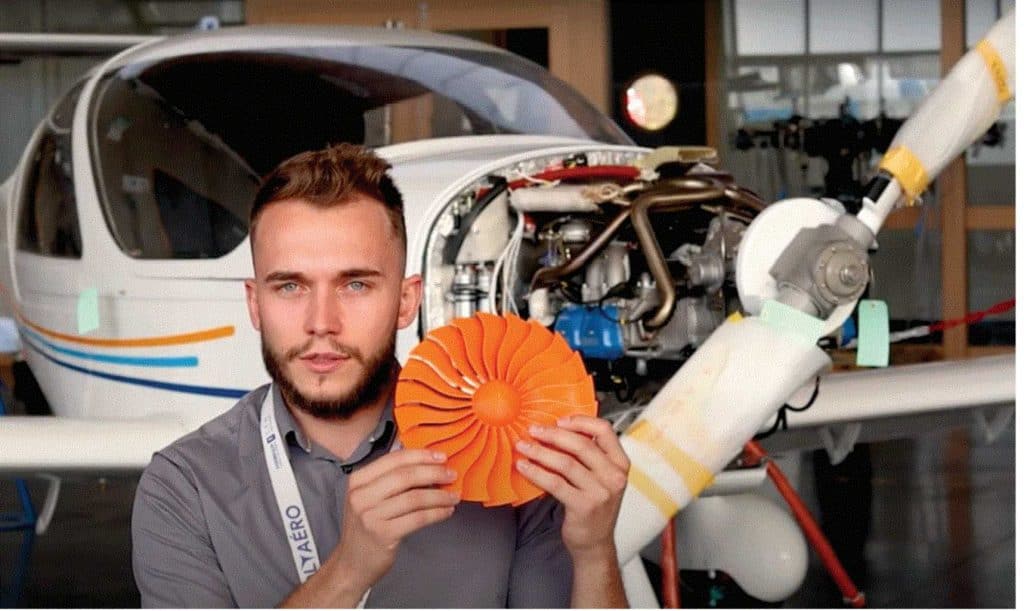

How the Aix-Marseille Université aerospace facility’s technology-enhanced degree program is made possible with BigRep’s large-format additive manufacturing systems.

Setting the Pace for Customized Electric Cars – The First BigRep PRO in China

XEV is an innovative, forward-thinking company, with a mission to provide sustainable urban mobility to everyone for a better shared future. And additive manufacturing plays an important role in development and production of their electric cars!

Large-Format 3D Printing Accelerates Fire Engine Manufacturing

3D printing has become an integral part of Magirus’ prototyping and product development workflows, especially for the production of aesthetic and ergonomic fire engine parts. The team frequently use the BigRep ONE to 3D print functional prototypes, which can be fitted and tested on trucks in order to validate the part design before tooling and production.

3D Printing Industry Meeting: Recap from Rapid + TCT 2021

The BigRep team was excited to be back live, in-person at RAPID+TCT, North America’s largest and most influential event for 3D printing and additive manufacturing. For BigRep, it was the perfect opportunity to showcase our large-format 3D printers and applications of our customers who #THINKBIG.

3D Printed Life-Size Dinosaur Models

CDM:Studio 3D printed over 110 models in just 9 months. In the past, each dinosaur or animal would have had to been modelled out of clay, which takes a very long time and very skilled sculptures to. And with a timeline of only 9 months, this could only be done with a 3D printer.